DISTRIBUTORS - LeMar Industries

DISTRIBUTORS - LeMar Industries

DISTRIBUTORS - LeMar Industries

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>DISTRIBUTORS</strong><br />

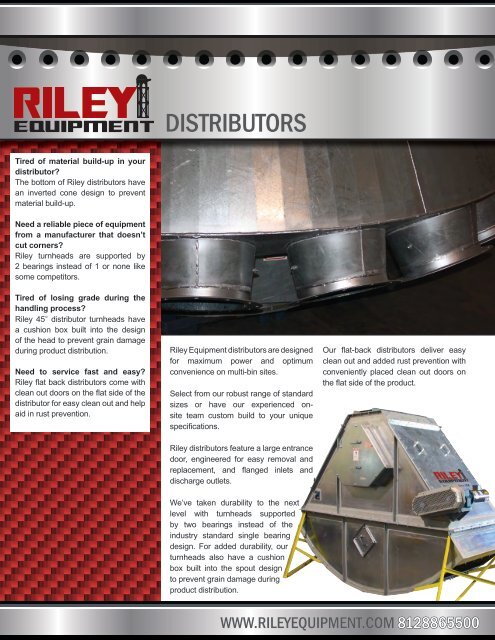

Tired of material build-up in your<br />

distributor?<br />

The bottom of Riley distributors have<br />

an inverted cone design to prevent<br />

material build-up.<br />

Need a reliable piece of equipment<br />

from a manufacturer that doesn’t<br />

cut corners?<br />

Riley turnheads are supported by<br />

2 bearings instead of 1 or none like<br />

some competitors.<br />

Tired of losing grade during the<br />

handling process?<br />

Riley 45 ◦ distributor turnheads have<br />

a cushion box built into the design<br />

of the head to prevent grain damage<br />

during product distribution.<br />

Need to service fast and easy?<br />

Riley flat back distributors come with<br />

clean out doors on the flat side of the<br />

distributor for easy clean out and help<br />

aid in rust prevention.<br />

Riley Equipment distributors are designed<br />

for maximum power and optimum<br />

convenience on multi-bin sites.<br />

Select from our robust range of standard<br />

sizes or have our experienced onsite<br />

team custom build to your unique<br />

specifications.<br />

Our flat-back distributors deliver easy<br />

clean out and added rust prevention with<br />

conveniently placed clean out doors on<br />

the flat side of the product.<br />

Riley distributors feature a large entrance<br />

door, engineered for easy removal and<br />

replacement, and flanged inlets and<br />

discharge outlets.<br />

We’ve taken durability to the next<br />

level with turnheads supported<br />

by two bearings instead of the<br />

industry standard single bearing<br />

design. For added durability, our<br />

turnheads also have a cushion<br />

box built into the spout design<br />

to prevent grain damage during<br />

product distribution.<br />

WWW.RILEYEQUIPMENT.COM 8128865500

DISTRIBUTOR DETAILS<br />

Choose from single and double, manual and electric distributors. Products include<br />

