forced convection heat transfer from a circular cylinder embedded in ...

forced convection heat transfer from a circular cylinder embedded in ...

forced convection heat transfer from a circular cylinder embedded in ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

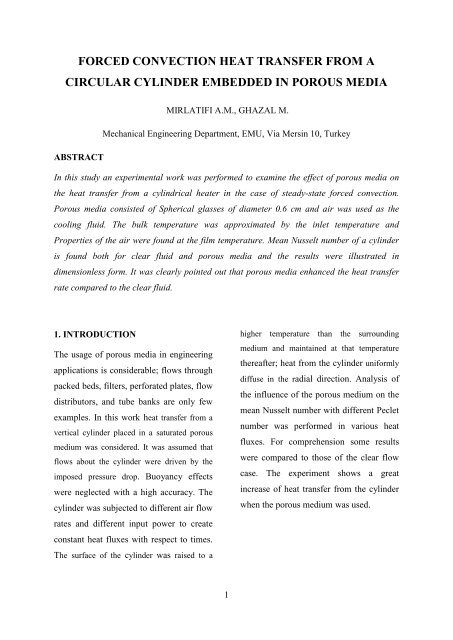

FORCED CONVECTION HEAT TRANSFER FROM A<br />

CIRCULAR CYLINDER EMBEDDED IN POROUS MEDIA<br />

MIRLATIFI A.M., GHAZAL M.<br />

Mechanical Eng<strong>in</strong>eer<strong>in</strong>g Department, EMU, Via Mers<strong>in</strong> 10, Turkey<br />

ABSTRACT<br />

In this study an experimental work was performed to exam<strong>in</strong>e the effect of porous media on<br />

the <strong>heat</strong> <strong>transfer</strong> <strong>from</strong> a cyl<strong>in</strong>drical <strong>heat</strong>er <strong>in</strong> the case of steady-state <strong>forced</strong> <strong>convection</strong>.<br />

Porous media consisted of Spherical glasses of diameter 0.6 cm and air was used as the<br />

cool<strong>in</strong>g fluid. The bulk temperature was approximated by the <strong>in</strong>let temperature and<br />

Properties of the air were found at the film temperature. Mean Nusselt number of a <strong>cyl<strong>in</strong>der</strong><br />

is found both for clear fluid and porous media and the results were illustrated <strong>in</strong><br />

dimensionless form. It was clearly po<strong>in</strong>ted out that porous media enhanced the <strong>heat</strong> <strong>transfer</strong><br />

rate compared to the clear fluid.<br />

1. INTRODUCTION<br />

The usage of porous media <strong>in</strong> eng<strong>in</strong>eer<strong>in</strong>g<br />

applications is considerable; flows through<br />

packed beds, filters, perforated plates, flow<br />

distributors, and tube banks are only few<br />

examples. In this work <strong>heat</strong> <strong>transfer</strong> <strong>from</strong> a<br />

vertical <strong>cyl<strong>in</strong>der</strong> placed <strong>in</strong> a saturated porous<br />

medium was considered. It was assumed that<br />

flows about the <strong>cyl<strong>in</strong>der</strong> were driven by the<br />

imposed pressure drop. Buoyancy effects<br />

were neglected with a high accuracy. The<br />

<strong>cyl<strong>in</strong>der</strong> was subjected to different air flow<br />

rates and different <strong>in</strong>put power to create<br />

constant <strong>heat</strong> fluxes with respect to times.<br />

The surface of the <strong>cyl<strong>in</strong>der</strong> was raised to a<br />

higher temperature than the surround<strong>in</strong>g<br />

medium and ma<strong>in</strong>ta<strong>in</strong>ed at that temperature<br />

thereafter; <strong>heat</strong> <strong>from</strong> the <strong>cyl<strong>in</strong>der</strong> uniformly<br />

diffuse <strong>in</strong> the radial direction. Analysis of<br />

the <strong>in</strong>fluence of the porous medium on the<br />

mean Nusselt number with different Peclet<br />

number was performed <strong>in</strong> various <strong>heat</strong><br />

fluxes. For comprehension some results<br />

were compared to those of the clear flow<br />

case. The experiment shows a great<br />

<strong>in</strong>crease of <strong>heat</strong> <strong>transfer</strong> <strong>from</strong> the <strong>cyl<strong>in</strong>der</strong><br />

