FFU Synthetic Sleeper I Railway Technology

FFU Synthetic Sleeper I Railway Technology

FFU Synthetic Sleeper I Railway Technology

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

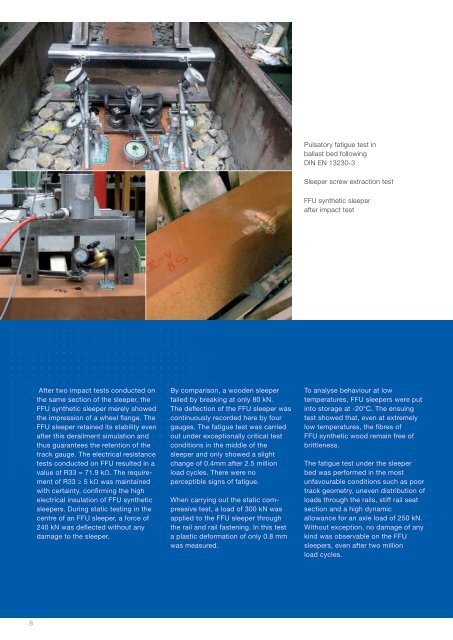

Pulsatory fatigue test in<br />

ballast bed following<br />

DIN EN 13230-3<br />

<strong>Sleeper</strong> screw extraction test<br />

<strong>FFU</strong> synthetic sleeper<br />

after impact test<br />

After two impact tests conducted on<br />

the same section of the sleeper, the<br />

<strong>FFU</strong> synthetic sleeper merely showed<br />

the impression of a wheel flange. The<br />

<strong>FFU</strong> sleeper retained its stability even<br />

after this derailment simulation and<br />

thus guarantees the retention of the<br />

track gauge. The electrical resistance<br />

tests conducted on <strong>FFU</strong> resulted in a<br />

value of R33 = 71.9 kΩ. The requirement<br />

of R33 ≥ 5 kΩ was maintained<br />

with certainty, confirming the high<br />

electrical insulation of <strong>FFU</strong> synthetic<br />

sleepers. During static testing in the<br />

centre of an <strong>FFU</strong> sleeper, a force of<br />

240 kN was deflected without any<br />

damage to the sleeper.<br />

By comparison, a wooden sleeper<br />

failed by breaking at only 80 kN.<br />

The deflection of the <strong>FFU</strong> sleeper was<br />

continuously recorded here by four<br />

gauges. The fatigue test was carried<br />

out under exceptionally critical test<br />

conditions in the middle of the<br />

sleeper and only showed a slight<br />

change of 0.4mm after 2.5 million<br />

load cycles. There were no<br />

perceptible signs of fatigue.<br />

When carrying out the static compressive<br />

test, a load of 300 kN was<br />

applied to the <strong>FFU</strong> sleeper through<br />

the rail and rail fastening. In this test<br />

a plastic deformation of only 0.8 mm<br />

was measured.<br />

To analyse behaviour at low<br />

temperatures, <strong>FFU</strong> sleepers were put<br />

into storage at -20°C. The ensuing<br />

test showed that, even at extremely<br />

low temperatures, the fibres of<br />

<strong>FFU</strong> synthetic wood remain free of<br />

brittleness.<br />

The fatigue test under the sleeper<br />

bed was performed in the most<br />

unfavourable conditions such as poor<br />

track geometry, uneven distribution of<br />

loads through the rails, stiff rail seat<br />

section and a high dynamic<br />

allowance for an axle load of 250 kN.<br />

Without exception, no damage of any<br />

kind was observable on the <strong>FFU</strong><br />

sleepers, even after two million<br />

load cycles.<br />

8