Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Copyright © 2012 Charles McGrory<br />

<strong>DISTANT</strong> <strong>BLUE</strong><br />

RENOVATION – A WORK IN PROGRESS…<br />

2011<br />

CHARLES MCGRORY<br />

0

Copyright © 2012 Charles McGrory<br />

Underbody Renovation 2011 Distant Blue<br />

Moisture readings standards.<br />

Readings are not actual percentages but a relative reading 0 – 100 with actual approximately 1 – 4%.<br />

0 ≤ 15 Very good Dry<br />

15 ≤ 20 Satisfactory: Slight moisture of no concern.<br />

21 ≤ 30 Moderate: Some moisture present but not considered a defect.<br />

30 ≤ 45 High: Risk of moisture-related defects.<br />

45 ≤ 60 Very High: Probable Osmotic condition<br />

60 ≤ 100 Extremely High: Probable Laminate Degradation<br />

Hull below waterline<br />

No evidence by tapping with hammer of delamination or voids. Actual state of laminate cannot be<br />

completely guaranteed without destructive testing.<br />

Distant Blue Moisture testing conditions: were good for testing<br />

Air temperature:<br />

21◦ C<br />

Above dew point:<br />

8.4 ◦ C<br />

Surface temperature:<br />

19.6 ◦ C<br />

Relative Humidity: 53%<br />

Readings were as follows: Sovereign Quantum: Scale 0 – 100<br />

Shallow Mode Deep Mode<br />

Range above waterline: 14 – 16 13 – 21<br />

Range below waterline: 16 – 32 21 – 36<br />

The surveyor cautioned that, “there was risk of moisture-related defects but none were visually<br />

apparent. He added that careful control of water in bilges, and ventilation, especially over winters<br />

ashore may assist in keeping moisture levels from rising and may allow them to diminish.”<br />

He added, “The epoxy layer on the hull was of unknown vintage, but judging from the number of<br />

different layers of antifouling on the hull above the epoxy, it had been in place for many years.<br />

Consideration should be given to removing all the layers of depleted antifouling and ‘keying’ the<br />

surface and applying more layers of epoxy as the moisture resistance of the original is outside the<br />

guaranteed performance criteria (normally 10 years).<br />

Osmosis chemistry and Boat Hulls<br />

“Osmosis is the movement of solvent molecules through a partially permeable membrane into a region<br />

of higher solute concentration, aiming to equalize the solute concentrations on the two sides.”<br />

Wikipedia<br />

1

Copyright © 2012 Charles McGrory<br />

My comments: Osmosis and Osmosis Blistering<br />

The actual osmotic travel of water into the laminate on a gross scale would not be good for the<br />

laminate. However, it is my understanding that the problem is substantially aggravated when such<br />

water migrates and finds a ‘void’ within the laminate and when such a ‘void’ contains un-reacted<br />

polyester, left over from production, then a reaction kicks in to result in osmosis blistering which can<br />

be severe. This is likely aggravated by salt water and any chemicals picked up in an industrial<br />

harbour. The longer the hull is immersed in water, the greater the potential for osmotic migration of<br />

the outside water into the boat hull.<br />

A winter ashore will help decrease the migration and given ventilation and heat there would be some<br />

release of the water back to atmosphere, restrained by the underbody coatings and shield which<br />

would be preventing release back to atmosphere.<br />

Distant Blue Construction<br />

I accepted the surveyor’s report, cautions and recommendations and bought the boat. I had seen no<br />

indications of blistering and noted that there were indications of good construction e.g. the hull deck<br />

joint flange of some 15-20mm was clean and stable with no indications of any leakage down through<br />

the teak toe-rail bolts from twisting or warping of the hull-deck. The original Lloyds A1 inspection<br />

certificate was present. A previous French potential buyer who was considering the boat for a sailing<br />

school backed off when he heard there was moisture present.<br />

Distant Blue hull was designed in 1960s built to 1960s specifications in 1979/80 in the days of thick<br />