the Flat Back 45 ◦ , Flat Back 60 ◦ , 360 ◦ - 45 ◦ and 360 ◦ - 60 ◦ .<br />

45° - FLATBACK DISTRIBUTOR<br />

Size (A) B C F G M<br />

6” Dia.<br />

6 Outlets 54 52½ 42¼ 46 8<br />

8 Outlets 54 52½ 42¼ 46 8<br />

10 Outlets 72 70¼ 51¼ 46 8<br />

12 Outlets 72 70¼ 51¼ 46 8<br />

8” Dia.<br />

6 Outlets 54 54¼ 41½ 46 8<br />

8 Outlets 54 54¼ 41½ 46 8<br />

10 Outlets 72 71½ 50½ 46 8<br />

12 Outlets 72 71½ 50½ 46 8<br />

10” Dia.<br />

6 Outlets 78 72 51¾ 50¼ 10<br />

8 Outlets 78 72 51¾ 50¼ 10<br />

10 Outlets 102 97½ 64½ 60¼ 10<br />

12 Outlets 102 97½ 64½ 60¼ 10<br />

12” Dia.<br />

6 Outlets 78 75 51¾ 50¼ 10<br />

8 Outlets 78 75 51¾ 50¼ 10<br />

10 Outlets 102 99½ 64 60¼ 10<br />

12 Outlets 102 99½ 64 60¼ 10<br />

14” Dia.<br />

6 Outlets 78 71½ 55½ 60½ 13<br />

8 Outlets 98 91½ 65½ 70½ 13<br />

16” Dia.<br />

6 Outlets 78 72½ 55 60½ 13<br />

8 Outlets 98 92 65 70½ 13<br />

60° - FLATBACK DISTRIBUTOR<br />

6” Dia.<br />

6 Outlets 56 49 58 60 ¼ 8<br />

8 Outlets 56 49 58 60 ¼ 8<br />

10 Outlets 80 73 78 ¾ 80 ¼ 8<br />

12 Outlets 80 73 78 ¾ 80 ¼ 8<br />

8” Dia.<br />

6 Outlets 80 55 61 60 ¼ 8<br />

8 Outlets 60 55 61 60 ¼ 8<br />

10 Outlets 60 75 78 ¼ 80 ¼ 8<br />

12 Outlets 80 75 78 ¼ 80 ¼ 8<br />

10” Dia.<br />

6 Outlets 80 70 79 ½ 82 10<br />

8 Outlets 80 70 79 ½ 82 10<br />

10 Outlets 106 96 101½ 97 10<br />

12 Outlets 106 96 101½ 97 10<br />

12” Dia.<br />

6 Outlets 80 72 79 ¼ 82 10<br />

8 Outlets 80 72 79 ¼ 82 10<br />

10 Outlets 106 98 101 ¼ 97 10<br />

12 Outlets 106 98 101 ¼ 97 10<br />

The 45° distributor includes a built-in cushion box, and the 60° distributor includes<br />

an AR steel liner in the lower half of the inner turn spout. Discharge outlets are lined<br />

with 14 gauge mild steel.<br />

Standard products are available in 6, 8, 10 or 12 outlets and diameters from 6 to 16<br />

inches. Galvanized and stainless steel finishes along with customization in larger<br />

sizes is available.<br />

Riley distributors are fully customizable with a full<br />

range of options including:<br />

• Linings, urethane or ceramic<br />

• Transition legs<br />

• Electric control panel<br />

• Distributor cable guide<br />

• Control rod standoff bracket<br />

• Upper cable pulley bracket<br />

• Lower cable control with crank<br />

• Lower floor stand control<br />

• Hole cover plates<br />

• Inner spout dust end seal<br />

Or let the expert Riley engineering team custom fabricate a unit from the ground up<br />

to your specifications.<br />

Distributors include angle flanged inlet, discharges and bolted access door. Inverted<br />

cone design helps prevent material build-up on the bottom. The inner turn spout is<br />

supported on two flange bearings and is designed for easy removal and replacement.<br />

The 45° distributor includes a built-in cushion box and the 60° distributor includes<br />

AR steel liner in lower half of inner turn spout. Standard discharge outlets are lined<br />

with 14 gauge mild steel, other liners are available.<br />

Controls include pipe, cable or electric. Pipe control includes the bottom floor<br />

stand, upper cable pulley bracket and foot pedal, less pipe and cable. Cable control<br />

includes upper cable pulley bracket, bottom control crank and foot pedal, less<br />

cable. Electric controls include the use of a positive,<br />

TEFC gear motor drive and switches in lower control<br />

tub. For Class II Group G requirements, consult the<br />

Engineering department.<br />

Standard distributor construction is galvanized<br />

with painted seams. Stainless steel construction is<br />

available as well as sizes other than those listed,<br />

please contact the engineering department with<br />

your specifications.

