Sericulture - Directorate General of Employment & Training

Sericulture - Directorate General of Employment & Training

Sericulture - Directorate General of Employment & Training

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Page 1 <strong>of</strong> 87<br />

COURSE CURRICULA FOR<br />

SERICULTURE SECTOR<br />

UNDER<br />

MODULAR EMPLOYABLE SKILLS (MES)<br />

DIRECTORATE GENERAL OF EMPLOYMENT & TRAINING<br />

MINISTRY OF LABOUR & EMPLOYMENT<br />

GOVERNMENT OF INDIA

Course Curricula for Short Term Courses based on Modular<br />

Employable Skills (MES) in the <strong>Sericulture</strong> Sector<br />

Page 2 <strong>of</strong> 87<br />

CONTENTS<br />

1. Background ................................. 3<br />

2. Frame Work for Skill Development based on Modular Employable Skills .............. 3<br />

3. Age <strong>of</strong> Participants .......................................................................... 4<br />

4. Curriculum Development Process .............................................................................. 4<br />

5. Development <strong>of</strong> Core Competencies ......................................................................... 4<br />

6. Duration <strong>of</strong> the Programmes .................................................................................... 5<br />

7. Pathways to acquire Qualification ............................................................................ 5<br />

8. Methodology ....................................................................................................... 5<br />

9. Instructional Media Packages ....................................................................................... 6<br />

10. Assessment .......................................................................................................... 6<br />

11. Certificate ............................................................................................................. 6<br />

12. Sector Skill Panel…………………………………………………………………………7<br />

13.Course Matrix ....................................................................................................... 12<br />

14.Module- Mulberry Sapling Producer ............................................................................ 14<br />

15. Mulberry Crop Protection Assistant…………………………………………………….17<br />

16. Chawki Rearer…………………………………………………………………………..19<br />

17. Pre-emergence Grainage Operator………………………………………………….......22<br />

18. Post emergence grainage operator………………………………………………………25<br />

19. Silk Handicrafts Maker…………………………………………………………………………28<br />

20. Mulberry Cosmetic Assistant…………………………………………………………………...31<br />

21. Mulberry Snack Maker…………………………………………………………………………34<br />

22. Silk Garland Maker……………………………………………………………………..37<br />

23. Mulberry Garden Establisher………………………………………………………......40<br />

24. Mulberry Garden Maintainer………………………………………………………......44<br />

25. Vermi compost Producer………………………………………………………………..49<br />

26. Sanitation and Disinfection Assistant………………………………………………......52<br />

27. Late age silkworm rearing assistant…………………………………………………….55<br />

28. Silkworm Protector…………………………………………………………………………….59<br />

29. Acid treatment technician………………………………………………………………62<br />

30. Silkworm Cold Storage Operator………………………………………………………65<br />

31. Silkworm Egg Marketing Assistant……………………………………………………..67<br />

32. Bamboo Appliances Maker for Silkworm Rearing……………………………………..69<br />

33. Wooden Appliances Maker for <strong>Sericulture</strong>……………………………………………………71<br />

34. Mulberry Crop Protector…………………………………………………………….....74<br />

35. Seed Cocoon Procurer…………………………………………………………………..77<br />

36. Pupa and Moth Tester…………………………………………………………………..79<br />

37. Silkworm Egg Production Supervisor………………………………………………..…83<br />

38. <strong>Sericulture</strong> Extension Worker…………………………………………………………..85<br />

39. Silkworm Egg Production Manager…………………………………………………….87

1 - Skill Development based on Modular Employable Skills (MES)<br />

Page 3 <strong>of</strong> 87<br />

1. a Background<br />

Number <strong>of</strong> forums have emphasised the need for the skill development, especially for the less<br />

educated, poor and out <strong>of</strong> school youth. The skill level and educational attainment <strong>of</strong> the work<br />

force determines the productivity, income levels as well as the adaptability <strong>of</strong> the working class in<br />

changing environment. Large percentage <strong>of</strong> population in India is living below poverty line, the<br />

main reason being the lower percentage <strong>of</strong> skilled persons in the workforce. Majority <strong>of</strong> them are<br />

staying in rural India and hilly areas.<br />

The skill development at present is taking place mostly in the informal way, i.e. persons acquire<br />

skill at the work-place when they help their parents, relatives and employers etc. Such persons do<br />

not have a formal certificate and thus earn lower wages and are exploited by employers. They<br />

have come through informal system due to socio-economic circumstances <strong>of</strong> the family and the<br />

compulsions <strong>of</strong> earning a livelihood rather than attending a formal course. While their<br />

productivity is low, their contribution to the national GDP cannot be ignored. If the country can<br />

create a system <strong>of</strong> certification which not only recognizes their skills but also provides education<br />

and training in a mode that suits their economic compulsions, it will not only benefit the<br />

workforce to earn a decent living but also contribute to the national economy by better<br />

productivity <strong>of</strong> this workforce.<br />

Another related problem is the large number <strong>of</strong> students drop outs (About 63% <strong>of</strong> the school<br />

students drop out at different stages before reaching Class-X).<br />

The third problem is that the industries are facing shortage <strong>of</strong> skilled people to operate the<br />

machines and produce the materials, and the skills available are not adequate considering the<br />

changing requirement <strong>of</strong> the technology.<br />

1. b. Frame work for Skill Development based on ‘Modular Employable Skills<br />

(MES)’<br />

Very few opportunities for skill development are available for the above referred groups (out <strong>of</strong><br />

school youth and existing workers especially in the informal sector). Most <strong>of</strong> the existing skill<br />

development programmes are long term in nature. Poor and less educated persons cannot afford<br />

long term training programmes due to higher entry qualifications, opportunity cost etc. Therefore,<br />

new frames work for skill development for the informal sector has been evolved by the DGET to<br />

address to the above mentioned problems. The key features <strong>of</strong> the new frame work for skill<br />

development are:<br />

Demand driven short term training courses based on modular employable skills decided<br />

in consultation with industry.<br />

Flexible delivery mechanism (part time, weekends, full time)<br />

Different levels <strong>of</strong> programmes (Foundation level as well as skill up gradation) to meet<br />

demands <strong>of</strong> various target groups.<br />

Central Government will facilitate and promote training while Vocational <strong>Training</strong><br />

Providers (VTP) under the Government and Private Sector will provide training<br />

Optimum utilization <strong>of</strong> existing infrastructure to make training cost effective.<br />

Testing <strong>of</strong> skills <strong>of</strong> trainees by independent assessing bodies who would not be involved<br />

in conducting <strong>of</strong> the training programme, to ensure that it is done impartially.<br />

Testing and certification <strong>of</strong> prior learning (skills <strong>of</strong> persons acquired informally)<br />

The short term courses would be based on „Modular Employable Skills (MES)‟.<br />

The concept for the MES is:

Page 4 <strong>of</strong> 87<br />

Identification <strong>of</strong> „minimum skills set‟ which is sufficient to get an employment in the<br />

labour market.<br />

It allows skills up-gradation, multiskilling, multi entry and exit, vertical mobility and life<br />

long learning opportunities in a flexible manner.<br />

It also allows recognition <strong>of</strong> prior learning (certification <strong>of</strong> skills acquired informally)<br />

effectively.<br />

The modules in a sector when grouped together could lead to a qualification equivalent<br />

to National Trade Certificate or higher.<br />

Courses could be available from level 1 to level 4 in different vocations depending upon<br />

the need <strong>of</strong> the employer organizations.<br />

MES would benefit different target groups like :<br />

Workers in industry and farm houses seeking certification <strong>of</strong> their skills acquired<br />

informally.<br />

Workers seeking skill upgradation.<br />

Early school drop-outs and unemployed.<br />

Previously child labour and their family.<br />

1. c. Age <strong>of</strong> participants<br />

The minimum age limit for persons to take part in the scheme is 14 years but there is no upper<br />

age limit.<br />

1. d. Curriculum Development Process<br />

Following procedure is used for developing course curricula<br />

Identification <strong>of</strong> Employable Skills set in a Sector based on division <strong>of</strong> work in the labour<br />

market.<br />

Development <strong>of</strong> training modules corresponding to skills set identified so as to provide<br />

training for specific and fit for purpose<br />

Organization <strong>of</strong> modules in to a Course Matrix indicating vertical and horizontal<br />

mobility. The course matrix depicts pictorially relation among various modules, pre<br />

requisites for higher level modules and how one can progress from one level to another.<br />

Development <strong>of</strong> detailed curriculum and vetting by a trade committee and by the NCVT<br />

(Close involvement <strong>of</strong> employers organizations, state governments, experts, vocational<br />

training providers and other stake holders is ensured at each stages).<br />

1. e. Development <strong>of</strong> Core Competencies<br />

Possession <strong>of</strong> proper attitudes is one <strong>of</strong> the most important attribute <strong>of</strong> a competent<br />

person. Without proper attitudes, the performance <strong>of</strong> a person gets adversely affected.<br />

