full screen - Umicore Precious Metals Refining

full screen - Umicore Precious Metals Refining

full screen - Umicore Precious Metals Refining

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

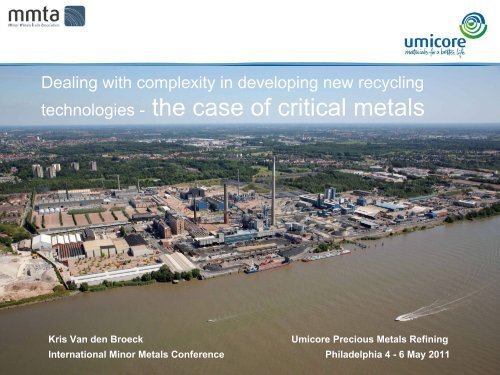

Dealing with complexity in developing new recycling<br />

technologies - the case of critical metals<br />

Kris Van den Broeck<br />

<strong>Umicore</strong> <strong>Precious</strong> <strong>Metals</strong> <strong>Refining</strong><br />

International Minor <strong>Metals</strong> Conference<br />

International Minor <strong>Metals</strong> Conference 2011<br />

Philadelphia 4 - 6 May 2011

Introduction to <strong>Umicore</strong><br />

• Global materials technology company<br />

• Mission: “materials for a better life”<br />

• Majority of growth comes from clean technologies:<br />

technologies that are specifically designed to optimize the use of<br />

natural resources and to reduce environmental impact<br />

• 2010: turnover €9.7 billion , 14,386 employees<br />

• Listed Euronext Brussels, market capitalization €4.5 billion<br />

• Visit us at www.umicore.com<br />

Dealing with complexity in developing<br />

new recycling technologies<br />

2<br />

International Minor <strong>Metals</strong> Conference 2011<br />

Kris Van den Broeck

Key megatrends for <strong>Umicore</strong><br />

Resource scarcity<br />

More stringent emission control<br />

Renewable energy<br />

Dealing with complexity in developing<br />

new recycling technologies<br />

3<br />

Electrification of the automobile<br />

International Minor <strong>Metals</strong> Conference 2011<br />

Kris Van den Broeck

Leading manufacturer of Special <strong>Metals</strong><br />

Tellurium<br />

Capacity: 150 t/y<br />

Quality: 2N5<br />

Form: powder<br />

Indium<br />

Capacity: 50 t/y<br />

Quality: 4N, 4N8<br />

Forms: ingots, shots, shells<br />

Selenium<br />

Capacity: 600 t/y<br />

Quality: 2N5, 3N, 4N5, 5N,<br />

5N+<br />

Forms: powder, shots<br />

Dealing with complexity in developing<br />

new recycling technologies<br />

4<br />

International Minor <strong>Metals</strong> Conference 2011<br />

Kris Van den Broeck

Roadmap<br />

● What are critical metals? Why recycling?<br />

● Complexitiy in recycling<br />

• Economic<br />

• Technological<br />

• Commercial<br />

● Case studies<br />

• ITO recycling<br />

• CIGS recycling<br />

• Battery recycling<br />

● Closing remarks<br />

International Minor <strong>Metals</strong> Conference 2011

Dealing with complexity in developing<br />

new recycling technologies<br />

6<br />

International Minor <strong>Metals</strong> Conference 2011<br />

Kris Van den Broeck

Critical raw materials (EU Commission)<br />

materials for which a threat to supply could involve harm to the national economy,<br />

and for which the risk is higher than for most other raw materials in the coming 10 years<br />

minor<br />

metal<br />

Source: Critical Raw Materials for the EU – European Commission Enterprise & Industry, July 2010<br />

Dealing with complexity in developing<br />

new recycling technologies<br />

7<br />

International Minor <strong>Metals</strong> Conference 2011<br />

Kris Van den Broeck

Critical raw materials (USA-DOE)<br />

importance to the clean energy economy and risk of supply disruption<br />

on short (0-5 years) and medium term (5-15 years)<br />

Source: U.S. Department of Energy – Critical materials strategy, December 2010<br />

Dealing with complexity in developing<br />

new recycling technologies<br />

8<br />

International Minor <strong>Metals</strong> Conference 2011<br />

Kris Van den Broeck

“Within the next five years (short-term perspective), Öko-Institut (DE)<br />

estimates metals tellurium, indium and gallium to be regarded as most<br />

critical due to rapid demand growth as well as serious supply risks<br />

combined with moderate recycling restrictions.”<br />

Source: UNEP report, July 2009<br />

Critical metals for future sustainable technologies and their recycling potential<br />

