Rust Veto 310 - Southern Lubricants

Rust Veto 310 - Southern Lubricants

Rust Veto 310 - Southern Lubricants

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Rust</strong> <strong>Veto</strong> <strong>310</strong><br />

Multi-purpose water-dilutable rust preventive concentrate<br />

DESCRIPTION<br />

ADVANTAGES<br />

<strong>Rust</strong> <strong>Veto</strong> <strong>310</strong> is a multi-purpose rust preventive used either<br />

neat or mixed with water to provide a wide range of rust<br />

preventive requirements. <strong>Rust</strong> <strong>Veto</strong> <strong>310</strong> contains rust<br />

inhibiting additives and emulsifiers which when mixed with<br />

water provides a versatile non-flammable emulsion.<br />

<strong>Rust</strong> <strong>Veto</strong> <strong>310</strong> emulsions eliminate fire hazards and improve<br />

plant safety and environmental conditions by replacing<br />

solvent based rust preventives in many applications.<br />

APPLICATION<br />

<strong>Rust</strong> <strong>Veto</strong> <strong>310</strong> is generally mixed with water at<br />

concentrations ranging from 5% to 25% depending upon the<br />

specific application. The thin oily film provided by <strong>Rust</strong> <strong>Veto</strong><br />

<strong>310</strong> emulsions provides excellent corrosion protection during<br />

indoor storage but can also be used neat to give extended<br />

corrosion protection.<br />

15% to 25% emulsions provide an alternative to conventional<br />

solvent or mineral oil based products. Applications include<br />

dewatering, inter-operational protection and final protection<br />

of finished parts during indoor storage, packing and<br />

shipment.<br />

10% to 15% emulsions can be used for the protection of<br />

steel strip after pickling or as a final pass for rolling sheet<br />

steel.<br />

5% to 10% emulsions are suitable for use as the final rinse<br />

stage in chemical treatment or cleaning operations to provide<br />

short-term protection.<br />

RECOMMENDATION FOR USE<br />

Emulsions can easily be prepared by adding the required<br />

amount of <strong>Rust</strong> <strong>Veto</strong> <strong>310</strong> to water and stirring continuously.<br />

<strong>Rust</strong> <strong>Veto</strong> <strong>310</strong> emulsions can be applied by dipping, spraying<br />

or brushing, or in the final stage of a power washing plant.<br />

<strong>Rust</strong> <strong>Veto</strong> <strong>310</strong> emulsions can be used at temperatures<br />

ranging from ambient to 80ºC. Whilst a drying time of 1 to 2<br />

hours can be expected when used at ambient temperature<br />

more rapid drying will be obtained at higher temperatures.<br />

When left to stand an oil/cream layer may form on the<br />

surface, constant mild agitation is therefore recommended<br />

during application. If applied to internal surfaces i.e. tubes,<br />

pumps etc. <strong>Rust</strong> <strong>Veto</strong> <strong>310</strong> emulsions should be allowed to dry<br />

thoroughly before components are subsequently sealed or<br />

capped. Warm air circulation will facilitate drying.<br />

Concentration control of <strong>Rust</strong> <strong>Veto</strong> <strong>310</strong> emulsions can be<br />