Hence, systematic efforts will be made to develop attitudes during the training<br />

programme.<br />

The trainees deal with men, materials and machines. They handle sophisticated tools and<br />

instruments. Positive attitudes have to be developed in the trainees by properly guiding<br />

them and setting up examples <strong>of</strong> good attitudes by demonstrated behaviours and by the<br />

environment provided during training.<br />

Some important core competencies to be developed are:<br />

1. Safety consciousness and safe working practices<br />

2. Care <strong>of</strong> equipment and tools

3. Punctuality, discipline and honesty<br />

4. Concern for quality<br />

5. Respect for rules and regulations<br />

6. Concern for health and hygiene<br />

7. Cordial relationship and cooperation with co-workers and team work<br />

8. Positive attitude and behaviour<br />

9. Responsibility and accountability<br />

10. Learn continuously<br />

11. Communication skills<br />

12. Concern for environment and waste disposal<br />

Page 5 <strong>of</strong> 87<br />

Following competencies should also be developed during level-II and higher courses:<br />

1. Ability for planning, organizing and coordinating<br />

2. Creative thinking, problem solving and decision making<br />

3. Leadership<br />

4. Ability to bear stress<br />

5. Negotiation<br />

1. f. 6. Duration <strong>of</strong> the Programmes<br />

Time taken to gain the qualification will vary according to the pathway taken and will be<br />

kept very flexible for persons with different backgrounds and experience. Duration has<br />

been prescribed in hours in the curriculum <strong>of</strong> individual module, which are based on the<br />

content and requirements <strong>of</strong> a MES Module. However, some persons may take more time<br />

than the prescribed time. They should be provided reasonable time to complete the<br />

course.<br />

1. g. Pathways to acquire Qualification:<br />

Access to the qualification could be through:<br />

• An approved training programme;<br />

Or<br />

• A combination <strong>of</strong> an approved training programme plus recognition <strong>of</strong> prior<br />

learning including credit transfer;<br />

Or<br />

• The recognition <strong>of</strong> prior learning that provides evidence <strong>of</strong> the achievement <strong>of</strong> the<br />

competencies for the qualification.<br />

1. h. Methodology<br />

The training methods to be used should be appropriate to the development <strong>of</strong><br />

competencies. The focus <strong>of</strong> the programme is on “Performing” and not on “Knowing”.<br />

Lecturing will be restricted to the minimum necessary and emphasis to be given for<br />

„Hands on training‟.<br />

The training methods will be individual centred to make each person a competent one.<br />

Opportunities for individual work will be provided. The learning process will be<br />

continuously monitored and feedback will be provided on individual basis.

Page 6 <strong>of</strong> 87<br />

Demonstrations using different models, audio visual aids and equipment, and visiting the<br />

actual spot <strong>of</strong> work like farmhouses, factories, mines, hospitals etc., will be used<br />

intensively.<br />

1. i. Instructional Media Packages<br />

In order to maintain quality <strong>of</strong> training uniformly all over the country, Instructional<br />

Media Packages (IMPs) will be developed by the National Instructional Media Institute<br />

(NIMI), Chennai.<br />

1. j. Assessment<br />

DGE&T will appoint assessing bodies to assess the competencies <strong>of</strong> the trained persons.<br />

The assessing body will be an independent agency, which will not be involved in<br />

conducting the training programmes. This, in turn, will ensure quality <strong>of</strong> training and<br />

credibility <strong>of</strong> the scheme. Keeping in view the target <strong>of</strong> providing training/testing <strong>of</strong> one<br />

million persons through out the country and to avoid monopoly, more than one assessing<br />

bodies will be appointed for a Sector or an area.<br />

1. k. Certificate<br />

Successful persons will be awarded certificates issued by National Council for<br />

Vocational <strong>Training</strong> (NCVT).<br />

1. l. MES courses approved by NCVT<br />

The NCVT released a list <strong>of</strong> 340 approved courses on 15 th September 2008, i.e. on the<br />

Engineers day (128 th birth day <strong>of</strong> Sir. M. Visweswariah). The courses were allotted 6<br />

digit alpha numerical codes with the following formula<br />

From Left side:<br />

1 st , 2 nd and 3 rd digits –Sector Codes (Alpha Codes)<br />

4 th digit – Level Code (1 for level 1, 2 for level 2, 3 for level 3 and so on. As the level<br />

increases, the position in the industry also increases)<br />

5 th and 6 th digits – Course serial number (separate series for courses at same level with in<br />

each sector)<br />

1. m. The <strong>Sericulture</strong> Sector<br />

Although various skills are covered in the list approved by NCVT on 15 th Sep 2008, it<br />

was found that a major sector viz. <strong>Sericulture</strong> was not covered in the list.<br />

The sericulture and silk sector are big sectors having an important role in the Indian<br />

economy and in job opportunities.<br />

• India is the second largest producer <strong>of</strong> silk after China.<br />

• Textile Sector, in which Silk is a part, is one <strong>of</strong> the largest employment providers<br />

in the country.<br />

• <strong>Sericulture</strong> is the backbone for silk industry and provides employment to farmers.<br />

• Majority <strong>of</strong> the silk produced in India is from Karnataka, and hence is a very<br />

important industry or the state. The other states having sericulture are Assam,<br />

West Bengal, Uttaranchal, Orissa, Madhya Pradesh and Maharashtra.<br />

• <strong>Sericulture</strong> gives employment to people from rural and hilly areas.

Page 7 <strong>of</strong> 87<br />

<strong>Sericulture</strong> is a multidimensional, export-oriented, employment generating and highly<br />

remunerative agro-based activity, playing a critical role in poverty alleviation. In recent<br />

years, sericulture has shifted from subsidiary activity to main source <strong>of</strong> income<br />

generation in the country, particularly during the past 10-15 years. The sericulture<br />

activity involves mulberry leaf production - the host plant cultivation, silkworm cocoon<br />

generation - silkworm rearing and raw silk production, i.e., silk reeling and weaving,<br />

etc., and is an integration <strong>of</strong> these respective specialized activities. The cocoon<br />

production (and mulberry cultivation) activity has a very short gestation period and can<br />

be started with low initial investment. One hectare <strong>of</strong> irrigated mulberry garden would<br />

fetch about Rs.70, 000 to 80,000 as net income/year and provides gainful employment for<br />

10-13 persons throughout the year. Since sericulture <strong>of</strong>fers regular employment and<br />

income generation, it plays an important role in alleviating rural poverty effectively and<br />

thereby improving the living conditions <strong>of</strong> rural poor and also plays a key role in arrest <strong>of</strong><br />

urban migration.<br />

<strong>Sericulture</strong> is being practiced in all the 29 districts <strong>of</strong> the Karnataka State at present, with<br />

77, 329 hectares <strong>of</strong> mulberry. The state has produced about 7,238 tons <strong>of</strong> raw silk out <strong>of</strong><br />

the total raw silk production <strong>of</strong> the country (15, 610 tons) in India (2008-09, Indian Silk,<br />

Aug. 2009).<br />

Mulberry cultivation, the input intensive agriculture and silkworm rearing are changing<br />

from traditional farming to improved farming.<br />

Keeping in view the potential <strong>of</strong> sericulture industry in income and employment<br />

generation, necessary supportive programmes were implemented by different State<br />

Governments in the past decades facilitating horizontal and vertical expansions <strong>of</strong> the<br />

sericulture industry in the States.<br />

It was therefore decided to form a Sectoral Skill Panel to identify the skills in sericulture<br />

sector. The panel was headed by Mr. S. J. Amalan, Director, Apex Hi-Tech Institute,<br />

Bangalore and Regional Director D.G.E&T, Ministry <strong>of</strong> Labour and <strong>Employment</strong>,<br />

Karnataka, Andhra Pradesh and Orissa and Dr. Munirajappa, Pr<strong>of</strong>essor, Department <strong>of</strong><br />

Studies in <strong>Sericulture</strong> / Life science, Bangalore University as vice chairman. The<br />

committee identified various skills in the sector and made proposals.<br />

1. n. The members <strong>of</strong> the Sectoral Skill Panel for <strong>Sericulture</strong> Sector<br />

The committee was guided by Mr. L. Nagarajamurthy, former Director <strong>of</strong> Vocational<br />

Education Government <strong>of</strong> Karnataka as an advisor and coordinated by Mr. B.<br />

Purushothama as coordinator. The members were drawn from different academic<br />

institutes, vocational teachers, research centres and progressive farmers and sericulturists.<br />

