AW PTT INDUSTRIAL front(cover)2

AW PTT INDUSTRIAL front(cover)2

AW PTT INDUSTRIAL front(cover)2

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>PTT</strong> MOLY-PLEX GREASE (NLGI 0, 2)<br />

<strong>PTT</strong> Moly EP Grease is premium grade for multi-purpose and special lubrication, and produced from high quality Lithium<br />

complex-based grease and contains anti-wear, rust inhibitor, anti-oxidation, and extreme pressure (EP) additives for<br />

extreme workload, water resistance, and long service life. Moreover, for more efficient, Molybdenum Disulfide (MoS 2 )<br />

is added to reduce friction at metal surface.<br />

Applications<br />

• Suitable for lubrication in automotive and industrial parts which have extreme workload and maximum<br />

temperature at 200 o C and the application where the vibration is existed such as heavy equipment especially<br />

in mining operation.<br />

• Can be used in the industry which involve with dust, mist, or high moisture, for example construction,<br />

mining and agriculture industries.<br />

Reference standards NLGI (National Lubricating Grease Institute) standard<br />

<strong>PTT</strong> LI-PLEX GREASE (NLGI 2, 3)<br />

<strong>PTT</strong> Li-plex Grease is premium quality heat resistance grease for high temperature applications, and produced from<br />

high quality Lithium complex-based grease and contains anti-wear, rust inhibitor, anti-oxidation, and prolongs your<br />

bearing life with excellent Extreme pressure additives thus reduce maintenance.<br />

Applications<br />

• Suitable for lubrication in automotive and industrial parts which have heavy workload and maximum<br />

temperature at 180 o C such as wheel truck bearing, moderate speed industrial hot air blower etc.<br />

Reference standards NLGI (National Lubricating Grease Institute) standard<br />

<strong>PTT</strong> MOLY EP GREASE (NLGI 2)<br />

<strong>PTT</strong> Moly EP Grease is high quality grease for multi-purpose lubrication, and produced from high quality<br />

Lithium-based grease and contains anti-wear, rust inhibitor, anti-oxidation and extreme pressure (EP) additives<br />

for extreme workload, water resistance, and long service life. Moreover, for more efficient, Molybdenum Disulfide<br />

(MoS 2 ) is added to reduce friction at metal surface.<br />

Applications<br />

• Suitable for lubrication in automotive and industrial parts which have extreme workload and maximum<br />

temperature at 130 o C and the application where the vibration is existed such as heavy equipment especially<br />

in mining operation.<br />

• Can be used in the industry which involve with dust, mist or high moisture, for example construction and<br />

agriculture industries.<br />

Reference standards (National Lubricating Grease Institute)<br />

<strong>PTT</strong> EP GREASE (NLGI 0, 1, 2, 3)<br />

<strong>PTT</strong> EP Grease is premium quality grease for multi-purpose lubrication, and is produced from high quality<br />

Lithium-based grease containing rust inhibitor, anti-oxidation and reliable extreme pressure (EP) additives for heavy<br />

workload and longer bearing life.<br />

Applications<br />

• Suitable for lubrication in automotive and industrial parts which have heavy workload and maximum temperature<br />

at 130 o C such as general vehicle wheel bearing, high load carrying bearing, bearing facing with shock load.<br />

Reference standards NLGI (National Lubricating Grease Institute)<br />

<strong>PTT</strong> MP GREASE (NLGI 2, 3)<br />

<strong>PTT</strong> MP Grease is high quality multi-purpose non-EP grease for general lubrication, and produced from high quality<br />

Lithium-based grease containing anti-wear, rust inhibitor and anti-oxidation additives for longer bearing life and<br />

provide good lubrication.<br />

Applications<br />

• Suitable for lubrication in general automotive and industrial parts with maximum temperature at 130 o C such<br />

as general motor bearing in industrial.<br />

Reference standards NLGI (National Lubricating Grease Institute)<br />

<strong>PTT</strong> CHASSIS GREASE (NLGI 2, 3)<br />

<strong>PTT</strong> Chasis Grease is general water resistance grease for moderate workload, and produced from high quality<br />

Calcium-based grease with fine fiber structure containing tackiness agent and rust inhibitor and additive for<br />

tackiness and water resistance property.<br />

Applications<br />

• Suitable for lubrication in moderate workload system with maximum temperature at 70 o C.<br />

• Designed for vehicle chassis system such as connecting joint, not recommended for wheel bearing<br />

Reference standards NLGI (National Lubricating Grease Institute)<br />

<strong>PTT</strong> CUP GREASE (NLGI 3)<br />

<strong>PTT</strong> Cup Grease is water resistance light duty grease for a light workload applications, and produced from high<br />

quality Calcium-based grease containing tackiness agent and rust inhibitor for tackiness and water resistance<br />

property.<br />

Applications<br />

• Suitable for lubrication in light workload system with maximum temperature at 70 o C such as light load<br />

agricultural equipment, water pump etc.<br />

Reference standards NLGI (National Lubricating Grease Institute)<br />

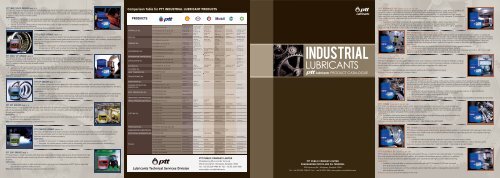

Comparison Table for <strong>PTT</strong> <strong>INDUSTRIAL</strong> LUBRICANT PRODUCTS<br />

