CERES 2.0 - König

CERES 2.0 - König

CERES 2.0 - König

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

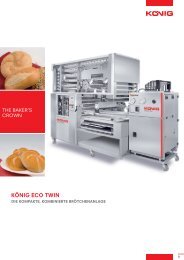

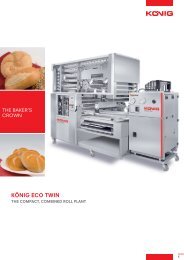

THE BAKER’S<br />

CROWN<br />

Bread<br />

<strong>CERES</strong> <strong>2.0</strong><br />

FOR BREAD IN ITS<br />

LARGEST DIVERSITY<br />

THE BAKER‘S<br />

CROWN<br />

headquaRters<br />

König Maschinen<br />

Gesellschaft m.b.H.<br />

Stattegger Straße 80<br />

8045 Graz-Andritz, Austria<br />

Tel.: +43 316.6901.0<br />

Fax: +43 316.6901.115<br />

info@koenig-rex.com<br />

www.koenig-rex.com<br />

E 148 90011 08/2007<br />

E

KÖNIG Ceres <strong>2.0</strong><br />

FOR ALL SORTS OF BREAD IN THIS WORLD.<br />

<strong>CERES</strong> <strong>2.0</strong> – THE ALL–ROUNDER.<br />

According to the knowledge of archaeologists unleavened<br />

bread was known more than 5,000 years<br />

ago, for instance in Egypt. Starting in Egypt, the art<br />

of baking bread spread to Greece and the Roman<br />

Empire and soon after captured all areas of Europe.<br />

On its way to our region many different shapes and<br />

sorts of bread developed.<br />

No matter what type of bread – wheat, rye-wheat<br />

or rye bread, Baguette or Ciabatta – today the consumer’s<br />

taste demands variety at the highest level.<br />

The baker’s challenge is to produce breads in perfect<br />

artisan quality. Ceres <strong>2.0</strong> made by König is the<br />

most technologically advanced bread-line that satisfies<br />

highest demands in terms of procedure (dough<br />

yield, bowl resting time, stress-free dough processing),<br />

accuracy, ease of cleaning and maintenance,<br />

set-up times, flexibility and product variety.<br />

The base unit consists of the bowl hoist with an integrated dough scraping device<br />

as standard as well as the patented gravitation dough dividing unit, which includes<br />

the weighing device, dividing the dough pieces absolutely gently and equally. Only<br />

by gravitation the dough is formed to a string by means of a disc, it is then discharged<br />

and weighed by a weighing belt. When the requested weight is reached,<br />

the guillotine cuts off the dough piece without any suction inside the hopper, without<br />

any pressure inside the piston and without any ejection. And if required, the<br />

proving bubbles certainly remain inside the dough.<br />

The eccentric round-moulding unit is made of a hygienic, dough-repellent material<br />

in the rounding area and gives dough pieces round shapes – as gently as the<br />

gravitation dough dividing unit does. From the eccentric round-moulding unit a<br />

transport belt transfers the dough pieces to the next processing station, for example<br />

the intermediate prover. – Due to the special design of the Ceres <strong>2.0</strong> treating<br />

the dough particularly gently, the resting process in the intermediate prover is in<br />

most cases not necessary. In this case, the dough pieces can be processed immediately,<br />

either manually or by means of a long rolling unit. A direct transfer belt<br />

can be used as an option to bypass the round moulding unit and to discharge the<br />

