Process Development for Cell-Based Influenza Vaccine

Process Development for Cell-Based Influenza Vaccine

Process Development for Cell-Based Influenza Vaccine

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Downstream <strong>Process</strong>ing<br />

<strong>Process</strong> <strong>Development</strong> <strong>for</strong><br />

<strong>Cell</strong>-<strong>Based</strong> <strong>Influenza</strong> <strong>Vaccine</strong><br />

<strong>Influenza</strong> virus vaccines have traditionally been produced<br />

by infection of fertilized hen eggs. this labor-intensive<br />

approach requires large facilities, which has led to the<br />

development of large-scale mammalian cell culture<br />

methods <strong>for</strong> future virus vaccine production processes.<br />

the main focus of these studies was to use generic,<br />

established, and scalable techniques <strong>for</strong> industrial production<br />

of live influenza vaccines (Figure 1) and potentially also <strong>for</strong><br />

other viruses independent of type or size. development of<br />

three different focus areas in live influenza processing are<br />

described: optimization of a disposable cell culture step; a<br />

downstream purification process <strong>for</strong> efficient removal of<br />

genomic dNa (gdNa) from live influenza virus cultured in<br />

Madine-darby Canine Kidney (MdCK) cells; and development of<br />

a fast, accurate live influenza assay.<br />

Ce l l Cu lt u r e De v e l o p m e n t<br />

Wave Bioreactor systems were originally designed <strong>for</strong> culturing<br />

cells in suspension. However, several cell types used <strong>for</strong> cell<br />

therapy and vaccine production are anchorage-dependent and<br />

require a surface to grow on. in this study, Cytodex<br />

microcarriers were used in a Wave Bioreactor to expand<br />

MdCK and vero cells. different mixing conditions were tested<br />

<strong>for</strong> both cell lines in order to optimize cell attachment.<br />

We found that composition of the cell culture medium had a<br />

significant effect on cell attachment; <strong>for</strong> example, MdCK and vero<br />

cells cultured in low serum-containing medium attached to the<br />

microcarriers with intermittent and continuous mixing. However,<br />

under serum-free conditions, high attachment of vero cells could<br />

be obtained only by using intermittent mixing. MdCK cells were<br />

grown on Cytodex 1 and Cytodex 3 microcarriers (Figure 2) in a<br />

Wave Bioreactor system at working volumes of 2 l and 10 l. the<br />

cells reached a maximum concentration of 3 × 10 6 cells/ml. vero<br />

cells were cultivated on Cytodex 1 and Cytodex 3 carriers at a<br />

working volume of 2 l and reached a maximum concentration of<br />

1.4 × 10 6 cells/ml — the same concentration of vero cells was<br />

obtained with experiments using spinner flasks.<br />

the data show that the Wave Bioreactor system is a versatile<br />

plat<strong>for</strong>m <strong>for</strong> microcarrier cultivation of MdCK and vero cells,<br />

and it is also a fast and convenient alternative to conventional<br />

stirred-tank bioreactors or roller-bottle systems.<br />

Do w n s t r e a m p r o C e s s D e v e l o p m e n t<br />

the method of vaccine administration determines the<br />

requirements <strong>for</strong> residual dNa in downstream process<br />

development. the WHo recommendation <strong>for</strong> orally administered<br />

vaccines is 100 µg dNa/dose (1 dose is assumed to be 45 µg<br />

hemagglutinin), whereas parenteral vaccines allow only<br />

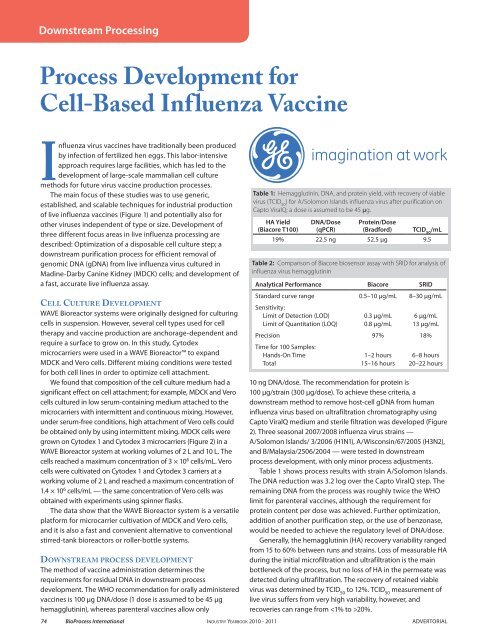

Table 1: Hemagglutinin, DNA, and protein yield, with recovery of viable<br />

virus (TCID 50 ) <strong>for</strong> A/Solomon Islands influenza virus after purification on<br />

