The effect of temperature on the flotation of pyrite - saimm

The effect of temperature on the flotation of pyrite - saimm

The effect of temperature on the flotation of pyrite - saimm

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

J. S. A fr. Inst. Min. Metal/., vol. 84, no. 12.<br />

Dec. 1984. pp. 389-394.<br />

<str<strong>on</strong>g>The</str<strong>on</strong>g> <str<strong>on</strong>g>effect</str<strong>on</strong>g> <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>temperature</str<strong>on</strong>g><br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>pyrite</strong><br />

<strong>on</strong> <strong>the</strong> flotati<strong>on</strong><br />

by C.T. O'CONNOR*, R.C. DUNNEt, and A.M.A. BOTELHO DE SOUSA*<br />

SYNOPSIS<br />

In <strong>the</strong> investigati<strong>on</strong> described here, it was found that <strong>the</strong> main <str<strong>on</strong>g>effect</str<strong>on</strong>g> <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>temperature</str<strong>on</strong>g> is <strong>on</strong> <strong>the</strong> rate <str<strong>on</strong>g>of</str<strong>on</strong>g> flotati<strong>on</strong>,<br />

and that adsorpti<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> reagent is not rate c<strong>on</strong>trolling. Above 10°C, <strong>the</strong> flotati<strong>on</strong> rate <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>pyrite</strong> and gangue<br />

increases almost exp<strong>on</strong>entially with a rise in <str<strong>on</strong>g>temperature</str<strong>on</strong>g>. Below that <str<strong>on</strong>g>temperature</str<strong>on</strong>g>, <strong>the</strong> flotati<strong>on</strong> rate <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>pyrite</strong> shows<br />

a sudden marked decrease, that <str<strong>on</strong>g>of</str<strong>on</strong>g> gangue increases, and <strong>the</strong> sulphur grades are significantly poorer.<br />

In <strong>the</strong> flotati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>pyrite</strong>, <strong>the</strong> mass transfer <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> <strong>pyrite</strong> from <strong>the</strong> pulp to <strong>the</strong> troth is thought to be <strong>the</strong> ratec<strong>on</strong>trolling<br />

step, whereas <strong>the</strong> flotati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> gangue is c<strong>on</strong>trolled by <strong>the</strong> combined <str<strong>on</strong>g>effect</str<strong>on</strong>g> <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> stability and velocity<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> froth and <strong>the</strong> viscosity <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> elutriating medium. <str<strong>on</strong>g>The</str<strong>on</strong>g> latter is probably <strong>the</strong> c<strong>on</strong>trolling <str<strong>on</strong>g>effect</str<strong>on</strong>g> at <str<strong>on</strong>g>temperature</str<strong>on</strong>g>s<br />

below 10°C.<br />

Little difference was noted in <strong>the</strong> recoveries (provided no time limit was set) with changes in <str<strong>on</strong>g>temperature</str<strong>on</strong>g>; hence<br />

adequate recoveries can be obtained at Iow <str<strong>on</strong>g>temperature</str<strong>on</strong>g>s by <strong>the</strong> introducti<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> l<strong>on</strong>ger residence times for <strong>the</strong><br />

pulp. <str<strong>on</strong>g>The</str<strong>on</strong>g> adverse <str<strong>on</strong>g>effect</str<strong>on</strong>g>s <str<strong>on</strong>g>of</str<strong>on</strong>g> Iow <str<strong>on</strong>g>temperature</str<strong>on</strong>g>s <strong>on</strong> grades can be overcome <strong>on</strong>ly by additi<strong>on</strong>al cleaning or by heating<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> pulp.<br />

SAMEVATTING<br />

Daar is in die <strong>on</strong>dersoek wat hier beskryf word, gevind dat die vernaamste uitwerking van temperatuur is dat dit<br />

die flottasietempo raak en dat die reagentsabsorpsie nie tempobeherend<br />

van piriet en aarsteen byna eksp<strong>on</strong>ensiaal met 'n styging in temperatuur.<br />

is nie. Bo 10°C versnel die flottasietempo<br />

Onder hierdie temperatuur to<strong>on</strong> die flottasietempo<br />

van piriet 'n skielike duidelike afname, terwyl die van die aarsteen toeneem en die swawelgrade<br />

beduidend laer is.<br />

In die flottasie van piriet word daar gereken dat die massa-oordrag van die piriet van die pulp ha die skuim die<br />

tempobeherende stap is, terwyl die aarsteenflottasie beheer word deur die gekombineerde uitwerking van die<br />

stabiliteit en snelheid van die skuim en die viskositeit van die elutrieermiddel. Laasgenoemde is waarskynlik die<br />

beherende faktor by <str<strong>on</strong>g>temperature</str<strong>on</strong>g> <strong>on</strong>der 10°C.<br />

Daar is min verskil in die herwinnings waargeneem met 'n verandering in temperatuur (mits da.ar geen tydgrens<br />

gestel word nie); gevolglik kan toereikende herwinnings by laer <str<strong>on</strong>g>temperature</str<strong>on</strong>g> verkry word deur langer residensietye<br />

vir die pulp te'gebruik. Die nadelige uitwerking van lae <str<strong>on</strong>g>temperature</str<strong>on</strong>g> op grade kan net oorkom word deur verdere<br />

sko<strong>on</strong>maak, <str<strong>on</strong>g>of</str<strong>on</strong>g> deur die pulp te verhit.<br />

Introducti<strong>on</strong><br />

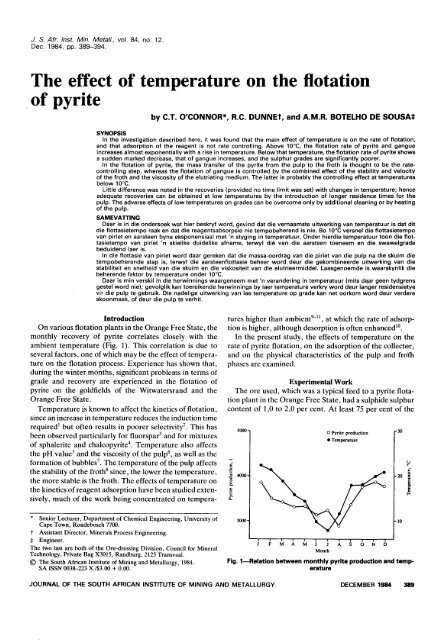

On various flotati<strong>on</strong> plants in <strong>the</strong> Orange Free State, <strong>the</strong><br />

m<strong>on</strong>thly recovery <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>pyrite</strong> correlates closely with <strong>the</strong><br />

ambient <str<strong>on</strong>g>temperature</str<strong>on</strong>g> (Fig. 1). This correlati<strong>on</strong> is due to<br />

several factors, <strong>on</strong>e <str<strong>on</strong>g>of</str<strong>on</strong>g> which may be <strong>the</strong> <str<strong>on</strong>g>effect</str<strong>on</strong>g> <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>temperature</str<strong>on</strong>g><br />

