RESIDENTIAL INSPECTION CHECKLIST GUIDELINE - City of Frisco

RESIDENTIAL INSPECTION CHECKLIST GUIDELINE - City of Frisco

RESIDENTIAL INSPECTION CHECKLIST GUIDELINE - City of Frisco

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

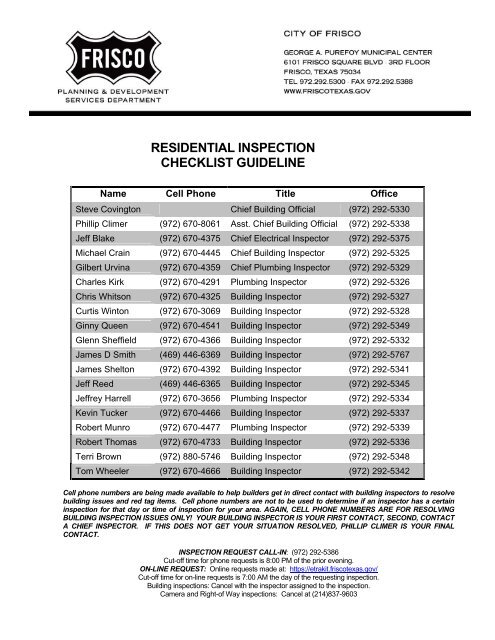

<strong>RESIDENTIAL</strong> <strong>INSPECTION</strong><br />

<strong>CHECKLIST</strong> <strong>GUIDELINE</strong><br />

Name Cell Phone Title Office<br />

Steve Covington Chief Building Official (972) 292-5330<br />

Phillip Climer (972) 670-8061 Asst. Chief Building Official (972) 292-5338<br />

Jeff Blake (972) 670-4375 Chief Electrical Inspector (972) 292-5375<br />

Michael Crain (972) 670-4445 Chief Building Inspector (972) 292-5325<br />

Gilbert Urvina (972) 670-4359 Chief Plumbing Inspector (972) 292-5329<br />

Charles Kirk (972) 670-4291 Plumbing Inspector (972) 292-5326<br />

Chris Whitson (972) 670-4325 Building Inspector (972) 292-5327<br />

Curtis Winton (972) 670-3069 Building Inspector (972) 292-5328<br />

Ginny Queen (972) 670-4541 Building Inspector (972) 292-5349<br />

Glenn Sheffield (972) 670-4366 Building Inspector (972) 292-5332<br />

James D Smith (469) 446-6369 Building Inspector (972) 292-5767<br />

James Shelton (972) 670-4392 Building Inspector (972) 292-5341<br />

Jeff Reed (469) 446-6365 Building Inspector (972) 292-5345<br />

Jeffrey Harrell (972) 670-3656 Plumbing Inspector (972) 292-5334<br />

Kevin Tucker (972) 670-4466 Building Inspector (972) 292-5337<br />

Robert Munro (972) 670-4477 Plumbing Inspector (972) 292-5339<br />

Robert Thomas (972) 670-4733 Building Inspector (972) 292-5336<br />

Terri Brown (972) 880-5746 Building Inspector (972) 292-5348<br />

Tom Wheeler (972) 670-4666 Building Inspector (972) 292-5342<br />

Cell phone numbers are being made available to help builders get in direct contact with building inspectors to resolve<br />

building issues and red tag items. Cell phone numbers are not to be used to determine if an inspector has a certain<br />

inspection for that day or time <strong>of</strong> inspection for your area. AGAIN, CELL PHONE NUMBERS ARE FOR RESOLVING<br />

BUILDING <strong>INSPECTION</strong> ISSUES ONLY! YOUR BUILDING INSPECTOR IS YOUR FIRST CONTACT, SECOND, CONTACT<br />

A CHIEF INSPECTOR. IF THIS DOES NOT GET YOUR SITUATION RESOLVED, PHILLIP CLIMER IS YOUR FINAL<br />

CONTACT.<br />

<strong>INSPECTION</strong> REQUEST CALL-IN: (972) 292-5386<br />

Cut-<strong>of</strong>f time for phone requests is 8:00 PM <strong>of</strong> the prior evening.<br />

ON-LINE REQUEST: Online requests made at: https://etrakit.friscotexas.gov/<br />

Cut-<strong>of</strong>f time for on-line requests is 7:00 AM the day <strong>of</strong> the requesting inspection.<br />

Building inspections: Cancel with the inspector assigned to the inspection.<br />

