Multi-Chamber PID Pressure Control - Performance Motion Devices

Multi-Chamber PID Pressure Control - Performance Motion Devices

Multi-Chamber PID Pressure Control - Performance Motion Devices

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Multi</strong>-<strong>Chamber</strong> <strong>PID</strong> <strong>Pressure</strong> <strong>Control</strong><br />

<strong>Control</strong>ling the pressure of a reaction chamber using off-the-shelf ICs<br />

Application Challenge<br />

High accuracy pressure control is a common requirement for many physical processes in biochemical, semiconductor<br />

and process control industries. OEM machine designers need an off-the-shelf and cost-effective solution for single as<br />

well as multiple chambers that provides accurate <strong>PID</strong> (Proportional, Integral, Derivative) control and flexible pressure<br />

control profiles.<br />

Application Considerations<br />

Feature/Function<br />

Units<br />

<strong>Pressure</strong> <strong>Control</strong> Range 800 – 25, 000 millibar<br />

<strong>Pressure</strong> <strong>Control</strong> Accuracy 10 millibar<br />

<strong>Pressure</strong> <strong>Control</strong> Resolution 2.5 millibar<br />

# of <strong>Chamber</strong>s 3<br />

<strong>Control</strong> Solution<br />

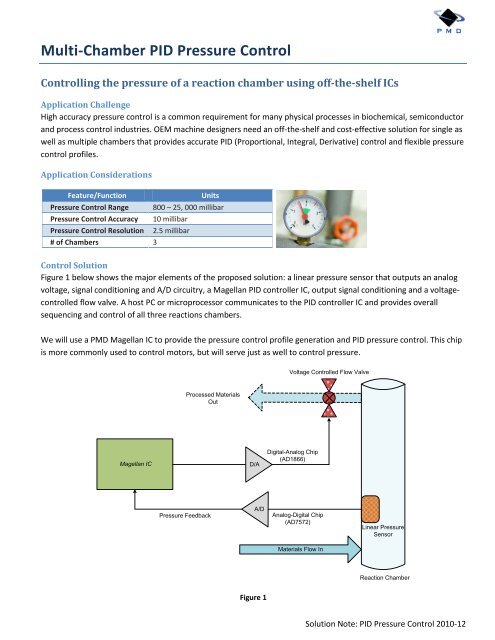

Figure 1 below shows the major elements of the proposed solution: a linear pressure sensor that outputs an analog<br />

voltage, signal conditioning and A/D circuitry, a Magellan <strong>PID</strong> controller IC, output signal conditioning and a voltagecontrolled<br />

flow valve. A host PC or microprocessor communicates to the <strong>PID</strong> controller IC and provides overall<br />

sequencing and control of all three reactions chambers.<br />

We will use a PMD Magellan IC to provide the pressure control profile generation and <strong>PID</strong> pressure control. This chip<br />

is more commonly used to control motors, but will serve just as well to control pressure.<br />

Voltage <strong>Control</strong>led Flow Valve<br />

Processed Materials<br />

Out<br />

Magellan IC<br />

D/A<br />

Digital-Analog Chip<br />

(AD1866)<br />

<strong>Pressure</strong> Feedback<br />

A/D<br />

Analog-Digital Chip<br />

(AD7572)<br />

Linear <strong>Pressure</strong><br />

Sensor<br />

Materials Flow In<br />

Reaction <strong>Chamber</strong><br />

Figure 1<br />

Solution Note: <strong>PID</strong> <strong>Pressure</strong> <strong>Control</strong> 2010-12

Solution Note: <strong>PID</strong> <strong>Pressure</strong> <strong>Control</strong> 2010-12<br />

The Magellan receives its parallel-word input by the analog voltage after it is converted to a digital signal. The<br />

Magellan's SPI output mode is used to create a command voltage to the valve using an SPI-input drive chip. There are<br />

several different types of valve control signals, such as 4-20ma signal and the +/- 10v dc signal, which will dictate the<br />

SPI drive chip to be used. This application will use a 4-20ma signal.<br />

Components Specification Description<br />

Analog-Digital Chip AD7572 Input feedback signal A/D converter<br />

Digital-Analog Chip AD1866 (SPI) The AD1866 uses SPI input and output voltage signals<br />

<strong>Control</strong>ler PMD 58000 Magellan IC Off the shelf <strong>Control</strong>ler IC<br />

Figure 2 shows the block diagram for the pressure profiling and <strong>PID</strong> controller. The Magellan's flexible architecture<br />

can be used to set a desired pressure, create pressure profiles with linear or parabolic ramps and set breakpoint<br />

conditions such as 'automatically change to a new target profile after a specified pressure set-point is reached'.<br />

P<br />

Profile<br />

Generation<br />

+<br />

_<br />

I<br />

+<br />

+<br />

+<br />

Output<br />

Signal<br />

D<br />

<strong>Pressure</strong><br />

Feedback<br />

Figure 2<br />

The <strong>PID</strong> sample/output rate should be set to match the system response. For typical pressure controllers, this means<br />

setting the <strong>PID</strong> loop sample time to between 10 mSec and 1 sec.<br />

Going Further<br />

The Magellan IC can also be used to control temperature. In fact, it is common to control both pressure and<br />

temperature in a single reaction chamber. This would take up two 'axes' of the Magellan control IC. The principle of<br />

control is the same; the input sensor provides the current temperature and the output from the <strong>PID</strong> drives a<br />

heater/cooler.<br />

The Magellan® Family of <strong>Motion</strong> <strong>Control</strong> ICs provides high performance<br />

chip-based motion control for multiple motor types. Magellan motion control<br />

ICs are available in 1, 2, 3, and 4-axis versions. They are designed for<br />

demanding and precise applications such as this pressure valve application and<br />

other automation and instrumentation challenges.<br />

Contact our customer support team at +1 781 674 9860 for more information including details on<br />

Developer’s Kits and application support. We would like to assist you in improving your motion system.<br />

<strong>Performance</strong> <strong>Motion</strong> <strong>Devices</strong>, Inc. Tel: +1 781 674 9860 www.pmdcorp.com email: motion-control@pmdcorp.com

![Navigator MC2800 Datasheet [PDF] - Performance Motion Devices](https://img.yumpu.com/25398470/1/190x245/navigator-mc2800-datasheet-pdf-performance-motion-devices.jpg?quality=85)

![Motion Control has a Field Day [PDF] - Performance Motion Devices](https://img.yumpu.com/22926252/1/190x245/motion-control-has-a-field-day-pdf-performance-motion-devices.jpg?quality=85)

![New Developments in Commutation & Motor Control [PDF]](https://img.yumpu.com/17401848/1/190x245/new-developments-in-commutation-motor-control-pdf.jpg?quality=85)