PRODUCTS<br />

HYDRAULIC OIL<br />

GEAR OIL<br />

TURBINE OIL<br />

COMPRESSOR OIL<br />

REFRIGERATION COMPRESSOR OIL<br />

CIRCULATING OIL<br />

<strong>PTT</strong> HLP 32, 46, 68, 100<br />

<strong>PTT</strong> HYDRAULIC 32, 37, 46, 68, 100<br />

<strong>PTT</strong> HYDRAULIC HVI 46, 68, 100<br />

<strong>PTT</strong> GEAR OIL EP 68, 100, 150, 220, 320, 460, 680<br />

<strong>PTT</strong> COMPRESSOR OIL 46,68,100,150<br />

<strong>PTT</strong> HIFREEZE R 68<br />

HYDRAULIC S1 M<br />

32, 46, 68, 100<br />

TELLUS S2 M<br />

32, 46, 68, 100<br />

TELLUS S2 V<br />

46, 68, 100<br />

OMALA S2 G 68, 100,<br />

150, 220, 320, 480, 680<br />

-<br />

TURBO OILS T<br />

32, 46, 68, 100<br />

TURBO OILS CC<br />

32, 46<br />

CORENA S2 P<br />

68, 100, 150<br />

CORENA S3 R<br />

46, 68<br />

CLAVUS<br />

68<br />

VITREA<br />

32, 46,<br />

MORLINA<br />

150, 220, 320<br />

TONNA T<br />

32, 68, 220<br />

-<br />

LUBRICOOL<br />

GREEN<br />

HYDRAULIC <strong>AW</strong><br />

32, 46, 68, 100<br />

NUTO H<br />

32, 46, 68, 100<br />

UNIVIS N<br />

46, 68<br />

-<br />

-<br />

HYDRAULIC <strong>AW</strong><br />

32, 46, 68, 100<br />

RANDO HD<br />

32, 46, 68, 100<br />

RANDO HDZ<br />

46, 68<br />

MEROPA<br />

150, 220, 320, 460<br />

REGAL R&O<br />

32, 46, 68, 100<br />

-<br />

HYDRAULIC <strong>AW</strong><br />

32, 46, 68, 100<br />

DTE<br />

24, 25, 26, 27<br />

DTE<br />

15M, 16M<br />

MOBIL GEAR<br />

629, 630, 632, 634<br />

DTE OIL<br />

LIGH, MEDIUM,<br />

HEAVY MEDIUM, HEAVY<br />

HYSPIN <strong>AW</strong>S<br />

32, 46, 68, 100<br />

HYSPIN <strong>AW</strong>H-M<br />

46, 68<br />

ALPHA SP<br />

150, 220, 320, 460<br />

SLIDING OIL<br />

<strong>PTT</strong> SLIDEWAY OIL 32, 68, 220<br />

FEBIS K<br />

32, 68, 220<br />

WAY LUBRICANT<br />

32, 68, 220<br />

VACTRA OIL<br />

NO. 1, 2, 4<br />

CYLINDER OIL<br />

<strong>PTT</strong> CYLINDER OIL 50, 90, 250<br />

-<br />

GREEN ELEPHANT<br />

5, 16<br />

-<br />

-<br />

-<br />

HEAT TRANSFER OIL <strong>PTT</strong> HITEMP 500, 600<br />

THERMIA B ESSOTHERM 500 TEXTAHERM MOBILTHERM 605 PERFECTO HT 5<br />

TRANSFORMER OIL<br />

<strong>PTT</strong> HIVOLT 99<br />

DIALA AX<br />

-<br />

-<br />

MAGNA GC MAGNA<br />

BD MAGNA CF<br />

ENERGOL HLP-HM<br />

32, 46, 68, 100<br />

ENERGOL HLP-HV<br />

46, 68<br />

ENERGOL GR-XF<br />

150, 220, 320, 460<br />

ENERGOL THB<br />

32, 46, 68, 100<br />

QUENCHING OIL <strong>PTT</strong> HIQUENCH<br />

VOLUTA C 202 FENSO 40 QUENCHTEX THERMREX V ILOQUENCH NO.33<br />

-<br />

CATENEX S FLEXON<br />

RUBBER PRODUCTION <strong>PTT</strong> RUBFLEX 105, 111, 130<br />

225, 842<br />

845, 875, 815<br />

- -<br />

- LEONA 200<br />

PROCESS OIL<br />

<strong>PTT</strong> AROMEX 2000, 3000, 4000<br />

-<br />

- - -<br />

- ENERFLEX 65<br />

RUST PREVENTION OIL<br />

<strong>PTT</strong> RUSTPROTEC M30<br />

PREVENTION T<br />

- - -<br />

-<br />

-<br />

<strong>PTT</strong> RUSTPROTEC S30 SHELL RUSTKOTE 943 - -<br />

-<br />

RUSTILO DWX 20<br />

-<br />

FIBER PRODUCTION PROCESS OIL <strong>PTT</strong> J.B.O. SPECIAL, SPECIAL L<br />