<strong>on</strong> <strong>the</strong> flotati<strong>on</strong> process. Experience has shown that,<br />

during <strong>the</strong> winter m<strong>on</strong>ths, significant problems in terms <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

grade and recovery are experienced in <strong>the</strong> flotati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

<strong>pyrite</strong> <strong>on</strong> <strong>the</strong> goldfields <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> Witwatersrand and <strong>the</strong><br />

Orange Free State.<br />

Temperature is known to affect <strong>the</strong> kinetics <str<strong>on</strong>g>of</str<strong>on</strong>g> flotati<strong>on</strong>,<br />

since an increase in <str<strong>on</strong>g>temperature</str<strong>on</strong>g> reduces <strong>the</strong> inducti<strong>on</strong> time<br />

requiredl but <str<strong>on</strong>g>of</str<strong>on</strong>g>ten results in poorer selectivity2. This has<br />

been observed particularly for fluorspar3 and for mixtures<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> sphalerite and chalco<strong>pyrite</strong>4. Temperature also affects<br />

<strong>the</strong> pH value5 and <strong>the</strong> viscosity <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> pulp6, as well as <strong>the</strong><br />

formati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> bubbles 7. <str<strong>on</strong>g>The</str<strong>on</strong>g> <str<strong>on</strong>g>temperature</str<strong>on</strong>g> <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> pulp affects<br />

<strong>the</strong> stability <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> froth8 since, <strong>the</strong> lower <strong>the</strong> <str<strong>on</strong>g>temperature</str<strong>on</strong>g>,<br />

<strong>the</strong> more stable is <strong>the</strong> froth. <str<strong>on</strong>g>The</str<strong>on</strong>g> <str<strong>on</strong>g>effect</str<strong>on</strong>g>s <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>temperature</str<strong>on</strong>g> <strong>on</strong><br />

<strong>the</strong> kinetics <str<strong>on</strong>g>of</str<strong>on</strong>g> reagent adsorpti<strong>on</strong> have been studied extensively,<br />

much <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> work being c<strong>on</strong>centrated <strong>on</strong> tempera-<br />

. Senior Lecturer, Department <str<strong>on</strong>g>of</str<strong>on</strong>g> Chemical Engineering, University <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

Cape Town, R<strong>on</strong>debosch 7700.<br />

t Assistant Director, Minerals Process Engineering.<br />

:j: Engineer.<br />

<str<strong>on</strong>g>The</str<strong>on</strong>g> two last are both <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> Ore-dressing Divisi<strong>on</strong>, Council for Mineral<br />

Technology, Private Bag X3015, Randburg, 2125 Transvaal.<br />

@ <str<strong>on</strong>g>The</str<strong>on</strong>g> South African Institute <str<strong>on</strong>g>of</str<strong>on</strong>g> Mining and Metallurgy, 1984.<br />

SA ISSN 0038-223 X 1$3.00 + 0.00.<br />

tures higher than ambient9--11, at which <strong>the</strong> rate <str<strong>on</strong>g>of</str<strong>on</strong>g> adsorpti<strong>on</strong><br />

is higher, although desorpti<strong>on</strong> is <str<strong>on</strong>g>of</str<strong>on</strong>g>ten enhancedlO.<br />

In <strong>the</strong> present study, <strong>the</strong> <str<strong>on</strong>g>effect</str<strong>on</strong>g>s <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>temperature</str<strong>on</strong>g> <strong>on</strong> <strong>the</strong><br />

rate <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>pyrite</strong> flotati<strong>on</strong>, <strong>on</strong> <strong>the</strong> adsorpti<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> collect)[,<br />

and <strong>on</strong> <strong>the</strong> physical characteristics <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> pulp and froth<br />

phases are examined.<br />

Experimental Work<br />

<str<strong>on</strong>g>The</str<strong>on</strong>g> ore used, which was a typical feed to a <strong>pyrite</strong> flotati<strong>on</strong><br />

plant in <strong>the</strong> Orange Free State, had a sulphide sulphur<br />

c<strong>on</strong>tent <str<strong>on</strong>g>of</str<strong>on</strong>g> 1,0 to 2,0 per cent. At least 75 per cent <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong><br />

c<br />

.g<br />

~4()()()<br />

0<br />

s.<br />

"~Po,<br />

5000 0 Pyrite producti<strong>on</strong><br />

. Temperature<br />

3000 10<br />

F M A M J J A s<br />

M<strong>on</strong>th<br />

0 N D<br />

30<br />

;;<br />

20 ~ "<br />

Fig. 1-Relati<strong>on</strong> between m<strong>on</strong>thly <strong>pyrite</strong> producti<strong>on</strong> and <str<strong>on</strong>g>temperature</str<strong>on</strong>g><br />

8-<br />

!<br />

JOURNAL OF THE SOUTH AFRICAN INSTITUTE OF MINING AND METALLURGY DECEMBER 1984 389

TABLE<br />

REPRODUCIBILITY OF PYRITE FLOTATION AT 23°C<br />

Float Cumulative recovery at various times, %<br />

k x 1OZS-I<br />

no.<br />

'"<br />

15 s - - 3Os 60s 120 s 240 s 420s %<br />

1 38,63 55,62 70,93 81,05 86,77 89,40<br />

I<br />

91,40 7,77<br />

2 39,94 56,10 70,37 81,10 87,35 90,31 91,67 7,88<br />

3 38,57 55,45 70,35 79,83 86,15 88,97 90,57 7,83<br />

s 0,78 0,34 0,32 0,12 0,60 0,68 0,57 0,06<br />

'Infinite-time' recovery, i.e. recovery for which no time limit was set<br />

'" k Rate c<strong>on</strong>stant<br />

s = Standard deviati<strong>on</strong><br />

I<br />

feed particles were smaller than 75/Lm, and approximately<br />

65 per cent were smaller than 38 /Lm. <str<strong>on</strong>g>The</str<strong>on</strong>g> ore was not<br />

leached with acid before being floated since initial studies<br />

had indicated that this reduces <strong>the</strong> recovery <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>pyrite</strong>. <str<strong>on</strong>g>The</str<strong>on</strong>g><br />

batch flotati<strong>on</strong> studies were carried out in a Leeds flotati<strong>on</strong><br />

cell, <strong>the</strong> design <str<strong>on</strong>g>of</str<strong>on</strong>g> which had been altered so that <strong>the</strong> cell<br />

could be housed in a <str<strong>on</strong>g>temperature</str<strong>on</strong>g>-c<strong>on</strong>trolled water-bath.<br />

After a few changes in <strong>the</strong> design <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> cell, highly reproducible<br />

results were obtained, as shown in Table I.<br />

Two modes <str<strong>on</strong>g>of</str<strong>on</strong>g> operati<strong>on</strong> were employed: <strong>on</strong>e in <strong>the</strong><br />

presence <str<strong>on</strong>g>of</str<strong>on</strong>g> a froth phase, and <strong>the</strong> o<strong>the</strong>r in its virtual<br />

absence. In <strong>the</strong> former mode, a froth height <str<strong>on</strong>g>of</str<strong>on</strong>g> 2,5 cmwas<br />

maintained by <strong>the</strong> c<strong>on</strong>stant additi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> water to <strong>the</strong> cell; in<br />

