Prospekt 165 CB (Page 4) - Bradshaw Industrial Welding

Prospekt 165 CB (Page 4) - Bradshaw Industrial Welding

Prospekt 165 CB (Page 4) - Bradshaw Industrial Welding

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

ORBITAL WELDING EQUIPMENT<br />

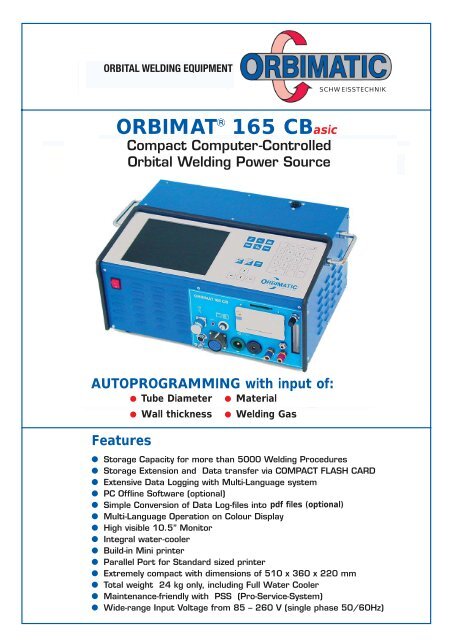

ORBIMAT <strong>165</strong> <strong>CB</strong>asic<br />

R R R<br />

ORBIMAT ORBIMATIC ORBIMAT ORBIMAT <strong>165</strong> <strong>165</strong> <strong>CB</strong>asic<br />

Compact Computer-Controlled<br />

Compact Computer-Controlled<br />

Orbital Compact <strong>Welding</strong> – Lightweight Power – Adaptable Source<br />

Orbital <strong>Welding</strong> Power Source<br />

Compact – Lightweight – Adaptable<br />

AUTOPROGRAMMING with input of:<br />

Features<br />

● Tube Diameter<br />

● Wall thickness<br />

● Material<br />

● <strong>Welding</strong> Gas<br />

SCHWEISSTECHNIK<br />

● Storage Capacity for more than 5000 <strong>Welding</strong> Procedures<br />

● Storage Extension and Data transfer via COMPACT FLASH CARD<br />

● Extensive Data Logging with Multi-Language system<br />

● PC Offline Software (optional)<br />

● Simple Conversion of Data Log-files into pdf WORD files or (optional) EXCEL (optional)<br />

● Multi-Language Operation on Colour Display<br />

● High visible 10.5” Monitor<br />

● Integral water-cooler<br />

● Build-in Mini printer<br />

● Parallel Port for Standard sized printer<br />

● Extremely compact with dimensions of 510 x 360 x 220 mm<br />

● Total weight 24 kg only, including Full Water Cooler<br />

● Maintenance-friendly with PSS (Pro-Service-System)<br />

● Wide-range Input Voltage from 85 – 260 V (single phase 50/60Hz)

ORBIMAT <strong>165</strong> <strong>CB</strong><br />

The<br />

The<br />

new<br />

new<br />

ORBIMAT<br />

ORBIMAT<br />

<strong>165</strong><br />

<strong>165</strong><br />

<strong>CB</strong>asic<br />

<strong>CB</strong>asic<br />

implements<br />

implements<br />

a completely<br />

a completely<br />

newly<br />

newly<br />

develo-<br />

developed computer<br />

ped<br />

system,<br />

computer<br />

which<br />

system,<br />

sets with<br />

which<br />

its various<br />

sets with<br />

field<br />

its<br />

of<br />

various<br />

applications<br />

field of<br />

new<br />

applications<br />

dimensions in Orbital Wel-<br />

new<br />

ding<br />

dimensions<br />

Technology.<br />

in<br />

Use<br />

Orbital<br />

of the<br />

<strong>Welding</strong><br />

latest<br />

Technology.<br />

power-electronic<br />

Use of<br />

components<br />

the latest power-<br />

allows a more compact<br />

electronic<br />

design which<br />

components<br />

gives massive<br />

allows<br />

reductions<br />

a more compact<br />

in weight.<br />

design<br />

Weighing<br />

which gives<br />

only<br />

mas-<br />

24 kg (incl. water coosiveling!)<br />

reductions<br />

and with dimensions<br />

in weight. Weighing<br />

of 510<br />

only<br />

x 370<br />

24<br />

x<br />

kg<br />

220<br />

(incl.<br />

mm,<br />

water<br />

the<br />

cooling!)<br />

ORBIMAT<br />

and<br />

<strong>165</strong> <strong>CB</strong>asic is une-<br />

with<br />

qualled<br />

dimensions<br />

world-wide<br />

of 510<br />

in relation<br />

x 370<br />

to<br />

x<br />

size<br />

220<br />

and<br />

mm,<br />

output.<br />

the ORBIMAT <strong>165</strong> <strong>CB</strong>asic<br />

is A unequall further new world-wide development in relation is the to “Wide-Range” size and output. input voltage of 85 – 260 V which allo-<br />

A ws further connection new to development all world-wide is single the phase “Wide-Range” supply systems. input voltage This also of allows the system<br />

85 to be – 260 uses V in which situations allows where connection is has to never all world-wide been able single to use phase this sup- type of system becauplyse<br />

systems. of the wide This variation also allows in input the voltage, system to such be used as with in situations mobile generators where and on unstable<br />

is power has never supply been systems able with to use extreme this type deviation of system outputs. becauseof the wide<br />

variation Obviously in the input ORBIMAT<strong>165</strong> voltage, such as <strong>CB</strong>asic with mobile includes generators the well and proven on unstaORBIMATIC<br />