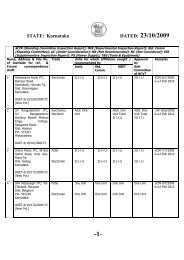

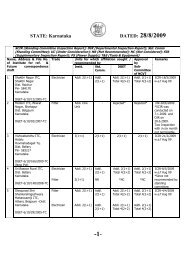

Sr.<br />

No<br />

Name<br />

Official Address<br />

Contact details - Phone<br />

and e-mail ID<br />

Role in<br />

committee

Page 8 <strong>of</strong> 87<br />

1 S. J. Amalan<br />

2 Dr. Munirajappa<br />

Director,<br />

Apex Hi-Tech Institute, Bangalore<br />

and Regional Director D.G.E&T,<br />

Ministry <strong>of</strong> Labour and<br />

<strong>Employment</strong>, Karnataka, Andhra<br />

Pradesh and Orissa.<br />

Pr<strong>of</strong>essor,<br />

Dept <strong>of</strong> Studies in <strong>Sericulture</strong> / Life<br />

science<br />

Jnanabharathi Campus,<br />

Bangalore University<br />

Bangalore 560056<br />

Also Mulberry cultivation<br />

080-23378335, +(91) 0<br />

9880361079<br />

sjamalan@yahoo.co.in<br />

9448224211<br />

munirajappa@rediffmail.co<br />

m<br />

Chairman<br />

Vice<br />

Chairman<br />

3 Dr. Govindaiah<br />

Pr<strong>of</strong>essor, Dept <strong>of</strong> Studies in<br />

<strong>Sericulture</strong> / Life science<br />

Jnanabharathi Campus, Bangalore<br />

University<br />

Bangalore 560056<br />

9916945253<br />

9448616444<br />

dr.govindaiah@rediffmail.c<br />

om<br />

Member<br />

4<br />

Dr. B. M.<br />

Shekharappa<br />

Scientist D, <strong>Sericulture</strong> Division,<br />

KSSRDI, Thalaghattapuara,<br />

Kanakapura Road, Bangalore<br />

560062<br />

Also specialist in Silk worm rearing<br />

technology, Seed Technology and<br />

Physiology<br />

9449064383<br />

sekharappa@gmail.com<br />

Member<br />

5<br />

Dr. R. S.<br />

Mallikarjunappa<br />

Scientist D, Moriculture Division,<br />

KSSRDI, Thalaghattapuara,<br />

Kanakapura Road,<br />

Bangalore 560062<br />

080-26710814<br />

greeshma.rm@gmail.com<br />

Member<br />

6 Dr. C. S Gururaj<br />

Scientist B, <strong>Sericulture</strong> Division,<br />

KSSRDI, Thalaghattapuara,<br />

Kanakapura Road,<br />

Bangalore 560062<br />

9980867300<br />

dr_gururajcs@yahoo.co.in<br />

Member<br />

7<br />

Dr. V. N.<br />

Yogananda<br />

Murthy<br />

8 Dr. H. L. Ramesh<br />

9<br />

10<br />

M.S.<br />

Nijagunamurthy<br />

H. N.<br />

Ramakrishna<br />

Principal,<br />

Ganga Kaveri Institute <strong>of</strong> Science<br />

and Management,<br />

1699 Dr. Rajkumar Road, 3rd<br />

Stage, Rajajinagar.<br />

Bangalore 560021<br />

Head, Dept <strong>of</strong> <strong>Sericulture</strong>,<br />

V.V. Pura college <strong>of</strong> Science,<br />

K.R. Road,<br />

Bangalore 560004<br />

Lecturer in <strong>Sericulture</strong>,<br />

Govt P.U. College, Gubbi,<br />

Tumukur Dist<br />

Lecturer, Govt Junior College,<br />

Vijayapuara, Devanahalli Taluk,<br />

Bangalore Rural Dist 562135<br />

9880091635<br />

yoga16@rediffmail.com<br />

9880880926<br />

ramesh64_hyadalu@rediffm<br />

ail.com<br />

Member<br />

Member<br />

9448748097 Member<br />

9845269905<br />

jaya_hnr69@yahoo.com<br />

Member

11 H. K. Suresh<br />

12 K. Anjanappa<br />

13 Mr. Rajanna<br />

14 Mr. H. Bhaskar<br />

15 Mr. S. Anand<br />

16 Chandrashekar<br />

17 Krishnappa<br />

18<br />

L. Nagaraja<br />

Murthy<br />

19 B. Purushothama<br />

State award winner for CRC<br />

Expert in Silk worm Chawki<br />

Rearing<br />

SLN Chawki Centre,<br />

Hittalahalli, Sidlaghatta Taluk,<br />

Chickaballapura Dist. 562105<br />

Expert in Silk worm seed<br />

production -grainage<br />

Sri Anjaneyaswamy Reshme Motte<br />

Utpadana Kendra,<br />

Bhodaguru, Malamachanahalli Post,<br />

Sidlaghatta Taluk,<br />

Chickaballapura Disr 562102<br />

Progressive sericulturists<br />

s/o Krishnappa,<br />

Ajjawara village and post,<br />

Chickaballapura Dist,<br />

Progressive sericulturists<br />

s/o Honnaiah,<br />

Ajjawara village and post,<br />

Chickaballapura Dist,<br />

Progressive sericulturists<br />

s/o Sri Ramiah<br />

Ajjawara village and post,<br />

Chickaballapura Dist,<br />

Proprietor<br />

M/s Scientific farm supply.<br />

Opp State Bank <strong>of</strong> Mysore,<br />

Chickaballapura<br />

Progressive sericulturists<br />

Ajjawara village and post,<br />

Chickaballapura Dist,<br />

Former Director <strong>of</strong> Vocational<br />

Education, Government <strong>of</strong><br />

Karnataka<br />

Consultant – QMS and Textiles<br />

B-17, Jayanthi Apartments,<br />

13th cross, 4th Main,<br />

Malleswaram,<br />

Bangalore 560003<br />

91- 0- 9448633189<br />

nagarajamurthyl@gmail.co<br />

m<br />

Page 9 <strong>of</strong> 87<br />

9845685478 Member<br />

9448358835 Member<br />

9008022020 Member<br />

9900905267 Member<br />

9844622875 Member<br />

9845013320 Member<br />

9448277929 Member<br />

+(91) 0 9448864028<br />

080-23461512<br />

purushothama1949@yahoo.<br />

co.in<br />

Advisor<br />

Coordinato<br />

r<br />

1. o. The Criteria<br />

The criteria adopted for identifying the skills were as follows<br />

• Skill required by the industry for the jobs<br />

• Safety precautions while working<br />

• Minimum education level for the job<br />

• Minimum age limit for all courses – 14 Years<br />

• Minimum time required for the course<br />

• Course content<br />

– Practical aspects<br />

– Theory aspects<br />

• Tools and Equipments needed

Page 10 <strong>of</strong> 87<br />

1. p Areas covered.<br />

The following areas were covered<br />

Modular employable skills identified for <strong>Sericulture</strong> Sector<br />

Level 1 2 3 4 Total<br />

Mulberry 2 3 1 6<br />

Rearing 4 3 4 1 12<br />

Accessories 2 2<br />

Stores and Despatch 2 2<br />

Value addition 4 4<br />

Total 10 10 5 1 26<br />

The chapter 2 gives the skills identified in a tabular form<br />

The Appendixes give the details <strong>of</strong> curricula and the minimum tools and equipments for<br />

training 20 candidates for each module identified<br />

1. q. Suggestions<br />

The committee made the following suggestions considering the practical problems in<br />

training the people for the required skills.<br />

• The trainees should work like a regular employee <strong>of</strong> the industry for the full time<br />

to acquire the skills as needed by a regular worker. We need to understand that<br />

just by seeing in a practical class and listening to lectures, the skill cannot be<br />

developed.<br />

• It shall not be practicable to any institute to have the equipments that are latest<br />

and the number <strong>of</strong> equipments or machines for each trainee to operate as they are<br />

costly and have innumerable varieties.<br />

• As the design features are different from make to make, the operator working with<br />

certain speed on particular equipment cannot operate another equipment <strong>of</strong><br />

different make with the same speed.<br />

• The training should be given in regular factories or process houses by making<br />

collaborations <strong>of</strong> industry and institution. The government must coordinate with<br />

the institutes and the industry.<br />

• The assessing bodies should test the trainees for their skill on the machines and<br />

equipment they practice and at the same environment <strong>of</strong> working.<br />

• The committee has identified certain skills, but does not claim that all skills are<br />

covered.<br />

• Each factory or a production unit has its own systems and the technology. The<br />

committee has tried to cover the common activities, and not the specialized one<br />

for a particular factory or an area.<br />

• The technology is changing continuously and there is a need to revise these skills<br />

at least every 5 years.