J B.O.-D - - -<br />

- J B.O.<br />

TEXTILE SPINNING MACHINE OIL <strong>PTT</strong> SPINDLE OIL 10, 22<br />

SPINDLE OIL<br />

10, 22<br />

SPINESSO<br />

10, 22<br />

SPINDURA<br />

10, 22<br />

VELOCITE OIL<br />

10, 22<br />

CUTTING OIL<br />

PROCESSING OIL<br />

SUGAR INDUSTRY LUBRICATING OIL<br />

ELECTRICAL GENERATOR OIL<br />

Grease<br />

<strong>PTT</strong> TERBIN 32, 46, 68, 100<br />

<strong>PTT</strong> TERBIN T 32, 46, 68, 100<br />

<strong>PTT</strong> TERBIN EP 32, 46<br />

<strong>PTT</strong> COMPRESSOR OIL S 32, 46,68<br />

<strong>PTT</strong> CIRCULAR 32, 46, 68, 100, 150<br />

<strong>PTT</strong> CIRCULAR P 150, 220, 320, 460<br />

<strong>PTT</strong> HIVOLT 88<br />

<strong>PTT</strong> HIKUT 66<br />

<strong>PTT</strong> HIKUT NLM<br />

<strong>PTT</strong> HIKUT NMH<br />

<strong>PTT</strong> HICOOL GL<br />

<strong>PTT</strong> HICOOL AL<br />

<strong>PTT</strong> SUPERCOOL GL<br />

<strong>PTT</strong> SUPERCOOL GD<br />

<strong>PTT</strong> PARAFEX 1000, 2000, 3000, 4000<br />

<strong>PTT</strong> SUTECH L, M, H, XH<br />

DIALA A<br />

DROMUS OIL B<br />

MACRON<br />

205 M 8, 401 F 22<br />

LUBRICOOL BLUE<br />

ADRANA D 208<br />

LUBRICOOL WHITE<br />

ADRANA D 2408<br />

Gadus S1<br />

KUTWELL 42<br />

DORTAN N<br />

SOLUBLE OIL D<br />

MOBIL CUT<br />

MOBILMET<br />

403, 424<br />

COLLEDGE BI<br />

ILOCUT<br />

171, 154<br />

CLEAREDGE<br />

EP 690<br />

SYNTILLO R<br />

<strong>PTT</strong> GASTECH 500 MYSELLA LA - HDAX LOW ASH<br />

PEGASUS<br />

705, 805, 605<br />

-<br />

<strong>PTT</strong> CHASSIS GREASE<br />

CHASSIS HD CHASSIS GEASE<br />

-<br />

-<br />

CHASSIS GEASE<br />

<strong>PTT</strong> MP GREASE<br />

<strong>PTT</strong> EP GREASE<br />

<strong>PTT</strong> LI-PLEX GREASE<br />

<strong>PTT</strong> MOLY-EP GREASE<br />

<strong>PTT</strong> MOLY-PLEX GREASE<br />

Gadus S2 V100<br />

Gadus S2 V220<br />

Gadus S3 V220C<br />

Gadus S2 V220C<br />

Lubricants Technical Services Division<br />

-<br />

SPARTAN EP<br />

150, 220, 320, 460<br />

TERESSO<br />

32, 46, 68, 100<br />

TERESSTIC T<br />

32, 46, 68, 100<br />

TERESSO GT EP<br />

-<br />

DTE OIL<br />

832, 846<br />

PERFECTO T<br />

32, 46, 68, 100<br />

-<br />

32<br />

- DTE<br />

724<br />

- TURBINOL EP<br />

32<br />

COMPRESSOR OIL<br />

68, 100<br />

RPM COMPRESSOR OIL<br />

100, 150<br />

RARUS<br />

427, 429<br />

AIRCOL PD<br />

46, 68, 100, 150<br />

ENERGOL RC<br />

32, 46, 68, 100<br />

-<br />

COMPRESSOR OIL RA<br />

46, 68<br />

-<br />

-<br />

-<br />

ZERICE<br />

68, 100<br />

CAPELLA WF<br />

68<br />

GARGOYLE ARCTIC<br />

300<br />

ICEMATIC<br />

99<br />

ENERGOL LPT<br />

68<br />

NURAY<br />

32, 46, 68, 100<br />

CANOPUS<br />

32, 46, 68, 100, 150<br />

-<br />

UNIVOLT N 534 MOBILLECT 35 TRANSFORMER OIL<br />

KUTWELL M 62<br />

KUTWELL M 64<br />

KUTWELL S 74<br />

EL CAPITAN<br />

BEACON<br />

AQUATEX M<br />

AQUATEX H 3<br />

AQUATEX H<br />

VACTRA<br />

LIGH, MEDIUM,<br />

HEAVY MEDIUM, HEAVY<br />

VACUOLINE<br />

133, 137<br />

- -<br />

-<br />

-<br />

MOBILCUT 222<br />

MOBILCUT 321<br />

SYNTILLO R 3350<br />

- - -<br />

-<br />

MARFAK<br />

-<br />

-<br />

SMR<br />

BEACON EP2 MOLY MOLYTEX EP<br />

MOBIL GREASE<br />

SPECIAL<br />

MS3/LMX GREASE<br />

- -<br />

MOBIL GREASE HP<br />

222<br />

-<br />

-<br />

MOBILGREASE MP<br />

-<br />

-<br />

SPHEEROL AP<br />

-<br />

ENERGOL CS<br />

100, 150<br />

ENERGOL PM<br />

320<br />

MACCURAT D<br />

68, 220<br />

-<br />

TRANSCAL N<br />

-<br />

-<br />

DAITSOL S<br />

-<br />

-<br />

LUTORA M2<br />

-<br />

-<br />

CHASSIS GEASE<br />

BEACON EP MULTIFAK EP MOBILLUX EPEX SPHEEROL EPL ENERGREASE LS EP<br />

RONEX MP STARPLEX 222/223 MOBILGREASE SP LMX GREASE ENERGREASE LC<br />

-<br />

ENERGREASE<br />

L21-M<br />

<strong>PTT</strong> PUBLIC COMPANY LIMITED<br />

Phrakhanong Office and Oil Terminal<br />

555 Artnarong Rd., Klongtoey, Bangkok 10260<br />

Tel : +66 (0) 2239-7985-87 Fax : +66 (0) 2239-7858<br />

www.pttplc.com/pttlubricants<br />

-<br />

PRODUCT CATALOGUE<br />

<strong>PTT</strong> PUBLIC COMPANY LIMITED<br />

PHAKHANONG OFFICE AND OIL TERMINAL<br />

555 Artnarong Rd., Klongtoey, Bangkok 10260<br />

Tel : +66 (0) 2239-7985-87 Fax : +66 (0) 2239-7858, www.pttplc.com/pttlubricants<br />

<strong>PTT</strong> HYDRAULIC HVI (ISO-VG 15, 32, 46, 68, 100)<br />