AUTO- Better control with 10,5” Colour screen<br />

blepower PROGRAMMING supply systems with easy with weld extreme procedure deviation generation, outputs. with requires input of Diameter,<br />

Obviously Wall thickness, the ORBIMAT Material <strong>165</strong> and <strong>CB</strong>asic Gas, as includes well as the well current proven slope ORBIMATIC function between AUTOPROGRAMMING a maximum 99 with different easy <strong>Welding</strong> weld procedure Levels. generation,<br />

The standard with requires version input of the of Diameter, ORBIMAT Wall <strong>165</strong> thickness, <strong>CB</strong>asic includes Material the and control Gas, as system well as for the cold-wire-feeding current slope function and is between therefor a able maximum to run<br />

99 the different complete <strong>Welding</strong> range of Levels. ORBIMATIC The standard Weld heads. version of the ORBIMAT <strong>165</strong> <strong>CB</strong>asic includes the control system for cold-wire-feeding<br />

and is therefore able to run the complete range of ORBIMATIC Weld heads.<br />

Data Logging<br />

A You wide have range a wide of range Data-Logging of Data-Logging options are available available with for multiple documentation<br />

choice of documentation and archiving. With and archiving. the use of With the full the function use of key- the<br />

board full function (supplied keyboard with the (supplied machine) with additional the machine) information additional can<br />

be information added to can the be data added log file to such the data as electrode log file such type, as welder’s electro-<br />

name, de type, detailed welder’s application name, detailed description application and so on. description and<br />

so on.<br />

ORBITWIN ORBITWIN <strong>165</strong> 300<br />

PSS System<br />

Since printing after every weld may not be practical under<br />

Since some printing conditions, after the every data weld log maybe files can unpractical be saved under temporarily some<br />

conditions, on a COMPACT-FLASH-Card.<br />

the data log files can be saved temporarily on a<br />

COMPACT-FLASH-Card.<br />

ORBIMATIC offers even an OFFLINE Soft/Hardware package,<br />

to to allow transfer of of Data Log files to any PC for archiving achieving and<br />

administration.<br />

The new PSS (Pro-Service-System) brings a new dimension to to Orbital <strong>Welding</strong>.<br />

PSS allows the operator to easily detect any failures on the system, which propermitsvides rapid rapid maintenance on on site. With a very systematic order of of each component,<br />

all all parts are are easy easy to to locate locate and and exchange. exchange. Key Key components components are are connected connec-<br />

by ted simple by simple plugs. plugs. An LED An panel LED panel is located is located on the on rear the side rear of the side machine of the machine and this<br />

allows and this the allows operator the operator to identify to an identify future an problems future problems without having without any having technical any<br />

knowledge, technical knowledge, or the need or for the any need other for any instruments. other instruments.<br />

Furthermore<br />

Furthermore<br />

specific<br />

specific<br />

control<br />

control<br />

functions<br />

functions<br />

of<br />

of the<br />

the<br />

system<br />

system<br />

can<br />

can<br />

be<br />

be<br />

temporarily<br />

temporarily<br />

switswitchedched<br />

off<br />

off<br />

in<br />

in<br />

order<br />

order<br />

to<br />

to complete,<br />

complete,<br />

with<br />

with<br />

extreme<br />

extreme<br />

care,<br />

care,<br />

an<br />

an<br />

immediate<br />

immediate<br />

application<br />

application<br />

on<br />

on<br />

site.<br />

site.<br />

The<br />

The<br />

machine<br />

machine<br />

can<br />

can<br />

then<br />

then<br />

be<br />

be<br />

taken<br />

taken<br />

to<br />

to<br />

a workshop<br />

a workshop<br />

to<br />

to<br />

be<br />

be<br />

serviced<br />

serviced<br />

and<br />

and<br />

repair<br />

repair<br />

the<br />

fault.<br />

the fault.<br />

For maximum production the the ORBITWIN <strong>165</strong> <strong>165</strong> <strong>CB</strong> can can be be used to allow simultaneous<br />

connect of 2 weld heads. The ORBITWIN <strong>165</strong> <strong>165</strong> <strong>CB</strong> will allow the connection of of two different<br />

head head models. models. Each Each weld head can can be assigned assigned a separate separate welding procedure and the<br />

ORBITWIN ORBITWIN <strong>165</strong> will CD automatically will automatically transfer transfer all services all services to the to weld the weld head head in use in and use recall and<br />

the recall associated the associated procedure. procedure. While While one head one head is in is use in the use other the other is isolated, is isolated, allowing allowing the<br />

operator the operator to set to one set one head head while while the the other other is welding<br />

is welding<br />

Technical Techncal Datas: Data:<br />

Dimensions: 510 x360 x 220 mm<br />

Weight: 24 kg<br />

Output Range: 2 -160 A at Input Voltage > 160 V<br />

2 -110 A at Input Voltage < 160 V<br />

Duty Cycle: 100% at100 A, 40% at 160 A<br />

Input Voltage: from 85 V – 260 V, 1 phase – 50/60Hz<br />

Specification subject to change without notice ORBIMATIC (UK) Limited<br />

7 The Manor Grove Centre<br />

Vicarage Farm Road<br />

Peterborough PE15UH<br />

Phone +44 (0) 1733 555285<br />

SCHWEISSTECHNIK<br />

SCHWEISSTECHNIK Fax +44 (0) 1733 847711<br />

E-mail: info@orbimatic.co.uk<br />

www.orbimatic.co.uk<br />

ORBIMATIC GmbH<br />

Flösser Weg 17<br />

D-35418 Buseck (Alten-Buseck)<br />

Telefon (0 64 08) 90 26-0<br />

Telefax (0 64 08) 90 26-50<br />

E-mail: Orbimatic@t-online.de<br />

Internet: www.orbimatic.com