Sr<br />

No<br />

2 – Skills identified in <strong>Sericulture</strong> Sector<br />

Code Level Title<br />

Entry<br />

Qualifications<br />

No<br />

<strong>of</strong><br />

hours<br />

Page 11 <strong>of</strong> 87<br />

Group<br />

1 SER101 1 Mulberry Sapling Producer 5th Std 200 Mulberry<br />

2 SER210 2 Mulberry Garden Establisher.<br />

3 SER211 2 Mulberry Garden Maintainer.<br />

4 SER212 2 Vermicompost Producer<br />

5th Std +<br />

SER101<br />

5th Std +<br />

SER101<br />

5th Std +<br />

SER101<br />

150 Mulberry<br />

200 Mulberry<br />

200 Mulberry<br />

5 SER321 3 Mulberry Crop Protector<br />

5th Std + SER<br />

102+ SER204<br />

200 Mulberry<br />

6 SER 102 1 Mulberry Crop Protection Assistant 5 th Std 150 Mulberry<br />

7 SER 213 2<br />

Sanitation and Disinfection<br />

Assistant.<br />

5th Std 200 Rearing<br />

8 SER103 1 Chawki Rearer 5th Std 150 Rearing<br />

9 SER 214 1 Late age silkworm rearing assistant<br />

10 SER 215 2 Silkworm Protector<br />

5th Std + SER<br />

103<br />

5th Std +<br />

SER105<br />

200 Rearing<br />

200 Rearing<br />

11 SER 322 3 Seed Cocoon Procurer 10th Std 150 Rearing<br />

12 SER 104 1 Pre-emergence Grainage Operator 5th Std 150 Rearing<br />

13 SER 105 1 Post emergence grainage operator 5th Std 150 Rearing<br />

14 SER 323 3 Pupa and Moth Tester. 10th Std 150 Rearing<br />

15 SER 216 2 Acid treatment technician 10th Std 150 Rearing<br />

16 SER 217 2 Silk worm Cold Storage operator 10th Std 150 Stores/Despatch<br />

17 SER 218 2 Silk Worm Egg Marketing Assistant<br />

18 SER 324 3 Egg Production Supervisor<br />

19 SER 426 4 Egg Production Manager<br />

20 SER 325 3 <strong>Sericulture</strong> extension worker<br />

21 SER 219 2<br />

22 SER 220 2<br />

Bamboo Appliances Maker for<br />

Silkworm Rearing<br />

Wooden Appliances Maker for<br />

<strong>Sericulture</strong><br />

10th Std + basic<br />

computer<br />

knowledge<br />

10th Std +<br />

SER103 +<br />

SER104 +<br />

SER105<br />

10th Std +<br />

SER304<br />

10 h Std + SER<br />

304<br />

150 Stores/Despatch<br />

150 Rearing<br />

150 Rearing<br />

150 Rearing<br />

5th Std 200 Accessories<br />

5th Std 200 Accessories<br />

23 SER 106 1 Silk Handicrafts Maker 5th Std 150 Value Addition<br />

24 SER 107 1 Mulberry Cosmetic Assistant 5th Std 150 Value Addition<br />

25 SER 108 1 Mulberry Snack Maker 5th Std 150 Value Addition<br />

26 SER 109 1 Silk Garland Maker 5th Std 150 Value Addition

Matrix<br />

<strong>Sericulture</strong><br />

Mulberry – Rearing – Stores Despatch – Accessories – Value Addition<br />

Page 12 <strong>of</strong> 87<br />

The Matrix is prepared to indicate the possible level enhancement for the candidates,<br />

direction <strong>of</strong> material flow and the interactions. Following symbols are used.<br />

Possible level enhancement<br />

Direction <strong>of</strong> material flow<br />

Interactions

Page 13 <strong>of</strong> 87<br />

<strong>Sericulture</strong><br />

SER101<br />

Mulberry Sapling Producer<br />

SER 102<br />

Mulberry Crop<br />

Protection Assistant<br />

SER 213<br />

Sanitation and<br />

Disinfection<br />

Assistant.<br />

SER210<br />

Mulberry<br />

Garden<br />

Establisher.<br />

SER211<br />

Mulberry<br />

Garden<br />

Maintainer.<br />

SER212<br />

Vermi compost<br />

Producer<br />

SER321<br />

Mulberry Crop<br />

Protector<br />

SER103<br />

Chawki<br />

Rearer<br />

SER 214<br />

Late age<br />

silkworm rearing<br />

assistant<br />

SER 215<br />

Silkworm Protector<br />

SER 104<br />

Pre-emergence<br />

Grainage Operator<br />

SER 322<br />

Seed Cocoon<br />

Procurer<br />

SER 105<br />

Post emergence<br />

grainage operator<br />

SER 323<br />

Pupa and Moth<br />

Tester.<br />

SER 324<br />

Egg Production Supervisor<br />

SER 216<br />

Acid treatment<br />

technician<br />

SER 218<br />

Silk Worm Egg<br />

Marketing Assistant<br />

SER 217<br />

Silk worm Cold<br />

Storage operator<br />

SER 325<br />

<strong>Sericulture</strong><br />

extension<br />

worker<br />

SER 106<br />

Silk Handicrafts Maker<br />

SER 107<br />

Mulberry Cosmetic Assistant<br />

SER 426<br />

Egg Production Manager<br />

SER 108<br />

Mulberry Snack Maker<br />

SER 109<br />

Silk Garland Maker<br />

Delivery<br />

to Market<br />

SER 219<br />

Bamboo<br />

Appliances<br />

Maker for<br />

Silkworm<br />

Rearing<br />

SER 220<br />

Wooden<br />

Appliances<br />

Maker for<br />

<strong>Sericulture</strong><br />

APPENDIX – 1

Practical competencies<br />

Page 14 <strong>of</strong> 87<br />

Course Curricla<br />

Under pinning knowledge (Theory)<br />

LEVEL – 1<br />

1. Module Name: Mulberry Sapling Producer<br />

2. Sector: <strong>Sericulture</strong><br />

3. Code: SER - 101<br />

4. Entry Qualification Minimum 5 th Standard and 14 years <strong>of</strong> age<br />

5. Terminal<br />

The successful candidate would be able to raise mulberry saplings<br />

Competency: for commercial purposes.<br />

6. Duration: 200 hours<br />

7. Preface: Mulberry is vegetatively propagated through stem cuttings. The<br />

cuttings are directly planted in the main field and some time<br />

nursery is raised. Due to direct planting <strong>of</strong> cuttings in main field the<br />

mortality <strong>of</strong> cuttings ranges from 30% - 40%. The use <strong>of</strong> saplings<br />

ensures quick establishment and uniform growth <strong>of</strong> plants.<br />

Therefore, saplings have to be used as planting materials instead <strong>of</strong><br />

cuttings.<br />

8. Job Pr<strong>of</strong>ile Employable in Kisan Nurseries and self-employment.<br />

9. Course Content:<br />

‣ Selection <strong>of</strong> suitable nursery site<br />

‣ Treat the soil with furadon to ensure<br />

nematode free plot.<br />

‣ Preparation <strong>of</strong> land, measurement and<br />

markings <strong>of</strong> beds and furrows as per the<br />

recommendations and types.<br />

Determination <strong>of</strong> the quantity <strong>of</strong> cuttings<br />

required.<br />

‣ Preparation <strong>of</strong> propagation mixture (red<br />

soil, sand and FYM to make 1:1:1 ratio)<br />

and application.<br />

‣ Methods <strong>of</strong> propagation.<br />

‣ Types <strong>of</strong> nursery beds (sunken and<br />

raised), season/time <strong>of</strong> raising<br />

nursery.<br />

‣ Knowledge about popular<br />

mulberry varieties.<br />

‣ Vegetative propagation <strong>of</strong><br />

mulberry and its advantages.<br />

‣ Selection <strong>of</strong> popular mulberry variety. ‣ Selection <strong>of</strong> suitable nursery site –<br />

assured irrigation, disease free<br />

soil.<br />

‣ Selection <strong>of</strong> shoots and preparation <strong>of</strong><br />

cuttings with 3 to 4 active buds;<br />

identification <strong>of</strong> active and deformed<br />

buds.<br />

‣ Treatment <strong>of</strong> cuttings with fungicide<br />

‣ Preparation <strong>of</strong> nursery beds –<br />

digging, leveling, weeding,<br />

cleaning etc.<br />

‣ Preparation <strong>of</strong> propagation mixture

solutions, and root hormones.<br />

‣ Application <strong>of</strong> bio-control agents and soil<br />

application <strong>of</strong> VAM.<br />

‣ Planting <strong>of</strong> cuttings – spacing, soil depth,<br />

number <strong>of</strong> cuttings per bed.<br />

‣ Maintenance <strong>of</strong> nursery beds. Irrigation –<br />

use <strong>of</strong> rose cans, micro sprinkler,<br />

weeding, application <strong>of</strong> fertilizers etc.<br />

‣ Plant protection measures – spray <strong>of</strong><br />

fungicides and pesticides for control <strong>of</strong><br />

pests and diseases in nursery.<br />

‣ Uprooting, packing and transportation <strong>of</strong><br />

mulberry saplings.<br />

‣ Safety measures while using cutting<br />

implements, pesticides and chemicals and<br />

practice <strong>of</strong> first aid.<br />

Page 15 <strong>of</strong> 87<br />

(red soil, sand and FYM<br />

‣ Application <strong>of</strong> organic manures –<br />

FYM/ compost/ vermicompost.<br />

‣ Selection <strong>of</strong> shoots and<br />

preparation <strong>of</strong> cuttings; length <strong>of</strong><br />

cuttings, number <strong>of</strong> active<br />

buds/cutting.<br />

‣ Treatment <strong>of</strong> cuttings with<br />

fungicide, root hormones, VAM<br />

and their importance.<br />

‣ Planting <strong>of</strong> cuttings – methods and<br />

spacing.<br />

‣ Maintenance <strong>of</strong> nursery -<br />

irrigation, manuring, weeding,<br />

protection, etc.<br />

‣ Uprooting, packing and<br />

transportation <strong>of</strong> mulberry saplings<br />

with care<br />

10. Tools and equipments required for a batch <strong>of</strong> 20 trainees.<br />

1. Suitable nursery site 5 beds <strong>of</strong> 2.4 x 1.2 m (8 x 4 ft)<br />

2.<br />

3.<br />

Garden implements - Crowbar, pickaxe, spade,<br />

machete, sickle, digger, rose can, hose pipe (30<br />

mt.), plastic pot, micro sprinkler, iron pan and<br />

plastic basket<br />

Farm yard manure, red soil, sand and chemical<br />

fertilizers.<br />

5 each<br />

As required<br />

4. Planting material – stem cuttings As required<br />

5. Fungicide – Diathane M 45 / Bavistin, furadon 100 g<br />

6. Insecticide - Nuvan 100 g<br />

7.<br />

Root promoting hormone – IAA<br />

/IBA/commercial formulation<br />

10ml<br />

8. Plastic basin – 20 lt. capacity 6 No.

9. Biocontrol agent and VAM 5 kg each<br />

Page 16 <strong>of</strong> 87<br />

10. Knapsack Sprayer 16 lt 1 No.<br />

11. Gunny cloth 10 mt<br />

12. Nylon rope 100 mt<br />

13. Measuring tape – 50 mt. 1 no.<br />

14. Measuring jar – 100 ml plastic 2 no.<br />

15. First Aid kit 1 set

Page 17 <strong>of</strong> 87<br />

LEVEL - 1<br />

1. Module Name: Mulberry Crop Protection Assistant<br />

2. Sector: <strong>Sericulture</strong><br />

3. Code: SER - 102<br />

4. Entry Qualification Minimum 5 th Standard and 18 years <strong>of</strong> age<br />

5. Terminal<br />

Competancy:<br />

After the completion <strong>of</strong> the course, the successful candidate would<br />

be able to assist in the control <strong>of</strong> pests and diseases <strong>of</strong> mulberry<br />

