Compression of microspheres: Theory and application

Compression of microspheres: Theory and application

Compression of microspheres: Theory and application

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

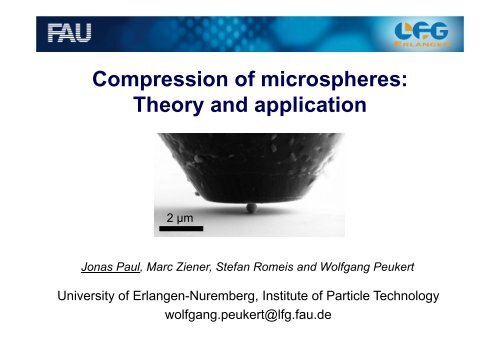

<strong>Compression</strong> <strong>of</strong> <strong>microspheres</strong>:<br />

<strong>Theory</strong> <strong>and</strong> <strong>application</strong><br />

2 µm<br />

Jonas Paul, Marc Ziener, Stefan Romeis <strong>and</strong> Wolfgang Peukert<br />

University <strong>of</strong> Erlangen-Nuremberg, Institute <strong>of</strong> Particle Technology<br />

wolfgang.peukert@lfg.fau.de

Experimental Setup<br />

Custom built SEM supported micromanipulator :<br />

(J. Paul et al., Rev. Sci. Instruments 2012)<br />

Characteristics:<br />

• Tunable spring constant<br />

• Precise determination <strong>of</strong> spring<br />

constant<br />

• Force resolution < 50nN<br />

• Deformation resolution < 5nm<br />

• Lateral scan field 80µm x 80µm<br />

Technical data:<br />

LVDT<br />

Electronic noise: 250nV pp @10kHz<br />

Sensitivity: 1.8·10 -7 V/nm<br />

Displacement resolution: ∆z = 1,4nm pp @10kHz<br />

J. Paul PiKo-Workshop Siegen 2012<br />

Force resolution: ∆F = ∆z·k > 50nN pp<br />

(35N/m < k < 15000N/m) @10kHz<br />

Strain gauge resolution: 5nm pp @10kHz<br />

Loadingrate: 50 – 5000µN/s<br />

2

Obtained Data<br />

Representative force-deformation plot <strong>of</strong> a silica sphere (x = 500nm):<br />

Information on:<br />

• Young’s modulus<br />

• Elastic range<br />

• Yield strength<br />

• Hardness<br />

• Crack initialization<br />

• Elastic energy<br />

• Dissipated energy<br />

• Elastic-plastic loading index<br />

Force [µN]<br />

1200<br />

1000<br />

800<br />

600<br />

400<br />

200<br />

Relative deformation<br />

0.00 0.18 0.37 0.55 0.73<br />

SiO 2<br />

(x=500nm)<br />

elastic-plastic<br />

loading<br />

elastic loading<br />

0<br />

0 100 200 300 400<br />

Deformation [nm]<br />

elastic<br />

unloading<br />

J. Paul PiKo-Workshop Siegen 2012<br />

3

Young’s modulus<br />

Hertzian contact theory: 4 3 ∗ <br />

/<br />

F<br />

: loading force<br />

∗ : reduced Young’s modulus<br />

: particle radius<br />

: contact deformation<br />

diamond<br />

∗ <br />

1 ²<br />

<br />

1 ²<br />

<br />

<br />

<br />

<br />

R<br />

<br />

<br />

<br />

<br />

measured variable: <br />

silicon<br />

single contact deformation <strong>and</strong> unknown<br />

J. Paul PiKo-Workshop Siegen 2012<br />

4

Young’s modulus<br />

Determination <strong>of</strong> single contact deformations <strong>and</strong> :<br />