Distributor Cable Guide<br />

Used on cable-controlled distributors.<br />

Suggested on 30 ft. centers.<br />

Distributor Accessories<br />

Upper Cable Pulley Bracket<br />

Lower Cable Control with Crank<br />

Lower Floor Stand Control<br />

OPTIONS AND ACCESSORIES<br />

Electric Control Panels:<br />

Control panels include motor starter, selector switch, location<br />

lights, transformer, reversing contactor (flat back only) and must<br />

be located in a “non-classified area” (NEMA 4/NEMA 12 type<br />

classification.) 110 V Electric Control Panel for Flat Back and<br />

360° Distributor.<br />

Control Rod Standoff Bracket<br />

Used on pipe controlled distributors.<br />

Suggested on 20 ft. centers.<br />

45° - 360° DISTRIBUTOR<br />

Size (A) B C E F G<br />

6” Dia.<br />

6 Outlets 48 46 28 39¼ 46<br />

8 Outlets 48 46 28 39 ¼ 46<br />

10 Outlets 54 52 ½ 36 42 ¼ 50 ¼<br />

12 Outlets 54 52 ½ 36 42 ¼ 50 ¼<br />

8” Dia.<br />

6 Outlets 48 47 ½ 28 38 ½ 46<br />

8 Outlets 48 47 ½ 28 38 ½ 46<br />

10 Outlets 54 54 ¼ 36 41 ½ 50 ¼<br />

12 Outlets 54 54 ¼ 36 41 ½ 50 ¼<br />

10” Dia.<br />

6 Outlets 60 55 36 43 ¼ 50 ¼<br />

8 Outlets 60 55 36 43 ¼ 50 ¼<br />

10 Outlets 78 73 36 51 ¾ 56 ¾<br />

12 Outlets 78 73 36 51 ¾ 56 ¾<br />

12” Dia.<br />

6 Outlets 60 57 36 43 50 ½<br />

8 Outlets 60 57 36 43 50 ½<br />

10 Outlets 78 75 36 51 ¾ 57<br />

12 Outlets 78 75 36 51 ¾ 57<br />

14” Dia.<br />

6 Outlets 66 60 ½ 36 55 ½ 60 ½<br />

8 Outlets 66 60 ½ 36 55 ½ 60 ½<br />

16” Dia.<br />

6 Outlets 66 62 36 55 60 ½<br />

8 Outlets 66 62 36 55 60 ½<br />

Hole Cover Plates and Inner Spout Dust End Seal<br />

Available on all models.<br />

60° - 360° DISTRIBUTOR<br />

6” Dia.<br />

6 Outlets 48 41 ½ 28 50 ¾ 58<br />

8 Outlets 48 41 ½ 28 50 ¾ 58<br />

10 Outlets 60 53 ½ 36 61 ¼ 66<br />

12 Outlets 60 53 ½ 36 61 ¼ 66<br />

8” Dia.<br />

6 Outlets 48 43 ½ 28 50 ¼ 58<br />

8 Outlets 48 43 ½ 28 50 ¼ 58<br />

10 Outlets 60 55 36 60 ¾ 66<br />

12 Outlets 60 55 36 60 ¾ 66<br />

10” Dia.<br />

6 Outlets 60 55 28 67 70<br />

8 Outlets 60 55 28 67 70<br />

10 Outlets 80 70 36 79 ½ 82<br />

12 Outlets 80 70 36 79 ½ 82<br />

12” Dia.<br />

6 Outlets 60 57 ½ 28 67 ¼ 70 ¼<br />

8 Outlets 60 57 ½ 28 67 ¼ 70 ¼<br />

10 Outlets 80 72 36 79 ¼ 82<br />

12 Outlets 80 72 36 79 ¼ 82<br />

WWW.RILEYEQUIPMENT.COM 8128865500

Experience a new standard of quality and<br />

service with Riley Equipment, a preferred<br />

designer and manufacturer of processing<br />

machinery and bulk material handling<br />

equipment for agriculture and a wide variety of<br />

industrial markets.<br />

This is next-level design and fabrication of<br />

customized equipment to meet our customers’<br />

very specific<br />

requirements, in<br />

addition to a robust<br />

standard equipment line. We manufacture<br />

all products in-house under stringent quality<br />

controls to ensure proper alignment and fit in<br />

the field.<br />

Riley<br />

Equipment,<br />

a division of <strong>LeMar</strong> <strong>Industries</strong>, offers<br />

a complete line of bucket elevators,<br />

distributors, spouting and accessories, drag<br />

conveyors and screw conveyors.<br />

<strong>LeMar</strong> <strong>Industries</strong> is an agricultural as well<br />

as sand & gravel design and manufacturing<br />

operation providing: support towers,<br />

catwalks, temporary storage, transport<br />

conveyors, bulk weighers, drive over conveyors, open belt conveyors,<br />

grain reclaim service and super structures along with specialty fabricated<br />

equipment. The <strong>LeMar</strong> <strong>Industries</strong><br />

family of companies also includes<br />

Hall <strong>Industries</strong>, a cutting-edge<br />

design and metal fabrication shop,<br />

and Midwest Bearing, a leading<br />

bearing and power transmission<br />

aftermarket supply house.<br />

www.lemarindustries.com<br />

WWW.RILEYEQUIPMENT.COM 8128865500