GRP construction. The Tyler reputation came from their use of clear laminates where they could see<br />

any voids and likely in those days, slow careful squeezing of the laminates and resin, reducing<br />

substantially the chances of voids and un-reacted polyester. Leaving the hull to cure carefully in the<br />

mould would assist in the completed reaction of any polyester leaving no reactant left.<br />

I considered that any problems were not imminent and could be prevented and the modern boat did<br />

not provide any more stable expectation and was not the sea boat I wanted.<br />

‘Modern’ Cored Construction and Design vs. <strong>Ohlson</strong> <strong>38</strong><br />

Many boats from the late 70s and on into 1980s, began to move to thin GRP skins and balsa-cored<br />

hulls; also the increased demand caused pressure on production managers to fast-cure or cut short<br />

the long cure-time in the moulds. CS Yachts in Toronto in the 1980s had severe problems of osmosis<br />

blisters in new yachts under five years old. They then offered new owners an upgrade cost option to<br />

seal the hull with shield; not sure if this changed their speed of process in the moulds.<br />

C & C yachts near Toronto had moved to balsa-cored hulls and decks. I know of one ten-year old boat,<br />

C & C 36 where the deck was rotting around the stanchions. The problem with balsa-cored boats,<br />

while claiming to have epoxy-sealed balsa segments in the core, is that if water migrates through the<br />

hull by osmosis into the balsa, then water may start to ‘liquefy’ the balsa. On this C & C 36, it was<br />

quite possible to take the stanchion, waggle it around and watch the deck deflect. Found this out<br />

halfway from Bermuda to Boston! Also the spade rudder was very tiring to steer in Force 7-8 seas.<br />

In our harbour in Sarnia, Ontario, a C & C 39 came in from the summer cruise in Lake Huron. She had<br />

hit a rock and divers sent down reported no obvious damage other than a dent in the lead fin keel.<br />

She was then sailed all summer. The end of season she was hauled out and later that winter at some<br />

20◦ C below, the hull all around the keel ‘exploded’. Water had migrated into the balsa from cracks in<br />

the hull along the keel base where the keel had torqued on the impact of the collision with the rock;<br />

the expansion of the water turning into ice ruptures the hull along the keel length and for nearly a<br />

metre outboard. So you can see I am not a great admirer of ‘modern’ sandwich construction.<br />

2

Copyright © 2012 Charles McGrory<br />

‘Modern’ Hull Design<br />

<strong>Ohlson</strong> <strong>38</strong> and Contessa 32 designs are with a long fin keel, skeg and rudder with long V overhanging<br />

bow and ‘wineglass’ hull sitting deep in the water. I was really pleased with the Contessa 32<br />

performance in all weathers especially in the steep seas of the Great Lakes but I wanted more space<br />

inside.<br />

A year before I bought Distant Blue, I had sailed a Beneteau in Toronto and a Bavaria 32 in Scotland’s<br />

Firth of Clyde. Both boats are ‘modern’ design with low weight sandwich construction which allows<br />

high topsides, large volume hulls, fat bows and spade rudders; they sit up on the water and with high<br />

windage and wide bows have poor upwind performance in choppy seas; they are tiresome to steer<br />

with the spade rudders. So that is part of the background why I searched for and bought an <strong>Ohlson</strong><br />

<strong>38</strong>. Any upgrade work was a valid investment on a known vessel of pedigree.<br />

Distant Blue Underbody Renovation<br />

The boat had been out of the water from spring 2010; the survey was in October 2010 so to that<br />

extent the hull may have dried a little. I followed the surveyor’s recommendation to provide<br />

ventilation and heat. There was only the small companionway louvre available which I left open; I set<br />

up a dehumidifier and a tube heater in the main cabin I removed all the cushions and removed the<br />

access wooden panels from the bunks etc.<br />

The boat was sandblasted in approximately March 2011; there had been years of antifouling which<br />

needed to come off; I was assured by Joshua of Suffolk Yacht Harbour that the light-touch blasting<br />

would not affect the gel coat. The hull underbody appeared quite sound with no blistering and was<br />

smooth other than damage to the keel which had been observed by the surveyor; it was worse than<br />

we thought and was repaired. The rudder showed signs of having been bored and drained of water at<br />

some time.<br />

After blasting<br />

3

Copyright © 2012 Charles McGrory<br />

The original Gelshield was much lower than the current waterline and somewhere the boat had<br />

become heavier than the designer’s marks. We think this is perhaps due to the heavy cabinetry or<br />

that the designer made a mistake or the hull layup was heavier than spec. Still a mystery…<br />