weighed batches in their precisely cut and angular shape.<br />

The modular design of the Ceres <strong>2.0</strong> enables the<br />

customised selection of components to meet individual<br />

needs and requirements.<br />

The era of the Ceres <strong>2.0</strong> made by König has begun.<br />

It can produce every type of bread. The reasons lie in<br />

the sophisticated technique of this line and naturally<br />

in your hands.<br />

2 3

The modules of the Ceres <strong>2.0</strong><br />

The potential of the Ceres <strong>2.0</strong><br />

Endless possibilities<br />

Bowl hoist<br />

The bowl hoist with the integrated dough scraping device automatically<br />

conveys the dough batches into the gravitation dough dividing unit.<br />

Ultimate load 700 kg.<br />

Tilting height 1,750 mm.<br />

With scraping device as standard.<br />

Gravitation dough dividing unit<br />

The weighing device of the gravitation dough dividing unit divides the<br />

dough string into equal dough pieces. As soon as the required weight of<br />

the dough pieces is reached, the guillotine cuts off the dough string.<br />

Rotating dough hopper, 300 l content, with inner cone.<br />

Rotating cutting disc.<br />

Transfer disc with duster.<br />

Dough string width 60 – 150 mm, adjustable via sensors.<br />

Electronic weighing system.<br />

1 Bowl hoist with scraping device.<br />

2 Gravitation dough dividing unit.<br />

3 Eccentric round-moulding unit.<br />

4 Take-over from weighing device.<br />

5 Guillotine.<br />

Dough yield: Flour ratio: Dough type: Hopper content: Weight range: Capacity: Connection:<br />

Multi voltage<br />

Pre-dough, direct,<br />

100% wheat up to<br />

300 – 1,200 kg/h ≈<br />

158 to 190*<br />

bowl resting time 300 l 250 – 1,800 g/pc.<br />

190 – 480 V, 50/60 Hz.,<br />

100% rye**<br />

300 – 1,500 pc./h<br />

120 min and more<br />

approx. 4 KVA<br />

* with dough divider; depending on the dough also higher dough yields possible<br />

** with dough divider; depending on the dough<br />

2<br />

3<br />

Due to the modular design of the Ceres <strong>2.0</strong> many optional units can be<br />

combined. Therefore the Ceres <strong>2.0</strong> is the all-rounder of bread production. The<br />

combination possibilities are nearly unlimited.<br />

The addition of an optional work table with a support frame for baking trays<br />

makes it possible to further process the formed and rounded dough batches<br />

manually. Alternatively, dough batches that have passed the transfer belt of the<br />

Ceres <strong>2.0</strong>, such as for Ciabatta or Baguette, can either be discharged directly<br />

by means of an adjustable transport belt with bypass device or they can be<br />

processed further.<br />

Dough pieces can be given shape and individual character by combining the<br />

Ceres <strong>2.0</strong> with different units, such as:<br />

Belt round-moulding unit for rye-wheat and rye doughs consisting of<br />

more than 60% rye.<br />

Intermediate prover.<br />

Long rolling unit.<br />

And additional units for decorating, seeding, cutting, discharging,<br />

transferring, transporting, final proving, baking, cooling, packaging, etc.<br />

1<br />

2<br />

Guillotine.<br />

Transport belt with duster.<br />

Height adjustable transfer belt.<br />

The uniqueness of the Ceres <strong>2.0</strong><br />

Eccentric round-moulding unit<br />

The dough pieces divided by the guillotine are rounded by the eccentric<br />

round-moulding unit. Due to the minimal mechanical stress the original<br />

structure of the dough remains unchanged.<br />

With duster.<br />

Transport belt with bypass for the round-moulding unit (optional)<br />

The transport belt conveys the rounded dough batches to be further<br />

processed manually or automatically. A height and length adjustable<br />

belt makes it possible to either directly remove – e.g. Ciabatta – or further<br />

process the dough pieces without the round-moulding unit – e.g.<br />

Baguettes. Naturally, the dough batches can also be transferred to an<br />

intermediate prover (not included) and/or to a long rolling unit.<br />

Work table with transport belt and support frame for baking trays<br />

(optional).<br />

1 4 5<br />

The Ceres <strong>2.0</strong> is a bread line for weighing and forming bread doughs to satisfy<br />

highest quality demands. The particular stress-free dividing and rounding<br />

procedures especially comply with all types of dough of high dough yield, long<br />

bowl resting times and to which high amounts of pre-dough are added:<br />

For all doughs with a dough yield between 158 and 190 (with dough<br />

dividing unit; depending on the dough also higher dough yields possible<br />

– trial run recommended).<br />

For all doughs ranging from 100% wheat to 100% rye (with dough dividing<br />

unit; depending on the dough – trial run recommended).<br />

For all doughs with pre-dough and long bowl resting times (possible resting<br />