6. Duration: 120 hours<br />

7. Preface: Mulberry is affected by number <strong>of</strong> pests and diseases through out<br />

the year and the leaf yield loss is about 20% - 30%. Affected leaves<br />

are poor in the nutrition which affects the silkworm growth, cocoon<br />

production and silk quality. There fore plant protection is very<br />

important in mulberry cultivation.<br />

8. Job Pr<strong>of</strong>ile: Employable in plant protection clinics. self entrepreneur<br />

9. Course Content:<br />

Practical competencies<br />

‣ Identification <strong>of</strong> pests and diseases <strong>of</strong><br />

mulberry.<br />

Under pinning knowledge (Theory)<br />

‣ Introduction to Pest and disease<br />

problem in mulberry.<br />

‣ Observation on the symptoms <strong>of</strong> pests<br />

and diseases attack.<br />

‣ Control <strong>of</strong> pests and diseases by<br />

cultural methods - practicing <strong>of</strong> field<br />

sanitation, soil solarisation, manuring,<br />

flooding, mulching, intercropping and<br />

weeding.<br />

‣ Observation on the symptoms <strong>of</strong> pests<br />

and diseases attack.<br />

‣ Control <strong>of</strong> pests and diseases by<br />

cultural methods - practicing <strong>of</strong> field<br />

sanitation, soil solarisation, manuring,<br />

flooding, mulching, intercropping and<br />

weeding.<br />

‣ Control <strong>of</strong> pests and diseases using<br />

fungicides and pesticides -<br />

Preparation <strong>of</strong> spray solution, method<br />

<strong>of</strong> spraying, handling <strong>of</strong> sprayers and<br />

maintenance, precaution during<br />

‣ <strong>General</strong> account on pests and diseases<br />

<strong>of</strong> mulberry and their identification<br />

based on symptoms.<br />

‣ Favourable weather conditions for<br />

pests and diseases out break.<br />

‣ <strong>General</strong> account on pests and diseases<br />

<strong>of</strong> mulberry and their identification<br />

based on symptoms.<br />

‣ Favourable weather conditions for<br />

pests and diseases out break.<br />

‣ Management <strong>of</strong> pests and diseases by<br />

cultural, chemical and biological<br />

methods.

spraying, safe period, safe disposal <strong>of</strong><br />

chemical containers, personal safety.<br />

LEVEL – 1<br />

Page 18 <strong>of</strong> 87<br />

‣ Control <strong>of</strong> pests and diseases using<br />

biocontrol agents - procurement <strong>of</strong><br />

useful microbes, predators and<br />

parasitoids, method <strong>of</strong> application,<br />

precaution while handling the<br />

biocontrol agents.<br />

‣ Residual toxicity <strong>of</strong> fungicides and<br />

pesticides.<br />

‣ Precautionary measures to be taken<br />

during spraying and handling <strong>of</strong><br />

biocontrol agents.<br />

10. Tools and equipments required for a batch <strong>of</strong> 20 trainees.<br />

1. Mulberry plot affected by pests and diseases As required<br />

2. Knapsack sprayers 2 No.<br />

3. Bucket and Mug 4 No. each<br />

4. Fungicides – Diathane M-45, Bavistin, 100 g each<br />

5. Streptocycline 100 g<br />

6. Insecticides - Nu van 100 ml each<br />

7.<br />

Biocontrol agents (Trichoderma, lady bird<br />

beetle, Trichograma chilonis)<br />

As required<br />

8. Masks 20 No.<br />

9. Hand Gloves 20 Pairs<br />

10. Hand Lens 2 No.<br />

11. Polythene covers 1 Kg<br />

12.<br />

Garden implements – Weeding Sickle, spade,<br />

pickaxe,and digger.<br />

5 No. each<br />

13 Mulberry plot affected by pests and diseases As required<br />

14 Knapsack sprayers 2 No.<br />

15 Bucket and Mug 4 No. each

1. Module Name: Chawki Rearer<br />

2. Sector: <strong>Sericulture</strong><br />

3. Code: SER - 103<br />

4. Entry Qualification Minimum 5 th Standard and 14 years <strong>of</strong> age<br />

‣ Disinfection <strong>of</strong> Chawki rearing room and<br />

appliances.<br />

‣ Transportation <strong>of</strong> eggs.<br />

‣ Practicing different types <strong>of</strong> Incubation.<br />

‣ Practicing black boxing.<br />

‣ Brushing and preparation <strong>of</strong> Chawki bed.<br />

‣ Selection, harvesting and preservation <strong>of</strong><br />

quality leaves. Practicing the chopping <strong>of</strong><br />

leaves to required size.<br />

‣ Bed spacing, Bed cleaning using nets and<br />

moulting care.<br />

‣ Practicing <strong>of</strong> rearing in isolation chamber<br />

and wrap up method.<br />

‣ Maintenance <strong>of</strong> optimum temperature and<br />

humidity during rearing and moulting.<br />

‣ Identification <strong>of</strong> moulting and out <strong>of</strong> moult<br />

larvae.<br />

‣ Identification <strong>of</strong> healthy, diseased and<br />

unequal worms.<br />

Page 19 <strong>of</strong> 87<br />

5. Terminal<br />

The successful candidate will be capable <strong>of</strong> undertaking<br />

Competency:<br />

chawki rearing and work in chawki rearing center.<br />

6. Duration: 150 hours<br />

7. Preface: The rearing <strong>of</strong> young age silkworm up to second moult is<br />

called chawki rearing. Rearing <strong>of</strong> young age Silkworms under<br />

ideal environmental conditions, feeding succulent, nutritious,<br />

tender leaves will make the larvae grow robust and make more<br />

stress tolerant during the late age rearing. Scientifically grown<br />

chawki will result in best performance in cocoon production.<br />

Therefore, skill development in chawki rearing is an important<br />

module.<br />

8. Job Pr<strong>of</strong>ile Employable in Chawki Rearing Centers (CRCs) and may be<br />

self employed.<br />

9. Course Content:<br />

Practical competencies<br />

‣ Cleaning <strong>of</strong> rearing room and appliances.<br />

‣ Preparation <strong>of</strong> disinfectants.<br />

Under pinning knowledge (Theory)<br />

‣ Introduction to chawki rearing.<br />

‣ Chawki rearing room and rearing<br />

equipments<br />

‣ Preparation for chawki rearing for<br />

required number <strong>of</strong> Dfls.<br />

‣ Knowledge about disinfectants and<br />

disinfections.<br />

‣ Method <strong>of</strong> Incubation and black<br />

boxing.<br />

‣ Brushing methods.<br />

‣ Chawki rearing methods including<br />

isolation chamber and wrap up<br />

methods.<br />

‣ Importance <strong>of</strong> environmental<br />

conditions like light, air<br />

temperature and humidity and their<br />

manipulation.<br />

‣ Bed Spacing, chopping <strong>of</strong> mulberry<br />

leaves, feeding, bed cleaning,<br />

moulting and care during moult.<br />

‣ Use <strong>of</strong> lime and bed disinfectants.<br />

‣ Concept <strong>of</strong> measuring volume area<br />

and weight.<br />

‣ Concept <strong>of</strong> chawki garden, leaf<br />

quality, harvest and preservation.<br />

‣ Leaf chopping machine and duster.