Camera and Right-<strong>of</strong> Way inspections: Cancel at (214)837-9603

HOW TO: SCHEDULE OR REQUEST AN <strong>INSPECTION</strong><br />

Inspections must be called in when ready, not before!!! Repeated inspections being called when they are obviously not<br />

ready or previous red tag items have not been repaired will result in a 48 hour suspension <strong>of</strong> inspections (i.e. Monday’s<br />

red tag states 24 hour suspension, re-inspection not available until Wednesday). Each inspector will have discretion<br />

based on the severity or number <strong>of</strong> violations. Inspection will be made within twenty-four (24) hours <strong>of</strong> receipt <strong>of</strong> telephone<br />

call. Requests made by telephone will cut-<strong>of</strong>f at 8:00 PM the prior evening and requests made through the Internet will cut-<strong>of</strong>f at<br />

7:00 AM on the requesting day <strong>of</strong> inspection. To cancel inspections please contact your inspector directly or leave a large and<br />

detailed note in the front <strong>of</strong> the permit pack. Camera and Right-<strong>of</strong>-Way inspections are cancelled at (214) 837-9603. All<br />

inspections denied are issued not acceptable tags (aka “red tags”) and will be assessed a $30.00 re-inspection fee. We urge<br />

builders to pay assessed re-inspection fees on a regular basis. As a means <strong>of</strong> control, any permit that has accrued $120.00 in<br />

unpaid re-inspection fees will have inspections suspended until all fees have been paid on that specific permit. In addition,<br />

the <strong>City</strong> reserves the right to deny inspections <strong>of</strong> any and all specific builders who have an excess <strong>of</strong> $1,500 in unpaid<br />

assessed re-inspection fees for all permits issued. Due to the inspection workload, we cannot accommodate<br />

scheduled appointment times.<br />

To CALL in an inspection, please call (972) 292-5386. When calling in an inspection, please ensure that you provide the<br />

following information in order and please speak clearly & slowly. If requesting multiple inspections please state so at beginning<br />

<strong>of</strong> message, giving complete information for each permit separately. If more than five (5) inspections are being requested<br />

by a specific builder, please use our internet service.<br />

1) Complete building permit number (i.e. Bxx-xxxx, Mxx-xxxx, etc.)<br />

2) Type <strong>of</strong> inspection<br />

3) Physical address <strong>of</strong> property to be inspected<br />

Should you receive a “busy signal” or any other technical difficulty, please try again. If you call and hear the phone line ringing<br />

continuously, inspections are currently being removed from the recorder and you will need to try again later.<br />

To request inspections ON-LINE, please go to our web site at: https://etrakit.friscotexas.gov/index.asp. If the website is down<br />

for any reason, please revert to the phone system. Extended hours for such circumstances are available.<br />

<br />

<br />

<br />

<br />

Select your company name from the drop down list and enter your company’s pin number,<br />

followed by clicking SIGN ON.<br />

You can search by Permit Number, Site APN (Tax Parcel number), or Site Address. The best way to locate<br />

the specific permit is to search all active permits.<br />

Once you have located the permit number/address you wish to request an inspection on, click on the<br />

Inspection Request tab, select inspection type and any remarks for the inspector and enter an email address.<br />

A request confirmation will be sent via email. If you do not have a pin number and wish to use our on-line<br />

system, please stop by the <strong>of</strong>fice.<br />

Note: The “Inspection request line” is NOT a message center to reach an inspector or to cancel an inspection. If you<br />

would like to cancel an inspection please contact your inspector.

Listed below are the required inspections and the order in which they are to be completed. The following pages will list<br />

what the inspector is looking for at the time <strong>of</strong> each inspection. First and foremost, every job site must be policed<br />

for loose and blowing trash each and every day. Our inspectors have the right to refuse any inspection due to<br />

loose and blowing trash. This trash policy will be strictly enforced.<br />

The permit packet must be posted on the job site in plain view. A set <strong>of</strong> the approved engineered plans must also be<br />

available on the job site, as well as all previous inspection tags, passed or failed. These previous inspection<br />

tags should be kept together in the front <strong>of</strong> the permit pack.<br />

1. T-Pole – Does not have to be first inspection<br />

2. Plumbing Rough-In<br />

3. Slab<br />

4. Sewer Camera Inspection – Automatically scheduled after pass <strong>of</strong> slab inspection.<br />

5. Flatwork – Can be called at any time<br />

6. Plumbing Top Out - Includes flue pipes on gas fired appliances<br />

7. Electrical Rough<br />

8. 2nds Framing – Includes 2 nd Framing and Mechanical Rough<br />

9. Insulation<br />

10. Drywall<br />

11. Brick/Wall ties – Can be called after passed 2nds<br />

12. Electrical Final – Gets final meter release and can be called when ready after passed drywall<br />

13. Plumbing Final - Gets final meter release and can be called when ready after passed drywall<br />

14. Utility/Right-<strong>of</strong>-Way Inspection – Please call (214) 837-9603 to cancel this inspection<br />

15. C/O - Building Final<br />

*Residential construction must adhere to the following codes with local amendments (See ordinance number):<br />

