On the instructions of CP Holder, KJ Coates and AC O'Keefe

On the instructions of CP Holder, KJ Coates and AC O'Keefe

On the instructions of CP Holder, KJ Coates and AC O'Keefe

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

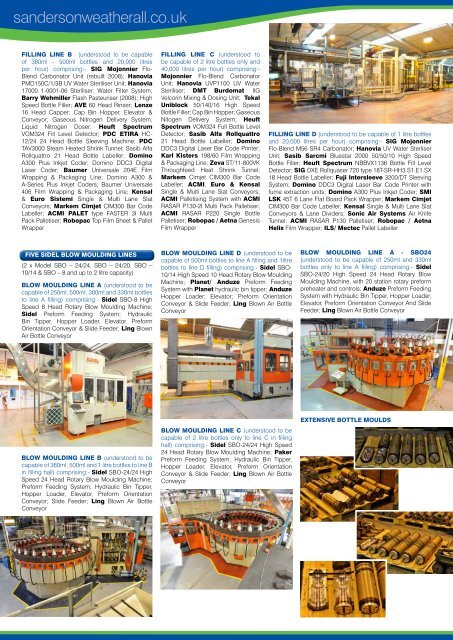

Filling Line B (understood to be capable<br />

<strong>of</strong> 380ml - 500ml bottles <strong>and</strong> 20,000 litres<br />

per hour) comprising:- SIG Mojonnier Flo-<br />

Blend Carbonator Unit (rebuilt 2008); Hanovia<br />

PMD150C/1/3B UV Water Steriliser Unit; Hanovia<br />

17000 1-0001-06 Steriliser; Water Filter System;<br />

Barry Wehmiller Flash Pasteuriser (2008); High<br />

Speed Bottle Filler; AVE 60 Head Rinser; Lenze<br />

16 Head Capper; Cap Bin Hopper, Elevator &<br />

Conveyor; Gaseous Nitrogen Delivery System;<br />

Liquid Nitrogen Doser; Heuft Spectrum<br />

VOM324 Fill Level Detector; PDC ETIRA HC-<br />

12/24 24 Head Bottle Sleeving Machine; PDC<br />

TAV3000 Steam Heated Shrink Tunnel; Sasib Alfa<br />

Rollquattro 21 Head Bottle Labeller; Domino<br />

A300 Plus Inkjet Coder; Domino DDC3 Digital<br />

Laser Coder; Baumer Universale 204E Film<br />

Wrapping & Packaging Line; Domino A300 &<br />

A-Series Plus Inkjet Coders; Baumer Universale<br />

406 Film Wrapping & Packaging Line; Kensal<br />

& Euro Sistemi Single & Multi Lane Slat<br />

Conveyors; Markem Cimjet CIM300 Bar Code<br />

Labeller; <strong>AC</strong>MI PALET type FASTER 3I Multi<br />

Pack Palletiser; Robopac Top Film Sheet & Pallet<br />

Wrapper<br />

Filling Line C (understood to<br />

be capable <strong>of</strong> 2 litre bottles only <strong>and</strong><br />

40,000 litres per hour) comprising:-<br />

Mojonnier Flo-Blend Carbonator<br />

Unit; Hanovia UVP1100 UV Water<br />

Steriliser; DMT Burdomat IIG<br />

Velcorin Mixing & Dosing Unit; Tekal<br />

Uniblock 50/140/16 High Speed<br />

Bottle Filler; Cap Bin Hopper; Gaseous<br />

Nitogen Delivery System; Heuft<br />

Spectrum VOM324 Full Bottle Level<br />

Detector; Sasib Alfa Rollquattro<br />

21 Head Bottle Labeller; Domino<br />

DDC3 Digital Laser Bar Code Printer;<br />

Karl Kisters 198/60 Film Wrapping<br />

& Packaging Line; Zeva ST/11-800VK<br />

Throughfeed Heat Shrink Tunnel;<br />

Markem Cimjet CIM300 Bar Code<br />

Labeller; <strong>AC</strong>MI, Euro & Kensal<br />

Single & Multi Lane Slat Conveyors;<br />

<strong>AC</strong>MI Palletising System with <strong>AC</strong>MI<br />

RASAR P130-2I Multi Pack Palletiser;<br />

<strong>AC</strong>MI RASAR P220 Single Bottle<br />

Palletiser; Robopac / Aetna Genesis<br />

Film Wrapper<br />

Filling Line D (understood to be capable <strong>of</strong> 1 litre bottles<br />

