You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

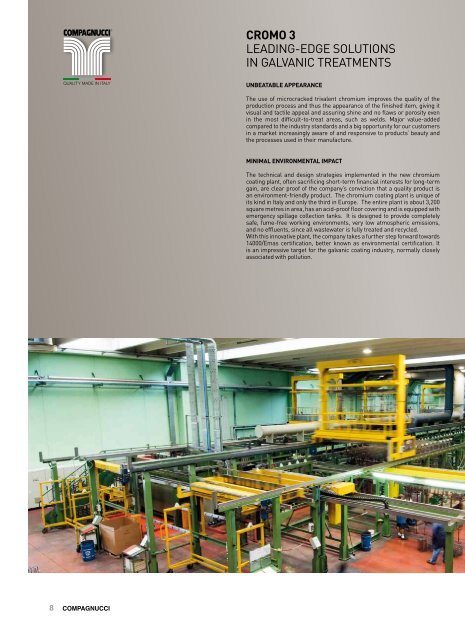

CROMO 3<br />

LEADING-EDGE SOLUTIONS<br />

IN GALVANIC TREATMENTS<br />

UNBEATABLE APPEARANCE<br />

The use of microcracked trivalent chromium improves the quality of the<br />

production process and thus the appearance of the finished item, giving it<br />

visual and tactile appeal and assuring shine and no flaws or porosity even<br />

in the most difficult-to-treat areas, such as welds. Major value-added<br />

compared to the industry standards and a big opportunity for our customers<br />

in a market increasingly aware of and responsive to products’ beauty and<br />

the processes used in their manufacture.<br />

MINIMAL ENVIRONMENTAL IMPACT<br />

The technical and design strategies implemented in the new chromium<br />

coating plant, often sacrificing short-term financial interests for long-term<br />

gain, are clear proof of the company’s conviction that a quality product is<br />

an environment-friendly product. The chromium coating plant is unique of<br />

its kind in Italy and only the third in Europe. The entire plant is about 3,2<strong>00</strong><br />

square metres in area, has an acid-proof floor covering and is equipped with<br />

emergency spillage collection tanks. It is designed to provide completely<br />

safe, fume-free working environments, very low atmospheric emissions,<br />

and no effluents, since all wastewater is fully treated and recycled.<br />

With this innovative plant, the company takes a further step forward towards<br />

14<strong>00</strong>0/Emas certification, better known as environmental certification. It<br />

is an impressive target for the galvanic coating industry, normally closely<br />

associated with pollution.<br />

8 COMPAGNUCCI