<strong>the</strong> latter, <strong>the</strong> froth height was below 0,5 cm, which gave a<br />

close simulati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> flotati<strong>on</strong> in <strong>the</strong> absence <str<strong>on</strong>g>of</str<strong>on</strong>g> a froth phase.<br />

<str<strong>on</strong>g>The</str<strong>on</strong>g> collector, sodium mercaptobenzothiazole (SMBT)<br />

was added at 40 glt, and <strong>the</strong> fro<strong>the</strong>r, triethoxybutane<br />

(TEB), at 12 glt. <str<strong>on</strong>g>The</str<strong>on</strong>g> pH value was set at 4,0 by <strong>the</strong> use <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

lime, <strong>the</strong> natural pH value <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> pulp being approximately<br />

3,6. <str<strong>on</strong>g>The</str<strong>on</strong>g> <str<strong>on</strong>g>temperature</str<strong>on</strong>g>s were maintained c<strong>on</strong>stant to within<br />

1,0°e. <str<strong>on</strong>g>The</str<strong>on</strong>g> ore was c<strong>on</strong>diti<strong>on</strong>ed for 4 minutes after <strong>the</strong><br />

additi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> collector, and for a fur<strong>the</strong>r 1 minute after<br />

<strong>the</strong> additi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> fro<strong>the</strong>r. <str<strong>on</strong>g>The</str<strong>on</strong>g> solids c<strong>on</strong>tent <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> pulp in<br />

all <strong>the</strong> tests was 30 per cent. Six c<strong>on</strong>centrates were<br />

collected, and Klimpel's model12was used in <strong>the</strong> analysis <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

<strong>the</strong> results. All <strong>the</strong> runs were repeated several times to<br />

ensure reproducibility <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> results, and sulphur assays<br />

were checked routinely by <strong>the</strong> Analytical Science Divisi<strong>on</strong><br />

at <strong>the</strong> Council for Mineral Technology (Mintek).<br />

Adsorpti<strong>on</strong> studies were carried out <strong>on</strong> a c<strong>on</strong>tinuously<br />

stirred tank reactor c<strong>on</strong>taining <strong>the</strong> collector soluti<strong>on</strong>. <str<strong>on</strong>g>The</str<strong>on</strong>g><br />

fracti<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> ore between 38 and 106 /Lm was added at time<br />

zero, and <strong>the</strong> soluti<strong>on</strong> was pumped via a 4/Lm sintered stick<br />

to an ultraviolet spectrophotometer for c<strong>on</strong>tinuous<br />

m<strong>on</strong>itoring <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> collector c<strong>on</strong>centrati<strong>on</strong>. In this way,<br />

informati<strong>on</strong> <strong>on</strong> kinetic and pseudo-equilibrium adsorpti<strong>on</strong><br />

were obtained. Batch tests were also d<strong>on</strong>e so that adsorpti<strong>on</strong><br />

iso<strong>the</strong>rms could be plotted.<br />

Results<br />

<str<strong>on</strong>g>The</str<strong>on</strong>g> <str<strong>on</strong>g>effect</str<strong>on</strong>g> <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>temperature</str<strong>on</strong>g> <strong>on</strong> <strong>the</strong> recovery <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>pyrite</strong> is<br />

shown in Fig. 2, and Fig. 3 illustrates <strong>the</strong> <str<strong>on</strong>g>effect</str<strong>on</strong>g> <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>temperature</str<strong>on</strong>g><br />

<strong>on</strong> <strong>the</strong> rate c<strong>on</strong>stant, k, as derived from Klimpel's<br />

model12 (c<strong>on</strong>sidered to be pseudo first order) for <strong>the</strong> two<br />

modes <str<strong>on</strong>g>of</str<strong>on</strong>g> operati<strong>on</strong>.<br />

Fig. 4 shows <strong>the</strong> rate c<strong>on</strong>stants for <strong>the</strong> flotati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong><br />

gangue at various <str<strong>on</strong>g>temperature</str<strong>on</strong>g>s. <str<strong>on</strong>g>The</str<strong>on</strong>g> froth can be seen to be<br />

more stable and its velocity significantly lower at <str<strong>on</strong>g>temperature</str<strong>on</strong>g>s<br />

below 20°e.<br />

Recovery for an unlimited time, i.e. 'infinite-time'<br />

recovery ('1\1),<str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>pyrite</strong> and gangue at various <str<strong>on</strong>g>temperature</str<strong>on</strong>g>s<br />

is shown for both operati<strong>on</strong>al modes in Fig. 5, and plots <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

grade versus recovery at three <str<strong>on</strong>g>temperature</str<strong>on</strong>g>s are given in<br />

Fig. 6 for <strong>the</strong>se two modes <str<strong>on</strong>g>of</str<strong>on</strong>g> operati<strong>on</strong>.<br />

Adsorpti<strong>on</strong> iso<strong>the</strong>rms determined over <strong>the</strong> range <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

<str<strong>on</strong>g>temperature</str<strong>on</strong>g>s under investigati<strong>on</strong> are shown in Fig. 7. <str<strong>on</strong>g>The</str<strong>on</strong>g><br />

pseudo-equilibrium time for adsorpti<strong>on</strong> was c<strong>on</strong>sidered to<br />

be 15 minutes.<br />

0<br />

~x<br />

...<br />

100<br />

80<br />

.r<br />

~ 60<br />

~<br />

u<br />

.~ 40<br />

...<br />

20<br />

0<br />

0<br />

Time. miD<br />

16<br />

14<br />

~12<br />

10<br />

6<br />

Fig. 2- Effect <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>temperature</str<strong>on</strong>g> <strong>on</strong> <strong>pyrite</strong> recovery<br />

. Froth<br />

.. N<str<strong>on</strong>g>of</str<strong>on</strong>g>roth<br />

0 20 40<br />

Temperature. .C<br />

Fig. 3-Effect <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>temperature</str<strong>on</strong>g> <strong>on</strong> rate <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>pyrite</strong> flotati<strong>on</strong><br />

'"<br />

1i:<br />

069.C<br />

. S2.C<br />

m23"C<br />

. 3.C<br />

60<br />

390 DECEMBER 1984 JOURNAL OF THE SOUTH AFRICAN INSTITUTE OF MINING AND METALLURGY

,<br />

~<br />

~<br />

x<br />

...<br />

0<br />

'100<br />

98<br />

11 96<br />

If<br />

.~<br />

'0 94<br />

..<br />

92<br />

90<br />

0<br />

. Froth<br />

0 N<str<strong>on</strong>g>of</str<strong>on</strong>g>roth<br />

0 20 40<br />

Temperature, .C<br />

Fig. 4-Effect <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>temperature</str<strong>on</strong>g> <strong>on</strong> rate <str<strong>on</strong>g>of</str<strong>on</strong>g> gangue flotati<strong>on</strong><br />