2006 International Residential Code, with local amendments. (See ordinance 08-01-12)<br />

2005 National Electrical Code, with local amendments. (See ordinance 08-01-10)<br />

2006 International Building Code, with local amendments (See ordinance 08-04-40)<br />

2006 International Mechanical Code, with local amendments (See ordinance 08-01-11)<br />

2006 International Plumbing Code, with local amendments (See ordinance 08-01-09)<br />

2006 International Fuel Gas Code, with local amendments (See ordinance 08-01-08)<br />

2006 International Fire Code, with local amendments. (See ordinance 08-04-39)<br />

2006 International Energy Conservation Code (See ordinance 08-01-07)<br />

All applicable subsequent supplements to International Codes will apply<br />

Current ACI Manual <strong>of</strong> Concrete Practice, ACI318<br />

Current Annual Book <strong>of</strong> ASTM Standards, Volume 04.02 Concrete and Aggregates<br />

Post Tension Institute Construction and Maintenance practices<br />

Adopted <strong>City</strong> <strong>of</strong> <strong>Frisco</strong> Zoning, Subdivision and Building Ordinances<br />

COMMON ITEMS TO EVERY <strong>INSPECTION</strong>:<br />

1. No permit packet/plans – R105.7<br />

2. No address – R321.1<br />

3. Pay fees – R108.2.1 Amended<br />

4. Clean street/lot – Ordinance. 89-04-02<br />

5. Add wind fence/erosion control - Ordinance 89-04-02<br />

6. Excessive trash - Ordinance 01-09-62<br />

7. Not ready – R109.3<br />

8. Move building material 10’ back <strong>of</strong> curb – Engineering Practices

1. T-POLE – DOES NOT HAVE TO BE FIRST <strong>INSPECTION</strong><br />

Proper bracing E3304.7 , E3304.9<br />

Properly grounded E3507.1<br />

220 and 110 receptacles GFI protected E3802.3<br />

Rusted, burnt, loose wires or clamps in meter can E3304.6<br />

Enclosure not weatherpro<strong>of</strong> E3901.7<br />

2. PLUMBING ROUGH-IN<br />

Form survey/building setback encroachments/finished floor street and alley elevation (form<br />

surveys will now require elevation at alley/street and anticipated driveway slope.<br />

Maximum slope 12%)<br />

Plumbing water, gas, sanitary systems on test – P2503 P2503.5.1<br />

Plumbing must be exposed for inspection – P2503.2<br />

Gas tracer wire/size/color - G2415.9<br />

Gas union wrapped properly – G2415.8<br />

Gas/sanitary/water lines properly bedded – G2415.10 P2604.1 P2605.1(2)<br />

“CT adapter” at change in material – P3003.4.2<br />

Minimum depth <strong>of</strong> services 12” – P2603.6 P2603.6.1<br />

Backfall/no fall on sanitary sewer – P3005.3 *P3112.2<br />

Minimum building sewer size 4” – P3004.1<br />

Yard/Double cleanouts not installed – P3005.2.7<br />

Island/foot vent not properly installed - P3112.2 P3112.3 Amended<br />

Trap arm too long/excessive fall – P3105.1<br />

Incorrect sanitary sewer fittings used – P3005.1<br />

Sanitary not properly vented – P3101.2.1<br />

No plastic in water service – P2904.4.2 Amended<br />

PVR must be located outside with valve to service - *P2903.3.1<br />

Water service minimum 3/4" – P2903.7<br />

House valve not installed/not fullport – P2903.9.1<br />

Water service not sleeved over sanitary ditch - P2904.4.2 Amended<br />

Under-slab joints in copper properly brazed – P2904.15<br />

Flux used does not comply with ASTM B 813 – P2904.13<br />

Hot water not insulated - IPC607.2

3. SLAB – Per ACI Manual <strong>of</strong> Concrete and Post Tension Institute Practices AND IRC<br />

Passed engineer inspection –R403.1.8 (We will no longer accept correct and proceed<br />

engineer tags that have structural items. Engineer’s must re-inspect and verify<br />

corrections)<br />

Proper bldg setbacks, Top <strong>of</strong> form elevation, Street/alley elevations, driveway slope – Zoning<br />

