In-depth Issue 17 - Rolls-Royce

In-depth Issue 17 - Rolls-Royce

In-depth Issue 17 - Rolls-Royce

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

www.rolls-royce.com<br />

09<br />

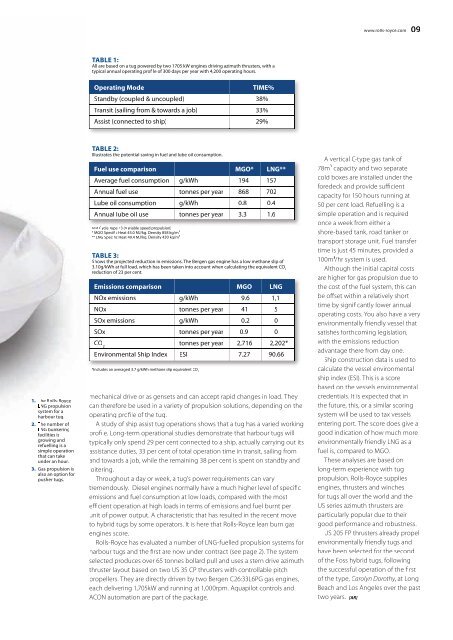

TABLE 1:<br />

All are based on a tug powered by two <strong>17</strong>05 kW engines driving azimuth thrusters, with a<br />

typical annual operating profile of 300 days per year with 4,200 operating hours.<br />

Operating Mode<br />

TIME%<br />

Standby (coupled & uncoupled) 38%<br />

Transit (sailing from & towards a job) 33%<br />

Assist (connected to ship) 29%<br />

1. The <strong>Rolls</strong>-<strong>Royce</strong><br />

LNG propulsion<br />

system for a<br />

harbour tug.<br />

2. The number of<br />

LNG bunkering<br />

facilities is<br />

growing and<br />

refuelling is a<br />

simple operation<br />

that can take<br />

under an hour.<br />

3. Gas propulsion is<br />

also an option for<br />

pusher tugs.<br />

TABLE 2:<br />

Illustrates the potential saving in fuel and lube oil consumption.<br />

Fuel use comparison MGO* LNG**<br />

Average fuel consumption g/kWh 194 157<br />

Annual fuel use tonnes per year 868 702<br />

Lube oil consumption g/kWh 0.8 0.4<br />

Annual lube oil use tonnes per year 3.3 1.6<br />

Test<br />

Cycle Type<br />

E3 (Variable speed propulsion)<br />

* MGO Specific Heat 43.0 MJ/kg. Density 858 kg/m³<br />

** LNG Specific Heat 49.4 MJ/kg. Density 430 kg/m³<br />

TABLE 3:<br />

Shows the projected reduction in emissions. The Bergen gas engine has a low methane slip of<br />

3.10g/kWh at full load, which has been taken into account when calculating the equivalent CO 2<br />

reduction of 23 per cent.<br />

Emissions comparison MGO LNG<br />

NOx emissions g/kWh 9.6 1,1<br />

NOx tonnes per year 41 5<br />

SOx emissions g/kWh 0.2 0<br />

SOx tonnes per year 0.9 0<br />

CO 2<br />

tonnes per year 2,716 2,202*<br />

Environmental Ship <strong>In</strong>dex ESI 7.27 90.66<br />

*<strong>In</strong>cludes an averaged 3.7 g/kWh methane slip equivalent CO 2<br />

mechanical drive or as gensets and can accept rapid changes in load. They<br />

can therefore be used in a variety of propulsion solutions, depending on the<br />

operating profile of the tug.<br />

A study of ship assist tug operations shows that a tug has a varied working<br />

profile. Long-term operational studies demonstrate that harbour tugs will<br />

typically only spend 29 per cent connected to a ship, actually carrying out its<br />

assistance duties, 33 per cent of total operation time in transit, sailing from<br />

and towards a job, while the remaining 38 per cent is spent on standby and<br />

loitering.<br />

Throughout a day or week, a tug’s power requirements can vary<br />

tremendously. Diesel engines normally have a much higher level of specific<br />

emissions and fuel consumption at low loads, compared with the most<br />

efficient operation at high loads in terms of emissions and fuel burnt per<br />

unit of power output. A characteristic that has resulted in the recent move<br />

to hybrid tugs by some operators. It is here that <strong>Rolls</strong>-<strong>Royce</strong> lean burn gas<br />

engines score.<br />

<strong>Rolls</strong>-<strong>Royce</strong> has evaluated a number of LNG-fuelled propulsion systems for<br />

harbour tugs and the first are now under contract (see page 2). The system<br />

selected produces over 65 tonnes bollard pull and uses a stern drive azimuth<br />

thruster layout based on two US 35 CP thrusters with controllable pitch<br />

propellers. They are directly driven by two Bergen C26:33L6PG gas engines,<br />

each delivering 1,705kW and running at 1,000rpm. Aquapilot controls and<br />

ACON automation are part of the package.<br />

A vertical C-type gas tank of<br />

78m3 capacity and two separate<br />

cold boxes are installed under the<br />

foredeck and provide sufficient<br />

capacity for 150 hours running at<br />

50 per cent load. Refuelling is a<br />

simple operation and is required<br />

once a week from either a<br />

shore-based tank, road tanker or<br />

transport storage unit. Fuel transfer<br />

time is just 45 minutes, provided a<br />

100m3/hr 3<br />

system is used.<br />

Although the initial capital costs<br />

are higher for gas propulsion due to<br />

the cost of the fuel system, this can<br />

be offset within a relatively short<br />

time by significantly lower annual<br />

operating costs. You also have a very<br />

environmentally friendly vessel that<br />

satisfies forthcoming legislation,<br />

with the emissions reduction<br />

advantage there from day one.<br />

Ship construction data is used to<br />

calculate the vessel environmental<br />

ship index (ESI). This is a score<br />

based on the vessels environmental<br />

credentials. It is expected that in<br />

the future, this, or a similar scoring<br />

system will be used to tax vessels<br />

entering port. The score does give a<br />

good indication of how much more<br />

environmentally friendly LNG as a<br />

fuel is, compared to MGO.<br />

These analyses are based on<br />

long-term experience with tug<br />

propulsion. <strong>Rolls</strong>-<strong>Royce</strong> supplies<br />

engines, thrusters and winches<br />

for tugs all over the world and the<br />

US series azimuth thrusters are<br />

particularly popular due to their<br />

good performance and robustness.<br />

US 205 FP thrusters already propel<br />

environmentally friendly tugs and<br />

have been selected for the second<br />

of the Foss hybrid tugs, following<br />

the successful operation of the first<br />

of the type, Carolyn Dorothy, at Long<br />

Beach and Los Angeles over the past<br />

two years. [AR]