Page 20 <strong>of</strong> 87<br />

‣ Practicing the use <strong>of</strong> lime powder and bed ‣ Care during transportation <strong>of</strong><br />

disinfectants<br />

chawki worms.<br />

‣ Personal and rearing hygiene. ‣ Care while handling the<br />

disinfectant.<br />

‣ Packing <strong>of</strong> chawki worms for transportation. ‣ Diseases in chawki and their<br />

control.<br />

‣ Safety measures and First aid.<br />

‣ Safety practices in chawki rearing.<br />

10. Tools and equipments required for a batch <strong>of</strong> 20 students. (25 Dfls / 2 students)<br />

1 Chawki rearing room with ante room and preparation<br />

room and corridor<br />

2 Chawki rearing trays (Plastic) (2‟ x 3‟) 60 No.<br />

3 Chawki rearing bottom Stand 06 No.<br />

4 Ant wells 36 No.<br />

5 Chopping board and knife 05 Sets<br />

6 Feeding stand 05 No.<br />

7 Foot cleaning tray 03 No.<br />

8 Wash basin 04 No.<br />

9 Sprayer and mask 01 Set<br />

10 Egg transportation box & Egg incubation chamber 02 unit<br />

11 Black boxes 20 No.<br />

12 Leaf baskets 10 No.<br />

13 Earthen pots 5 No.<br />

14 Foam rubber 30 strips<br />

15 Paraffin paper 60 meters<br />

16 Wet and dry bulb thermometer 03 No.<br />

17 Room heater with thermostat 02 No.<br />

18 Air cooler 01 Unit<br />

19 Chop sticks 25 pairs<br />

20 Feather 25 No.<br />

21 Nylon bed cleaning nets, 2 mtr squares 60 No.

22 Measuring jars (Plastic) – 500 ml 02 No.<br />

23 Napkin 20 No.<br />

24 Leaf mat (Bamboo) 02 No.<br />

25 Black colour cloth 10 Meters<br />

26 Plastic bucket and mug, litter basket 02 Unit<br />

27 Plastic basin 10 No.<br />

Page 21 <strong>of</strong> 87<br />

29 Kora cloth, muslin cloth 05 meter each<br />

30 Plastic box with lid (5 kg) , different colour 05 No.<br />

31 Isolation chamber 02 no.<br />

32 Hygrometer 03 no.<br />

33 Sieve for dusting 02 no.<br />

34 Magnifying glass with illumination 10 no.<br />

35 Student microscope 2 no.<br />

36 Slides and cover slips 3 boxes<br />

37 Leaf chamber 1 no.<br />

38 Rearing stand (double) 2 no.<br />

39 Loose egg frames 15 no.<br />

Rearing consumables<br />

1 Silkworm eggs 150 dfls sheet eggs/100<br />

dfls loose eggs<br />

2 <strong>General</strong> disinfectants 5 lts<br />

3 Bleaching powder 5 kg<br />

4 Lime powder 5 kg<br />

5 Old news paper 5 kg

Page 22 <strong>of</strong> 87<br />

LEVEL – I<br />

1. Module Name: Pre-emergence Grainage Operator<br />

2. Sector: <strong>Sericulture</strong><br />

3. Code: SER - 104<br />

4. Entry Qualification Minimum 5 th Standard and 14 years <strong>of</strong> age<br />

5. Terminal<br />

Competency:<br />

The successful candidate would be able to separate male and<br />

female cocoons, preservation <strong>of</strong> cocoons/pupae and<br />

synchronization <strong>of</strong> male and female moths.<br />

6. Duration: 150 hours<br />

7. Preface: Preservation and sexing <strong>of</strong> cocoons/pupae and preservation <strong>of</strong><br />

seed cocoons is an important activity to produce quality<br />

silkworm eggs. Therefore, development <strong>of</strong> skill is important in<br />

the pre-emergence grainage operations.<br />

8. Job Pr<strong>of</strong>ile: Employable In silkworm grainage and self employable<br />

9. Course Content<br />

Practical Competencies Under Pinning Knowledge (Theory)<br />

‣ Identification <strong>of</strong> different silkworm ‣ Knowledge about the races used in<br />

races used in egg preparation.<br />

the grainage<br />

‣ Deflossing and sorting <strong>of</strong> seed<br />

cocoons<br />

‣ Selection <strong>of</strong> places to store different<br />

seed cocoons.<br />

‣ Learning the method <strong>of</strong> fixing the<br />

weight <strong>of</strong> male and female cocoons<br />

<strong>of</strong> the given lot.<br />

‣ Identification <strong>of</strong> male and female<br />

cocoons based on cocoon colour in<br />

sex linked breeds.<br />

‣ Principles <strong>of</strong> separation <strong>of</strong> male and<br />

female cocoons/pupae and their<br />

preservation.<br />

‣ Storing bivoltine and multivoltine<br />

seed cocoons separately in the<br />

grainage.<br />

‣ Care during preservation <strong>of</strong> seed<br />

cocoons and pupae.<br />

‣ To learn the need for separate<br />

emergence room for BV and MV<br />

seed cocoons.<br />

‣ Practicing weighing <strong>of</strong> cocoons and<br />

segregation <strong>of</strong> male and female<br />

cocoons.<br />

‣ Skill to use exhaust fan, wet and dry<br />

thermometer, hygrometer, thermo<br />

hygrograph, heater /cooler,<br />

humidifier etc., in grainage.<br />

‣ Practicing cocoon cutting for easy<br />

‣ Sexing based on cocoon weight,<br />

colour and larval markings.<br />

‣ Principle <strong>of</strong> fixing weight <strong>of</strong> male<br />

and female cocoons <strong>of</strong> a given lot.<br />

‣ Basic knowledge about cocoon

emergence <strong>of</strong> moth<br />

‣ Preservation <strong>of</strong> male and female<br />

cocoons/ pupae separately.<br />

‣ Learning the synchronization and<br />

emergence <strong>of</strong> male and female<br />

moths.<br />

‣ Safety practices in grainage<br />

operation against use <strong>of</strong> grainage<br />

equipments. Precaution to avoid<br />

dust and scale allergy,<br />

Page 23 <strong>of</strong> 87<br />

weighing balance and weighing<br />

measures.<br />

‣ Synchronization and emergence <strong>of</strong><br />

male and female moths.<br />

‣ Eco friendly disposal <strong>of</strong> wastes.<br />

‣ Importance <strong>of</strong> cleanliness and<br />

personal safety. Fire fighting and<br />

first aid.<br />

‣ Eco friendly disposal <strong>of</strong> wastes<br />

materials.<br />

‣ Discipline and punctuality.<br />

10. Tools, equipments and chemicals required for a batch <strong>of</strong> 20 students.<br />

1. Electronic top loading balance 1 No.<br />

2. Cocoon preserving plastic trays (2‟ x 3‟) 25 No.<br />

3. Moth Preservation Trays (plastic/metal: 12” x 8”) 30 No.<br />

4. Deflossing Machine 1 No.<br />

5. Room Heater with thermostat 5 No.<br />

6. Humidifiers with humidistat 2 No.<br />

7. Cocoon preservation stands with ant wells 5 No.<br />

8. Wall clock 1 No.<br />

9. Refrigerator 300 lt capacity 2 No.<br />

10. Magnifying lens 5 No.<br />

11. Wet and Dry Thermometer 2 No.<br />

12. Hygrometer 2 No.<br />

13. Thermo hygrograph 2 No.

14. Heater/Cooler 2 No.<br />

Page 24 <strong>of</strong> 87<br />

15. Blades 25

Page 25 <strong>of</strong> 87<br />

LEVEL - 1<br />

1. Module Name: Post emergence grainage operator<br />

2. Sector: <strong>Sericulture</strong><br />

3. Code: SER - 105<br />

4. Entry Qualification Minimum 5 th Standard and 14 years <strong>of</strong> age<br />

5. Terminal<br />

The successful candidate would be able to carry out works<br />

Competency:<br />

starting from moth emergence to egg laying and packing.<br />

6. Duration: 150 hours<br />

7. Preface: The silkworm moth emergence and preparation <strong>of</strong> eggs are<br />

important activities in grainage to produce quality eggs.<br />

Therefore, development <strong>of</strong> skill is a pre-requisite for quality<br />

eggs production.<br />

8. Job Pr<strong>of</strong>ile: Employable In silkworm grainage and self employable<br />

9. Course Content<br />

Practical Competencies<br />

‣ To use safety gadgets during moth<br />

emergence.<br />

‣ Use <strong>of</strong> light in moth emergence.<br />

Identification <strong>of</strong> male and female<br />

moths, separation and preservation.<br />

‣ Practice <strong>of</strong> maintenance <strong>of</strong><br />

temperature, humidity, light and<br />

other conditions during oviposition<br />

‣ Preparation <strong>of</strong> starch paper for loose<br />

egg preparation.<br />

‣ Skill to use cellule, hygrometer, egg<br />

laying paper, starch paper and loose<br />

egg preparation, news paper.<br />

Under Pinning Knowledge (Theory)<br />

‣ Importance <strong>of</strong> light and dark<br />

condition during moth emergence<br />

and pattern <strong>of</strong> male and female moth<br />

emergence.<br />

‣ Knowledge about the difference in<br />

male and female pupae and moths.<br />

‣ Knowledge about hybrid egg<br />

production.<br />

‣ Knowledge <strong>of</strong> parents involved in<br />

crossing, mating/pairing, depairing,<br />

placing female moth for egg laying<br />

and male moth preservation.<br />

‣ Principle and scope <strong>of</strong> sheet and<br />

loose egg preparation – Advantages<br />

and disadvantages.<br />

‣ Labeling and preservation <strong>of</strong> moths ‣ Environmental conditions during<br />

emergence, pairing, oviposition and<br />

oviposition room.<br />

‣ Pairing <strong>of</strong> male and female moths.<br />

‣ Depairing and placing the female for<br />

egg laying in cellule/on starch paper<br />

‣ Silk moth scale and its impact on<br />

human health.<br />

‣ Safe disposal <strong>of</strong> grainage wastes.