Ordinance<br />

Proper beam depth and width – R403.1, per engineer plans R403.1.8 Amendment<br />

Beams clear <strong>of</strong> debris and water R403.1.8 Amendment<br />

Minimum 4” concrete depth top <strong>of</strong> pads<br />

Chairs and cables properly tied<br />

Cables and rebar placed per plans<br />

Cable ends secured<br />

Cables chaired <strong>of</strong>f plumbing<br />

Cables properly routed and spaced <strong>of</strong>f bottom <strong>of</strong> beams<br />

Plumbing sleeved and wrapped properly – P2603.5 P2603.3<br />

Tub boxes installed R403.1.8 Amendment<br />

Brick ledge installed<br />

String lines installed , for measurement purposes<br />

Driveway and yard slope (are drops required) – Max slope 12% driveways, 33% yards<br />

Engineering Procedure manual<br />

Missing/repair poly on interior pads – R 506.2.3<br />

Piers installed per plans / passed pier inspection R401.1.8<br />

Live ends taped ACI manual<br />

4. SEWER CAMERA <strong>INSPECTION</strong><br />

<br />

This inspection is completed by the <strong>City</strong> <strong>of</strong> <strong>Frisco</strong> Public Works Department and is automatically<br />

scheduled after an approved Slab inspection.<br />

To cancel please call (214) 837-9603<br />

5. FLATWORK – CAN BE CALLED AT ANY TIME<br />

PER ACI MANUAL OF CONCRETE PRACTICE AND FRISCO ENGINEERING PRACTICES<br />

Sidewalk at correct width – See plat or PD<br />

Sidewalk sloped at 1/4” per foot from property line to curb<br />

Expansion joints at abutting concrete and every 20’ in sidewalk<br />

Street or alley joint continued in approach<br />

Reinforcement with #3 rebar at 18” on center, each way<br />

Rebar chaired above grade<br />

Maximum 1” <strong>of</strong> sand<br />

Smooth dowels installed at expansion boards<br />

No meter boxes in sidewalk/driveway<br />

Handicap ramps installed per ADA requirements<br />

Driveway approaches at 8” minimum depth within first 12” <strong>of</strong> street and then 5” minimum depth<br />

provided

Driveway approaches with #3 rebar doweled into existing concrete on 18” centers placed on<br />

compacted subgrade – No expansion joint at street or alley<br />

Minimum 5’ driveway turning radius<br />

Flatwork area dry, no standing water<br />

Do not dowell leadwalk to curb<br />

6. PLUMBING TOP OUT - INCLUDES FLUE PIPES ON GAS FIRED APPLIANCES<br />

Waste/vent not properly supported – P2605<br />

Leak on waste/vent 10” <strong>of</strong> head – P2503.4<br />

Trap arm too long/excessive grade – P3105<br />

Proper grade on waste/vent – P3005.3 – P3104.2<br />

Accessibility to clean outs – P3005.2.5<br />

C/O on island and foot vent – P3112.3<br />

No low dry venting – P3104.3<br />

Test entire system, hot and cold tied together – P2503.6<br />

PRV not acceptable in house P2903.3.1 Amended<br />

Reaming <strong>of</strong> copper pipe – P2607.1<br />

Gas test required on entire system/wrong measurement - *G2417.4<br />

Identification <strong>of</strong> CSST piping (med pressure warning tag) – G2412.5 Amended<br />

Reaming <strong>of</strong> gas piping – P2414.7<br />

Swing joints not allowed – G2415.3<br />

Gas breakers at manifold – G2420.6.3<br />

Approved shower pans must be water tested - P2503.5.2<br />

Tubs must be tested to overflow – P2503.5.2<br />

Water heater ignition source not less than 18” – P2801.6<br />

B-vent horizontal not greater than 75% <strong>of</strong> vertical rise – G2427.6.8.2<br />

Proper clearance from combustibles and B-vents – G2427.6.1<br />

Water heater T&P and pan line cannot terminate on concrete – P2803.6.1<br />

Pan drain required at water heater – P2801.5<br />

Gas vents shall terminate no less than 8’ <strong>of</strong> vertical wall or 2’ above ro<strong>of</strong> – G2427.6.3<br />