<strong>PTT</strong> Hydraulic HVI is designed as premium grade hydraulic oil for wide temperature range working condition of<br />

hydraulic system. It provides the excellence in anti-wear performance (pass severe OEMs pump test),<br />

high resistance to oxidation, foam forming prevention and thermal stability. It is produced from high quality<br />

base stock with anti-wear, anti-foam, and anti-oxidation additives for long service life. Moreover, it also contains<br />

shear stable viscosity index improver to minimize viscosity loss.<br />

Applications<br />

• Suitable for heavy duty workload with wide temperature range hydraulic system requiring minimal<br />

viscosity change with temperature such as construction machine and agricultural equipments<br />

Reference standards ISO 11158 (HV), ASTM D 6158 (HV), DIN 51524 Part 3, Denison HF-0, HF-1, HF-2, Cincinnati<br />

Milacron P-68, P-69, P-70, Vickers I-286-S, M-2950-S, US Steel 127, 136<br />

<strong>PTT</strong> HYDRAULIC (ISO-VG 32, 37, 46, 68, 100)<br />

<strong>PTT</strong> Hydraulic is designed as high quality grade hydraulic oil for use in general hydraulic system. It is produced<br />

from high quality base stock and contains anti-wear, anti-oxidation, and anti-foam additives, which are compatible<br />

with rubber seal. Therefore, <strong>PTT</strong> Hydraulic provides excellent in anti-wear performance, excellent oxidation stability<br />

to extend its service life along with preventing sludge formation minimizing valve sticking problem. Moreover,<br />

it exhibits good foam forming and water separation properties in order to maximize hydraulic pump lifetime.<br />

Applications<br />

• Suitable for power and control transmission systems in many general industries<br />

• Can be used in both industrial and automotive hydraulic systems.<br />

Reference standards ISO 11158 (HM), ASTM D 6158 (HM), DIN 51524 Part 2, Denison HF-0, HF-1, HF-2, Cincinnati<br />

Milacron P-68, P-69, P-70, Vickers I-286-S, M-2950-S, US Steel 127, 136<br />

<strong>PTT</strong> HLP (ISO-VG 32, 46, 68, 100)<br />

<strong>PTT</strong> HLP is designed as standard grade hydraulic oil for use in hydraulic system which requires frequent oil top up.<br />

This product is produced from high quality base stock and contains most of necessary hydraulic oil additives such<br />

as anti-wear, anti-oxidation and anti-foam additives which are compatible with rubber seal.<br />

Applications<br />

• Suitable for light to moderate duty hydraulic systems which need frequent oil top up.<br />

Reference standards Denison HF-2, Vickers I-286-S<br />

<strong>PTT</strong> TERBIN EP (ISO-VG 32, 46)<br />

<strong>PTT</strong> Terbin EP is premium quality turbine oil for using in turbine system which working in high temperature<br />

and pressure. It is designed to provide the excellence anti-rust performance and high resistance to oxidation,<br />

thermal and humidity stability. It is produced from severely hydroprocessed base oil, anti-oxidation additives,<br />

and rust inhibitor. In addition, <strong>PTT</strong> Terbin EP also contains extreme pressure (EP) additive to support extreme<br />

pressure and temperature condition.<br />

Applications<br />

• Suitable for lubricating bearing, hydraulic control of steam and gas turbines or even combined<br />

cycle turbine system where steam and gas turbine are used.<br />

• Recommended for highly loaded geared turbine<br />

• Can be used in rotary compressor<br />

Reference standards General Electric GEK-32568F, GEK 107395, GEK 101941A, Siemens/KWU TLV 9013/04-01, DIN 51524<br />

Part 1 (HL), DIN 51515 Part 1 (L-TD), BS 489 (CIGRE)<br />

<strong>PTT</strong> TERBIN T (ISO-VG 32, 46, 68, 100)<br />

<strong>PTT</strong> Terbin T is premium quality turbine oil for using in turbine system which working in high temperature<br />

operation such as steam and gas turbine. It is produced from severely hydroprocessed base oil, rust inhibitor<br />

and anti-oxidation additive for long service life; therefore, it provides excellence anti-rust performance, high<br />

resistance to oxidation and good thermal and humidity stability.<br />

Applications<br />

• Suitable for lubricating bearing, hydraulic control of steam and gas turbines and also combined cycle<br />

turbine system where steam and gas turbine are used.<br />

• Can be used as rust and oxidation inhibited (R&O) oil.<br />

Reference standards DIN 51524 Part 1, DIN 51515 Part 1, GEK 32568 E, BS 489 (CIGRE)<br />