Pyrite<br />

.Froth<br />

0 No froth<br />

GanlUe<br />

. Froth<br />

" N<str<strong>on</strong>g>of</str<strong>on</strong>g>roth<br />

20 40 60<br />

Temperature, .C<br />

Fig. 5-Effect <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>temperature</str<strong>on</strong>g> <strong>on</strong> 'infinite-time' recovery ('1/')<str<strong>on</strong>g>of</str<strong>on</strong>g><br />

<strong>pyrite</strong> and gangue<br />

30 . Froth<br />

0 N<str<strong>on</strong>g>of</str<strong>on</strong>g>roth<br />

25<br />

23'C<br />

60<br />

21<br />

19<br />

17<br />

15<br />

11<br />

13 I<br />

'0<br />

..<br />

11<br />

Fig. 8 gives <strong>the</strong> results <str<strong>on</strong>g>of</str<strong>on</strong>g><strong>the</strong> tests <strong>on</strong> froth stability. For<br />

<strong>the</strong>se tests, <strong>the</strong> time taken for <strong>the</strong> froth to break down from<br />

its maximum height to a predetermined height (termed<br />

durati<strong>on</strong> and measured in sec<strong>on</strong>ds) was measured at<br />

different <str<strong>on</strong>g>temperature</str<strong>on</strong>g>s. Also shown are similar results<br />

obtained <strong>on</strong> a two-phase froth by G6tte13 using sodium<br />

dodecyl sulphate as fro<strong>the</strong>r.<br />

<str<strong>on</strong>g>The</str<strong>on</strong>g> results <str<strong>on</strong>g>of</str<strong>on</strong>g> varying reagent c<strong>on</strong>centrati<strong>on</strong>s, aerati<strong>on</strong><br />

rates, and impeller speeds are presented in Tabks 11to VII.<br />

As can be seen from Tables 11 to V, variati<strong>on</strong> in <strong>the</strong><br />

c<strong>on</strong>centrati<strong>on</strong>s <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> flotati<strong>on</strong> reagents had little significant<br />

<str<strong>on</strong>g>effect</str<strong>on</strong>g> <strong>on</strong> <strong>the</strong> rate <str<strong>on</strong>g>of</str<strong>on</strong>g> flotati<strong>on</strong> or <strong>on</strong> <strong>the</strong> infinite-time<br />

recoveries <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>pyrite</strong>.<br />

However, as Tables VI and VII indicate, variati<strong>on</strong>s in <strong>the</strong><br />

aerati<strong>on</strong> rate and <strong>the</strong> impeller speed had a significant <str<strong>on</strong>g>effect</str<strong>on</strong>g><br />

<strong>on</strong> <strong>the</strong> infinite-time recovery and flotati<strong>on</strong> rate <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>pyrite</strong>.<br />

Fig. 9 shows <strong>the</strong> <str<strong>on</strong>g>effect</str<strong>on</strong>g> <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>temperature</str<strong>on</strong>g> <strong>on</strong> <strong>the</strong> viscosity <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

pulps <str<strong>on</strong>g>of</str<strong>on</strong>g> different densities. <str<strong>on</strong>g>The</str<strong>on</strong>g>se tests were carried out<br />

with a St6rmer viscometer. Also shown is a plot for which<br />

Mo<strong>on</strong>ey's correlati<strong>on</strong> for pUlpSl4 was used:<br />

In ILm = 2,5s<br />

ILl 1-cs'<br />

where ILmand ILl are <strong>the</strong> respective viscosities <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> pulp<br />

and water in centipoises, sis <strong>the</strong> volume fracti<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong><br />

solids, and <strong>the</strong> coefficient c has a value <str<strong>on</strong>g>of</str<strong>on</strong>g> from 1 to 1,5. For<br />

<strong>the</strong>se calculati<strong>on</strong>s, c was taken as 1 and swas taken as<br />

0,18. <str<strong>on</strong>g>The</str<strong>on</strong>g> results show <strong>the</strong> expected increase in viscosity<br />

with decrease in <str<strong>on</strong>g>temperature</str<strong>on</strong>g>.<br />

<str<strong>on</strong>g>The</str<strong>on</strong>g> photographic studies showed that, at <strong>the</strong> higher<br />

viscosity, <strong>the</strong> rate at which <strong>the</strong> bubbles rose was lower and<br />

<strong>the</strong> number <str<strong>on</strong>g>of</str<strong>on</strong>g> bubbles per unit volume greater.<br />

Discussi<strong>on</strong><br />

As was expected from a c<strong>on</strong>siderati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> fundamentals<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> flotati<strong>on</strong> process, this study showed that<br />

<str<strong>on</strong>g>temperature</str<strong>on</strong>g> affects mainly <strong>the</strong> rate <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>pyrite</strong> flotati<strong>on</strong> and<br />

has little <str<strong>on</strong>g>effect</str<strong>on</strong>g> <strong>on</strong> <strong>the</strong> final recoveries. It was also shown<br />

that, at <str<strong>on</strong>g>temperature</str<strong>on</strong>g>s below 1O0C, a marked change occurs<br />

in <strong>the</strong> trend <str<strong>on</strong>g>of</str<strong>on</strong>g> decreasing rate c<strong>on</strong>stants for <strong>the</strong> flotati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

<strong>pyrite</strong>. This change was highly reproducible, and occurred<br />

in <strong>the</strong> presence <str<strong>on</strong>g>of</str<strong>on</strong>g> a froth phase and in its absence. In <strong>the</strong><br />

presence <str<strong>on</strong>g>of</str<strong>on</strong>g> a froth phase, <strong>the</strong> rate <str<strong>on</strong>g>of</str<strong>on</strong>g> flotati<strong>on</strong> was slightly<br />

lower, probably because <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> superimposed <str<strong>on</strong>g>effect</str<strong>on</strong>g> <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong><br />

3<br />

e } 2<br />

. sO'C<br />

.30.C<br />

0 IO'C<br />

[;J 2.C<br />

<strong>on</strong> 20<br />

If<br />

~<br />

0 15<br />

10<br />

3'C<br />

,.C~<br />

-0<br />

.t:><br />

CS "<br />

-g<br />

1<br />

'";<br />

~<br />

5<br />

20 40 60<br />

Pyrite<br />

recovery.<br />

Fig. 6--Grade versus recovery at different <str<strong>on</strong>g>temperature</str<strong>on</strong>g>s and<br />

modes <str<strong>on</strong>g>of</str<strong>on</strong>g> operati<strong>on</strong><br />

'10<br />

80<br />

100<br />

0<br />

0 20 40<br />

60<br />

Equilibrium c<strong>on</strong>centrati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> 5MBT <strong>on</strong>to <strong>pyrite</strong>. glt<br />

Fig. 7-Adsorpti<strong>on</strong> iso<strong>the</strong>rms for sodium mercaptobenzothiazole<br />