Minimum 5’ rise on gas vents – M1804.2.3<br />

Combustion air for confined locations – M1702<br />

Unions for water heater connections – P2904.17.1<br />

7. ELECTRICAL ROUGH<br />

Number <strong>of</strong> circuits in panel – E3603.5<br />

Romex fanned out at panel – E3605.3<br />

2 - 20 amp circuits in kitchen – E3603.2<br />

Proper stapling at boxes – Table 3702.1 Footnote I<br />

Check box fill – E3805.12<br />

Check required receptacles – E3801.2.1<br />

Sleeve romex ran through brick – Table E3701.4<br />

Sleeve romex in R/A’s – M1601.1 #6

CWG location – E3508.1.1<br />

Minimum 12-2 with ground – E3306.3 Amendment<br />

No Aluminum wire – E3306.3 Amendment<br />

Check flue and gas lines for bonding – E3509.7 amendment<br />

Laundry circuit can’t leave utility – E3603.3<br />

Check arc fault circuits – E3802<br />

Smoke detectors and carbon monoxide detectors installed – R313.1, R313.3 Amendment<br />

Outlet at stair landing – E3801.2.2(1)<br />

I.C. rated cans – E3904.8<br />

Fan rated boxes with bond screw –E4001.6<br />

Correct attic lighting – E3803.4 E3305.6<br />

No wire under or on attic decking (catwalk) –E3702.2<br />

Block floor plugs – E3805.8<br />

Ground at metal boxes (stingers) – E3901.5<br />

All receptacles within 6’ <strong>of</strong> sinks must be GFCI protected E3802.7<br />

8. 2NDS FRAMING – INCLUDES FRAMING AND MECHANICAL ROUGH<br />

2NDS FRAMING<br />

Passed PTO – R109.1.2 R109.1.4<br />

Passed engineer inspection with no pending structural items<br />

(We will no longer accept correct and proceed engineer tags that have structural items.<br />

Engineer’s must re-inspect and verify corrections)<br />

Windows/construction doors installed Per manufacturers instructions<br />

Windows flashed – R703.8<br />

Wind bracing –R 602.10.3 Table R602.10.1<br />

Nail OSB wind bracing 6” entire perimeter –Table R602.3(1)<br />

Brick ties installed – R703.7.4.<br />

Poly on brick ledge – R703.7.5<br />

Triple green rafters at brick on wood –R703.7.2.2<br />

All holes and penetrations in exterior sheathing sealed – N1102.4 Green building Ordinance<br />

All holes between floors sealed –R 502.12<br />

All penetrations through slab sealed – R320<br />

Slab bolts, nuts & washers installed correctly – R403.1.6<br />

Interior plates anchored at 36” – R403.1.6<br />

Chases draft stopped out <strong>of</strong> attic/floor space –R 602.8<br />

Fire blocking installed – R602.8<br />

Fireplace flue boxed in attic – R808.1<br />

Solid block OSB wind bracing seams – R602.10.7<br />

Over bored/notched stud/top plate/ joist/ rafter properly repaired – R602.6 Amended R602.6.1<br />

2”x6” studs at horizontal plumbing – R602.6 Amendments<br />

Attic access required – R807.1

Joist properly supported, j hanger/pressure block –R502.6Hangers properly web stiffened on<br />

LPI/TJI joist – Manufacturers’’ spec<br />

Double studs under double joist – R601.2<br />

Add support under water heaters – R501.2<br />

Roll block floating beam – R802.8<br />

OSB both sides <strong>of</strong> rafter splice/properly brace rafter splice – R802.3<br />

Lateral restraint <strong>of</strong> joists – R802.8<br />

Treated wood on slab – R319.1<br />

Add support stairs stringers – R311.2.1<br />

Stair rise/run not to code/add nosing’s to stairs – R311.5.3.3<br />

Tempered glass at hazardous locations – R308.4<br />

Proper joist and rafter spans – Tables R802.4(1&2), R802.5(1thru9) R502.3 (1) & (2)<br />

Adequate air hock/s<strong>of</strong>fit vents – R806.1 R806.2<br />

7 1/2” under attic decking/furr vaulted ceilings, R22 insulation required – R806.3<br />

Vaulted ceilings baffled – R806.3<br />

Glass block one hour rated on zero side – R302.1<br />

Penetrations on zero side –Table R302.1 Amended<br />

Bored engineered lumber – R502.8.2<br />

MECHANICAL ROUGH<br />

Return plenum properly sealed – M1601.1.1(7.4)<br />

Fresh air intake/gravity and volume damper – R1006.2<br />

Restricted A/C ducts – M603.1<br />

Exhaust vent terminations 48” minimum from openings into building – M1804.2.6<br />

Chimney capped – R1005<br />

Refrigerant suction line 1” in size or less to be insulated with 1/2” minimum insulation except<br />

when length exceeds 5’ exposed to outdoor air, then it shall be minimum 1” in thickness outdoors<br />

