Workshop Brochure - Society of Petroleum Engineers

Workshop Brochure - Society of Petroleum Engineers

Workshop Brochure - Society of Petroleum Engineers

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Early Bird Registration Deadline:<br />

5 October 2012<br />

<strong>Society</strong> <strong>of</strong> <strong>Petroleum</strong> <strong>Engineers</strong><br />

20–21 November 2012 | Amwaj Rotana Hotel | Dubai, UAE<br />

SPE Applied Technology <strong>Workshop</strong><br />

Flow Assurance and Production Chemistry:<br />

Finding Integrated Solutions Across the Value Chain<br />

Who Should Attend<br />

• <strong>Petroleum</strong> and Process <strong>Engineers</strong><br />

• Production <strong>Engineers</strong> and Chemists<br />

• Reservoir <strong>Engineers</strong><br />

• Petrophysicists<br />

• Geoscientists<br />

• Lab Technicians<br />

• Interested Managers, Specialists, and<br />

<strong>Engineers</strong> from Exploration and Appraisal,<br />

Field Development Planning and<br />

Production<br />

Committee Members<br />

Co-Chairperson<br />

Morten Stenhaug<br />

Schlumberger<br />

Co-Chairperson<br />

Sanjay Misra<br />

ADCO<br />

Alistair Strachan<br />

Baker Hughes<br />

Ardian Nengkoda<br />

<strong>Petroleum</strong> Development Oman<br />

Bader Al Harbi<br />

Saudi Aramco<br />

Daniel Merino Garcia<br />

Repsol<br />

Dennis Naafs<br />

Shell<br />

Francisco Vargas<br />

The <strong>Petroleum</strong> Institute<br />

Ghada Basssioni<br />

The <strong>Petroleum</strong> Institute/Ain Shams<br />

University, Egypt<br />

Hua Guan<br />

M-I Swaco<br />

Jamal Al Ashhab<br />

ZADCO<br />

Martijn Huijgen<br />

Champion Technologies<br />

Myles Jordan<br />

NALCO<br />

Ping Chen<br />

Champion Technologies<br />

Solomon Lekia<br />

Chevron<br />

<strong>Workshop</strong> Abstract<br />

Flow assurance is anticipating, preventing, and mitigating problems from borehole to refinery which<br />

come in the way <strong>of</strong> realising production potential <strong>of</strong> an asset. Multiphase flow modelling has enabled<br />

our understanding <strong>of</strong> fluid flow behaviour in large networks. Recent advances in dynamic/transient<br />

modelling have opened new vistas <strong>of</strong> technology applications. Deep water developments have pushed<br />

us to hereto unchartered part <strong>of</strong> the phase envelope. Debottlenecking single and multiphase flow<br />

problems in the well, process, and line transport like capacity utilisation, unstable flow, slugging,<br />

foaming, and well loading are being understood with great curiosity. The challenges call for developing<br />

novel engineering and chemical solutions. The age old discipline <strong>of</strong> production chemistry is very much<br />

intertwined with flow assurance. It deals with lab studies like PVT analyses, crude assays, chemical<br />

evaluation, environmental monitoring on one hand and finding novel techno-economic chemical<br />

applications for process and flow assurance problems on the other. PVT analysis combined with<br />

robust sampling techniques, solid dropout measurements, gas and CO 2<br />

flooding experiments, paraffin<br />

and asphaltenes depositional modelling, heavy fraction characterisation has created new awakening<br />

among the development engineers. Historically the domain <strong>of</strong> production chemistry was limited to<br />

demulsification, deoiling, corrosion mitigation, water treatment, and gas dehydrating and sweetening.<br />

But new challenges in the form <strong>of</strong> scales, asphaltenes, wax and naphthenates deposition, wax and<br />

heavy oil related transport problems, drag reduction, multiphase pumping, gas hydrates, tank bottom<br />

sludge, organic matter remediation, environmental compliance, and problems in deep sea developments<br />

has opened new challenges for the production chemists to develop cost effective chemistries and<br />

applications. Maturing fields and heavy oil developments involving steam injection has not only caused<br />

problems <strong>of</strong> large water handling but adequate treatment strategies. Many issues in the realm <strong>of</strong> heavy<br />

oil flow assurance demand innovative solutions to achieve economies <strong>of</strong> scale.<br />