(SMBT) <strong>on</strong>to <strong>pyrite</strong><br />

JOURNAL OF THE SOUTH AFRICAN INSTITUTE OF MINING AND METALLURGY DECEMBER 1984 391

30<br />

'"<br />

ci' 20<br />

0<br />

';::<br />

C\S<br />

....<br />

::s<br />

"0<br />

..c:<br />

(5 10<br />

.....<br />

~<br />

0 This work<br />

. Gotte13<br />

300<br />

'"<br />

ci'<br />

0<br />

';::<br />

C\S<br />

....<br />

200 ::s<br />

"0<br />

..c:<br />

.....<br />

0 ....<br />

~100<br />

0<br />

0<br />

10<br />

20 30<br />

Temperature, °C<br />

40<br />

50<br />

0<br />

60<br />

Fig. 8- Tests <strong>on</strong> froth stability<br />

TABLE 11<br />

EFFECT OF COLLECTOR CONCENTRATION ON RECOVERY<br />

OF PYRITE AND GANGUE<br />

5MBT c<strong>on</strong>centrati<strong>on</strong><br />

Pyrite<br />

Gangue<br />

'1' k x 1O2s-1 '1' k X 1O2s-1<br />

g/t % %<br />

10 91,99 7,60 13,08 1,74<br />

20 92,65 7,59 12,47 1,40<br />

40 90,61 7,76 12,58 1,48<br />

100 95,04 8,68 14,44 1,50<br />

200 94,64 7,84 11,43 1,92<br />

TABLE V<br />

EFFECT OF ACTIVATOR CONCENTRAnON ON RECOVERY<br />

OF PYRITE AND GANGUE<br />

CUSO4<br />

Pyrite<br />

Gangue<br />

c<strong>on</strong>centrati<strong>on</strong><br />

g/t %'1' k x 1O2s-1<br />

%'1' k X IOZs-1<br />

'1' = 'Infinite-time'<br />

- 89,37 9,33 12,14 1,56<br />

20 88,61 9,19 12,67 1,51<br />

50 90,25 8,52 12,9 1,26<br />

100 89,32 8,39 11,30 1,43<br />

recovery<br />

'1' = 'Infinite-time' recovery TABLE III<br />

EFFECT OF FROTHER CONCENTRAnON ON RECOVERY<br />

OF PYRITE AND GANGUE<br />

Pyrite<br />

Gangue<br />

DOWFROTH 250<br />

c<strong>on</strong>centrati<strong>on</strong><br />

'1' kx1O2s-1<br />

g/t '1' kx 1O2s-1<br />

% %<br />

- 85,12 7,91 7,01 1,41<br />

10 87,37 7,96 10,26 1,65<br />

20 89,66 7,72 12,67 1,38<br />

40 88,55 8,02 15,72 1,72<br />

80 88,66 8,80 17,75 1,68<br />

160 91,20 8,33 21,64 1,50<br />

TABLE VI<br />

EFFECT OF AERATION RATE ON RECOVERY<br />

OF PYRITE AND GANGUE<br />

Pyrite<br />

Gangue<br />

Aerati<strong>on</strong> rate<br />

l/min '1' k X 1O2s-1 '1' k X 1O2s-1<br />

% %<br />

3 82,31 2,38 8,93 0,17<br />

5 86,38 5,89 8,96 0,70<br />

7 88,55 8,02 15,72 1,72<br />

9 91,06 10,75 19,69 1,92<br />

'1'<br />

= 'Infinite-time' recovery TABLE IV<br />

EFFECT OF DEPRESSANT CONCENTRAnON ON RECOVERY<br />

OF PYRITE AND GANGUE<br />

Pyrite<br />

Gangue<br />

ACROL (J2P350)<br />

c<strong>on</strong>centrati<strong>on</strong><br />

g/t '1' k x 1O2s-1 '1' kx IOZs-1<br />

% %<br />

- 89,37 9,33 12,14 1,56<br />

10 86,91 8,90 11,22 1,45<br />

20 88,00 8,11 11,55 1,17<br />

50 90,46 7,19 11,97 0,94<br />

lOO 89,15 6,68 9,73 0,87<br />

'1' = 'Infinite-time' recovery TABLE VII<br />

EFFECT OF IMPELLER SPEED ON RECOVERY<br />

OF PYRITE AND GANGUE<br />

Pyrite<br />

Gangue<br />

Impeller speed<br />

r/min '1' k x 1O2s-1 '1' k X 1O2s-]<br />

% %<br />

800 85,77 4,57 11,45 0,52<br />

950 83,97 6,89 10,24 1,02<br />

1100 88,11 5,97 11,04 0,68<br />

1300 89,66 7,72 12,67 1,38<br />

1450 89,11 8,94 11,90 1,49<br />

1600 89,63 8,45 12,12 1,57<br />

'1'<br />

= 'Infinite-time'<br />

recovery<br />

'1'<br />

= 'Infinite-time' recovery<br />

392 DECEMBER 1984 JOURNAL OF THE SOUTH AFRICAN INSTITUTE OF MINING AND METALLURGY

'"~<br />

0<br />

'h<br />

.~ ~~<br />

";: I<br />

IcP=I.OxlO-'P..s<br />

0<br />

0 10 20<br />

30<br />

Tem"",.!u,e. "C<br />

Fig. 9- Effect <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>temperature</str<strong>on</strong>g> <strong>on</strong> pulp viscosity<br />

lower velocity <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> froth. A similar trend in <strong>the</strong> rates <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

flotati<strong>on</strong> was observed by Klimpel12 in <strong>the</strong> flotati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> silica<br />

from a tac<strong>on</strong>ite ore.<br />

Slightly less <strong>pyrite</strong> was recovered (92 per cent as<br />

compared with 98 per cent) when a froth phase was present,<br />

probably as a result <str<strong>on</strong>g>of</str<strong>on</strong>g> normal froth <str<strong>on</strong>g>effect</str<strong>on</strong>g>s such as crowding<br />

and bubble breakage. Lowering <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> pulp <str<strong>on</strong>g>temperature</str<strong>on</strong>g><br />

decreased <strong>the</strong> rate <str<strong>on</strong>g>of</str<strong>on</strong>g> flotati<strong>on</strong> since it decreased <strong>the</strong><br />

velocity <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> froth, increased <strong>the</strong> viscosity <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> pulp, and<br />

reduced <strong>the</strong> rate <str<strong>on</strong>g>of</str<strong>on</strong>g> mass transfer <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> <strong>pyrite</strong> from <strong>the</strong> pulp<br />

to <strong>the</strong> froth. <str<strong>on</strong>g>The</str<strong>on</strong>g> influence <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>temperature</str<strong>on</strong>g> <strong>on</strong> <strong>the</strong> rate <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

<strong>pyrite</strong> flotati<strong>on</strong> was virtually <strong>the</strong> same in <strong>the</strong> presence <str<strong>on</strong>g>of</str<strong>on</strong>g> a<br />

froth phase as it was in its absence (Figs. 3 and 5); so <strong>the</strong><br />

most important <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong>se factors is probably <strong>the</strong> rate <str<strong>on</strong>g>of</str<strong>on</strong>g> mass<br />

transfer <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> <strong>pyrite</strong> from <strong>the</strong> pulp to <strong>the</strong> froth phase.<br />

