MultiSpace wood lockers.pdf - Snyder Equipment, Inc.

MultiSpace wood lockers.pdf - Snyder Equipment, Inc.

MultiSpace wood lockers.pdf - Snyder Equipment, Inc.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

S p e c i f i c a t i o n s<br />

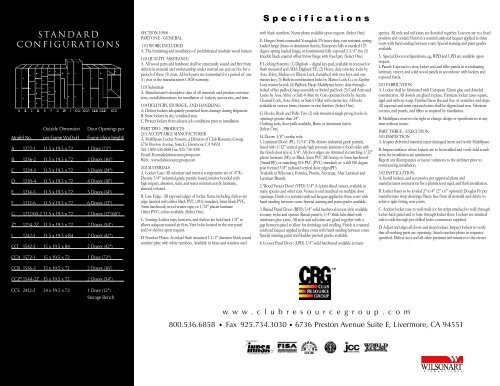

S TA N D A R D<br />

C O N F I G U R AT I O N S<br />

Outside Dimension<br />

Door Openings per<br />

Model No. per Frame WxDxH Frame (door height)<br />

A 1272-1 11.5 x 19.5 x 72 1 Door (72")<br />

B 1236-2 11.5 x 19.5 x 72 2 Doors (36")<br />

C 1224-3 11.5 x 19.5 x 72 3 Doors (24")<br />

D 1218-4 11.5 x 19.5 x 72 4 Doors (18")<br />

E 1214-5 11.5 x 19.5 x 72 5 Doors (14")<br />

F 1212-6 11.5 x 19.5 x 72 6 Doors (12")<br />

G 1212/60-2 11.5 x 19.5 x 72 2 Doors (12"/60")<br />

Z* 1254-2Z 11.5 x 19.5 x 72 2 Doors (54")<br />

I 1242-2 11.5 x 19.5 x 84 2 Doors (42")<br />

CCI 1542-2 15 x 19.5 x 84 2 Doors (42")<br />

SECTION 10500<br />

PART ONE - GENERAL<br />

1.01 WORK INCLUDED<br />

A. The furnishing and installation of prefabricated modular <strong>wood</strong> <strong>lockers</strong>.<br />

1.02 QUALITY ASSURANCE<br />

A. All <strong>wood</strong> parts and hardware shall be structurally sound and free from<br />

defects in material and workmanship under normal use and service for a<br />

period of three (3) years. All lock parts are warrantied for a period of one<br />

(1) year or the manufacturers OEM warranty.<br />

1.03 Submittals<br />

A. Manufacturer’s descriptive data of all materials and product construction,<br />

overall dimensions for installation of <strong>lockers</strong>, accessories, and trim.<br />

1.04 DELIVERY, STORAGE, AND HANDLING<br />

A. Deliver <strong>lockers</strong> adequately protected from damage during shipment.<br />

B. Store <strong>lockers</strong> in dry, ventilated area.<br />

C. Protect <strong>lockers</strong> from adverse job conditions prior to installation<br />

PART TWO - PRODUCTS<br />

2.01 ACCEPTABLE MANUFACTURER<br />

A. <strong>MultiSpace</strong> Locker Systems, a Division of Club Resource Group,<br />

6736 Preston Avenue, Suite E, Livermore, CA 94551<br />

Tel: 1-800-536-6858 Fax: 925-734-3030<br />

Email: Ecom@clubresourcegroup.com<br />

Web: www.clubresourcegroup.com<br />

2.02 MATERIALS<br />

A. Locker Case: All substrate and interior components are of 47 lb.<br />

Density 3/4” industrial grade particle board, interior bonded with<br />

high impact, abrasion, stain, and water resistant acrylic laminate,<br />

almond colored.<br />

B. Case Edge: All exposed edges of locker frame including shelves are<br />

edge banded with either black PVC (.016) standard; 3mm black PVC,<br />

3mm hard<strong>wood</strong>; <strong>wood</strong> veneer tape; or 1/32“ plastic laminate<br />

Other P.V.C. colors available. (Select One)<br />

C. Venting: Locker tops, bottoms, and shelves are held back 1/8” to<br />

allows adequate natural air flow. Vent holes located in the rear panel<br />

and/or shelves upon request.<br />

D. Number Plates: An inlaid flush mounted 1-1/2” diameter black round<br />

number plate with white numbers. Available in brass and stainless steel<br />

with black numbers. Name plates available upon request. (Select One)<br />

E. Hinges: Semi-concealed Youngdale #5 heavy duty, rust resistant, spring<br />

loaded hinge (brass or aluminum finish); European fully concealed 125<br />

degree spring loaded hinge; or Institutional fully exposed 2-3/4” five (5)<br />

knuckle black enamel offset throw hinge with fixed pin. (Select One)<br />

F. Locking Systems: (1) Digilock – digital key-pad, available in recessed or<br />

flush mounted and ADA Digilock TE; (2) Heavy duty cam key locks by<br />

Assa Abloy, Medeco or Illinois Lock, furnished with two keys and one<br />

master key; (3) Built-in combination locks by Master Lock Co. or Zephyr<br />

Lock master keyed; (4) Padlock Hasp: <strong>MultiSpace</strong> heavy duty throughbolted<br />

