The effect of temperature on the flotation of pyrite - saimm

The effect of temperature on the flotation of pyrite - saimm

The effect of temperature on the flotation of pyrite - saimm

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

TABLE<br />

REPRODUCIBILITY OF PYRITE FLOTATION AT 23°C<br />

Float Cumulative recovery at various times, %<br />

k x 1OZS-I<br />

no.<br />

'"<br />

15 s - - 3Os 60s 120 s 240 s 420s %<br />

1 38,63 55,62 70,93 81,05 86,77 89,40<br />

I<br />

91,40 7,77<br />

2 39,94 56,10 70,37 81,10 87,35 90,31 91,67 7,88<br />

3 38,57 55,45 70,35 79,83 86,15 88,97 90,57 7,83<br />

s 0,78 0,34 0,32 0,12 0,60 0,68 0,57 0,06<br />

'Infinite-time' recovery, i.e. recovery for which no time limit was set<br />

'" k Rate c<strong>on</strong>stant<br />

s = Standard deviati<strong>on</strong><br />

I<br />

feed particles were smaller than 75/Lm, and approximately<br />

65 per cent were smaller than 38 /Lm. <str<strong>on</strong>g>The</str<strong>on</strong>g> ore was not<br />

leached with acid before being floated since initial studies<br />

had indicated that this reduces <strong>the</strong> recovery <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>pyrite</strong>. <str<strong>on</strong>g>The</str<strong>on</strong>g><br />

batch flotati<strong>on</strong> studies were carried out in a Leeds flotati<strong>on</strong><br />

cell, <strong>the</strong> design <str<strong>on</strong>g>of</str<strong>on</strong>g> which had been altered so that <strong>the</strong> cell<br />

could be housed in a <str<strong>on</strong>g>temperature</str<strong>on</strong>g>-c<strong>on</strong>trolled water-bath.<br />

After a few changes in <strong>the</strong> design <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> cell, highly reproducible<br />

results were obtained, as shown in Table I.<br />

Two modes <str<strong>on</strong>g>of</str<strong>on</strong>g> operati<strong>on</strong> were employed: <strong>on</strong>e in <strong>the</strong><br />

presence <str<strong>on</strong>g>of</str<strong>on</strong>g> a froth phase, and <strong>the</strong> o<strong>the</strong>r in its virtual<br />

absence. In <strong>the</strong> former mode, a froth height <str<strong>on</strong>g>of</str<strong>on</strong>g> 2,5 cmwas<br />

maintained by <strong>the</strong> c<strong>on</strong>stant additi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> water to <strong>the</strong> cell; in<br />

<strong>the</strong> latter, <strong>the</strong> froth height was below 0,5 cm, which gave a<br />

close simulati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> flotati<strong>on</strong> in <strong>the</strong> absence <str<strong>on</strong>g>of</str<strong>on</strong>g> a froth phase.<br />

<str<strong>on</strong>g>The</str<strong>on</strong>g> collector, sodium mercaptobenzothiazole (SMBT)<br />

was added at 40 glt, and <strong>the</strong> fro<strong>the</strong>r, triethoxybutane<br />

(TEB), at 12 glt. <str<strong>on</strong>g>The</str<strong>on</strong>g> pH value was set at 4,0 by <strong>the</strong> use <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

lime, <strong>the</strong> natural pH value <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> pulp being approximately<br />

3,6. <str<strong>on</strong>g>The</str<strong>on</strong>g> <str<strong>on</strong>g>temperature</str<strong>on</strong>g>s were maintained c<strong>on</strong>stant to within<br />

1,0°e. <str<strong>on</strong>g>The</str<strong>on</strong>g> ore was c<strong>on</strong>diti<strong>on</strong>ed for 4 minutes after <strong>the</strong><br />

additi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> collector, and for a fur<strong>the</strong>r 1 minute after<br />

<strong>the</strong> additi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> fro<strong>the</strong>r. <str<strong>on</strong>g>The</str<strong>on</strong>g> solids c<strong>on</strong>tent <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> pulp in<br />

all <strong>the</strong> tests was 30 per cent. Six c<strong>on</strong>centrates were<br />

collected, and Klimpel's model12was used in <strong>the</strong> analysis <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

