981623 Rhodorsil MF 950 U EN

981623 Rhodorsil MF 950 U EN

981623 Rhodorsil MF 950 U EN

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

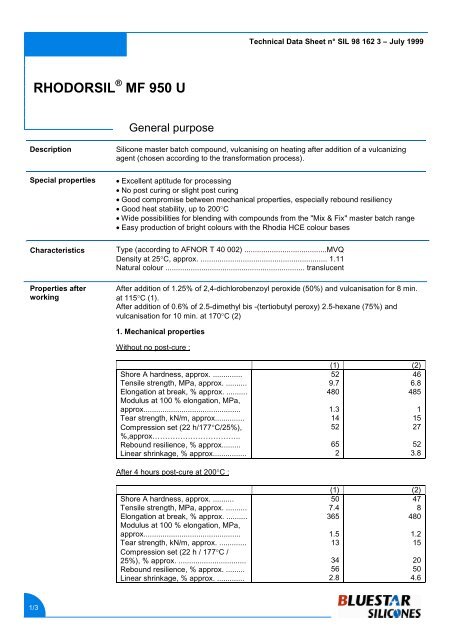

Technical Data Sheet n° SIL 98 162 3 – July 1999<br />

RHODORSIL ® <strong>MF</strong> <strong>950</strong> U<br />

General purpose<br />

Description<br />

Silicone master batch compound, vulcanising on heating after addition of a vulcanizing<br />

agent (chosen according to the transformation process).<br />

Special properties<br />

Characteristics<br />

Properties after<br />

working<br />

• Excellent aptitude for processing<br />

• No post curing or slight post curing<br />

• Good compromise between mechanical properties, especially rebound resiliency<br />

• Good heat stability, up to 200°C<br />

• Wide possibilities for blending with compounds from the "Mix & Fix" master batch range<br />

• Easy production of bright colours with the Rhodia HCE colour bases<br />

Type (according to AFNOR T 40 002) .......................................MVQ<br />

Density at 25°C, approx. ............................................................ 1.11<br />

Natural colour .................................................................. translucent<br />

After addition of 1.25% of 2,4-dichlorobenzoyl peroxide (50%) and vulcanisation for 8 min.<br />

at 115°C (1).<br />

After addition of 0.6% of 2.5-dimethyl bis -(tertiobutyl peroxy) 2.5-hexane (75%) and<br />