offset padlock hasp assembly or Swivel pad lock (5) Card Activated<br />

Locks by Assa Abloy or Safe-0-Mat: (6) Coin operated locks by Secura<br />

Channel Lock, Assa Abloy or Safe-O-Mat with master key. All locks<br />

available in various brass, chrome or zinc finishes. (Select One)<br />

G. Hooks, Rods and Pulls: Two (2) side mounted single prong hooks in<br />

openings greater than 24”.<br />

Clothing rods, door pulls available, Brass or aluminum finish.<br />

(Select One)<br />

H. Doors: 3/8” overlay style.<br />

1. Laminate Door: (PL) 11/16“ 47lb. density industrial grade particle,<br />

fused with 1/32” vertical grade high pressure laminate to both sides with<br />

the finish door size at 3/4“. All door edges are trimmed in matching 1/32”<br />

plastic laminate (SE); or Black 3mm PVC (SE3mm); or 3mm hard<strong>wood</strong><br />

(3mmHW); or matching. 016 PVC (PVC) standard; or a full 180 degree<br />

post formed 3/8” radiused vertical door edges(PF).<br />

Available in Wilsonart, Formica, Pionite, Nevamar, Abet Laminati and<br />

Laminart Brands.<br />

2. Wood Veneer Door: (VPD) 3/4” A-l plain sliced veneer, available in<br />

many species and other cuts. Veneer is end matched on multiple door<br />

openings. Finish is a natural catalyzed lacquer applied in three coats with<br />

hand sanding between coats. Special staining and paint grades available.<br />

3. Raised Panel Door: (RPD) 3/4” solid hard<strong>wood</strong> revere style available<br />

in many styles and species. Raised panel is 3/4” thick kiln dried with<br />

minimum glue joints. All style and rail joints are glued together with a<br />

gap between panel to allow for shrinkage and swelling. Finish is a natural<br />

catalyzed lacquer applied in three coats with hand sanding between coats.<br />

Special staining, paint and bladder pressed grades available.<br />

4. Louver Panel Door: (LPD) 3/4” solid hard<strong>wood</strong> available in many<br />

species. All style and rail joints are doweled together. Louvers are in a fixed<br />

position and vented. Finish is a natural catalyzed lacquer applied in three<br />

coats with hand ending between coats. Special staining and paint grades<br />

available.<br />

5. Special Door configurations, eg., RPD and LPD are available upon<br />

request.<br />

I. Panels: Exposed to view, locker end and filler panels in coordinating<br />

laminate, veneer, and solid <strong>wood</strong> panels in accordance with <strong>lockers</strong> and<br />

exposed fascia.<br />

2.03 FABRICATION<br />

A. Locker shall be fabricated with European 32mm glue and doweled<br />

construction. All dowels are glued in place. Fabricate locker cases square,<br />

rigid and without warp. Finished faces flat and free of scratches and chips.<br />

All exposed and semi-exposed joints shall be aligned and true. Fabricate<br />

corners, end panels, and fillers as required by installation.<br />

B. <strong>MultiSpace</strong> reserves the right to change design or specifications at any<br />

time without notice.<br />

PART THREE - EXECUTION<br />

3.01 INSPECTION<br />

A. Inspect delivered material; reject damaged items and notify <strong>MultiSpace</strong>.<br />

B. Inspect surfaces where <strong>lockers</strong> are to be installed and verify field conditions<br />

for installation are satisfactory.<br />

Report any discrepancies or layout variations to the architect prior to<br />

commencing installation.<br />

3.02 INSTALLATION<br />

A. Install <strong>lockers</strong>, and accessories per approved plans and<br />

manufacturers instructions for a plumb, level rigid, and flush installation.<br />

B. Locker bases to be leveled 2” to 4” (2” x 6” optional) Douglas Fir per<br />

manufacturer shop drawings. Bases free from all material and debris, to<br />

achieve tight fitting, neat joints.<br />

C. Anchor locker case to wall studs (or fur strips attached to wall) through<br />

locker back panel and to base through locker floor. Lockers are attached<br />

side to side through pre-drilled holes, connectors supplied.<br />

D. Adjust and align all doors and clean <strong>lockers</strong>. Inspect <strong>lockers</strong> to verify<br />

that all working parts are operating. Attach number plates in sequence<br />

specified. Deliver keys and all other pertinent information to the owner.<br />

CCA 1572-1 15 x 19.5 x 72 1 Door (72")<br />

CCB 1536-2 15 x 19.5 x 72 2 Doors (36")<br />

CCZ* 1544-2Z 15 x 19.5 x 72 2 Doors (54")<br />

CCS 2412-2 24 x 19.5 x 72 1 Door (12")<br />

Storage Bench<br />

w w w . c l u b r e s o u r c e g r o u p . c o m<br />

800.536.6858 • Fax 925.734.3030 • 6736 Preston Avenue Suite E, Livermore, CA 94551