tray.<br />

Page 26 <strong>of</strong> 87<br />

‣ Processing egg sheets and starched for<br />

sheet egg and loose eggs.<br />

‣ Surface disinfection <strong>of</strong> egg using 2%<br />

formalin.<br />

‣ Dispatching the eggs for<br />

incubator/cold storage and acid<br />

treatment.<br />

‣ Discipline and punctuality.<br />

‣ Dispatch <strong>of</strong> female moths for testing<br />

‣ Safety practices in grainage operation<br />

against use <strong>of</strong> grainage equipments.<br />

Precaution to avoid dust and scale<br />

allergy,<br />

10. Tools, equipments and chemicals required for a batch <strong>of</strong> 20 students.<br />

1. Cocoon preserving plastic trays (2‟ x 3‟) 25 No.<br />

2. Moth Preservation Trays (plastic/metal: 12” x 8”) 30 No.<br />

3. Wash Basin 2 Nos.<br />

4. Mask and Gloves 1 Set.<br />

5. Room Heater with thermostat 2 Nos.<br />

6. Humidifiers with humidistat 1 Nos.<br />

7. Alarm time piece 1 No.<br />

8. Cellules 250 No.<br />

9. Thermometer 5 Nos.<br />

10. Refrigerator 300 lt capacity 1 Nos.<br />

11. Emergency solar lamp 3 No.<br />

12. Diesel Generator Set 1 No.<br />

13. Egg Sheet 500 sheets<br />

14. Egg Cabinet 1 No.

Page 27 <strong>of</strong> 87<br />

15. Calculator 5 No.<br />

16. Thermo-hygrograph 2 No.<br />

17. Magnifying lens 5 No.<br />

18. Starch 10 Kg.<br />

19. Measuring jar 250 ml Plastic 2 No.<br />

20. Hot Plate 1 No.<br />

22. Loose egg box 25 No.<br />

23 Aluminium vessel with spoon (5 lt capacity) 1 No.<br />

24 Face Mask 25 No.

LEVEL –1<br />

Page 28 <strong>of</strong> 87<br />

1. Module name Silk Handicrafts Maker<br />

2. Sector <strong>Sericulture</strong><br />

3. Code SER 106<br />

4. Entry Qualification Minimum 5th standard and 14 years <strong>of</strong> age<br />

5. Terminal competency Successful candidate would be able to produce silk<br />

handicrafts like greeting cards, bouquets, toys, dolls,<br />

wall hangings and decorative items from cut cocoons,<br />

waste silk, silk cloth and paper.<br />

6. Duration 150 hours<br />

7. Preface Cocoons and silk are very good materials to make<br />

beautiful handicrafts like greeting cards, bouquets,<br />

flower cuttings, wall hangings etc. This work involves<br />

colouring the raw materials, designing the handicraft<br />

and actual preparation. Since this involves skill and<br />

creativity there is a scarcity <strong>of</strong> skilled manpower,<br />

Therefore, this module will help to develop the skill.<br />

8. Job Pr<strong>of</strong>ile Employable in cottage industries or self employed.<br />

9. Course Content:<br />

Practical Competencies<br />

GENERAL<br />

A) Safety Precautions<br />

‣ Safety working methods with blades,<br />

threads, needles and scissors.<br />

‣ Practice good housekeeping.<br />

‣ Basics <strong>of</strong> First Aid<br />

B) Pr<strong>of</strong>essional ethics<br />

‣ Obedience and punctuality.<br />

‣ Importance <strong>of</strong> personnel safety.<br />

APPLICATION<br />

‣ Safe handling cutting tools like blades<br />

threads, needles and scissors.<br />

‣ Plant Layout & Working<br />

‣ Material Handling<br />

‣ Preparing silk handicrafts (list<br />

enclosed)<br />

Underpinning Knowledge(Theory)<br />

‣ Importance <strong>of</strong> safety <strong>of</strong> during<br />

production <strong>of</strong> silk handicrafts.<br />

‣ Protective clothing and<br />

equipments<br />

‣ First aid for minor cuts; foreign<br />

body in eye etc.<br />

‣ Basic <strong>of</strong> hygiene, personal<br />

hygiene.<br />

‣ Desirable qualities <strong>of</strong> good<br />

human relationship.<br />

‣ Importance <strong>of</strong> time &<br />

communication Skills.<br />

‣ Types <strong>of</strong> greeting cards, wall<br />

hangings, bouquets, toys, dolls,<br />

and decorative items that can be<br />

produced using cut cocoons,

‣ Types <strong>of</strong> scissors and methods <strong>of</strong> using<br />

them.<br />

PROCESSING<br />

‣ Identification <strong>of</strong> the layout.<br />

‣ Methods to maintain and store raw<br />

materials like cut cocoons, silk and<br />

other required materials<br />

‣ Procurement <strong>of</strong> quality raw materials,<br />

colours, threads, paper and methods <strong>of</strong><br />

storing.<br />

‣ Different types <strong>of</strong> greeting cards.<br />

‣ Methods <strong>of</strong> colouring cocoons and<br />

silk.<br />

‣ Mixing <strong>of</strong> dyes.<br />

‣ Prepare different types <strong>of</strong> toys, dolls<br />

and decorating items<br />

‣ Maintenance <strong>of</strong> inventory and book<br />

keeping.<br />

‣ Packing <strong>of</strong> products in suitable boxes<br />

so as to maintain quality.<br />

‣ Sale <strong>of</strong> products<br />

‣ Market survey and identification <strong>of</strong><br />

suitable markets for sale <strong>of</strong> products.<br />

Page 29 <strong>of</strong> 87<br />

waste silk and silk cloths.<br />

‣ Methods <strong>of</strong> making handicrafts.<br />

‣ Maintenance <strong>of</strong> accounts and<br />

books.<br />

10. Tools and Equipments to train 20 candidates per batch<br />

Sl. No.<br />

Item<br />

1 Scissors – standard type. 20 no<br />

2 Scissors – zig zag cutting type. 20 no<br />

3 Scissors – bent type. 20 no<br />

4 Steel blades. 5 doz<br />

5 Twine threads 50 rolls<br />

6 Nylon threads 50 rolls<br />

7 Tange wire 2 kg<br />

8 Dye stuff – 100g per colour, basic colours 100 g<br />

9 Plastic crates (2‟ x 3‟). 10 no<br />

10 Sealing machine. 02 no<br />

11 Weighing scale (electronic weighing scale) (10 – 1000g 02 no<br />

capacity).<br />

12 Plastic bins 2‟ x 1.5‟ x 1.5‟ h. 5 no<br />

13 Working tables 4 no<br />

14 Measuring scale 10 no<br />

15 Sewing needles – assorted size 20 sets<br />

16 Steel containers for dyeing the cocoons and silk 10 no<br />

17 Plastic drums for cut cocoon storing 10 no<br />

18 Vacuum cleaner. 1 no<br />

19 Garland decorative materials like colour papers, colour As needed

Page 30 <strong>of</strong> 87<br />

strips, etc.<br />

20 Fevicol As needed<br />

21 Satin Ribbon 20 rolls<br />

22 Satin flowers As needed<br />

23 Chamble As needed<br />

24 Rivets for bags As needed<br />

25 Cellophane Tape 20 rolls<br />

26 Packing materials like, polythene covers, paper covers, As needed<br />

etc.<br />

27 Reege As needed<br />

28 Handicraft Decorative Mix As needed<br />

29 Clipper As needed<br />

30 Cutters As needed<br />

31 Hand made paper boards As needed<br />

32 Recycled paper As needed<br />

33 Glitter tubes As needed<br />

34 Land Board As needed

Page 31 <strong>of</strong> 87<br />

LEVEL – 1<br />

1. Module name Mulberry Cosmetic Assistant<br />

2. Sector <strong>Sericulture</strong><br />

3. Code SER 107<br />

4. Entry Qualification Minimum 5th standard and 14 years <strong>of</strong> age<br />

5.Terminal competency<br />

After completion <strong>of</strong> this level the trained person would be having<br />

the basic skill <strong>of</strong> the production <strong>of</strong> mulberry based cosmetic<br />

materials<br />

6. Duration 150 hours<br />

7. Preface Mulberry leaves and fruits have several useful chemicals and<br />

molecules having cosmetic value for humans. Preparation <strong>of</strong><br />

cosmetic products from mulberry will be an important economic<br />

activity increasing the income per unit area <strong>of</strong> garden.<br />

8. Job Pr<strong>of</strong>ile The trained person can be employable in cosmetic manufacturing<br />

factories, cottage industries and self-employment.<br />

9. Course Content:<br />

Practical Competencies<br />

GENERAL<br />

A) Safety Precautions<br />

‣ Safety working procedures and the<br />

necessary precautions. To handle steam;<br />

LPG; electrical; mixing and grinding<br />

equipments.<br />

‣ Practice good housekeeping like<br />

preventing misuse <strong>of</strong> raw materials and<br />

end products.<br />

‣ Practice <strong>of</strong> First Aid<br />

B) Washing and Sanitation<br />

‣ Procedure for hand washing and personal<br />

hygiene.<br />

‣ Sanitization <strong>of</strong> equipments and workplace<br />

(before and after work)<br />

C) Pr<strong>of</strong>essional ethics<br />

‣ Obedience and punctuality.<br />

‣ Adhering to regulations like not using<br />

banned colours, chemicals, verifying the<br />

expiry dates, and purity <strong>of</strong> the ingredients.<br />

‣ Follow statutory instructions.<br />

Underpinning Knowledge(Theory)<br />

‣ Types <strong>of</strong> cosmetic products form<br />

mulberry.<br />

‣ Desirable qualities <strong>of</strong> good human<br />

relationship.<br />

‣ Importance <strong>of</strong> time &<br />

communication Skills.<br />

‣ Importance <strong>of</strong> safety <strong>of</strong> use <strong>of</strong><br />

cosmetic products.<br />

‣ Importance <strong>of</strong> safe handling <strong>of</strong><br />

mixing and grinding equipments;<br />

diesel/gas furnaces; steam kettles<br />

etc.<br />

‣ Protective clothing and equipments<br />

‣ First aid for burns steam/oil/<br />

electrical; minor cuts; safety <strong>of</strong> eye,<br />

etc.<br />

‣ Basic <strong>of</strong> Personal and product<br />

hygiene.<br />

‣ Importance <strong>of</strong> hand washing and<br />

sanitation in ensuring health and<br />

safety <strong>of</strong> workers while handling<br />

chemicals.