Capto ViralQ; a dose is assumed to be 45 µg.<br />

HA Yield<br />

(Biacore T100)<br />

DNA/Dose<br />

(qPCR)<br />

Protein/Dose<br />

(Brad<strong>for</strong>d) TCID 50 /mL<br />

19% 22.5 ng 52.5 µg 9.5<br />

Table 2: Comparison of Biacore biosensor assay with SRID <strong>for</strong> analysis of<br />

influenza virus hemagglutinin<br />

Analytical Per<strong>for</strong>mance Biacore SRID<br />

Standard curve range 0.5–10 µg/ml 8–30 µg/ml<br />

Sensitivity:<br />

limit of detection (lod)<br />

limit of Quantitation (loQ)<br />

0.3 µg/ml<br />

0.8 µg/ml<br />

6 µg/ml<br />

13 µg/ml<br />

Precision 97% 18%<br />

time <strong>for</strong> 100 Samples:<br />

Hands-on time<br />

total<br />

1–2 hours<br />

15–16 hours<br />

6–8 hours<br />

20–22 hours<br />

10 ng dNa/dose. the recommendation <strong>for</strong> protein is<br />

100 µg/strain (300 µg/dose). to achieve these criteria, a<br />

downstream method to remove host-cell gdNa from human<br />

influenza virus based on ultrafiltration chromatography using<br />

Capto viralQ medium and sterile filtration was developed (Figure<br />

2). three seasonal 2007/2008 influenza virus strains —<br />

a/Solomon islands/ 3/2006 (H1N1), a/Wisconsin/67/2005 (H3N2),<br />

and B/Malaysia/2506/2004 — were tested in downstream<br />

process development, with only minor process adjustments.<br />

table 1 shows process results with strain a/Solomon islands.<br />

the dNa reduction was 3.2 log over the Capto viralQ step. the<br />

remaining dNa from the process was roughly twice the WHo<br />

limit <strong>for</strong> parenteral vaccines, although the requirement <strong>for</strong><br />

protein content per dose was achieved. Further optimization,<br />

addition of another purification step, or the use of benzonase,<br />

would be needed to achieve the regulatory level of dNa/dose.<br />

Generally, the hemagglutinin (Ha) recovery variability ranged<br />

from 15 to 60% between runs and strains. loss of measurable Ha<br />

during the initial microfiltration and ultrafiltration is the main<br />

bottleneck of the process, but no loss of Ha in the permeate was<br />

detected during ultrafiltration. the recovery of retained viable<br />

virus was determined by tCid 50 to 12%. tCid 50 measurement of<br />

live virus suffers from very high variability, however, and<br />

recoveries can range from 20%.<br />

74 Bio<strong>Process</strong> International In d u s t r y ye a r b o o k 2010 - 2011 advertorial

Figure 1: Overview of a cell-based influenza vaccine process showing<br />

reduction of total DNA content (purple)<br />

HiPrep 26/10<br />

<strong>Cell</strong> culture<br />

MDCK cells on Cytodex 3 carriers<br />

116.4 × 10 6 ng DNA<br />

Clari�cation<br />

ULTA Prime GF 2 µm -<br />

ULTA Prime GF 0.6 µm<br />

39.3 × 10 6 ng DNA<br />

Ultra�ltration/Dia�ltration<br />

Cross�ow �ltration, UFP-500-C<br />

9.50 × 10 6 ng DNA<br />

Nonbinding Anion-Exchange<br />

Chromatography<br />

Capto ViralQ �ltration<br />

5.06 × 10 3 ng DNA<br />

Ultra�ltration/Dia�ltration<br />

Cross�ow �ltration, UFP-500-C<br />

3.99 × 10 3 ng DNA<br />

Sterile �ltration<br />

ULTA Pure SF 0.2 µm<br />

2.06 × 10 3 ng DNA<br />

In f l u e n z a an a ly s I s De v e l o p m e n t<br />

the potency of influenza vaccines are mainly determined by<br />

quantitation of Ha using the single radial immunodiffusion (Srid)<br />

assay. this method, although approved by both Fda and eMea, is<br />

labor-intensive and suffers from low precision and sensitivity.<br />

Biacore biosensor assays offer an alternative to Srid <strong>for</strong><br />

vaccine development and manufacturing. Quantitation of<br />

influenza Ha using Biacore biosensor assay is per<strong>for</strong>med in an<br />

indirect manner as an inhibition assay (Figure 3). Biacore<br />

biosensor quantitation of influenza Ha using Biacore t100 system<br />

shows significantly higher sensitivity and precision compared<br />

with Srid (table 2). in addition, the analysis time is shorter.<br />

Co n C l u s I o n s<br />

optimal microcarrier conditions in Wave Bioreactor were<br />

developed demonstrating the potential <strong>for</strong> fully disposable<br />

influenza vaccine manufacturing from adherent MdCK cells. a<br />

generic and efficient purification process was developed <strong>for</strong> the<br />

removal of gdNa and host cell–derived impurities from MdCK<br />

cell-based influenza. a further purification step is, however,<br />

required to achieve vaccine purity according to WHo<br />

recommendations. a Biacore based influenza analysis was<br />

developed and shown to be more accurate and faster than Srid.<br />

advertorial In d u s t r y ye a r b o o k 2010 - 2011<br />

Figure 2: Morphology of Vero cells on Cytodex 1 (top) and Cytodex 3<br />

(bot tom) microcarriers after four days’ growth in a WAVE bioreactor system<br />

Cytodex 1<br />

Cytodex 3<br />

Figure 3: Principle of inhibition in Biacore T100 system; HA is first<br />

immobilized on a dextran matrix (red-filled circles); virus is then mixed with a<br />

fixed concentration of serum and injected over the surface. Free antibodies<br />

(not bound to virus at equilibrium) bind to the surface HA, giving a response.<br />

Low concentration of virus in the sample a) gives high antibody binding,<br />

whereas high virus concentration b) results in low binding level.<br />

A) B)<br />

Björn Lundgren is the vaccine marketing manager at GE Healthcare<br />

Bio-Sciences AB, Björkgatan 30, 75184 Uppsala, Sweden, bjorn.<br />

lundgren@ge.com; www.gelifesciences.com/bioprocess.<br />

Bio<strong>Process</strong> International 75