when the porous medium was used.<br />

1

NOMENCLATURE<br />

L<br />

Diameter of the porous<br />

Diameter of the <strong>cyl<strong>in</strong>der</strong> (16 mm)<br />

Darcy Number,<br />

Permeability<br />

Thermal conductivity of Spheres<br />

Thermal conductivity of air<br />

Thermal conductivity,<br />

( )<br />

Length of the bed<br />

Prandtl number<br />

Q Heat flux ( )<br />

Heat flux per unit area ( )<br />

Reynolds number<br />

Inlet temperature<br />

Surface temperature of the <strong>cyl<strong>in</strong>der</strong><br />

Average velocity<br />

Diffusivity<br />

Porosity<br />

Nu Nusselt number (( – ) )<br />

P Pressure<br />

Pe Peclet number,<br />

K<strong>in</strong>ematic viscosity<br />

ρ Density of air<br />

µ Viscosity<br />

3. EXPERIMENTAL METHOD<br />

The experiment <strong>in</strong>cludes a bed of porous<br />

media <strong>in</strong> an <strong>in</strong>sulated duct. Inlet velocity<br />

was measured by hot wire transducer and<br />

pressure drop was measured before and<br />

after the porous bed us<strong>in</strong>g a monometer. A<br />

power supply was connected to a<br />

cyl<strong>in</strong>drical <strong>heat</strong>er <strong>embedded</strong> <strong>in</strong> the porous<br />

media to generate <strong>heat</strong> ( ). T-type<br />

thermocouples were used to measure the<br />

surface temperature of the <strong>cyl<strong>in</strong>der</strong> ( ) as<br />

well as the flow temperature <strong>in</strong> the<br />

downstream, (figures 1 & 2). The porosity<br />

( ) was found to be 0.388. Subsequently,<br />

permeability was obta<strong>in</strong>ed by us<strong>in</strong>g<br />

Kozeny-Carman equation:<br />

( )<br />

where is the diameter of the spheres, (6<br />

mm). Thermal conductivity of the porous<br />

material was taken as 1.3 W/m °C.<br />

Permeability was found to be<br />

and Darcy number was calculated<br />

as .<br />

2

Figure 1 : Experimental Setup (Front<br />

View)<br />

each air flow five different <strong>heat</strong> fluxes<br />

were supplied to the element. By chang<strong>in</strong>g<br />

the <strong>heat</strong> flux and wait<strong>in</strong>g for a while to<br />

reach to a steady state surface temperature,<br />

all temperatures were automatically<br />

recorded by the means of a data acquisition<br />

system. The whole process was done for<br />

both the clear flow and flow <strong>in</strong> the porous<br />

medium. To compare the <strong>heat</strong> <strong>transfer</strong> rate<br />

for each medium, Nusselt number versus<br />

Reynolds number were plotted for all the<br />

cases.<br />

4. RESULTS AND DISCUSSION<br />

Figure 2 : Experimental Setup (top view)<br />

The air flow was supplied by the use of a<br />

suction type w<strong>in</strong>d tunnel. The <strong>in</strong>let<br />

temperature, the surface temperature of the<br />

cyl<strong>in</strong>drical <strong>heat</strong>er, and downstream<br />

temperature <strong>in</strong> the porous media, were<br />

recorded through the data acquisition<br />

system. The experiment was carried out for<br />

three different air velocities, which were<br />

measured us<strong>in</strong>g the hot wire transducer.<br />

Pressure drop before and after the porous<br />

bed was measures us<strong>in</strong>g a manometer. For<br />

Table 1 shows different <strong>heat</strong> fluxes and<br />

their correspond<strong>in</strong>g steady state surface<br />

temperature for various numbers. The<br />

difference between the surface temperature<br />

of the cyl<strong>in</strong>drical <strong>heat</strong>er and <strong>in</strong>let<br />

temperature <strong>in</strong> the case of porous media is<br />

much lower than the case of clear fluid.<br />

For example, <strong>in</strong> the case of Re = 1800 and<br />

Q=15.9 W the difference between the <strong>in</strong>let<br />

temperature and the surface temperature is<br />

17.2 ºc <strong>in</strong> the porous medium case and<br />

50.1 ºc <strong>in</strong> the case of clear flow. One of the<br />

ma<strong>in</strong> aims of such setup is to enhance the<br />

<strong>heat</strong> <strong>transfer</strong> and to decrease the<br />

temperature of the element to the lowest<br />

degree possible. Here, we can see the<br />

difference <strong>in</strong> the <strong>heat</strong> <strong>transfer</strong><br />

effectiveness. That is, the temperature of<br />

the surface of the <strong>cyl<strong>in</strong>der</strong> recorded 35.7 ºc<br />