<strong>and</strong> 20,000 litres per hour) comprising:- SIG Mojonnier<br />

Flo-Blend M56 SR4 Carbonator; Hanovia UV Water Sterliser<br />

Unit; Sasib Sarcmi Bluestar 2000 50/50/10 High Speed<br />

Bottle Filler; Heuft Spectrum NBBVX1136 Bottle Fill Level<br />

Detector; SIG OXE Rollquaser 720 type 18T-SR-HH3.S1.E1.SX<br />

18 Head Bottle Labeller; Fuji Intersleeve 3200/DT Sleeving<br />

System; Domino DDC3 Digital Laser Bar Code Printer with<br />

fume extraction units; Domino A300 Plus Inkjet Coder; SMI<br />

LSK 45T 6 Lane Flat Board Pack Wrapper; Markem Cimjet<br />

CIM300 Bar Code Labeller; Kensal Single & Multi Lane Slat<br />

Conveyors & Lane Dividers; Sonic Air Systems Air Knife<br />

Tunnel; <strong>AC</strong>MI RASAR P130 Palletiser; Robopac / Aetna<br />

Helix Film Wrapper; ILS/ Mectec Pallet Labeller<br />

FIVE Sidel BLOW MOULDING LINES<br />

(2 x Model SBO – 24/24, SBO – 24/20, SBO –<br />

10/14 & SBO – 8 <strong>and</strong> up to 2 litre capacity)<br />

Blow Moulding Line A (understood to be<br />

capable <strong>of</strong> 250ml, 500ml, 300ml <strong>and</strong> 330ml bottles<br />

to line A filling) comprising:- Sidel SBO-8 High<br />

Speed 8 Head Rotary Blow Moulding Machine;<br />

Sidel Preform Feeding System; Hydraulic<br />

Bin Tipper, Hopper Loader, Elevator, Preform<br />

Orientation Conveyor & Slide Feeder; Ling Blown<br />

Air Bottle Conveyor<br />

Blow Moulding Line D (understood to be<br />

capable <strong>of</strong> 500ml bottles to line A filling <strong>and</strong> 1litre<br />

bottles to line D filling) comprising:- Sidel SBO-<br />

10/14 High Speed 10 Head Rotary Blow Moulding<br />

Machine; Planet/ Anduze Preform Feeding<br />

System with Planet hydraulic bin tipper; Anduze<br />

Hopper Loader; Elevator; Preform Orientation<br />

Conveyor & Slide Feeder; Ling Blown Air Bottle<br />

Conveyor<br />

Blow Moulding Line A - SBO24<br />

(understood to be capable <strong>of</strong> 250ml <strong>and</strong> 330ml<br />

bottles only to line A filling) comprising:- Sidel<br />

SBO-24/20 High Speed 24 Head Rotary Blow<br />

Moulding Machine, with 20 station rotary preform<br />

preheater <strong>and</strong> controls; Anduze Preform Feeding<br />

System with Hydraulic Bin Tipper, Hopper Loader,<br />

Elevator, Preform Orientation Conveyor And Slide<br />

Feeder; Ling Blown Air Bottle Conveyor<br />

Blow Moulding Line B (understood to be<br />

capable <strong>of</strong> 380ml, 500ml <strong>and</strong> 1 litre bottles to line B<br />

in filling hall) comprising:- Sidel SBO-24/24 High<br />

Speed 24 Head Rotary Blow Moulding Machine;<br />

Preform Feeding System; Hydraulic Bin Tipper,<br />

Hopper Loader, Elevator, Preform Orientation<br />

Conveyor; Slide Feeder; Ling Blown Air Bottle<br />

Conveyor<br />

Blow Moulding Line C (understood to be<br />

capable <strong>of</strong> 2 litre bottles only to line C in filling<br />

hall) comprising:- Sidel SBO-24/24 High Speed<br />

24 Head Rotary Blow Moulding Machine; Paker<br />

Preform Feeding System, Hydraulic Bin Tipper,<br />

Hopper Loader, Elevator, Preform Orientation<br />

Conveyor & Slide Feeder; Ling Blown Air Bottle<br />

Conveyor<br />

Extensive Bottle Moulds