Dealing with complexity in developing<br />

new recycling technologies<br />

9<br />

International Minor <strong>Metals</strong> Conference 2011<br />

Kris Van den Broeck

Policies for secure access & materials efficiency<br />

EU Commission:<br />

US – Department Of Energy:<br />

• improve access to and extraction of<br />

primary resources<br />

• diversify global supply chains<br />

• level playing field in trade & investment<br />

• recycling<br />

• substitution<br />

• materials efficiency<br />

• reuse<br />

• recycling<br />

• substitution<br />

• materials efficiency<br />

Criticality factors & need for recycling do not come out of the blue<br />

Dealing with complexity in developing<br />

new recycling technologies<br />

10<br />

International Minor <strong>Metals</strong> Conference 2011<br />

Kris Van den Broeck

Clean tech applications: impact on demand<br />

Compound Annual Growth Rate by 2015 [%]<br />

50<br />

40<br />

30<br />

20<br />

10<br />

0<br />

Selenium Indium Tellurium Gallium<br />

Glass & pigments Metallurgy (incl alloys) Optics & electronics (incl LCD)<br />

Photovoltaics<br />

Others (incl chem & pharma)<br />

Source: <strong>Umicore</strong> scenario for PV: 80 GW/y in 2020, 35% share Thin Film PV<br />

Dealing with complexity in developing<br />

new recycling technologies<br />

11<br />

International Minor <strong>Metals</strong> Conference 2011<br />

Kris Van den Broeck

jan/11<br />

jul/10<br />

apr/11<br />

jan/11<br />

In,Se,Te,Ga - price evolution [$/kg] update 26-Apr-11<br />

150<br />

140<br />

130<br />

120<br />

110<br />

100<br />

90<br />

80<br />

70<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

0<br />

jul/00<br />

jan/01<br />

jul/01<br />

jan/02<br />

jul/02<br />

jan/03<br />

jul/03<br />

jan/04<br />

jul/04<br />

jan/05<br />

jul/05<br />

jan/06<br />

jul/06<br />

jan/07<br />

jul/07<br />

jan/08<br />

jul/08<br />

jan/09<br />

jul/09<br />

jan/10<br />

jul/10<br />

jan/11<br />

jan/00<br />

jul/00<br />

jan/01<br />

jul/01<br />

jan/02<br />

jul/02<br />

jan/03<br />

jul/03<br />

jan/04<br />

jul/04<br />

jan/05<br />

jul/05<br />

jan/06<br />

jul/06<br />

jan/07<br />

jul/07<br />

jan/08<br />

jul/08<br />

jan/09<br />

jul/09<br />

jan/10<br />

1100<br />

1000<br />

900<br />

800<br />

700<br />

600<br />

500<br />

400<br />

300<br />

200<br />

100<br />

0<br />

Dealing with complexity in developing<br />

new recycling technologies<br />

12<br />

International Minor <strong>Metals</strong> Conference 2011<br />

Kris Van den Broeck<br />

jan/00<br />

450<br />

425<br />

400<br />

375<br />

350<br />

325<br />

300<br />

275<br />

250<br />

225<br />

200<br />

175<br />

150<br />

125<br />

100<br />

75<br />

50<br />

25<br />

0<br />

Indium, AvgMetalBulletin 2000-2011 Selenium, AvgMetalBulletin 2000-2011<br />

Tellurium, AvgMetalPrices 2004-2011 Gallium, LowMetalPages 2005-2011<br />

jan/04 jul/04 jan/05 jul/05 jan/06 jul/06 jan/07 jul/07 jan/08 jul/08 jan/09 jul/09 jan/10 jul/10 jan/11<br />

