938G, 950G 962G, 966G 972G, 980G - Finning (UK)

938G, 950G 962G, 966G 972G, 980G - Finning (UK)

938G, 950G 962G, 966G 972G, 980G - Finning (UK)

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

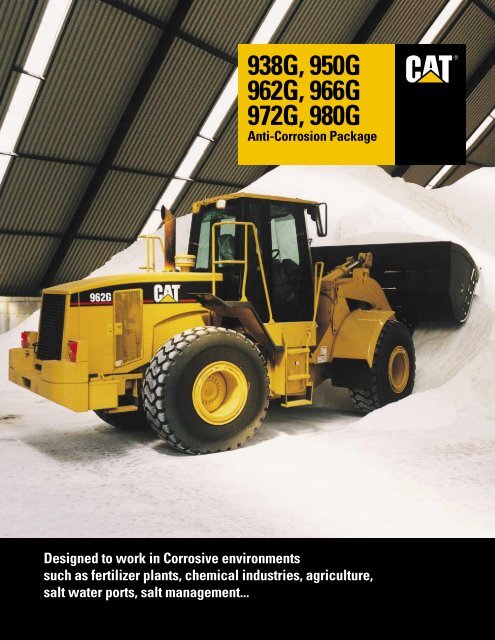

<strong>938G</strong>, <strong>950G</strong><br />

<strong>962G</strong>, <strong>966G</strong><br />

<strong>972G</strong>, <strong>980G</strong><br />

Anti-Corrosion Package<br />

®<br />

Designed to work in Corrosive environments<br />

such as fertilizer plants, chemical industries, agriculture,<br />

salt water ports, salt management...

Anti-Corrosion Package<br />

Provided by Caterpillar ® for value-added protection in harsh corrosive applications.<br />

The Caterpillar Anti-Corrosion Package is an industry exclusive<br />

factory treatment available for <strong>938G</strong> thru <strong>980G</strong> wheel loaders.<br />

It provides extensive protection to vital machine components and<br />

other surfaces typically affected by corrosive materials. This package<br />

improves machine reliability and durability in demanding corrosive<br />

environments. Combined with the productivity, serviceability,<br />

and operator comfort of G-Series wheel loaders, this anti-corrosion<br />

package adds real value in corrosive applications by protecting<br />

your machine investment.<br />

Anti-corrosion Paint Process*<br />

This special paint process provides a paint thickness which is more<br />

than two times more than the standard thickness, giving it extra<br />

resistance against corrosion.<br />

1 The primary yellow coat is identical to Caterpillar standard<br />

painting process<br />

2 Extra Primer Coat number 1 is a black primer coat applied<br />

to the entire machine. Easily removed components are painted<br />

separately to allow better coverage.**<br />

3 Extra Primer Coat number 2 is a yellow primer coat applied<br />

to the entire machine and easily removed components to<br />

enhance protection.**<br />

4 Standard Yellow Top Coat is applied to internal components,<br />

engine compartment, and machine exterior to complete<br />

the process.<br />

5 Extra care to avoid shocks and damages, is given to the assembly<br />

process as all the components are treated separately.<br />

Wheel Rims are also included in the four-stage paint process for<br />

extra protection.<br />

Electro-Static Powder Painting is applied to zinc-plated and<br />

aluminum parts such as tubes, brackets and covers before assembly.<br />

* Some parts will be yellow instead of black, e.g. handrails, side panels.<br />

Also, with the Anti-corrosion paint process, the paint surface might be<br />

slightly different.<br />

** Cabs follow the same paint process apart the <strong>938G</strong> cab which receives<br />

an electrolytic coating in place of the Extra Primer Coat number 1 and number 2.<br />

1<br />

2<br />

3<br />

4<br />

5

Electrical System and Component Protection<br />

Caterpillar combines extensive electrical system protection with specialized component<br />

modifications to increase reliability and life expectancy.<br />

1 Electrical Connectors are protected internally with<br />

Di-electric grease, including connectors inside the cab.<br />

The anti-corrosion paint process protects the connector<br />

exterior.<br />

2 Exterior Lighting electrical lines and connectors receive<br />

special care to extend service life and increase reliability.<br />

3 Silicon Protection is placed over many electrical<br />

components on the machine including the battery<br />

connections, starter motor, and supplemental<br />

steering motor.<br />

4 Rubber Blankets on the front loader frame and above<br />

the rear axle help protect the hydraulic control valve,<br />

and prevent corrosive material from entering the engine<br />

compartment.<br />

5 Plastic Fuel Cap replaces the standard fuel cap to help<br />

eliminate fuel contamination from material that may fall<br />

from a corroding steel or aluminum cap.<br />

6 Electrical Relay/Fuse Panel inside the engine compartment<br />

is protected internally for additional reliability.<br />

Stainless Steel Hardware replaces corrosion-prone<br />

components on the ladder, platform, battery box, tool box,<br />

kick-out, and mudguard under the cab.<br />

Engine Coolant, Oil Cooler, and Air Conditioner (if equipped)<br />

Cores are treated for extra corrosion protection.<br />

3<br />

1<br />

2<br />

4<br />

5<br />

Before<br />

6<br />

After<br />

6

Additional Options<br />

Choosing the proper options may increase reliability, durability, and component life<br />

expectancy in a corrosive atmosphere.<br />

Air conditioner can be protected by treating<br />

the air conditioner, evaporator, and heater<br />

cores before installation.<br />

Wider Space Radiator is available with six<br />

fins per inch to reduce radiator plugging<br />

from airborne materials. A cooling system<br />

with on-demand fan and trash grill is also<br />

available for applications with severe<br />

airborne debris.<br />

Turbine Pre-cleaner reduces the amount of<br />

corrosive airborne debris entering the engine<br />

air filters by trapping larger particles.<br />

Automatic lubrication system with stainless<br />

steel lines, supplies the required quantity of<br />

grease at the right interval to the grease points<br />

automatically, without manual interference.<br />

Heavy Duty Alternator<br />

is waterproof to reduce<br />

potential corrosion<br />

damage (standard on<br />

<strong>966G</strong>, <strong>972G</strong>, and <strong>980G</strong><br />

anti-corrosion package).<br />

Stainless Steel Brake<br />

Lines replace standard<br />

lines for added protection<br />

against corrosion<br />

(lines shown before<br />

paint process).<br />

Cat Turbine Precleaner<br />

This trash precleaner<br />

provides efficient and<br />

cost effective cleaning<br />

of air intake, featuring<br />

an additional filtering<br />

screen.<br />

HEHL5383 (04/2000) hr<br />

Materials and specifications are subject to change without notice.<br />

Featured machines in photos may include additional equipment.<br />

See your Caterpillar dealer for available options.<br />

www.CAT.com<br />

© 2000 Caterpillar<br />

®