South Bowie Library - Art in Public Places - Prince George's County

South Bowie Library - Art in Public Places - Prince George's County

South Bowie Library - Art in Public Places - Prince George's County

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

LUMINOUS OAK<br />

MID-PROJECT UPDATE<br />

May 21, 2012<br />

Roger White Stoller<br />

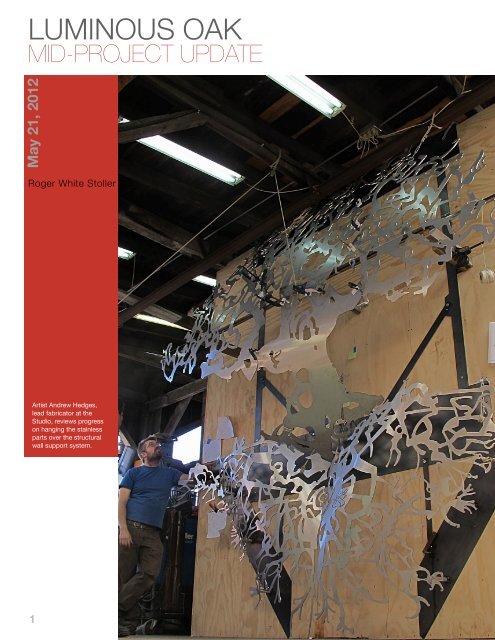

<strong>Art</strong>ist Andrew Hedges,<br />

lead fabricator at the<br />

Studio, reviews progress<br />

on hang<strong>in</strong>g the sta<strong>in</strong>less<br />

parts over the structural<br />

wall support system.<br />

1

STOLLERSTUDIO May 21, 2012<br />

Partners with<br />

Stoller Studio on<br />

numerous<br />

projects, we<br />

rema<strong>in</strong> grateful<br />

Nor Cal for their<br />

skill, dedication,<br />

and attention to<br />

detail, required<br />

for the high-craft<br />

artwork Stoller<br />

Studio creates.<br />

Laser Cutt<strong>in</strong>g & Form<strong>in</strong>g<br />

The structural support and all the<br />

artwork panels designed at the Studio<br />

started fabrication at Nor Cal Metal Fab<br />

<strong>in</strong> Oakland, CA. Without this type of<br />

<strong>in</strong>dustrial mach<strong>in</strong>ery, Lum<strong>in</strong>ous Oak<br />

could not be built.<br />

2

STOLLERSTUDIO May 21, 2012<br />

The structural wall<br />

plates shown at left<br />

are be<strong>in</strong>g used first<br />

to fabricate the<br />

attachment system<br />

of the sculpture.<br />

When this has been<br />

completed at the<br />

Studio, they will be<br />

disassembled and<br />

shipped to the <strong>South</strong><br />

<strong>Bowie</strong> <strong>Library</strong> to be<br />

permanently built<br />

<strong>in</strong>to the fireplace<br />

wall.<br />

“Attachments”<br />

The image below<br />

shows an <strong>in</strong>ner post<br />

welded to a<br />

structural wall panel.<br />

The concentric<br />

square tube slid over<br />

the post will be<br />

welded to the back<br />

side of the sculpture.<br />

Structural Support<br />

System<br />

This wood wall was created <strong>in</strong> the<br />

Studio as a scaffold upon which to<br />

fabricate the sculpture.<br />

3

STOLLERSTUDIO May 21, 2012<br />

“Connector” plate<br />

detail at right<br />

shows how the<br />

connection is<br />

expressed from<br />

the outside - as<br />

part of the artwork.<br />

The welds will be<br />

ground out later <strong>in</strong><br />

the f<strong>in</strong>ish<strong>in</strong>g<br />

process.<br />

Below, the back of<br />

two connectors are<br />

shown with<br />

temporary nuts<br />

and clamps<br />

hold<strong>in</strong>g the parts<br />

for assembly.<br />

Connectors<br />

Attachments<br />

Image to the right shows the <strong>in</strong>terface<br />

between the structural posts and the back<br />

of the sculpture. After a perfect<br />

alignment is achieved the sleeves will be<br />

welded to the back of the sculpture,<br />

lock<strong>in</strong>g the alignment <strong>in</strong> place. This<br />

assures that after the support structure is<br />

built <strong>in</strong>to the <strong>Library</strong> wall, the sculpture<br />