– NTCOG amendments Table 503.3.3.1 IRC N1103.5<br />

Minimum duct insulation to be in compliance with one <strong>of</strong> the State <strong>of</strong> Texas ESL Residential Duct<br />

Trade Offs effective 1/23/06 or IRC N1103.3 – Energy Star/Green Building will be R-6 insulation<br />

Flex duct to be supported every 4’ horizontally and 6’ vertically. Bending radius must not restrict<br />

air flow. Splice collars are required at duct splices (manufactured specs) – M1601.3.2<br />

Mastic seal all seams and connections <strong>of</strong> ductwork and equipment – M1601.3.1 IECC503.3.3.4<br />

(Tapes not approved for air tight sealing)<br />

Main condensate drains to be tied into a wet drain. Secondary drains to discharged to an<br />

obvious location (over doors, windows, patios, etc.) – M1411.3<br />

All exhaust fans to be vented outside <strong>of</strong> the building with metal ductwork – M1501.1 M1505.1<br />

Dryer vent maximum length is 25’. The maximum developed length shall be reduced 2.5’ for<br />

each 45 degree bend and 5’ for each 90 degree bend – M1501.3 Amendments<br />

A minimum 24” wide by 30” high unobstructed, solid catwalk is required from the point <strong>of</strong> attic<br />

entry to the attic furnace service panels and filters – NTCOG Amendments M1305.1.3<br />

The “Line <strong>of</strong> Travel” distance between the attic entry point and the attic furnace access panels<br />

shall not exceed 20’ - M1305.1.3

A 30 x 30” level work platform and 30” clear work are required in front <strong>of</strong> attic furnace access and<br />

filters - M1305.1.3<br />

Air conditioning condensers are to be level and firmly supported 3” above adjoining grade –<br />

M1401 and M1305.1.4.1 Amendments<br />

Self closing dampers are required in Green Building furnace fresh air intakes – IECC 503.3.3.5<br />

Green Building supply plenums shall not have insulation in the air stream; insulation must be on<br />

the exterior <strong>of</strong> the plenums – Green Building Ordinance<br />

Gas flue pipes (B-Vent) shall not terminate within 8’ <strong>of</strong> any vertical wall or similar structure on the<br />

ro<strong>of</strong> – G2427.6.5<br />

Environmental exhaust ducts shall not terminate within 36” <strong>of</strong> building openings – IMC 502.7.3.6<br />

Only materials with a flame spread index greater than 200 shall be allowed in the Return Air duct<br />

system (Protect all wiring, elec. Boxes, PVC, OSB, etc) – M1601.1 #6<br />

The Mechanical Start-Up Checklist shall be completed by the A/C company and presented to the<br />

Building Inspector at C.O. – M1401.1.1 Amendments<br />

9. INSULATION<br />

House built as Green Building shall conform to the Energy Summary provided by the design<br />

engineer<br />

Insulation installed in dwellings other than Green Building shall conform to Tables 502.2.4(1) to<br />

502.2.4(9) – IRC N1101.4.1 N1102.1 *Higher R-factors are better<br />

No vapor retardant (paper) shall be installed on batts in climate zone 5B – 502.1.1<br />

Vaulted ceilings and under attic decks require a minimum R-22 insulation<br />

10. DRYWALL<br />

5/8 in garage adjoining living space/under stairs (entire area) – R311.2.2 Amendment R309.2<br />