3

<strong>in</strong> the porous medium case and 70 ºc <strong>in</strong> the<br />

case of clear flow. This advantage can be<br />

implemented <strong>in</strong> <strong>heat</strong> exchangers; if our<br />

element is to be considered as a part of<br />

<strong>heat</strong> exchanger, the surface temperature of<br />

the f<strong>in</strong> or the pipe is go<strong>in</strong>g to be less <strong>in</strong> the<br />

case of porous medium than that of the<br />

clear flow.<br />

The pressure drop measured dur<strong>in</strong>g the<br />

experiment was found to be 667, 588, and<br />

379 ( ) for Reynolds numbers 1800,<br />

1600, and 1200 respectively.<br />

Calculat<strong>in</strong>g the correspond<strong>in</strong>g Darcy<br />

velocities by equation:<br />

velocities. Therefore, this equation was<br />

discarded <strong>in</strong> the further calculations.<br />

Instead, the velocities, measured us<strong>in</strong>g the<br />

hot wire transducer, were taken <strong>in</strong>to<br />

account as the real velocities.<br />

Figure 3 shows versus Renolds<br />

number. The more is the <strong>heat</strong> flux the<br />

higher is the mean Nusselt number, which<br />

is nearly constant for different Reynolds<br />

numbers. The results show conformity<br />

with the similarity solution, which is<br />

<strong>in</strong> the porous media, [1].<br />

( )<br />

resulted <strong>in</strong> 4.4, 3.98, and 2.56<br />

, which<br />

is twice as higher as the measured<br />

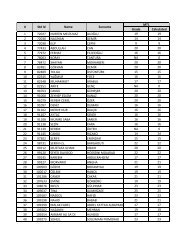

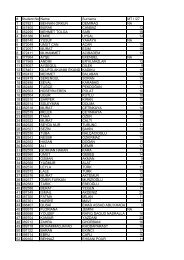

Table 1: <strong>in</strong>let, element’s surface temperature, and the difference between them, for different<br />

Re and <strong>heat</strong> flux for both of the cases.<br />

With porous medium<br />

Clear flow<br />

Re Q(W)<br />

1800 15.9 35.7 18.6 17.2 71.0 20.9 50.1<br />

1800 13.3 32.2 17.5 14.7 63.4 20.0 43.4<br />

1800 11.4 30.6 18.0 12.5 58.0 20.0 38.0<br />

1800 9.6 28.3 17.6 10.7 52.0 19.9 32.1<br />

1800 8.0 26.6 17.8 8.8 47.3 19.7 27.6<br />

1600 15.9 35.7 17.4 18.3 73.9 19.6 54.2<br />

1600 13.3 33.2 17.3 15.9 66.4 19.6 46.7<br />

1600 11.4 30.4 17.1 13.3 59.8 19.6 40.2<br />

1600 9.6 28.4 17.2 11.2 53.3 19.7 33.7<br />

1600 8.0 26.6 17.1 9.5 47.4 19.5 27.9<br />

1200 15.9 39.1 17.1 22.0 74.0 19.2 54.8<br />

1200 13.3 36.1 17.3 18.8 66.0 19.3 46.8<br />

1200 11.4 33.1 17.0 16.1 59.3 19.3 40.0<br />

1200 9.6 30.7 17.1 13.6 52.7 19.2 33.6<br />

1200 8.0 28.2 17.0 11.2 46.9 19.2 27.7<br />

4

Variation of Nu <strong>in</strong> porous medium<br />

us<strong>in</strong>g porous media for <strong>heat</strong> <strong>transfer</strong><br />