<strong>PTT</strong> TERBIN (ISO-VG 32, 46, 68, 100, 150, 220, 320)<br />

<strong>PTT</strong> Terbin is standard grade turbine oil for general turbine system. It is produced from high quality base stock<br />

and contains rust inhibitor and anti-oxidation additive; therefore, it provides good anti-rust property and high<br />

resistance to oxidation.<br />

Applications<br />

• Suitable for lubricating bearing, hydraulic control of water and steam turbines<br />

• Can be used with other machines as rust and oxidation inhibited (R&O) oil such as vacuum pump<br />

Reference standards DIN 51524 Part 1, DIN 51515 PART 1, GEK 32568 E, BS 489 (CIGRE)<br />

<strong>PTT</strong> SLIDEWAY OIL (ISO-VG 32, 68, 220)<br />

<strong>PTT</strong> Slideway oil is designed as special lubricant product for use in machine tool, slide and table. It is produced<br />

from high quality base stock with rust inhibitor, anti-oxidation and extreme pressure additives. In addition,<br />

It also contains special tackiness agent to prevent stick-slip and provide high accurate table positioning.<br />

Applications<br />

• Suitable for slide and table in machine system both vertical (<strong>PTT</strong> Slideway Oil 220) and horizontal<br />

(<strong>PTT</strong> Slideway Oil 68) slideway.<br />

• Can be used as hydraulic oil in the combined system where the system is designed to use one oil for<br />

both slideway and hydraulic<br />

Reference standards Cincinnati Milacron P-47, P-50

<strong>PTT</strong> GEAR OIL EP (ISO-VG 68, 100, 150, 220, 320, 460, 680)<br />

<strong>PTT</strong> Gear Oil EP is high quality industrial gear oil. It is produced from high quality base stock and contains anti-wear,<br />

anti-foam, extreme pressure (EP) and anti-oxidation additives. It helps to reduce gear tooth and bearing wear of<br />

high load conditions and provides long service life. In addition, base stock and all additives are<br />

carefully selected with non-lead types; therefore, it is safe to human and environment.<br />

Applications<br />

• Suitable for enclosed-gear system with high load-carrying and shock load.<br />

• Can be used in circulating, splash and some oil-mist lubricating systems.<br />

Reference standards U.S. Steel 224, AGMA 250.4, DIN 51517 Part 3<br />

<strong>PTT</strong> HITACK (<strong>PTT</strong> HITACK M and <strong>PTT</strong> HITACK H)<br />

<strong>PTT</strong> Hitack is high quality open gear oil with special high viscosity base stock and contains extreme pressure (EP)<br />

additive, therefore it provides high tackiness and excellence resistance to heavy workload, heat, and water.<br />

Applications<br />

• Suitable for open-gear system with low speed and high load-carrying.<br />

Reference standards The product properties are developed by follow machine technology.<br />

<strong>PTT</strong> CIRCULAR (ISO-VG 32, 46, 68, 100, 150)<br />

<strong>PTT</strong> Circular is designed as quality grade for multi-purposes and circulating systems. This product is produced from<br />

high quality base stock which is good oxidation stability for long service life and compatible with rubber seal.<br />

Applications<br />

• Suitable for lubrication in circulating system and gear systems, which operate in moderate temperature and workload.<br />

• Can be use as hydraulic oil working under low pressure condition and workload.<br />

Reference standards The product properties are developed by follow machine technology.<br />

<strong>PTT</strong> CIRCULAR P (ISO-VG 150, 220, 320, 460)<br />

<strong>PTT</strong> Circular P is high quality multi-purposes and circulating oil. It is produced from high quality base stock and contains<br />

rust-inhibitor and anti-oxidation additive, which are compatible with rubber seal, for long service life. In addition,<br />

<strong>PTT</strong> Circular P provides water separation property that is necessary feature in steel mill industry.<br />

Applications<br />

• Suitable for lubrication in circulating system which requires rust-inhibitor and anti-oxidation additives.<br />

• Can be used in air pump, bearing, and gear sets which operate at low to moderate temperature and workload.<br />

Reference standards DIN 51524 Part 1<br />

<strong>PTT</strong> SUPERCOOL GL, GD<br />

<strong>PTT</strong> Supercool GL and <strong>PTT</strong> Supercool GD are designed as water soluble synthetic cutting fluid which has excellent<br />

cooling property. Both of them have good rust and corrosion prevention properties. They provide very long service life<br />

and low maintenance without bacteria and fungi growth. These products do not contain toxic substances such as<br />

Chlorine and Nitrate/Nitrite compound and, therefore, are operator friendly products.<br />

Applications<br />

• <strong>PTT</strong> Supercool GL and <strong>PTT</strong> Supercool GD are water-soluble fluid which is suitable for grinding process of general<br />

metal especially accuracy and precision requiring process. These products also suit for the application where<br />

the visible of work pieces is required as it becomes clear transparent liquid when mixed with water such as<br />

small computer parts, tiny bearing.<br />

• <strong>PTT</strong> Supercool GL is suitable for turning, drilling and milling process by using 4-5% dissolved in water depended<br />

on metal type and method.<br />

• <strong>PTT</strong> Supercool GD is suitable for grinding process by using 4-5% dissolved in water depended on metal type and method.<br />