will slide right <strong>in</strong>to place.<br />

4

STOLLERSTUDIO May 21, 2012<br />

Studio Director<br />

David Naisuler<br />

checks the overall<br />

structural-design<br />

and rigg<strong>in</strong>g system<br />

he designed for this<br />

stage of the<br />

fabrication.<br />

Billow<strong>in</strong>g Sta<strong>in</strong>less<br />

The tree canopy & trunk billow<br />

far from the wall - these four<br />

sections are jo<strong>in</strong>ed to each other<br />

by “connector” plates, shown <strong>in</strong><br />

detail previously on page 4..<br />

The roots below are made up of<br />

two panels. Noth<strong>in</strong>g below the<br />

trunk requires a “connector”,<br />

only attachment posts.<br />

5

STOLLERSTUDIO May 21, 2012<br />

Turn<strong>in</strong>g the Corners<br />

The roots run out to the sides of the<br />

sculpture to take a 90º turn around<br />

the corners of the fireplace wall.<br />

David and Andrew align the<br />

side root panels that will be<br />

welded and f<strong>in</strong>ished to become<br />

a s<strong>in</strong>gle piece.<br />

6<br />

6

STOLLERSTUDIO May 21, 2012<br />

Shown above is a<br />

panel with l<strong>in</strong>es<br />

laser-etched <strong>in</strong>to<br />

the steel. These<br />

will guide the<br />

hand-brushed<br />

textur<strong>in</strong>g <strong>in</strong> the<br />

next phase. This<br />

process will<br />

create the<br />

f<strong>in</strong>ished surface<br />

of the sculpture.<br />

To the right is a<br />

full scale one foot<br />

square test<br />

section show<strong>in</strong>g<br />

how the different<br />

textures will look<br />

on the f<strong>in</strong>al<br />

artwork.<br />

Brushed Textures<br />

7

STOLLERSTUDIO May 21, 2012<br />

This computer<br />

model image of the<br />

artwork on the<br />

fireplace wall <strong>in</strong> the<br />

<strong>South</strong> <strong>Bowie</strong> <strong>Library</strong><br />

shows the second<br />

prelim<strong>in</strong>ary light<strong>in</strong>g<br />

test. We are<br />

currently test<strong>in</strong>g<br />

three LED lamps,<br />

one on the center of<br />

the roots and two on<br />

the canopy.<br />

Next, Hydrell<br />

Light<strong>in</strong>g will be<br />

provid<strong>in</strong>g additional<br />

computer test<strong>in</strong>g<br />

with virtual LED<br />

specifications.<br />

From these tests we<br />

will order fixtures<br />

and locate<br />

placement on the<br />

<strong>Library</strong> ceil<strong>in</strong>g, to be<br />

<strong>in</strong>stalled by the GC.<br />

Light<strong>in</strong>g<br />

Detail-Design & Eng<strong>in</strong>eer<strong>in</strong>g<br />

Prior to this update the team completed the detaildesign<br />

and eng<strong>in</strong>eer<strong>in</strong>g phases of the project. Ma<br />

Chi Chen, Ph.D. of CES Eng<strong>in</strong>eer<strong>in</strong>g completed<br />

Stoller Studio’s calculations on the support structure<br />

and attachment po<strong>in</strong>ts. This was reviewed by Matt<br />

McArdle of Columbia Eng<strong>in</strong>eer<strong>in</strong>g <strong>in</strong> Maryland<br />

and has been <strong>in</strong>corporated <strong>in</strong>to the f<strong>in</strong>al<br />

eng<strong>in</strong>eer<strong>in</strong>g package to be wet-stamped by Mr.<br />

McArdle for PGC.<br />

LUMINOUS OAK<br />

NEXT STEPS...................<br />

• LED light<strong>in</strong>g<br />

• weld<strong>in</strong>g & fab<br />

• certified weld<strong>in</strong>g<br />

• ship wall-structure to <strong>Bowie</strong><br />

• GC builds structure <strong>in</strong>to wall<br />

• hand-brushed f<strong>in</strong>ish<strong>in</strong>g<br />

• brace & pack sculpture parts<br />

• ship sculpture to <strong>Bowie</strong><br />

• <strong>in</strong>stallation<br />

8<br />

7