5/8 zero side – Table 302.1<br />

Ceiling board or 5/8 24” joists – Table R702.3.5 Note D<br />

Correct nail pattern – Table R702.3.5<br />

Excessive gaps/broken<br />

11. BRICK/WALL TIES – CAN BE CALLED AFTER PASSED 2NDS<br />

Clean mortar from behind brick<br />

Remove every 3rd brick bottom row<br />

Moisture barrier for OSB – R703.2<br />

Protect romex Table E3701.4<br />

Poly under brick – R703.7.5<br />

Brick ties – R703.7.4<br />

Weep holes – R703.7.6 R703.7.2.1<br />

12. ELECTRICAL FINAL – GETS FINAL METER RELEASE AND CAN BE CALLED WHEN READY<br />

AFTER PASSED DRYWALL

Receptacles out <strong>of</strong> wall/not plated – E3902.5<br />

Remove panel cover for inspection – E3303.2<br />

Identify CWG location in panel – Inspector Guideline<br />

Mark neutral with phase tape – E3307.1<br />

Neutral double lugged – E3306.9<br />

Main bonding jumper – E3509.2<br />

Isolate ground and neutral in sub-panel – E3808.6<br />

Loose connection in panel – E3306.9<br />

Sufficient workspace and clearances – E3305.1<br />

A/C condenser fusing – E3602.11<br />

Connect/tighten supplemental/CWG ground – E3511.3<br />

Expose CWG – R3511.2<br />

Overcut conductors at meter – E3306.9<br />

CWG not within 5’ <strong>of</strong> slab – E3508.1.1<br />

Clean panel/busses – E3511.5<br />

Outlet covers missing –E3901.11 E3902.5<br />

Ground Jacuzzi motor with # 8 solid – E4109.4<br />

Properly connect A/C disconnect – E3304.7 E3805.3.2<br />

13. PLUMBING FINAL/GAS FINAL FOR METERS<br />

Gas excessive flow valve/meter – G2420.6.3 Amended<br />

Gas valves to appliances – missing/plug/not accessible gas completed to appliances - G2417.6.2<br />

G2420.1.2 G2420.1.3<br />

Hard pipe gas thru cabinet/partition – G2422.1.2<br />

Caulk all fixtures – P2705.1<br />

Slip joints at tub concealed – P2704.1<br />

Leak at fixtures/fixtures missing – P2705.1 P2503.5.2<br />

Outside plumbing protected from freeze – P2603.6<br />

Plumbing vents too close to intake air – P3103.5<br />

Trap primer on floor drain – P3201.2<br />

Dishwasher air gap – P2717.1 P2717.2 P2717.3<br />

No test master bath tub – P2503.5.2<br />

No gas pressure warning tags at both ends <strong>of</strong> service – G2412.5 Amended<br />

Fire caulk fireplace at log liter manufacture require re-factory to be sealed at log liter penetration<br />

appliance vents to short – G2427.6.5<br />

Improper combustion air – G2407<br />

Appliance vent clearances manufacture listing<br />

Extend clean outs past masonry – P3005.2.5<br />

Top/pan drain lines – P2801.5.2 P2803.6.1 P2801.5.2<br />

Fixture cross connect/improper air gap – P2902<br />

Mil-wrap/paint exposed gas piping – G2415.8 G24158.2<br />

Island fixture venting/clean outs – P3112.1 P3112.3

14. RIGHT-OF-WAY – COMPLETED BY PUBLIC WORKS<br />

Water meter can centered/in good condition/at grade level/ on meter<br />

All dirt removed around water meter<br />

Water meter level<br />

Water meter can lid must have hole for auto read attachment<br />

Sod must be laid in right-<strong>of</strong>-way<br />

All valves and valve pads must be uncovered and at grade level<br />

All valve pads must be 2’ by 2’<br />

Valve stack must be centered over square nut valve<br />

All sewer man hole and clean outs must be uncovered and at grade level<br />

15. BUILDING FINAL – CERTIFICATE OF OCCUPANCY (C.O.)<br />

Required paperwork in permit packet – final grade survey, engineer final acceptance letter for<br />

foundation and framing inspection approval, third party rater form with final approval for energy<br />

star/green building, foundation maintenance letter signed by homeowner (or signed by builder<br />

and notarized), Thermal Bypass Checklist, backflow assembly test report, right-<strong>of</strong>-way inspection<br />

All fees paid<br />

Clean street/sidewalk/alley<br />

Lot drainage per survey/positive drainage from foundation – R401.3<br />

Gutters installed/ downspouts extended 5’ from slab where needed – R401.3<br />

Expose gutter pop up drains at grade level<br />

Trees from approved list in place<br />

Landscaping/erosion control in place Ordinance 89-04-02<br />

HVAC units start up and work properly – M1401.1<br />

Gas meter installed/gas appliances operable – M109.1.6<br />

Condenser pads level and raised 3” minimum above adjacent grade – M1305.1.4.1<br />

