Inside This Issue - Plant Operations - University of Michigan

Inside This Issue - Plant Operations - University of Michigan

Inside This Issue - Plant Operations - University of Michigan

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

UTILITIES &<br />

PLANT ENGINEERING<br />

Chiller <strong>Plant</strong> Upgrade Provides Over<br />

$1 Million in Utility Savings<br />

by Mark Mau, P.E.<br />

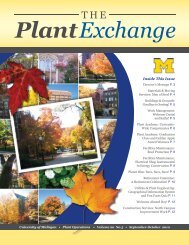

in a net $1 million savings for the year. It is expected<br />

that with a full season <strong>of</strong> operation, the savings next<br />

year will be even higher.<br />

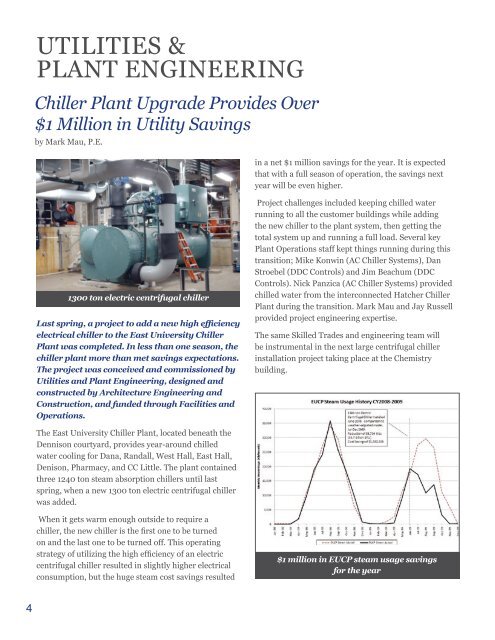

1300 ton electric centrifugal chiller<br />

Last spring, a project to add a new high efficiency<br />

electrical chiller to the East <strong>University</strong> Chiller<br />

<strong>Plant</strong> was completed. In less than one season, the<br />

chiller plant more than met savings expectations.<br />

The project was conceived and commissioned by<br />

Utilities and <strong>Plant</strong> Engineering, designed and<br />

constructed by Architecture Engineering and<br />

Construction, and funded through Facilities and<br />

<strong>Operations</strong>.<br />

Project challenges included keeping chilled water<br />

running to all the customer buildings while adding<br />

the new chiller to the plant system, then getting the<br />

total system up and running a full load. Several key<br />

<strong>Plant</strong> <strong>Operations</strong> staff kept things running during this<br />

transition; Mike Konwin (AC Chiller Systems), Dan<br />

Stroebel (DDC Controls) and Jim Beachum (DDC<br />

Controls). Nick Panzica (AC Chiller Systems) provided<br />

chilled water from the interconnected Hatcher Chiller<br />

<strong>Plant</strong> during the transition. Mark Mau and Jay Russell<br />

provided project engineering expertise.<br />

The same Skilled Trades and engineering team will<br />

be instrumental in the next large centrifugal chiller<br />

installation project taking place at the Chemistry<br />

building.<br />

The East <strong>University</strong> Chiller <strong>Plant</strong>, located beneath the<br />

Dennison courtyard, provides year-around chilled<br />

water cooling for Dana, Randall, West Hall, East Hall,<br />

Denison, Pharmacy, and CC Little. The plant contained<br />

three 1240 ton steam absorption chillers until last<br />

spring, when a new 1300 ton electric centrifugal chiller<br />

was added.<br />

When it gets warm enough outside to require a<br />

chiller, the new chiller is the first one to be turned<br />

on and the last one to be turned <strong>of</strong>f. <strong>This</strong> operating<br />

strategy <strong>of</strong> utilizing the high efficiency <strong>of</strong> an electric<br />

centrifugal chiller resulted in slightly higher electrical<br />

consumption, but the huge steam cost savings resulted<br />

$1 million in EUCP steam usage savings<br />

for the year<br />

4