vulcanisation for 10 min. at 170°C (2)<br />

1. Mechanical properties<br />

Without no post-cure :<br />

Shore A hardness, approx. ..............<br />

Tensile strength, MPa, approx. ..........<br />

Elongation at break, % approx. ..........<br />

Modulus at 100 % elongation, MPa,<br />

approx..............................................<br />

Tear strength, kN/m, approx..............<br />

Compression set (22 h/177°C/25%),<br />

%,approx……………………………..<br />

Rebound resilience, % approx.........<br />

Linear shrinkage, % approx................<br />

(1) (2)<br />

52<br />

46<br />

9.7<br />

6.8<br />

480<br />

485<br />

1.3<br />

14<br />

52<br />

65<br />

2<br />

1<br />

15<br />

27<br />

52<br />

3.8<br />

After 4 hours post-cure at 200°C :<br />

Shore A hardness, approx. ..........<br />

Tensile strength, MPa, approx. ..........<br />

Elongation at break, % approx. ..........<br />

Modulus at 100 % elongation, MPa,<br />

approx..............................................<br />

Tear strength, kN/m, approx. .............<br />

Compression set (22 h / 177°C /<br />

25%), % approx. ................................<br />

Rebound resilience, % approx. .........<br />

Linear shrinkage, % approx. .............<br />

(1) (2)<br />

50<br />

47<br />

7.4<br />

8<br />

365<br />

480<br />

1.5<br />

13<br />

34<br />

56<br />

2.8<br />

1.2<br />

15<br />

20<br />

50<br />

4.6<br />

1/3

Technical Data Sheet n° SIL 9 8 162 3 – July 1999<br />

RHODORSIL ® <strong>MF</strong> <strong>950</strong> U<br />

2. Heat stability<br />

2.1 Properties after 10 days at 177°C<br />

Shore A hardness, approx. ...............<br />

Tensile strength,MPa, approx. ..........<br />

Elongation at break, % approx. ........<br />

Tear strength, kN/m, approx. ............<br />

2.2 Heat stability with the addition of 0.4p of additive 744<br />

Properties after 10 days at 200°C<br />

Shore A hardness, approx. ...............<br />

Tensile strength,MPa, approx. ..........<br />

Elongation at break, % approx. ........<br />

Properties after 3 days at 225°C<br />

Shore A hardness, approx. ...............<br />

Tensile strength,MPa, approx. ..........<br />

Elongation at break, % approx. ........<br />

Properties after 7 days at 225°C<br />

Shore A hardness, approx. ...............<br />

Tensile strength,MPa, approx. ..........<br />

Elongation at break, % approx. ........<br />

Properties after 3 days at 250°C<br />

Shore A hardness, approx. ...............<br />

Tensile strength,MPa, approx. ..........<br />

Elongation at break, % approx. ........<br />

Properties after 7 days at 250°C<br />

Shore A hardness, approx. ...............<br />

Tensile strength,MPa, approx. ..........<br />

Elongation at break, % approx. ........<br />

3. Dielectric properties<br />

Dielectric strength (on 2 mm thick<br />

specimens), kV/mm, approx…………<br />

Breakdown voltage, kV......................<br />

Dielectric constant at 1 MHz, approx..<br />

Dielectric dissipation factor at 1MHz,<br />

approx.................................................<br />

Volume Resistivity, Ohm.cm, approx..<br />

49<br />

7<br />

350<br />

12<br />

47<br />

6.1<br />

360<br />

49<br />

6.5<br />

370<br />

47<br />

6.5<br />

375<br />

46<br />

6.8<br />

410<br />

48<br />

5.2<br />

275<br />

23<br />

45.4<br />

2.8<br />

3.5x10-3<br />

2.2x1014<br />

45<br />

6.6<br />

420<br />

15<br />

47<br />

7<br />

500<br />

46<br />

6.8<br />

490<br />

45<br />

6.1<br />

460<br />

45<br />

5.1<br />

405<br />

49<br />

5.1<br />

290<br />

Application<br />

Extruding, moulding and injecting translucent or coloured articles, good compromise<br />

between mechanical properties, especially rebound resiliency.<br />

2/3

Technical Data Sheet n° SIL 9 8 162 3 – July 1999<br />

RHODORSIL ® <strong>MF</strong> <strong>950</strong> U<br />

Packaging<br />

Storage and<br />

shelf life<br />

RHODORSIL <strong>MF</strong> <strong>950</strong> U is delivered in 25 kg reinforced cardboard boxes or in 500 kg<br />

containers.<br />

RHODORSIL <strong>MF</strong> <strong>950</strong> U may be stored in its original unopened packaging at a temperature<br />

below 40 °C for up to 18 months from the date of manufacture marked clearly on the<br />

packaging.<br />

Past this date, Bluestar Silicones no longer guarantees that the product meets the sales<br />

specifications.<br />

Safety Consult the Safety Data Sheet of RHODORSIL <strong>MF</strong> <strong>950</strong> U.<br />

Visit our website www.bluestarsilicones.com<br />

EUROPE<br />

NORTH AMERICA<br />

LATIN AMERICA<br />

ASIA PACIFIC<br />

Bluestar Silicones France<br />

21 Avenue Georges Pompidou<br />

F69486 Lyon Cedex 03<br />

FRANCE<br />

Tel. (33) 4 72 13 19 00<br />

Fax (33) 4 72 13 19 88<br />

Bluestar Silicones USA<br />

Two Tower Center Boulevard<br />

Suite 1601<br />

East Brunswick, NJ 08816-1100<br />

United States<br />

Tel. (1) 732 227 2060<br />

Fax (1) 732 249 7000<br />

Bluestar Silicones Brasil Ltda.<br />

Av. Maria Coelho Aguiar, 215, Bloco<br />

G -1º Andar<br />

05804-902 - São Paulo - SP - Brasil<br />

Tel. (55)-11-37477887<br />

Bluestar Silicones Hong Kong<br />

Trading Co., Ltd.<br />

29/ F, 88 Hing Fat Street<br />

Causeway Bay - Hong Kong<br />

Tel. (852) 3106 8200<br />

Fax (852) 2979 0241<br />

Warning to the users<br />

The information contained in this document is given in good faith based on our current knowledge. It is only an indication and is in no way binding, particularly as<br />

regards infringement of or prejudice to third party rights through the use of our products. BLUESTAR SILICONES guarantees that its products comply with its<br />

sales specifications. This information must on no account be used as a substitute for necessary prior tests which alone can ensure that a product is suitable for<br />

given use. Users are responsible for ensuring compliance with local legislation and for obtaining the necessary certifications and authorisations. Users are<br />

requested to check that they are in possession of the latest version of this document and BLUESTAR SILICONES is at their disposal to supply any additional<br />

information.<br />

3/3