<str<strong>on</strong>g>The</str<strong>on</strong>g> reas<strong>on</strong> for <strong>the</strong> decrease in <strong>the</strong> rate <str<strong>on</strong>g>of</str<strong>on</strong>g> mass transfer<br />

has not yet been identified, but this decrease may be due to<br />

<strong>on</strong>e <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> following factors:<br />

(a) poorer loading <str<strong>on</strong>g>of</str<strong>on</strong>g> bubbles as <strong>the</strong> result <str<strong>on</strong>g>of</str<strong>on</strong>g> decreased<br />

inducti<strong>on</strong> time,<br />

(b) lower rate <str<strong>on</strong>g>of</str<strong>on</strong>g> bubble rise, or<br />

(c) fewer bubbles per unit volume <str<strong>on</strong>g>of</str<strong>on</strong>g> pulp.<br />

Inducti<strong>on</strong> time, defined as <strong>the</strong> time necessary for <strong>the</strong><br />

thinning <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> bubble liquid layer to a critical thickness at<br />

which rupture occurs, is affected by several variables15 such<br />

as <strong>the</strong> viscosity <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> bul~ liquid and <strong>the</strong> c<strong>on</strong>centrati<strong>on</strong>s <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

<strong>the</strong> flotati<strong>on</strong> reagents. Less collector is adsorbed at lower<br />

<str<strong>on</strong>g>temperature</str<strong>on</strong>g>s, but <strong>the</strong> rate <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>pyrite</strong> flotati<strong>on</strong> is hardly<br />

affected by a change in collector c<strong>on</strong>centrati<strong>on</strong>. <str<strong>on</strong>g>The</str<strong>on</strong>g>refore,<br />

<strong>the</strong> extent <str<strong>on</strong>g>of</str<strong>on</strong>g> collector adsorpti<strong>on</strong> does not appear to be<br />

resp<strong>on</strong>sible for <strong>the</strong> marked change in <strong>the</strong> flotati<strong>on</strong> rate. <str<strong>on</strong>g>The</str<strong>on</strong>g><br />

o<strong>the</strong>r parameters that affect inducti<strong>on</strong> time have yet to be<br />

evaluated.<br />

<str<strong>on</strong>g>The</str<strong>on</strong>g> rate <str<strong>on</strong>g>of</str<strong>on</strong>g> bubble rise was observed to be slower for<br />

colder pulps <str<strong>on</strong>g>of</str<strong>on</strong>g> higher viscosity. Although this is c<strong>on</strong>sistent<br />

with <strong>the</strong> observed lower rate <str<strong>on</strong>g>of</str<strong>on</strong>g> flotati<strong>on</strong> at low <str<strong>on</strong>g>temperature</str<strong>on</strong>g>s,<br />

o<strong>the</strong>r factors, e.g. inducti<strong>on</strong> time, may be as important,<br />

or more important.<br />

Photographic studies showed that, at low <str<strong>on</strong>g>temperature</str<strong>on</strong>g>s,<br />

40<br />

o~.<br />

<strong>the</strong>re were more bubbles per unit volume than at high<br />

<str<strong>on</strong>g>temperature</str<strong>on</strong>g>s. This, and <strong>the</strong> fact that <strong>the</strong> flotati<strong>on</strong> rate did<br />

not vary c<strong>on</strong>siderably with varying quantities <str<strong>on</strong>g>of</str<strong>on</strong>g> fro<strong>the</strong>r, do<br />

not sustain <strong>the</strong> hypo<strong>the</strong>sis that <strong>the</strong> slower rate <str<strong>on</strong>g>of</str<strong>on</strong>g> flotati<strong>on</strong><br />

at low <str<strong>on</strong>g>temperature</str<strong>on</strong>g> is caused by <strong>the</strong> presence <str<strong>on</strong>g>of</str<strong>on</strong>g> fewer<br />

bubbles per unit volume.<br />

At lower <str<strong>on</strong>g>temperature</str<strong>on</strong>g>s, flotati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> gangue is<br />

affected as follows. <str<strong>on</strong>g>The</str<strong>on</strong>g> rate <str<strong>on</strong>g>of</str<strong>on</strong>g> mass transfer from <strong>the</strong> pulp<br />

to <strong>the</strong> froth, <strong>the</strong> elutriati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> gangue from <strong>the</strong> froth phase,<br />

and <strong>the</strong> velocity <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> froth are lower, and <strong>the</strong> froth is more<br />

stable. At <str<strong>on</strong>g>temperature</str<strong>on</strong>g>s below lOoC, <strong>the</strong> k and 'IjJ<str<strong>on</strong>g>temperature</str<strong>on</strong>g><br />

pr<str<strong>on</strong>g>of</str<strong>on</strong>g>iles for gangue (Figs. 4 and 5) are markedly<br />

different from those for <strong>pyrite</strong> in <strong>the</strong> presence <str<strong>on</strong>g>of</str<strong>on</strong>g> a froth<br />

phase, in that <strong>the</strong> rate <str<strong>on</strong>g>of</str<strong>on</strong>g> gangue flotati<strong>on</strong> increases. This<br />

phenomen<strong>on</strong> is ascribed to <strong>the</strong> <str<strong>on</strong>g>effect</str<strong>on</strong>g> <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> increased<br />

stability <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> froth and <strong>the</strong> viscosity <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> elutriating<br />

medium, which cause less gangue to return to <strong>the</strong> pulp by<br />

bubble breakage or by elutriati<strong>on</strong>. In <strong>the</strong> flotati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

gangue at lower <str<strong>on</strong>g>temperature</str<strong>on</strong>g>s, <strong>the</strong>se two <str<strong>on</strong>g>effect</str<strong>on</strong>g>s appear to<br />

overshadow <strong>the</strong> <str<strong>on</strong>g>effect</str<strong>on</strong>g> <str<strong>on</strong>g>of</str<strong>on</strong>g> reduced froth velocity and <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

lower mass-transfer rates from <strong>the</strong> pulp to <strong>the</strong> froth. <str<strong>on</strong>g>The</str<strong>on</strong>g><br />

different pr<str<strong>on</strong>g>of</str<strong>on</strong>g>iles obtained for <strong>the</strong> rate <str<strong>on</strong>g>of</str<strong>on</strong>g> gangue flotati<strong>on</strong><br />

in <strong>the</strong> presence <str<strong>on</strong>g>of</str<strong>on</strong>g> a froth phase and in its absence indicate<br />

that, with respect to <strong>the</strong> rate <str<strong>on</strong>g>of</str<strong>on</strong>g> gangue flotati<strong>on</strong>, <strong>the</strong> <str<strong>on</strong>g>effect</str<strong>on</strong>g><br />