Reference standards The product properties are developed by follow machine technology.<br />

<strong>PTT</strong> HICOOL AL, ML, GL<br />

<strong>PTT</strong> Hicool AL, <strong>PTT</strong> Hicool ML and <strong>PTT</strong> Hicool GL are designed as water emulsified semi-synthetic bio stable cutting fluid<br />

which has very good lubricity and excellent cooling property. They offer (provide) good rust and corrosion prevention.<br />

These products have good resistance to bacteria and fungi growth without toxic substance such as Chlorine and<br />

Nitrate/Nitrite compound. With those properties, these will offer user a long fluid life and low maintenance.<br />

Applications<br />

• <strong>PTT</strong> Hicool AL is designed as a multi-purpose cutting fluid for turning, milling, grinding process of aluminium, mild steel<br />

and general metal which require good lubrication and cooling property by mixing 3-7% with water depended on metal<br />

type and method.<br />

• <strong>PTT</strong> Hicool ML and <strong>PTT</strong> Hicool GL are suitable for general turning, drilling, milling and grinding process of general metal<br />

by mixing 3-10% with water depended on metal type and method.<br />

Reference standards The product properties are developed by follow machine technology.<br />

<strong>PTT</strong> WHITECH<br />

<strong>PTT</strong> Whitech is designed as high purity paraffin oil. It is produced from high-quality hydrotreated paraffinic base oil<br />

containing high purity of saturated paraffin. <strong>PTT</strong> Whitech is exceptional in oxidation stability which is suitable for<br />

many manufacturing as raw material such as rubber, plastic and textile industry.<br />

Applications<br />

• <strong>PTT</strong> Whitech can be used as raw material, paint, coat, dip or soak for many manufacturing such as rubber,<br />

plastic, paint, furniture, textile and printing ink manufacturing industry.<br />

Reference standards The product properties are developed by follow process technology.<br />

<strong>PTT</strong> PARAFEX (<strong>PTT</strong> PARAFEX 1000, 2000, 3000, 4000)<br />

<strong>PTT</strong> Parafex is designed as high stable processing oil and general purpose lubricating oil which is used as raw<br />

material for general industrial products. It is produced from high quality paraffinic base oil with high thermal stability,<br />

oxidation resistance, high flash point and low volatility.<br />

Applications<br />

• <strong>PTT</strong> Parafex can be used in production process such as rubber compounding, elastomer manufacturing,<br />

plastics, and other industrial products and processes which has mineral oil as component of the product<br />

such as inner tire tube and can be used as economical once through lubricating oils for light duty application.<br />

Reference standards The product properties are developed by follow process technology.<br />

<strong>PTT</strong> SUTECH (<strong>PTT</strong> SUTECH L, M, H, XH)<br />

<strong>PTT</strong> Sutech is a special high viscosity product for using in machine of sugar mill industries. It is produced from high<br />

quality bitumen with extreme pressure (EP) additive and tackiness agent.<br />

Applications<br />

• Suitable for lubricating and cooling low speed bearing and open-gear system with high load-carrying<br />

especially in sugar mill machine.<br />

• Suitable for lubricating other parts such as wire rope which requires high viscosity lubricant.<br />

Reference standards The product properties are developed by follow machine technology.<br />

<strong>PTT</strong> SPINDLE OIL (ISO-VG 10, 22)<br />

<strong>PTT</strong> Spindle Oil is designed as special lubricant product for using in high speed machines. It is produced from high quality<br />

base stock with rust inhibitor and anti-wear additive. Moreover, <strong>PTT</strong> spindle oil is specially designed to reduce friction,<br />

maximizing machine efficiency while offer superior bearing wear protection.<br />

Applications<br />

• Suitable for lubrication bearing in high speed machines, such as textile machines and electronic/automated<br />

machine tools.<br />

• Can be used as heat dissipation purpose in small industrial machine.<br />

Reference standards The product properties are developed by follow machine technology.<br />

<strong>PTT</strong> HIKUT 66<br />

<strong>PTT</strong> Hikut 66 is designed as water emulsified cutting fluid which offers good lubricity and cooling property. Effective<br />

bio-stable additive is used to minimize bacteria and fungi growth without toxic substance such as Chlorine and<br />

Nitrate/Nitrite compound.<br />

Applications<br />

• <strong>PTT</strong> Hikut 66 is suitable for general metal cutting operation by mixing 3-5% with water for grinding and slow<br />

sawing process, 5-10% for cutting, milling and drilling process depended on metal type and method.<br />

Reference standards The product properties are developed by follow machine technology.<br />

<strong>PTT</strong> AROMEX (<strong>PTT</strong> AROMEX 2000, 3000, 4000)<br />

<strong>PTT</strong> Aromex is processing oil and multipurpose lubricating oil which is used as raw material for general industrial<br />

products. It is produced from aromatic base oil with high viscosity, high thermal stability, good oxidation resistance<br />

and high ability to dissolve other raw material component.<br />

Applications<br />

• <strong>PTT</strong> Aromex can be used as raw material in manufacturing that has lubricating oil blended in the product,<br />

product coating, and economical once through lubricating oils.<br />

Reference standards The product properties are developed by follow process technology.<br />