<strong>the</strong> results. All <strong>the</strong> runs were repeated several times to<br />

ensure reproducibility <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> results, and sulphur assays<br />

were checked routinely by <strong>the</strong> Analytical Science Divisi<strong>on</strong><br />

at <strong>the</strong> Council for Mineral Technology (Mintek).<br />

Adsorpti<strong>on</strong> studies were carried out <strong>on</strong> a c<strong>on</strong>tinuously<br />

stirred tank reactor c<strong>on</strong>taining <strong>the</strong> collector soluti<strong>on</strong>. <str<strong>on</strong>g>The</str<strong>on</strong>g><br />

fracti<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> ore between 38 and 106 /Lm was added at time<br />

zero, and <strong>the</strong> soluti<strong>on</strong> was pumped via a 4/Lm sintered stick<br />

to an ultraviolet spectrophotometer for c<strong>on</strong>tinuous<br />

m<strong>on</strong>itoring <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> collector c<strong>on</strong>centrati<strong>on</strong>. In this way,<br />

informati<strong>on</strong> <strong>on</strong> kinetic and pseudo-equilibrium adsorpti<strong>on</strong><br />

were obtained. Batch tests were also d<strong>on</strong>e so that adsorpti<strong>on</strong><br />

iso<strong>the</strong>rms could be plotted.<br />

Results<br />

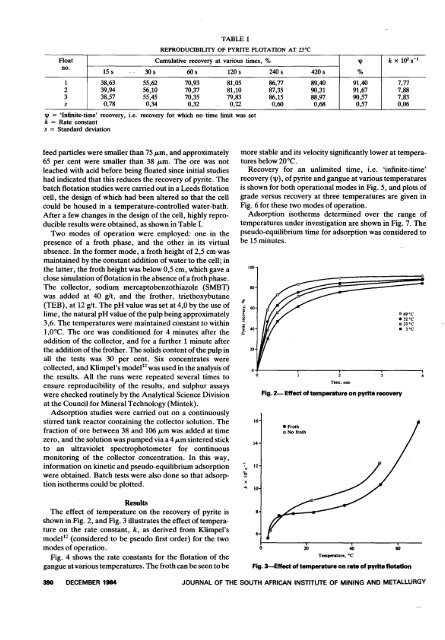

<str<strong>on</strong>g>The</str<strong>on</strong>g> <str<strong>on</strong>g>effect</str<strong>on</strong>g> <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>temperature</str<strong>on</strong>g> <strong>on</strong> <strong>the</strong> recovery <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>pyrite</strong> is<br />

shown in Fig. 2, and Fig. 3 illustrates <strong>the</strong> <str<strong>on</strong>g>effect</str<strong>on</strong>g> <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>temperature</str<strong>on</strong>g><br />

<strong>on</strong> <strong>the</strong> rate c<strong>on</strong>stant, k, as derived from Klimpel's<br />

model12 (c<strong>on</strong>sidered to be pseudo first order) for <strong>the</strong> two<br />

modes <str<strong>on</strong>g>of</str<strong>on</strong>g> operati<strong>on</strong>.<br />

Fig. 4 shows <strong>the</strong> rate c<strong>on</strong>stants for <strong>the</strong> flotati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong><br />

gangue at various <str<strong>on</strong>g>temperature</str<strong>on</strong>g>s. <str<strong>on</strong>g>The</str<strong>on</strong>g> froth can be seen to be<br />

more stable and its velocity significantly lower at <str<strong>on</strong>g>temperature</str<strong>on</strong>g>s<br />

below 20°e.<br />

Recovery for an unlimited time, i.e. 'infinite-time'<br />

recovery ('1\1),<str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>pyrite</strong> and gangue at various <str<strong>on</strong>g>temperature</str<strong>on</strong>g>s<br />

is shown for both operati<strong>on</strong>al modes in Fig. 5, and plots <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

grade versus recovery at three <str<strong>on</strong>g>temperature</str<strong>on</strong>g>s are given in<br />

Fig. 6 for <strong>the</strong>se two modes <str<strong>on</strong>g>of</str<strong>on</strong>g> operati<strong>on</strong>.<br />

Adsorpti<strong>on</strong> iso<strong>the</strong>rms determined over <strong>the</strong> range <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

<str<strong>on</strong>g>temperature</str<strong>on</strong>g>s under investigati<strong>on</strong> are shown in Fig. 7. <str<strong>on</strong>g>The</str<strong>on</strong>g><br />

pseudo-equilibrium time for adsorpti<strong>on</strong> was c<strong>on</strong>sidered to<br />

be 15 minutes.<br />

0<br />

~x<br />

...<br />

100<br />

80<br />

.r<br />

~ 60<br />

~<br />

u<br />

.~ 40<br />

...<br />

20<br />

0<br />

0<br />

Time. miD<br />

16<br />

14<br />

~12<br />

10<br />

6<br />

Fig. 2- Effect <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>temperature</str<strong>on</strong>g> <strong>on</strong> <strong>pyrite</strong> recovery<br />

. Froth<br />

.. N<str<strong>on</strong>g>of</str<strong>on</strong>g>roth<br />

0 20 40<br />

Temperature. .C<br />

Fig. 3-Effect <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>temperature</str<strong>on</strong>g> <strong>on</strong> rate <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>pyrite</strong> flotati<strong>on</strong><br />

'"<br />

1i:<br />

069.C<br />

. S2.C<br />

m23"C<br />

. 3.C<br />

60<br />

390 DECEMBER 1984 JOURNAL OF THE SOUTH AFRICAN INSTITUTE OF MINING AND METALLURGY