Presstek Dimension Pro 800

Presstek Dimension Pro 800

Presstek Dimension Pro 800

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Dimension</strong> <strong>Pro</strong> <strong>800</strong> Features:<br />

Easy, Streamlined CTP: A <strong>Dimension</strong> <strong>Pro</strong> <strong>800</strong> fits any<br />

existing prepress environment. Using <strong>Presstek</strong> chemistry-free CTP,<br />

you will produce high quality press-ready plates in just two easy<br />

steps. Only a water wash is required after imaging and the plates<br />

are ready to print. No chemical processing, gumming or baking<br />

is required. The need to purchase, store, handle and dispose of<br />

noxious chemistry is eliminated.<br />

Reliable and <strong>Pro</strong>ven Performance: The <strong>Dimension</strong> <strong>Pro</strong><br />

supports up to 2400 dpi resolution and 200 line screen imaging<br />

with a 25 micron spot size.<br />

The imaging head employs multiple-laser technology. In the<br />

unlikely event that one or several emitters should fail, power is<br />

automatically increased to the others to ensure continuous<br />

operation without any change in resolution or image quality.<br />

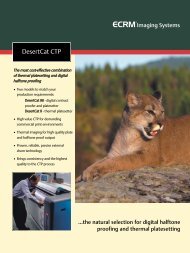

<strong>Presstek</strong> Chemistry-free CTP<br />

<strong>Presstek</strong>’s chemistry-free CTP plates deliver the<br />

reliability and performance of traditional grained<br />

anodized aluminum plates without the problems and<br />

expense of chemical plate processing. Daylight-safe<br />

<strong>Presstek</strong> plates require only a simple wash with water<br />

and they are ready for printing.<br />

<strong>Presstek</strong>’s exclusive <strong>Pro</strong> graining provides exceptional<br />

ink/water latitude, resulting in faster roll-up and stable<br />

color throughout the press run.<br />

Superior Image Control: Using a combination of pin mounts<br />

and optical sensing, registration is automatic, eliminating operator<br />

intervention and error. Dynamic autofocus reproduces subtle<br />

tonal variations and eliminates hot spots. Automatic clamping<br />

adjusts to fit any size plate (see specifications).<br />

Semiautomatic Operation: Convenient top loading and<br />

unloading; produces up to 11 full-size plates per hour using<br />

<strong>Presstek</strong> Anthem <strong>Pro</strong>, or 15 plates per hour using <strong>Presstek</strong><br />

Aurora <strong>Pro</strong>, with minimal operator involvement.<br />

<br />

baking or gumming is required<br />

<br />

and image definition<br />

<br />

<br />

<br />

<br />

Ink receptive (oleophilic)<br />

layer produces a high<br />

resolution dot structure<br />

Low Cost of Ownership: With chemistry-free CTP, the labor,<br />

space, equipment and materials required for platemaking are<br />

minimized, so you save time, money and resources.<br />

Connectivity<br />

Through the use of 1-bit TIFF files, <strong>Dimension</strong> <strong>Pro</strong> systems are<br />

compatible with a wide-range of industry standard workflows.<br />

<strong>Presstek</strong>’s integrated digital solutions include workflow solutions<br />

that optimize the performance of your <strong>Presstek</strong> equipment and<br />

increase the productivity of your prepress department.<br />

Grained anodized<br />

aluminum base<br />

Microporous water-loving<br />

(hydrophilic) layer retains<br />

grain texture of aluminum