<strong>PTT</strong> COMPRESSOR OIL S (ISO-VG 32, 46, 68)<br />

<strong>PTT</strong> Compressor Oil S is premium quality compressor oil. It is produced from high quality base stock and contains<br />

selective ashless anti oxidation and anti-wear additive. Moreover, it also contains high quality anti rust and<br />

anti foam additives. Therefore, with such best in class properties, it will prolong compressor parts service life<br />

and minimize the chance of run down problem. It can be used up to 4,000 hours<br />

Applications<br />

• Suitable for specific rotary compressor system, screw and vane types, which requires high load-carrying<br />

property and ashless anti-oxidation and rust additives such as compressor from Major OEMS; Atlas Copco,<br />

Ingersoll Rand etc.<br />

Reference standards The product properties are developed by follow machine technology.<br />

<strong>PTT</strong> COMPRESSOR OIL (ISO-VG 46, 68, 100, 150)<br />

<strong>PTT</strong> Compressor Oil is high quality reciprocating compressor oil. It is produced from high quality base stock and<br />

contains anti-wear, rust inhibitor, anti-oxidation, and anti-foam additives and all are ashless type in order to<br />

minimize the deposit problems on valves and other parts of compressor. It also provides good demulsibility and<br />

rust and corrosion protection properties.<br />

Applications<br />

• Suitable for general reciprocating compressor systems both stationary and mobile which require ashless<br />

anti-oxidation and rust additives.<br />

Reference standards DIN 51506 VDL<br />

<strong>PTT</strong> HIFREEZE R (ISO-VG 68)<br />

<strong>PTT</strong> Hifreeze R is designed as high quality grade for use as compressor oil in refrigeration system. It is produced<br />

from high quality Naphthenic base stock, separated wax; therefore, <strong>PTT</strong> Hifreeze R provides low waxing tendency<br />

and can be used in very low temperature and be compatible with rubber seal and other system materials.<br />

Applications<br />

• Suitable for both piston and rotary refrigeration system and designed to use with Ammonia and Freon R12<br />

systems.<br />

• Not recommended for using in R-134a refrigeration system.<br />

Reference standards DIN 51503, BS 2626:1992<br />

<strong>PTT</strong> HITEMP (<strong>PTT</strong> HITEMP 500, 600)<br />

<strong>PTT</strong> Hitemp is high quality heat transfer fluid for using in industrial heat transfer system. It is produced from high<br />

quality base stock and contains carefully selected anti-oxidation additive to suit the application and provide longer<br />

service life. It also provides high heat transfer coefficient and viscosity/temperature characteristics.<br />

Applications<br />

• Suitable for both open (<strong>PTT</strong> Hitemp 600) and closed (<strong>PTT</strong> Hitemp 500) heat transfer system, such as dye - works,<br />

bleaching plants and plastics industry<br />

Reference standards The product properties are developed by follow machine technology.<br />

<strong>PTT</strong> NEEDELA (ISO-VG 10, 22, 32)<br />

<strong>PTT</strong> Needela is designed as special lubricant product for using in knitting machines. It is produced from high quality base<br />

stock with rust inhibitor and anti-oxidation additive for long service life. In addition, <strong>PTT</strong> Spindle oil is soluble with water<br />

and effectively minimizes formation of spray mist therefore it can be rinsed out easily.<br />

Applications<br />

• Suitable for all types of industrial knitting machines, both circular double knit and circular single knit machines.<br />

• Can be used in all knitting machine speeds and needle types.<br />

Reference standards The product properties are developed by follow machine technology.<br />

<strong>PTT</strong> HIVOLT 99<br />

<strong>PTT</strong> Hivolt 99 is premium quality electrical insulating oil. It is produced from highly refined Naphthenic base stock with<br />

a selective anti-oxidant additive (inhibited type, ASTM Type II) for long service life and high dielectric strength. In addition,<br />

there is no chemical reaction between <strong>PTT</strong> Hivolt 99 and any parts of the transformer.<br />

Applications<br />

• Suitable for all types of transformer, if desired to use for EDM please contact us for more information<br />

• Can be used to transfer heat and used as dielectric in transformers, gear switches, circuit breakers, and other<br />

electric equipments.<br />

Reference standards ASTM D 3487:2000 Type II, IEC 60296:2003 (Inhibited)<br />

<strong>PTT</strong> HIVOLT 88<br />

<strong>PTT</strong> Hivolt 88 is high quality electrical insulating oil. It is produced from highly refined Naphthenic basestock (Uninhibited<br />

type, ASTM type I). <strong>PTT</strong> Hivolt 88 provides high dielectric strength and thermal and oxidation stability.<br />

Applications<br />

• Recommended for general transformers, gear switches, circuit breakers, and other electric equipments.<br />

Reference standards IEC 60296:2003 (Uninhibited), BS 148:1998 Class I&II<br />

<strong>PTT</strong> HIQUENCH<br />

<strong>PTT</strong> Hiquench is designed as high quality grade for use in metal quenching process. It is produced from high quality base<br />

stock which provides thermal stability, low volatility, high flash point and good flow characteristic for long service life.<br />

Applications<br />

• Suitable for general quenching process to harden and modify metal surface with stable quenching rate.<br />

Reference standards The product properties are developed by follow manufacturing process.<br />