<strong>on</strong> <strong>the</strong> froth phase at lower <str<strong>on</strong>g>temperature</str<strong>on</strong>g>s is most significant,<br />

resulting in greater recoveries <str<strong>on</strong>g>of</str<strong>on</strong>g> gangue and seriously<br />

reduced grades. This is shown clearly in Fig. 6.<br />

It has been shown 16 that <strong>the</strong> rate <str<strong>on</strong>g>of</str<strong>on</strong>g> adsorpti<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> 5MBT<br />

<strong>on</strong>to <strong>pyrite</strong> decreases with <str<strong>on</strong>g>temperature</str<strong>on</strong>g>. Fig. 7 shows <strong>the</strong><br />

<str<strong>on</strong>g>effect</str<strong>on</strong>g> <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>temperature</str<strong>on</strong>g> <strong>on</strong> <strong>the</strong> equilibrium adsorpti<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

5MBT. However, in all instances, a pseudo-equilibrium<br />

adsorpti<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> collector, approximately equivalent to a<br />

double layer <str<strong>on</strong>g>of</str<strong>on</strong>g> reagent molecules, is obtained after 4<br />

minutes. M<strong>on</strong>olayer coverage is obtained at all <str<strong>on</strong>g>temperature</str<strong>on</strong>g>s<br />

after less than 1 minute. <str<strong>on</strong>g>The</str<strong>on</strong>g> adsorpti<strong>on</strong> iso<strong>the</strong>rms<br />

show that, at higher <str<strong>on</strong>g>temperature</str<strong>on</strong>g>s, desorpti<strong>on</strong> may occur.<br />

<str<strong>on</strong>g>The</str<strong>on</strong>g> equilibrium adsorpti<strong>on</strong> at 2 °C is significantly lower<br />

than at ambient <str<strong>on</strong>g>temperature</str<strong>on</strong>g>, but is never<strong>the</strong>less adequate<br />

for flotati<strong>on</strong> to occur. Hence, since adequate amounts <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

reagent are adsorbed within <strong>the</strong> normal c<strong>on</strong>diti<strong>on</strong>ing time,<br />

viz 4 minutes, <strong>the</strong> rate <str<strong>on</strong>g>of</str<strong>on</strong>g> reagent adsorpti<strong>on</strong> is not c<strong>on</strong>sidered<br />

to be rate c<strong>on</strong>trolling.<br />

C<strong>on</strong>clusi<strong>on</strong>s<br />

This study showed that <strong>the</strong> flotati<strong>on</strong> rate <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>pyrite</strong><br />

decreases with <str<strong>on</strong>g>temperature</str<strong>on</strong>g> owing to a reducti<strong>on</strong> in <strong>the</strong> rate<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> mass transfer <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>pyrite</strong> from <strong>the</strong> pulp to <strong>the</strong> froth. This,<br />

in turn, is probably partly because <strong>the</strong> bubbles rise more<br />

slowly at lower <str<strong>on</strong>g>temperature</str<strong>on</strong>g>s, and hence higher viscosities.<br />

<str<strong>on</strong>g>The</str<strong>on</strong>g> <str<strong>on</strong>g>effect</str<strong>on</strong>g> <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>temperature</str<strong>on</strong>g> <strong>on</strong> inducti<strong>on</strong> time was not investigated.<br />

It was also shown that <strong>the</strong> rate <str<strong>on</strong>g>of</str<strong>on</strong>g> gangue flotati<strong>on</strong><br />

is influenced mainly by <strong>the</strong> <str<strong>on</strong>g>effect</str<strong>on</strong>g> <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>temperature</str<strong>on</strong>g> <strong>on</strong> <strong>the</strong><br />

stability <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> froth and <strong>the</strong> viscosity <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> elutriating<br />

medium.<br />

<str<strong>on</strong>g>The</str<strong>on</strong>g>se <str<strong>on</strong>g>effect</str<strong>on</strong>g>s <str<strong>on</strong>g>of</str<strong>on</strong>g> a decrease in <str<strong>on</strong>g>temperature</str<strong>on</strong>g> cannot be<br />

overcome by changes in reagent c<strong>on</strong>centrati<strong>on</strong>s. As this<br />

study simulated <strong>the</strong> <str<strong>on</strong>g>effect</str<strong>on</strong>g> <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>temperature</str<strong>on</strong>g> <strong>on</strong> <strong>the</strong> rougher<br />

banks <str<strong>on</strong>g>of</str<strong>on</strong>g> flotati<strong>on</strong> plants, it is c<strong>on</strong>cluded that, for adequate<br />

grades to be maintained at lower <str<strong>on</strong>g>temperature</str<strong>on</strong>g>s, <strong>the</strong> load <strong>on</strong><br />

<strong>the</strong> cleaner will have to be increased. An increase in aera-<br />

JOURNAL OF THE SOUTH AFRICAN INSTITUTE OF MINING AND METALLURGY DECEMBER 1984 393

ti<strong>on</strong> rate would improve <strong>the</strong> flotati<strong>on</strong> rate and infinite-time<br />

recovery <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>pyrite</strong>, This al<strong>on</strong>e does not <str<strong>on</strong>g>of</str<strong>on</strong>g>fer a soluti<strong>on</strong> to<br />

<strong>the</strong> problem encountered during <strong>the</strong> winter m<strong>on</strong>ths (Fig.<br />

1), since <strong>the</strong>re will be a similar increase in gangue flotati<strong>on</strong>.<br />

<str<strong>on</strong>g>The</str<strong>on</strong>g> use <str<strong>on</strong>g>of</str<strong>on</strong>g> higher impeller speeds results in improved<br />

flotati<strong>on</strong> rates and recoveries <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>pyrite</strong> without a reducti<strong>on</strong><br />

in grade, and this may overcome <strong>the</strong> <str<strong>on</strong>g>effect</str<strong>on</strong>g>s <str<strong>on</strong>g>of</str<strong>on</strong>g> decreased<br />

<str<strong>on</strong>g>temperature</str<strong>on</strong>g>s.<br />

Finally, it is c<strong>on</strong>cluded that, although heating <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> pulp<br />

may improve <strong>the</strong> recoveries, <strong>the</strong> ec<strong>on</strong>omics must be carefully<br />

evaluated for each flotati<strong>on</strong> plant. An example <str<strong>on</strong>g>of</str<strong>on</strong>g> such<br />

an evaluati<strong>on</strong> is given in <strong>the</strong> addendum.<br />

Acknowledgements<br />

This paper is published by permissi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> Council for<br />

Mineral Technology (Mintek) which, with <strong>the</strong> University<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> Cape Town, was resp<strong>on</strong>sible for funding this work. <str<strong>on</strong>g>The</str<strong>on</strong>g><br />

authors thank <strong>the</strong>m, as well as <strong>the</strong> Ore-dressing, Mineralogy,<br />

and Analytical Science Divisi<strong>on</strong>s <str<strong>on</strong>g>of</str<strong>on</strong>g> Mintek for <strong>the</strong>ir<br />

assistance in many aspects <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> work.<br />