You can see the original LWL and original dark Gelshield.<br />

And the massive oversize boot-top limit.<br />

Now the LWL is about 6cm above the tip of the aft tip of the rudder.<br />

Rudder with signs of prior maintenance drainage of water<br />

4

Copyright © 2012 Charles McGrory<br />

Keel damage was a wee bit of a shock.<br />

Worse than we thought<br />

Now fully repaired<br />

After the sanding etc three coats of new Gelshield were applied.<br />

Gelshield Topside and Gold Coveline applied<br />

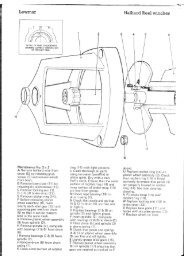

The mountings for the Hydrovane can be seen on the counter<br />

The topsides were repainted with ‘Awlgrip’ to a superb finish; actually it is ‘Awlcraft’ which is easier to<br />

retouch which was put to test after an incident at the dock. A novice sailor though they were doing me<br />

a favour by applying power as the boat was being handed off the dock; the power caused the bow<br />

cutwater to collide with the dock and scuff the paint; this was buffed off with no additional painting;<br />

the Awlcraft is soft enough and was thick enough to be moved over the scuff. The yard Suffolk Yacht<br />

Harbour had applied four coats of paint, baked on. The novice has not been invited back as yet… still<br />

thinking about it…<br />

We had a lot of concern as to where the waterline was truly since she was on the hard when I bought<br />

her and she had a massive boot-top which made the boat look clumsy and inelegant. The yard gave<br />

me a free hoist and dunk and Nick Fairhurst marked the LWL as she floated, with a margin of some<br />

50mm for safe loading.<br />

5

Copyright © 2012 Charles McGrory<br />

Distant Blue – just out of shop<br />

I am delighted with the results; she is much admired. Many other yachtsmen came by and asked what<br />

type of boat she was. Right now she is out of the water and being further upgraded. In all perhaps she<br />

will have been out of the water about 23 months total again with heater and dehumidifier.<br />

Looking forward to next launch!<br />

I am also very pleased with the all the staff at Suffolk Yacht Harbour who gave me their skill and<br />

enthusiasm to bring her back to pedigree standing and in particular Joshua Major for his overall<br />

coordination and interest; Nick Fairhurst who managed the project with detailed care and helpful<br />

suggestions; Howard who did the woodwork, Robert who installed the Hydrovane and Andrew who<br />

installed the new Forehatch.<br />

6

Copyright © 2012 Charles McGrory<br />

Distant Blue – new beginnings<br />

The Dream-Ship tugs....<br />

with the stirring of the sea.<br />

The creaking tackle...<br />

break the stillness of the dawn,<br />

while morning dew glistens...<br />

chill in the thin light.<br />

Hushed voices knock on the hollow air.<br />

Ropes run out, halyards running,<br />

shaking her sails as flapping happy wings,<br />

My Ship wakens from her sleep<br />

to slip and slide thro the ruffled water.<br />

Ropes alive, tiller kicking,<br />

Bow wave tumbling, hissing,<br />

Quivering.... she leans,<br />

to hear the whispers of the wind.<br />

As she dips in gentle curtsey<br />

to the heave of the ocean roller,<br />

the clouds rush by on the ocean of the sky.<br />

Sunlight dances on the golden brine.<br />

Bear up! My Ship,<br />

that we may find, in the Distant Blue...<br />

the promise of this day, that's yours and mine!<br />

Copyright (c) 2011 Charles McGrory<br />

7