APPLICATION<br />

‣ Safe handling <strong>of</strong> pulvarizers, mixers,<br />

cutting implements and grinders; gas;<br />

furnaces; steam kettles etc.<br />

‣ Use <strong>of</strong> protective clothing and<br />

equipments.<br />

‣ Reading <strong>of</strong> Plant Layout & Working<br />

‣ Preparation <strong>of</strong> cosmetic products by<br />

cooking, mixing/blending and distilling.<br />

A) Principles and Processing<br />

‣ Preservation and storing <strong>of</strong> raw materials,<br />

equipments and surroundings to meet<br />

standards.<br />

‣ Harvesting suitable quality <strong>of</strong> mulberry<br />

leaves from suitable mulberry variety.<br />

‣ Preparation and preservation <strong>of</strong> mulberry<br />

leaf powder.<br />

‣ Cleaning and storing raw materials/<br />

ingredients.<br />

‣ Prepare different cosmetic items as per the<br />

standard recipe (list <strong>of</strong> cosmetic products<br />

<strong>of</strong> commercial value are enclosed).<br />

‣ Practicing different methods <strong>of</strong> packing <strong>of</strong><br />

cosmetics to improve shelf life and safety<br />

<strong>of</strong> the products.<br />

‣ Maintenance <strong>of</strong> inventory and<br />

bookkeeping.<br />

Page 32 <strong>of</strong> 87<br />

‣ Basics <strong>of</strong> mulberry cultivation<br />

method, package <strong>of</strong> practice,<br />

harvesting <strong>of</strong> mulberry leaves and<br />

fruits and their preservation.<br />

‣ Drying and powdering <strong>of</strong> mulberry<br />

leaves.<br />

‣ Types <strong>of</strong> cosmetic products that can<br />

be produced using mulberry leaves<br />

and fruits.<br />

‣ Recipe <strong>of</strong> the cosmetic products and<br />

packing methods for long-term<br />

preservation and transportation.<br />

‣ Disposal <strong>of</strong> wastes.<br />

List <strong>of</strong> cosmetic products from mulberry leaves and fruits <strong>of</strong> commercial value:<br />

Mulberry hair oil (2 types), Mulberry hair conditioner, Mulberry hair pack, Mulberry face<br />

pack, Mulberry body scrubber, Mulberry soap nut powder.<br />

10. Tools and Equipments to train 20 candidates per batch<br />

Sl. No.<br />

Item<br />

1 LPG stove with LPG cylinders 3 sets<br />

2 Electric hot plate – 02 no.<br />

3 Mini pulveriser - 01<br />

4 Refrigerator (300 lt. capacity) – 01 no.<br />

5 Commercial powder mixers -1<br />

6 Weighing scale (electronic weighing scale) (10 – 1000g capacity) – 02 no.<br />

7 Working tables (4‟ x 12‟) – 4 no.<br />

8 Plastic crates (2‟ x 3‟) – 20 no.<br />

9 Sealing machine – 02 no.<br />

10 Plastic drum – 5 no.<br />

11 Oil drums (50 lt. capacity) – 5 no.<br />

12 Measuring Jar-2

13 Frying Pan-2<br />

14 Filling Machine-2<br />

15 Packing materials like, bottles for hair oil, polythene covers etc.<br />

16 Powder storing air tight containers (10 kg capacity) – 10 no.<br />

17 Steel dabara big size (24” dia) – 06 no.<br />

18 Steel dabara small size (12” dia) – 06 no.<br />

Page 33 <strong>of</strong> 87

Page 34 <strong>of</strong> 87<br />

LEVEL –1<br />

1. Module name Mulberry Snack Maker<br />

2. Sector <strong>Sericulture</strong><br />

3. Code SER 108<br />

4. Entry Qualification Minimum 5th standard and 14 yrs <strong>of</strong> age<br />

5. Terminal competency Successful candidate would be able to produce marketable<br />

edible products from mulberry leaves and fruits. Person<br />

would be having the basic knowledge <strong>of</strong> the cooking, food<br />

safety and processing<br />

6. Preface Mulberry leaves and fruits are a good source <strong>of</strong> proteins,<br />

carbohydrates, vitamins and natural minerals. Therefore,<br />

healthy food products can be prepared and marketed giving<br />

the consumers a good choice<br />

7. Duration 150 hours<br />

8. Job Pr<strong>of</strong>ile Employable in edible product‟s cottage industries, Selfemployment<br />

9. Course Content:<br />

Practical Competencies<br />

GENERAL<br />

A) Safety Precautions<br />

‣ Safety working procedures and the<br />

necessary precautions.<br />

‣ Handling steam; LPG; electrical; micro<br />

oven, conduction cooker, cutting and<br />

grinding equipments.<br />

‣ Practice good housekeeping like<br />

preventing misuse <strong>of</strong> raw materials and<br />

end products.<br />

‣ Practice <strong>of</strong> First Aid<br />

B) Washing and Sanitation<br />

‣ Procedure for hand washing and personal<br />

hygiene.<br />

‣ Sanitization <strong>of</strong> equipments and workplace<br />

(before and after work)<br />

C) Pr<strong>of</strong>essional ethics<br />

‣ Obedience and punctuality.<br />

Underpinning Knowledge(Theory)<br />

‣ Importance <strong>of</strong> food safety<br />

‣ Importance <strong>of</strong> safe handling <strong>of</strong><br />

cutting and grinding equipments;<br />

diesel/gas furnaces; steam kettles<br />

etc.<br />

‣ Protective clothing and<br />

equipments<br />

‣ First aid for burns steam/oil/<br />

electrical); minor cuts; foreign<br />

body in eye etc.<br />

‣ Basic <strong>of</strong> Hygiene, Personal<br />

hygiene.<br />

‣ Importance <strong>of</strong> hand washing and<br />

sanitation in ensuring food safety<br />

quality along with health <strong>of</strong><br />

workers.<br />

‣ Desirable qualities <strong>of</strong> good<br />

human relationship.

‣ Importance <strong>of</strong> food safety.<br />

APPLICATION<br />

‣ Safe handling cutting and grinding<br />

equipments; gas; furnaces; steam kettles<br />

etc.<br />

‣ Protective clothing and equipments.<br />

‣ Basics <strong>of</strong> Material Handling<br />

‣ Basic Method <strong>of</strong> Cooking<br />

PROCESSING<br />

‣ Identification and weighing/measuring <strong>of</strong><br />

various raw materials used in making<br />

different snacks (list enclosed).<br />

‣ Maintenance <strong>of</strong> equipments and<br />

surroundings to meet the food standards.<br />

‣ Prepare mulberry leaves from suitable<br />

mulberry variety and quality.<br />

‣ Preserving the mulberry powder to<br />

maintain food quality.<br />

‣ Cleaning and storing raw materials/<br />

ingredients to maintain quality.<br />

‣ Prepare different food items as per the<br />

standard recipe (list <strong>of</strong> food products <strong>of</strong><br />

commercial value are enclosed).<br />

‣ Practicing different methods <strong>of</strong> packing to<br />

improve shelf-life and safety <strong>of</strong> the<br />

products.<br />

‣ Maintenance <strong>of</strong> inventory and<br />

bookkeeping.<br />

‣ Safe transportation.<br />

Page 35 <strong>of</strong> 87<br />

‣ Importance <strong>of</strong> time &<br />

communication Skills.<br />

‣ Mulberry cultivation method,<br />

package <strong>of</strong> practice.<br />

‣ Method <strong>of</strong> harvesting <strong>of</strong><br />

mulberry leaves and fruits.<br />

‣ Drying and powdering <strong>of</strong><br />

mulberry leaves.<br />

‣ Types <strong>of</strong> edible products that can<br />

be produced using mulberry<br />

leaves and fruits.<br />

‣ Recipe <strong>of</strong> the food products.<br />

‣ Maintenance <strong>of</strong><br />

inventory/accounts and books.<br />