This workshop will cover the entire spectrum <strong>of</strong> areas related with flow assurance and related<br />

production chemistry in the form <strong>of</strong> six interactive sessions. It will provide an excellent opportunity for<br />

process, development, production, petroleum and reservoir engineers, geoscientists, flow assurance<br />

experts, and production chemists to discuss emerging trends in technologies and solutions. Recent<br />

advances in laboratory measurements, new modelling approaches, novel chemical applications, and<br />

integrated solutions will be discussed in the form <strong>of</strong> case studies and trend setting research paradigms<br />

to stimulate discussion by industry experts.<br />

www.spe.org/events/12adu7

WORKSHOP<br />

Flow Assurance and Production Chemistry:<br />

Finding Integrated Solutions Across the Value Chain<br />

Sponsorship Support<br />

Sponsorship support helps <strong>of</strong>fset the<br />

cost <strong>of</strong> producing workshops and<br />

allows SPE to keep the attendance<br />

price within reach <strong>of</strong> operations-level<br />

individuals, those who benefit most<br />

from these technical workshops.<br />

Sponsors benefit both directly and<br />

indirectly by having their names<br />

associated with a specific workshop.<br />

While SPE prohibits any type <strong>of</strong><br />

commercialism within the conference<br />

hall itself, the society recognises that<br />

sponsoring companies <strong>of</strong>fer valuable<br />

information to attendees outside the<br />

technical sessions.<br />

Sponsorship Categories<br />

Sponsorships are <strong>of</strong>fered on a first<br />

come basis. Please contact SPE to<br />

verify the availability <strong>of</strong> a particular<br />

sponsorship. Existing sponsors<br />

have the opportunity to renew the<br />

same level <strong>of</strong> sponsorship for annual<br />

workshops. Sponsorship packages<br />

remaining are as follows:<br />

• Gold<br />

• Silver<br />

• Luncheons—Per Day<br />

• C<strong>of</strong>fee Breaks—Per Day<br />

• Audio-Visual Equipment<br />

Sponsorship Benefits<br />

In addition to onsite recognition; SPE<br />

will recognise sponsors on the SPE<br />

website and in all printed material<br />

for the workshop. Based on the<br />

sponsorship selected, sponsoring<br />

companies can also receive logo<br />

visibility on promotional workshop<br />

items.<br />

For More Information<br />

For a detailed list <strong>of</strong> available<br />

sponsorships, including benefits<br />

and pricing, contact Norvie Tungcul at<br />

ntungcul@spe.org.<br />

SAVE USD 700<br />

BY REGISTERING<br />

BEFORE<br />

5 OCTOBER 2012<br />

<strong>Workshop</strong> Sponsors<br />

Gold Sponsor<br />

Schedule<br />

Tuesday, 20 November 2012<br />

0800–0845 hours Welcome Refreshments, Registration, and Badge Collection<br />

0845–0900 hours Hotel Safety/Security Briefing/Co-Chair’s Welcome Remarks<br />

0900–0920 hours Opening Keynote Address<br />

0920–1100 hours Session 1: Prevention and Remediation <strong>of</strong> Flow Assurance Issues Caused by Inorganic/<br />

Organic Scales, NORM, and Corrosion<br />

Session Chairs: Jamal Al Ashhab, ZADCO; Bader Al Harbi, Saudi Aramco<br />

Organic scales, e.g. wax, asphaltene, and inorganic scales such as calcium carbonate, barium sulphate, and iron sulphide<br />

have been recognised as one <strong>of</strong> the most potential problems encountered in production wells. These scales can block<br />

the perforations, valves, tubing, and surface facilities and subsequently reduce the production significantly. Additionally,<br />

NORM materials create HSE concerns during production, transport, and decommissioning stages. This session intends to<br />

explore all aspects <strong>of</strong> these flow assurance issues from their formation/inhibition and damage mechanisms to prevention/<br />

remediation and stimulation techniques. We welcome presentations in the areas <strong>of</strong> innovative laboratory studies, the use<br />

<strong>of</strong> simulation tools, and field case histories. There will be a breakout session after the presentations to give attendees the<br />

opportunity to share and discuss a range <strong>of</strong> topics pertaining to inorganic and organic scales and the treatment <strong>of</strong> NORM.<br />