References<br />

1. EIGELES,M.A., and VOLOVA,M.L. Kinetic investigati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>effect</str<strong>on</strong>g><br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> c<strong>on</strong>tact time, <str<strong>on</strong>g>temperature</str<strong>on</strong>g> and surface c<strong>on</strong>diti<strong>on</strong> <strong>on</strong> <strong>the</strong><br />

adhesi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> bubbles to mineral surfaces. Mineral Research Institute,<br />

Ministry <str<strong>on</strong>g>of</str<strong>on</strong>g> Geology and Protecti<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> Mineral<br />

Resources <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> USSR.<br />

2. GLEMBOTSKII.,V.A., KLASSEN.V.L, and PLAKSIN,LN. Flotati<strong>on</strong>.<br />

New York, Primary Sources, 1972. pp. 355-356.<br />

3. KLASSEN.V.L, and MoKRoussov, V.A. An introducti<strong>on</strong> to <strong>the</strong><br />

<strong>the</strong>ory <str<strong>on</strong>g>of</str<strong>on</strong>g>flotati<strong>on</strong>. L<strong>on</strong>d<strong>on</strong>, Butterworth, 1963. p. 258.<br />

4. MARAIS, P. Some practical c<strong>on</strong>siderati<strong>on</strong>s in <strong>the</strong> design and<br />

operati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> a plant for <strong>the</strong> differential flotati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> mixed<br />

sulphides, especially copper and zinc. J. S. Afr. Inst. Min. Metal/.,<br />

vo!. 80, no. 11. 1980. pp. 385-394.<br />

5. SUTHERLAND,K.L., and WARK, LW. Principles <str<strong>on</strong>g>of</str<strong>on</strong>g> flotati<strong>on</strong>.<br />

Melbourne, Australasian Institute <str<strong>on</strong>g>of</str<strong>on</strong>g> Mining and Metallurgy,<br />

1955. pp. 178-188.<br />

6. MARSDEN, D.D. <str<strong>on</strong>g>The</str<strong>on</strong>g> <str<strong>on</strong>g>effect</str<strong>on</strong>g> <str<strong>on</strong>g>of</str<strong>on</strong>g> pH value, <str<strong>on</strong>g>temperature</str<strong>on</strong>g> and density<br />

<strong>on</strong> <strong>the</strong> kinematic viscosity <str<strong>on</strong>g>of</str<strong>on</strong>g> some South African gold-mine slurries.<br />

J. S. Afr. Inst. Min. Metal/., vo!. 62, no. 6. 1962. pp. 391-398.<br />

7. DAVIDSON, J.F., and SHOLER, B.O.G. Bubble formati<strong>on</strong> at an<br />

orifice in a viscous liquid. Trans. Inst. Chem. Eng., vo!. 38. 1960.<br />

pp. 144-154.<br />

8. KLASSEN. V.L, and MoKRoussov, V.A., op. cit., p. 368.<br />

9. SUTHERLAND, K.L., and WARK, LW., op. cit., p. 350.<br />

10. KUBOTA, T., YOSHIDA, M., HASHIMOTO, S., and SHIMOIZAKA, J.<br />

A new method for copper-lead separati<strong>on</strong> by raising <strong>the</strong> <str<strong>on</strong>g>temperature</str<strong>on</strong>g><br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> bulk float. Proceedings <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> I1 th Internati<strong>on</strong>al<br />

Mineral Processing C<strong>on</strong>gress, Cagliari, April 1975. Cagliari,<br />

Instituto di Arte Mineraria Universita di Cagliari, 1975.<br />

pp. 623-637.<br />

11. HUKKI, R. T. Hot flotati<strong>on</strong> improves selectivity and raises mineral<br />

recoveries. World Min., vo!. 26, no. 3.1973. pp. 74-76.<br />

12. KUMPEL, R.R. <str<strong>on</strong>g>The</str<strong>on</strong>g> engineering analysis <str<strong>on</strong>g>of</str<strong>on</strong>g> dispersi<strong>on</strong> <str<strong>on</strong>g>effect</str<strong>on</strong>g>s in<br />

selected mineral processing operati<strong>on</strong>s. Proceedings <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> Internati<strong>on</strong>al<br />

Symposium <strong>on</strong> Fine Particles Processing, Las Vegas,<br />

Nevada, February 1980. Somasundaran, P. (ed.). New York,<br />

AIME, 1980. pp. 1129-1151.<br />

13. KLASSEN, V.L, and MoKRoussov, V.A. op. cit., p. 368.<br />

14. MoONEY, J. J. Colloid Interface Sci., vo!. 6. 1951. p. 162.<br />

15. LEJA, J. Surface chemistry <str<strong>on</strong>g>of</str<strong>on</strong>g> froth flotati<strong>on</strong>. New York, Plenum<br />

Press, 1982.<br />

16. O'CONNOR, C.T., MccLEAN, D.M., and DELPoRT, L. University<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> Cape Town, private communicati<strong>on</strong>, 1982.<br />

Addendum<br />

If a flotati<strong>on</strong> plant with a feed rate <str<strong>on</strong>g>of</str<strong>on</strong>g> 19 000 t/d yields<br />

500 t <str<strong>on</strong>g>of</str<strong>on</strong>g> c<strong>on</strong>centrate and 3800 g <str<strong>on</strong>g>of</str<strong>on</strong>g> gold per day during<br />

winter and a 10°C rise in <str<strong>on</strong>g>temperature</str<strong>on</strong>g> will result in<br />

an increase <str<strong>on</strong>g>of</str<strong>on</strong>g> 7,5 per cent in <strong>the</strong> amount <str<strong>on</strong>g>of</str<strong>on</strong>g> c<strong>on</strong>centrate<br />

produced,<br />

4085 gld.<br />

Thus,<br />

<strong>the</strong> feed rate <str<strong>on</strong>g>of</str<strong>on</strong>g> pulp<br />

<strong>the</strong> heat capacity <str<strong>on</strong>g>of</str<strong>on</strong>g> pulp<br />

<strong>the</strong> enthalpy <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> steam<br />

(100 kPa, 250°C)<br />

<strong>the</strong> steam costs<br />

<strong>the</strong> gold recovery will be approximately<br />

= 19000 t/d<br />

= 3,15 kJ/(kg.K), calculated<br />

<strong>on</strong> a weighted<br />

average at a pulp density<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> 30 per cent and<br />

a heat capacity <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong><br />

solids <str<strong>on</strong>g>of</str<strong>on</strong>g> 0,7 kJ/(kg.K)<br />

= 2944 kJ/kg<br />

= R3,;>O(including capital<br />

costs)<br />

<strong>the</strong> gold price<br />

= R12000per kilogram.<br />

<str<strong>on</strong>g>The</str<strong>on</strong>g>refore, if <strong>the</strong> heat losses are 40 per cent, <strong>the</strong> cost <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

heating <strong>the</strong> pulp will be RU85 per day, and <strong>the</strong> increased<br />

revenue from gold will be R3420 per day.<br />

394 DECEMBER 1984 JOURNAL OF THE SOUTH AFRICAN INSTITUTE OF MINING AND METALLURGY