Nu/Pe^.5<br />

14.4<br />

14.2<br />

14<br />

13.8<br />

13.6<br />

q''=2.53 kw/m^2<br />

q''=2.12 kw/m^2<br />

q''=1.86 kw/m^2<br />

q''=1.53 kw/m^2<br />

q''=1.27 kw/m^2<br />

problems is emphasized.<br />

3.50<br />

Comparison of Nu for both <strong>heat</strong> <strong>transfer</strong> <strong>in</strong> porous<br />

medium and <strong>in</strong> a clear flow<br />

13.4<br />

3.00<br />

13.2<br />

2.50<br />

13<br />

1200 1610 1810<br />

Re<br />

Nu/pe^.5<br />

2.00<br />

1.50<br />

1.00<br />

With porous<br />

Clear flow<br />

Figure 3:<br />

and <strong>heat</strong> fluxes<br />

For the clear fluid<br />

for various Reynolds<br />

versus<br />

Reynolds number is presented <strong>in</strong> figure 4.<br />

In this case the results show conformity<br />

with the similarity solution. That is, the<br />

relation<br />

exists <strong>in</strong> the clear fluid [2].<br />

Figure 4: versus Reynolds<br />

number <strong>in</strong> clear fluid.<br />

0.50<br />

0.00<br />

Figure 5: Comparison of Nusselt number<br />

for <strong>heat</strong> <strong>transfer</strong> <strong>in</strong> porous media and clear<br />

fluid.<br />

4. Conclusions<br />

The steady state <strong>forced</strong> <strong>convection</strong> <strong>heat</strong><br />

<strong>transfer</strong> around the cyl<strong>in</strong>drical <strong>heat</strong>er<br />

<strong>embedded</strong> <strong>in</strong> the porous media was<br />

exam<strong>in</strong>ed experimentally. The results<br />

compared with the clear fluid case shows<br />

that the porous media enhances the <strong>heat</strong><br />

<strong>transfer</strong> rate. The value of<br />

porous media <strong>in</strong>creases by <strong>in</strong>creas<strong>in</strong>g the<br />

<strong>heat</strong> fluxes and it rema<strong>in</strong>s approximately<br />

constant by <strong>in</strong>creas<strong>in</strong>g the Reynolds<br />

number.<br />

1200 1610 1800<br />

Re<br />

<strong>in</strong><br />

The comparison of Nusselt number is<br />

plotted <strong>in</strong> figure 5. It is evident that porous<br />

media enhance the <strong>heat</strong> <strong>transfer</strong> <strong>from</strong> the<br />

<strong>embedded</strong> <strong>cyl<strong>in</strong>der</strong>. Thus the superiority of<br />

5

5. REFERENCES<br />

[1] D. A. Nield, A. Bejan, “Convection <strong>in</strong><br />

Porous Media”, Second Edition, Spr<strong>in</strong>ger,<br />

1998.<br />

[2] Y. A. Cengel, Heat Transfer, A<br />

Practical Approach”, McGraw-hill, 1998,<br />

P. 367.<br />

[3] L.B.Y. Aldabbagh, H.F. Manesh, and<br />

A.A.Mohammad. Unsteady Natural<br />

Convection <strong>in</strong>side a Porous Enclosure<br />

Heated <strong>from</strong> the Side.<br />

[4] S. Kımura, Transient <strong>forced</strong> and<br />

natural <strong>convection</strong> <strong>heat</strong> <strong>transfer</strong> about a<br />

vertical <strong>cyl<strong>in</strong>der</strong> <strong>in</strong> a porous medium, In,.<br />

J. Hear Mass Transfer. Vol. 32, No. 3, pp.<br />

617-520, 1989.<br />

[5] J. Theven<strong>in</strong>, Transıent Forced<br />

Convectıon Heat Transfer From A<br />

Cırcular Cylınder Embedded In A Porous<br />

Medıum, Int. Comm. Heat Mass Transfer,<br />

Vol. 22, No. 4, Pp. 507-516, 1995.<br />

[6] J. Thevenın And D. Sadaou, About<br />

Enhancement Of Heat Transfer Over A<br />

Cırcular Cylınder Embedded In A Porous<br />

Medıum, International Communications İn<br />

Heat And Mass Transfer, Vol. 22, No. 2,<br />

pp. 295-304, 1995.<br />

6