1000<br />

900<br />

800<br />

700<br />

600<br />

500<br />

400<br />

300<br />

200<br />

100<br />

0<br />

oct/10<br />

jan/05<br />

apr/05<br />

jul/05<br />

okt/05<br />

jan/06<br />

apr/06<br />

jul/06<br />

okt/06<br />

jan/07<br />

apr/07<br />

jul/07<br />

okt/07<br />

jan/08<br />

apr/08<br />

jul/08<br />

oct/08<br />

jan/09<br />

apr/09<br />

jul/09<br />

okt/09<br />

jan/10<br />

apr/10<br />

jul/10

continuously increasing demand for a.o.<br />

clean tech applications<br />

&<br />

government policies<br />

&<br />

consumer + producer policies<br />

<br />

need for recycling<br />

International Minor <strong>Metals</strong> Conference 2011

Recycling: clear benefits<br />

<br />

De-coupling from primary production<br />

production scrap is a significant, readily available resource<br />

<br />

Economically justifiable<br />

production scrap has an economic value<br />

<br />

<br />

<br />

<br />

Lower environmental impact<br />

recycling needs less energy & has lower CO 2<br />

emissions<br />

Mitigate metal scarcity by resource conservation<br />

special metals are reused in products, instead of landfilled<br />

Remove impact of metal price fluctuations<br />

the producer may remain owner of the metal in the scrap<br />

Secure access to raw materials<br />

you know the location, the recycler and the owner<br />

Dealing with complexity in developing<br />

new recycling technologies<br />

14<br />

International Minor <strong>Metals</strong> Conference 2011<br />

Kris Van den Broeck

Roadmap<br />

What are critical metals? Why recycling?<br />

● Complexitiy in recycling<br />

• Economic<br />

• Technological<br />

• Commercial<br />

● Case studies<br />

• ITO recycling<br />

• CIGS recycling<br />

• Battery recycling<br />

● Closing remarks<br />

International Minor <strong>Metals</strong> Conference 2011

Recycling: as easy as in the movies?<br />

Wall-E (Pixar movies)<br />

Dealing with complexity in developing<br />

new recycling technologies<br />

16<br />

International Minor <strong>Metals</strong> Conference 2011<br />

Kris Van den Broeck

Economic complexity<br />

Positive vs negative value materials<br />

Production scraps vs End-Of-Life materials<br />

Value<br />

Contained<br />

metals<br />

Positive value recycling<br />

Lost metals<br />

Recovered<br />

metals<br />

Supplier’s<br />

return<br />

Recycler’s<br />

return<br />

• e-scrap / printed circuit boards<br />

• spent automotive catalysts<br />

• spent industrial catalysts<br />

• spent ITO targets<br />

• CIGS production scraps<br />

Recycling cost<br />

The value of the material is sufficient to cover<br />

suppliers return + recyclers return + recycling cost<br />

no direct need for regulation or incentives<br />

Dealing with complexity in developing<br />

new recycling technologies<br />

17<br />

International Minor <strong>Metals</strong> Conference 2011<br />

Kris Van den Broeck

Recycling potential<br />

From production wastes -TODAY<br />

Very high<br />

High<br />

Medium<br />

Low<br />

Very low<br />

Selenium Indium Tellurium Gallium<br />

Glass & pigments Metallurgy (incl alloys) Optics & electronics (incl LCD)<br />

Photovoltaics<br />

Source: <strong>Umicore</strong><br />

Others (incl chem & pharma)<br />

Dealing with complexity in developing<br />

new recycling technologies<br />

18<br />

International Minor <strong>Metals</strong> Conference 2011<br />

Kris Van den Broeck

Economic complexity (2)<br />

Positive vs negative value materials<br />

Production scraps vs End-Of-Life materials<br />

Negative value recycling<br />

Value<br />

Lost metals<br />

Recycler’s<br />

return<br />

• rechargeable batteries<br />

• LCD displays<br />

• PhotoVoltaic (end-of-life) modules<br />

Contained<br />

metals<br />

Recovered<br />

metals<br />

Recycling cost<br />

Supplier’s recycling fee<br />

The value of the material is not sufficient to cover<br />

suppliers return + recyclers return + recycling cost<br />

financing models, government incentives or legislation is needed<br />

Dealing with complexity in developing<br />

new recycling technologies<br />

19<br />

International Minor <strong>Metals</strong> Conference 2011<br />

Kris Van den Broeck

Recycling potential<br />

From End-of-LIfe wastes –FUTURE<br />

Very high<br />

High<br />

Medium<br />

Low<br />

Very low<br />

Selenium Indium Tellurium Gallium<br />

Glass & pigments Metallurgy (incl alloys) Optics & electronics (incl LCD)<br />

Photovoltaics<br />

Source: <strong>Umicore</strong><br />

Others (incl chem & pharma)<br />

Dealing with complexity in developing<br />

new recycling technologies<br />

20<br />

International Minor <strong>Metals</strong> Conference 2011<br />

Kris Van den Broeck

Technological complexity<br />

Multi-metal (complex) materials require:<br />

• State-of-the-art technology;<br />

• combination pyro-& hydrometallurgy<br />

• Knowledge management (knowhow, IP)<br />

• R&D support;<br />

• continuous improvement<br />

• break-through ideas<br />

In<br />

Pb<br />

Au<br />

Pd<br />

Cu<br />

As<br />

Sb<br />

Bi<br />

Sn<br />

Se<br />

Ir<br />

Ru<br />

Ag Rh<br />

Te Pt<br />

Ni<br />

• Sampling & assaying essential to determine return distribution<br />

• Environmental management excellence;<br />

• resource efficiency (materials and energy)<br />

• eco-efficiency<br />

Dealing with complexity in developing<br />

new recycling technologies<br />

21<br />

International Minor <strong>Metals</strong> Conference 2011<br />

Kris Van den Broeck

Commercial complexity<br />

• Market intelligence;<br />

• supply market<br />

• metals market<br />

• worldwide sales network in order to secure access to scraps<br />

• ethical supply<br />

• Credit worthiness important in business where high (metal) values are in the<br />