Rain/freeze sensor for irrigation system installed – Ordinance 01-05-39<br />

Smoke detectors and carbon monoxide detectors installed – R313.1, R313.3<br />

Address numbers posted front and rear – R321.1<br />

Weep holes at brick ledge and window lintels – R703.7.6<br />

Caulk brick expansion joints – Per engineer requirements<br />

Seal penetration in brick – R703.1<br />

Plumbing/exhaust vents painted – P2608.2<br />

Range downdraft exhaust complete – M1503.1<br />

Microwave exhaust vent complete – M1502.1 M1503.1<br />

Front/rear entrance lights working – E3803.3<br />

GFCI receptacles operable and at required locations – E3802<br />

AFCI receptacles in bedrooms operable – E3802.12<br />

Safety glass installed in hazardous locations – R308.4<br />

Three way switch at stairway lighting – E3803.3<br />

Stairway handrail/guardrail to code – R311.5.6<br />

Closet light clearance from shelves to code – E3903.11

Blown insulation certificate at attic – N1101.4<br />

Self closing door from house to garage – R309.1 Amended<br />

Garage overhead door and safety sensor operable<br />

Exit doors operable from inside without a key – R311.4.4<br />

Attic appliances accessible – M1305.1.3<br />

Exterior/garage/attic doors weather stripped – R703.1<br />

Final grade 4” below brick – R404.1.6

BUILDING SITE ORGANIZATION<br />

1. <strong>City</strong> <strong>of</strong> <strong>Frisco</strong> ordinances 89-04-02 (erosion control) and 01-09-62 (trash & rubbish) address key issues as to how each<br />

builder and any subcontractors are to maintain the building site throughout the construction process. Paramount to both<br />

ordinances are the streets, and alleys, as well as adjacent property(ies) (whether vacant under construction or occupied)<br />

being kept free <strong>of</strong> all construction debris.<br />

2. On-site portable sanitation facilities must be provided at the time <strong>of</strong> initial construction activity. The portable sanitation<br />

facilities must be serviced, as needed. One facility per five building sites, but not to exceed 200 feet walking distance<br />

between facilities, is required.<br />

3. Site identification signage indicating property address, as well as lot and block must be visible from the street not alley.<br />

4. Trash bins on site, and emptied and replaced as needed during construction.<br />

5. Required building lot erosion control and rubbish containment as per sketch on the following page. Must be continuously<br />

maintained throughout construction process. Inspector may require additional erosion control.<br />

6. On-site working hours are Monday – Friday, 7:00 am till 10:00 pm. Per the Noise Ordinance. Saturday working hours are<br />

8:00 am till 7:00 pm. No exceptions after initial subdivision occupancy.<br />

7. The water meter box must be set to grade and exposed before the water department will install the water meter. For water<br />

meter information, please call the water department @ (972) 292-5800. It cannot be located within paving <strong>of</strong> sidewalks or<br />

driveways. The meter box cover must remain exposed through C.O.<br />

8. Streets (at streets and alleys) must be kept clean from mud, trash and/or other debris at all times. Stop work orders will be<br />

issued if the builders are in violation <strong>of</strong> the trash, rubbish, and erosion control. Our inspectors have the right to refuse any<br />

inspection due to loose and blowing trash and/or dirty streets or alleys.<br />

9. Must provide clean safe pathway to job site and inspection area.<br />

10. No material storage on the building lot within 10’-0” from back <strong>of</strong> curb.

BUILDERS DESIGNATED SUBDIVISION WASH-OUT PIT<br />

Temporary Signage<br />

“Builders Name”<br />

“Concrete Washout Area”<br />

CURB PROTECTION<br />

PROPERTY LINE<br />

8" GRAVEL<br />

DRIVE<br />

SURFACE<br />

2'-0" DEEP<br />

WASH-OUT<br />

PIT-AREA<br />

PERIMETER<br />

SILT FENCE<br />

1. Necessary compliance with EPA requirements will require each builder to direct transit ready-mix concrete<br />

trucks to a designated wash out area.<br />

2. This area will be on a centrally located lot that is owned, maintained, and returned back to building pad state<br />

at the near completion <strong>of</strong> a subdivision built out.<br />

3. Waste concrete from the site <strong>of</strong> the washout pit will require legal disposal.<br />

4. It is the building contractor’s responsibility to direct the concrete truck drivers to the designated wash out area<br />

for his subdivision.<br />

5. Street, alleyway or vacant lot washout is strictly prohibited.

SUMMARY<br />

This guideline has been prepared to assist the builder and his/her field supervisors. Builders are encouraged<br />

to share the content <strong>of</strong> this guideline with their administrative staff, third party rater, architects, engineers,<br />

subcontractors, starts coordinators and material suppliers.<br />

Periodically, the <strong>City</strong> <strong>of</strong> <strong>Frisco</strong> intends to update this guideline to reflect building code changes, newly<br />

adopted ordinances, and any other information pertinent to residential construction. All builders currently<br />

building residential structures within the <strong>City</strong> <strong>of</strong> <strong>Frisco</strong> will be responsible for obtaining the most current<br />

publication available. Please ask the customer service representative at the Development Services lobby for<br />

the most current edition.<br />

The guideline is not a full disclosure <strong>of</strong> all codes and/or ordinances; it is<br />

only a supplement to help our residential house builders and our<br />

residents.