<strong>PTT</strong> HIKUT NLM (ISO-VG 10, 22)<br />

<strong>PTT</strong> Hikut NLM is designed as light to medium duty neat cutting oil which provides very good lubricity, corrosion and rust<br />

prevention property without chloride. With selective EP additive, it allows faster machining rates, extend tool life, and<br />

protect against staining of yellow metals. <strong>PTT</strong> Hikut NLM is available in 2 viscosity grades ISO VG 10 and 22 and appropriate<br />

for fast machining operation due to its excellent heat removing and chip removing possessions. <strong>PTT</strong> Hikut NLM also has<br />

a property to reduce smoke and oil mist.<br />

Applications<br />

• <strong>PTT</strong> Hikut NLM is suitable for light to moderate range machining operations of general metal including yellow metal such as copper and brass.<br />

Reference standards The product properties are developed by follow machine technology.<br />

<strong>PTT</strong> HIKUT NMH<br />

<strong>PTT</strong> Hikut NMH is designed as medium to high duty neat cutting oil which has good lubricity, corrosion and rust<br />

prevention property without chloride. With a selective EP additive and its strong film thickness, it allows to use with<br />

high severe machining operation with faster machining rates, maximize your tool life.<br />

Applications<br />

• <strong>PTT</strong> Hikut NMH is suitable for moderate to high range machining operations of hard metal such asaluminium,<br />

copper and steel.<br />

Reference standards The product properties are developed by follow machine technology.<br />

<strong>PTT</strong> RUSTPROTEC M30<br />

<strong>PTT</strong> Rustprotec M30 is designed as general propose rust preventive oil (oil film type). It is a combination of high quality<br />

base oil and selective rust inhibitor. <strong>PTT</strong> Rustprotec M30 forms sufficient oil film to protect metal surface from rust and<br />

corrosion under high humidity atmospheric condition and best for application where solvent based product are<br />

unacceptable<br />

Applications<br />

• <strong>PTT</strong> Rustprotec M30 can be applied by spraying, hand painting, or misting to form oil film on metal surface which<br />

can protect metal surface from rust during process, storage and transportation. This product is suitable for automotives<br />

industrial and other machine part industrial with 1-3 months protection period.<br />

Reference standards The product properties are developed by follow process technology.<br />

<strong>PTT</strong> RUSTPROTEC S30<br />

<strong>PTT</strong> Rustprotec S 30 is designed as general propose rust preventive oil (solvent type). Selective solvent and combination<br />

of special additives are used to protect metal surface in short period with an effective thin film. <strong>PTT</strong> Rustprotec S30<br />

also provides dewatering ability that can use in water wetting or high moisture process.<br />

Applications<br />

• <strong>PTT</strong> Rustprotec S30 can be applied by spraying, hand paining, or misting to form thin oil film on metal surface<br />

which can remove water and protect metal surface from rust after machining with soluble cutting fluid, or part<br />

that have been washed, storage and transportation and provides 1-3 months protection period.<br />

Reference standards The product properties are developed by follow process technology.<br />

<strong>PTT</strong> RUBBERA 400<br />

<strong>PTT</strong> Rubbera is designed as low aromatic rubber process and extender oil. It is used as a raw material in rubber<br />

process to enhance homogeneous miscibility of rubber and additive chemicals. <strong>PTT</strong> RUBBERA is produced from<br />

high solvency and high quality base oil containing %PCA lower than 3% which is environmental friendly.<br />

Applications<br />

• <strong>PTT</strong> Rubbera is suitable for using in rubber process so that grinding and homogeneous mixing rubber are easily<br />

achieved as a raw material in rubber process for automotive tire industry, rubber shoe and rubber tube.<br />

Reference standards The product properties are developed by follow process technology.<br />

<strong>PTT</strong> RUBTEDA 401, 502<br />

<strong>PTT</strong> Rubteda is designed as low aromatic rubber process and extruder oil. <strong>PTT</strong> produced this product from high quality<br />

base oil with high solvency, high flash point and low volatility (TDAE technology). It is suitable for using in rubber<br />

production processes to improve rubber quality containing %PCA lower than 3% which is environmental friendly.<br />

Applications<br />

• <strong>PTT</strong> Rubteda is suitable for using in rubber production process to improve rubber quality which has mineral oil<br />

as one component of the product such as tire manufacturing.<br />

Reference standards The product properties are developed by follow process technology.<br />

<strong>PTT</strong> CYLINDER OIL (<strong>PTT</strong> Cylinder Oil 50, 90, 250)<br />

<strong>PTT</strong> Cylinder Oil is general purpose lubricating oil produced from selective base oil.<br />

Applications<br />

• <strong>PTT</strong> Cylinder Oil is suitable for general machine in general industry especially for use as once through<br />

lubricating oil such as steam engine in rice mill industry, saw mill industry and other machine run with<br />

slow to moderate speed.<br />

Reference standards The product properties are developed by follow machine technology.<br />

<strong>PTT</strong> MOLD OIL C<br />

<strong>PTT</strong> Mold Oil C is designed as mold released oil. This product is water soluble oil formulated from good quality base<br />

oil with emulsifier additive. It is applicable for mold release in construction such as tile mold release or other<br />

concrete form release.<br />

Applications<br />

• <strong>PTT</strong> Mold Oil C is suitable for mold releasing in concrete process by diluting with water in the ratio of 1: 10<br />

(oil: water) or adjust the ratio with appropriate application.<br />

Reference standards The product properties are developed by follow process technology.