loop<br />

• Control the costs<br />

• Offer a no-worries service (pick-up, customs formalities, metal account)<br />

• EHS support: MSDS, CLP, REACh-compliant<br />

• Auditing<br />

Dealing with complexity in developing<br />

new recycling technologies<br />

22<br />

International Minor <strong>Metals</strong> Conference 2011<br />

Kris Van den Broeck

Roadmap<br />

What are critical metals? Why recycling?<br />

Complexitiy in recycling<br />

• Economic<br />

• Technological<br />

• Commercial<br />

● Case studies<br />

• ITO recycling<br />

• CIGS recycling<br />

• Battery recycling<br />

● Closing remarks<br />

International Minor <strong>Metals</strong> Conference 2011

ITO target recycling<br />

Closed loop recycling of indium in Providence (US)<br />

• Spent ITO targets have a high value, which drives recycling<br />

• <strong>Umicore</strong> combines production of indium and ITO targets with recycling<br />

of spent targets, all in-house<br />

• Old target can easily be swapped for new target via regional centers in<br />

US, Taiwan and Liechtenstein<br />

• Indium (as ITO target) quickly enters the life cycle again<br />

Efficient material usage and a closed material loop<br />

Dealing with complexity in developing<br />

new recycling technologies<br />

24<br />

International Minor <strong>Metals</strong> Conference 2011<br />

Kris Van den Broeck

CIGS production scrap recycling<br />

New process in Hoboken (BE) [capacity 50 t/y]<br />

• <strong>Umicore</strong> has closed the cycle for production wastes<br />

from sputtering and evaporation chambers<br />

• Convert hazardous waste into valuable materials<br />

• Cu, In, Ga and Se are recovered for use in the PV or<br />

other industries<br />

• Business model:<br />

• Customer pays a treatment charge for the recycling service<br />

• <strong>Metals</strong> return is based on sampling and assaying of the<br />

production scrap<br />

• The customer may remain owner of the metals, so no<br />

impact of price fluctuations<br />

• Assistance with waste shipments etc. can be provided<br />

Dealing with complexity in developing<br />

new recycling technologies<br />

25<br />

International Minor <strong>Metals</strong> Conference 2011<br />

Kris Van den Broeck

Battery Recycling<br />

New process in Hoboken (BE) [capacity 7,000 t/y]<br />

First ever developed process with a specific focus<br />

on the need for rechargeable battery recycling<br />

Li-ion & NiMh<br />

• Unique recycling process with a maximum<br />

valorisation of valuable metals Co & Ni<br />

• Clean process with minimum energy use, CO 2 and<br />

waste generation<br />

• Safe and <strong>full</strong> service from battery transport to<br />

recycling, all complying with the strictest regulations<br />

First industrial pilot plant under construction, to be<br />

commissioned mid 2011<br />

• Future volume of this business is driven by the<br />

merging electrification of transport<br />

Dealing with complexity in developing<br />

new recycling technologies<br />

26<br />

International Minor <strong>Metals</strong> Conference 2011<br />

Kris Van den Broeck

Roadmap<br />

What are critical metals? Why recycling?<br />

Complexitiy in recycling<br />

• Economic<br />

• Technological<br />

• Commercial<br />

Case studies<br />

• ITO recycling<br />

• CIGS recycling<br />

• Battery recycling<br />

● Closing remarks<br />

International Minor <strong>Metals</strong> Conference 2011

Closing remarks<br />

• Present and expected future growth of the clean tech & high tech<br />

industry will place strong demand on specific “critical” materials<br />

that leads to a debate on their respective future availability<br />

• Recycling of production scraps (today) and End-of-Life modules<br />

(future) can make significant contributions to ensuring a secure<br />

metals supply<br />

• This recycling potential is found in currently minor applications,<br />

with high CAGR creating future material resources<br />

• <strong>Umicore</strong> operates appropriate technologies for efficient and<br />

environmentally sound recycling of production scraps<br />

• Effective recycling goes beyond technology aspects.<br />

Dealing with complexity in developing<br />

new recycling technologies<br />

28<br />

International Minor <strong>Metals</strong> Conference 2011<br />

Kris Van den Broeck

Thank you<br />

Contact<br />

Kris Van den Broeck<br />

Christina Meskers<br />

Address Adolf Greinerstraat 14<br />

2660 Hoboken<br />

Belgium<br />

e-mail<br />

kris.vandenbroeck@umicore.com<br />

christina.meskers@eu.umicore.com<br />

Website<br />

www.preciousmetals.umicore.com<br />

www.pvmaterials.umicore.com<br />

International Minor <strong>Metals</strong> Conference 2011