∗<br />

silicon-silica contact: <br />

∗<br />

diamond-silica contact: <br />

<br />

/ <br />

<br />

∗<br />

<br />

<br />

1 <br />

/ <br />

<br />

∗<br />

<br />

<br />

<br />

<br />

<br />

4 3 1<br />

∗<br />

1<br />

∗<br />

<br />

<br />

<br />

/ 1 / <br />

/<br />

Example: Stöber silica (R = 250nm)<br />

∗<br />

Q = 0.500 <br />

∗<br />

Q = 0.530 <br />

27.7 1.9 <br />

25.9 1.8 <br />

J. Paul PiKo-Workshop Siegen 2012<br />

Q = δ 1<br />

/δ t<br />

0.8<br />

0.7<br />

0.6<br />

0.5<br />

PS<br />

fused<br />

silica<br />

diamond<br />

0.1 1 10 100 1000<br />

E * particle [GPa] Si (100)<br />

5

Young’s modulus<br />

Comparison <strong>of</strong> different contact theories:<br />

Hertz , , , ∗ <br />

0.1 ∗ 27.7 1.9 non-adhesive<br />

Tatara , , , ∗ , <br />

0.6 ∗ 22.7 1.7 non-adhesive<br />

JKR , , , ∗ , <br />

0.1 ∗ 27.5 1.9 adhesive<br />

DMT , , , ∗ , <br />

0.1 ∗ 27.4 1.9 adhesive<br />

Hertz/JKR/DMT: similar ∗<br />

Weak adhesive forces compared<br />

to applied load<br />

Tatara: decreased ∗ compared to Hertz<br />

/ 0.1<br />

J. Paul PiKo-Workshop Siegen 2012<br />

Force [µN]<br />

800<br />

600<br />

400<br />

200<br />

Rel. deformation<br />

0.00 0.21 0.42 0.63 0.84<br />

Hertz<br />

Tatara<br />

JKR<br />

DMT<br />

SiO 2<br />

(R = 250nm)<br />

0<br />

0 100 200 300 400<br />

Deformation [nm]<br />

6

Yield strength<br />

Yield criteria:<br />

max , , <br />

1/2 ² ² ²<br />

stress/ρ 0<br />

1.0<br />

0.8<br />

0.6<br />

0.4<br />

ν = 0.17<br />

σ z /ρ 0<br />

σ r/θ /ρ 0<br />

τ/ρ 0<br />

τ max<br />

( : principal stress; : maximum shear stress)<br />

0.2<br />

| / | <br />

Hertzian theory:<br />

• Calculation <strong>of</strong> principle stresses <br />

• Hertzian pressure: ∗ /<br />

Example: Stöber silica (R = 250nm)<br />

2∙0.34 3.9 <br />

J. Paul PiKo-Workshop Siegen 2012<br />

Force [µN]<br />

0.0<br />

0.0 0.5 1.0 1.5 2.0 2.5 3.0<br />

800<br />

600<br />

400<br />

200<br />

z/a<br />

Rel. deformation<br />

0.00 0.21 0.42 0.63 0.84<br />

SiO 2<br />

(R = 250nm)<br />

yield point<br />

Hertz<br />

0<br />

0 100 200 300 400<br />

Deformation [nm]<br />

7

Hardness<br />

Abbott & Firestone:<br />

Contact area & 2<br />

Hardness / &<br />

& 2.8 0.1 <br />

• Simplification <strong>of</strong> contact mechanics<br />

• No volume conservation<br />

• Discontinuities at yield point<br />

• Fixed relation <strong>of</strong> yield strength <strong>and</strong> hardness<br />

• Conservative<br />

CEB:<br />

Contact area 2 <br />

Hardness / <br />

( 0.454 0.41)<br />

5.3 0.2 <br />

• Volume conservation<br />

• Small plastic deformation<br />

• Discontinuities at yield point<br />

• Fixed relation <strong>of</strong> yield strength <strong>and</strong> hardness<br />

in fully plastic regime<br />

Force [µN]<br />

J. Paul PiKo-Workshop Siegen 2012<br />

Count<br />

800<br />

600<br />

400<br />

200<br />

20<br />

16<br />

12<br />

0.00 0.21 0.42 0.63 0.84<br />

0<br />

0 100 200 300 400<br />

8<br />

4<br />

SiO 2<br />

(R = 250nm)<br />

yield point<br />

Rel. deformation<br />

Hertz<br />

A&F/CEB<br />

Deformation [nm]<br />

Abbott&Firestone<br />

SiO 2<br />

(R = 250nm)<br />

0<br />

2 3 4 5 6<br />

Hardness [GPa]<br />

CEB<br />

8

Unloading<br />

Young’s modulus:<br />

Fully elastic unloading process<br />

Unknown particle shape<br />

Unknown correlation to ∗<br />

Residual stresses<br />

L.-Y. Li et al. (2002):<br />

4 3 ∗ /<br />

<br />

4 3<br />

∗<br />

<br />

/<br />

Uniform pressure distribution:<br />

̅<br />

16<br />

3 ∗ 16<br />

3² ∗<br />

Average true stress/strain:<br />

<br />

̅ <br />

<br />

<br />

<br />

<br />

/<br />

Red. E-Modul (GPa)<br />

70<br />

60<br />

50<br />

40<br />

30<br />

20<br />

Sphere Cap Cylinder<br />

10<br />

0.0 0.1 0.2 0.3 0.4<br />

Rel. deformation<br />

Hertz<br />

Cyl-fit (uniform pressure) Cap-fit (uniform pressur<br />

Cyl-fit (true stress/strain) Li-fit<br />

J. Paul PiKo-Workshop Siegen 2012<br />

9

Calculation <strong>of</strong> Energy<br />

Calculation <strong>of</strong>:<br />

• Expended energy: d<br />

• Elastic energy: <br />

• Elastic plastic loading index:<br />

1 <br />

<br />

Energy / volume [mJ/µm³]<br />

6 SiO 2<br />

:<br />

5<br />

4<br />

3<br />

2<br />

1<br />

0<br />

x = 500nm<br />

x = 1000nm<br />

0.2 0.4 0.6 0.8 1.0<br />

Max. relative deformation<br />

Rel. force<br />

1.0 Polystyrene (EPL = 0.67)<br />

Silica (EPL = 0.87)<br />

0.8<br />

0.6<br />

0.4<br />

0.2<br />

0.0<br />

0.0 0.2 0.4 0.6<br />

Rel. deformation<br />

J. Paul PiKo-Workshop Siegen 2012<br />

Elastic-plastic index<br />

1.0<br />

0.8<br />

0.6<br />

SiO 2<br />

:<br />

x = 500nm<br />

x = 1000nm<br />

0.4<br />

0.2 0.4 0.6 0.8 1.0<br />

Max. relative deformation<br />

10

Thank you for your attention!<br />

For financial support:<br />

DFG (SPP 1486/2)<br />

For excellent cooperation:<br />

All colleagues at LFG Erlangen<br />

Anfatec AG for continuous support<br />

J. Paul PiKo-Workshop Siegen 2012<br />

11