time 120 min and more).<br />

One-man operation.<br />

Dough dividing unit with patented gravitation dough string technique.<br />

Hopper with 300 litre content – no pre-portioning hopper necessary.<br />

Bowl hoist with integrated scraping device to be combined directly.<br />

Sensor controlled weighing device.<br />

Hygienic materials conforming to FDA-guidelines.<br />

Nearly maintenance and wear free.<br />

Minimal cleaning efforts, shortest set up times when changing dough sorts.<br />

Siemens-S7-PLC-control with touch-panel.<br />

3<br />

1 By-passing the eccentric<br />

round-moulding device with<br />

height and length adjustable<br />

discharge belt.<br />

2 The unrounded dough<br />

batches are transported<br />

to the work table.<br />

3 Manual processing on the<br />

work table.<br />

4 Simple to open. For especially<br />

quick sort changing and easy<br />

cleaning.<br />

maximum width: 1,600<br />

unit of measurements in millimeters<br />

4 5<br />

5a<br />

4

The stress-free programme by König at a glance<br />

SFC Artisan<br />

SFR Artisan<br />

SFI Artisan<br />

Ceres <strong>2.0</strong><br />

Capacity kg per hour 400 600 1,000 1,200<br />

Bread/ bread rolls<br />

Baguette<br />

Ciabatta<br />

White bread<br />

Flat bread<br />

Rye-wheat bread<br />

Rye bread<br />

Round bread rolls<br />

Angular bread rolls<br />

Flexibility has a name:<br />

Ceres <strong>2.0</strong><br />

1<br />

possible under certain conditions<br />

3 2 4<br />

5<br />

Stress-free-competence<br />

of the market leader.<br />

What can be produced with Ceres <strong>2.0</strong><br />

Due to the possibility of producing a wide variety of breads the Ceres <strong>2.0</strong> can be<br />

called the all-rounder of the bakery. No matter what type of bread, either traditional<br />

bread such as rye bread or rye-wheat bread or typical Mediterranean bread, the<br />

Ceres <strong>2.0</strong> is the answer. Baguette, Ciabatta, white or flat bread, even pizza dough<br />

can easily be portioned with the Ceres <strong>2.0</strong>.<br />

1 Rye bread:<br />

Especially in Central and Eastern Europe rye bread is very popular. Bread made of<br />

rye flour is mellow and durable and it is characterised by a dark-coloured and tasty<br />

dough. Rich bread doughs of high dough density, such as rye bread doughs, can<br />

be easily portioned by the gravitation dough dividing unit of the Ceres <strong>2.0</strong>.<br />

2 Rye-wheat bread:<br />

Rye-wheat bread is an original bread type available in unlimited shapes and<br />

variations. The ratio between wheat and rye flour content determines the taste of<br />

the bread. The more rye flour is used, the stronger and spicier the taste. A rising<br />

proportion of wheat flour results in an increasingly light dough structure and mild<br />

taste. The integrated weighing device of the Ceres <strong>2.0</strong> divides every type of ryewheat<br />

dough equally. The doughs can also be processed by the eccentric roundmoulding<br />

unit, provided ratio of wheat exceeds 40%.<br />

3 White bread:<br />

According to the ancient Egyptians the rising lightness of wheat flour determines its<br />

nutritional value. Even today white bread ranges among the precious delicacies of the<br />

modern times. The light and mellow wheat dough is divided with minimum mechanical<br />

stress and rounded very gently by the eccentric round-moulding device of the<br />

Ceres <strong>2.0</strong>. This results in the fact that even for producing white bread in most cases no<br />

intermediate prover is needed.<br />

4 Baguette:<br />

Similar to bread itself, also the baguette is an all-rounder. According to a French legend<br />

the first baguette (“baguette” simply means “bar” in French) is said to have been baked<br />

by an Austrian baker in Paris. It is characterised by its coarse pores and crusty surface.<br />

With the Ceres <strong>2.0</strong> the dough is kept cool over a longer period of time, which results in<br />

coarse pores that are typical for the baguette.<br />

5 Ciabatta:<br />

The white bread of Italian origin based on wheat flour, yeast and water is no longer<br />

only the favourite bread of the Italians but it is also well known and popular even<br />

beyond the borders of the Mediterranean region. This cubically shaped type of bread<br />

(Italian “ciabatta” originally means: slipper, worn-out shoe, clog) differs from other<br />

wheat bread sorts because of its coarse pores. With the Ceres <strong>2.0</strong> Ciabatta can easily<br />

be produced: dividing, discharging, finished!<br />

5b<br />

6 7