achieved by refractive index measurement or acid splitting<br />

techniques.<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

Free from VOC’S<br />

Non-flammable emulsions eliminate fire hazards<br />

Improves plant safety by replacing solvent based rust<br />

preventives<br />

Economical in use<br />

Extremely versatile in application<br />

Short-term inter-operational protection up to long-term<br />

indoor protection depending upon concentration<br />

Resistant to microbial attack<br />

Possesses water displacing characteristics<br />

Thin oily film<br />

Readily applied<br />

Easily removed by solvents or alkaline cleaners<br />

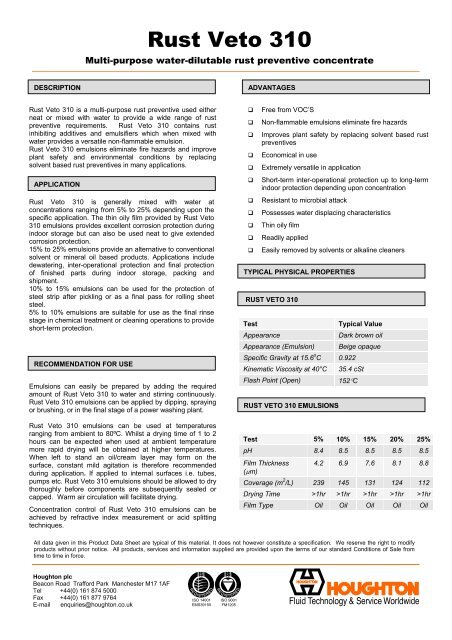

TYPICAL PHYSICAL PROPERTIES<br />

RUST VETO <strong>310</strong><br />

Test<br />

Appearance<br />

Appearance (Emulsion)<br />

Specific Gravity at 15.6 o C 0.922<br />

Kinematic Viscosity at 40°C<br />

RUST VETO <strong>310</strong> EMULSIONS<br />

Typical Value<br />

Dark brown oil<br />

Beige opaque<br />

35.4 cSt<br />

Flash Point (Open) 152°C<br />

Test 5% 10% 15% 20% 25%<br />

pH 8.4 8.5 8.5 8.5 8.5<br />

Film Thickness<br />

(µm)<br />

4.2 6.9 7.6 8.1 8.8<br />

Coverage (m 2 /L) 239 145 131 124 112<br />

Drying Time >1hr >1hr >1hr >1hr >1hr<br />

Film Type Oil Oil Oil Oil Oil<br />

All data given in this Product Data Sheet are typical of this material. It does not however constitute a specification. We reserve the right to modify<br />

products without prior notice. All products, services and information supplied are provided upon the terms of our standard Conditions of Sale from<br />

time to time in force.<br />

Houghton plc<br />

Beacon Road Trafford Park Manchester M17 1AF<br />

Tel +44(0) 161 874 5000<br />

Fax +44(0) 161 877 9764<br />

E-mail enquiries@houghton.co.uk<br />

21 HI

REMOVAL AND STORAGE<br />

HEALTH AND SAFETY<br />

<strong>Rust</strong> <strong>Veto</strong> <strong>310</strong> should be stored indoors, preferably at a<br />

temperature of 10 to 25ºC, and freezing should be avoided.<br />

Tops should be replaced on all containers when marked with<br />

the contents and should be used in delivery rotation.<br />

The recommended shelf life for <strong>Rust</strong> <strong>Veto</strong> <strong>310</strong> is 12 months<br />

If required <strong>Rust</strong> <strong>Veto</strong> <strong>310</strong> can be removed from components<br />

using one of the comprehensive range of Houghton cleaners.<br />

Details of both the Houghto-Clean Series and concentration<br />

control test methods are readily available on request.<br />

Health and Safety Data Sheets are supplied to customers to<br />

comply with Section 6 of the Health and Safety at Work Act<br />

1974, and should be closely studied prior to handling or use<br />

of the product. Copies are available from your Technical<br />

Health and Safety Officer. Various other advisory<br />

publications are available from the Health and Safety<br />

Executive and Her Majesty's Stationery Office<br />

68<strong>310</strong><br />

09/05<br />

Houghton plc<br />

Beacon Road Trafford Park<br />

Manchester M17 1AF<br />

Tel 0161 874 5000<br />

Fax 0161 877 9764<br />

e-mail enquiries@houghton.co.uk<br />

All data given in this Product Data Sheet are typical of this<br />

material. It does not however constitute a specification. We<br />

reserve the right to modify products without prior notice. All<br />

products, services and information supplied are provided upon<br />

the terms of our standard Conditions of Sale from time to time<br />

in force.