1100–1120 hours C<strong>of</strong>fee Break/Group Photo<br />

1120–1300 hours Session 2: Flow Modelling and Network Analysis–Pursuing a Systematic Approach<br />

Session Chairs: Ping Chen, Champion Technologies; Sanjay Mirsa, ADCO<br />

Flow assurance for a field life cycle is very important considering variations in the production volumes and compositions<br />

in terms <strong>of</strong> water cut and GOR. Multi-phase flow modelling and network analysis provide essential tools for FFD and<br />

facility design. Nodal analysis provides accurate answers to our well productivity issues as well as field production<br />

optimisation. Robust correlations are essential to cover full spectrum <strong>of</strong> flow variations and temperature regimes.<br />

Future bottlenecks can be anticipated and mitigating strategies can be planned. Deep sea developments have created<br />

a vistas flow assurance challenges in terms <strong>of</strong> unstable flow and hydrate formation. Accurate prediction <strong>of</strong> potential<br />

challenges becomes essential as tremendous capital costs are involved in such developments. Recent developments in<br />

understanding unstable flow behaviour like slugging and well loading has provided renewed interest in the industry. Limits<br />

<strong>of</strong> the technology had confined us to application <strong>of</strong> wax and asphaltenes precipitation in flow modelling but developments<br />

in depositional modelling <strong>of</strong> these species have unlocked a plethora <strong>of</strong> new interest. In this session we will discuss sound<br />

concepts <strong>of</strong> tackling flow assurance challenges through well analysis, flow modelling, network analysis, and multi-phase<br />

flow behaviour.<br />

1300–1400 hours Luncheon<br />

Silver Sponsor<br />

1400–1540 hours Session 3: Advanced Laboratory and Modelling Techniques for Flow Assurance<br />

Session Chairs: Dennis Naafs, Shell; Francisco Vargas, The <strong>Petroleum</strong> Institute;<br />

Martijn Huijgen, Champion Technologies<br />

The increasing complexity <strong>of</strong> current flow assurance problems has motivated the development <strong>of</strong> novel experimental<br />

procedures and enhanced modelling methods with the intention <strong>of</strong> assessing, predicting, and mitigating these problems.<br />

Some <strong>of</strong> the key elements for a successful assessment <strong>of</strong> potential flow assurance problems are a correct sampling<br />

procedure, accurate PVT techniques, and proper restoration <strong>of</strong> samples to reservoir conditions. It is also very important<br />

to identify and understand the limitations <strong>of</strong> prevalent methods to evaluate the stability <strong>of</strong> organic and inorganic materials<br />

during primary and enhanced recovery. New ideas have emerged that are promising in determining more accurate<br />

experimental values and modelling approaches for predicting the precipitation and deposition <strong>of</strong> organic and inorganic<br />

materials. Upscaling the models to predict the phase separation in reservoir, well, and surface system is an ongoing<br />

challenge that requires a close interaction between the research centres and the members <strong>of</strong> service and operating<br />

companies around the world.<br />

This session will highlight recent advances in understanding the most common flow assurance problems in the region,<br />

new approaches to study, forecast, and treat the formation <strong>of</strong> organic and inorganic deposits at different stages <strong>of</strong> the<br />

oil production and developments in improved correlation between lab data and field results. Experts from the industry<br />

and the academia will present and discuss novel experimental and modelling methods available to assess, predict, and<br />

mitigate these flow assurance problems.<br />

1540–1600 hours C<strong>of</strong>fee Break/Poster Presentation<br />

1600–1645 hours Breakout Session<br />

1645–1700 hours Report-Back Findings/Day 1 Wrap-Up<br />

1800–2000 hours Networking Dinner<br />

20 November<br />

Luncheon Sponsor

Registration Deadline: 5 November 2012<br />

www.spe.org/events/12adu7<br />

General Information<br />

Wednesday, 21 November 2012<br />

0900–1040 hours Session 4: Innovative Technologies and Non-Conventional Solutions for Flow<br />

Assurance in Challenging Environments<br />

Session Chairs: Alistair Strachan, Baker Hughes; Solomon Lekia, Chevron<br />

Flow assurance challenges are common to all onshore/shallow water/deepwater fields; over the years<br />

numerous methods have been applied to tackle specific issues (such as heavy oil not flowing freely, organic/<br />

inorganic deposition, multiphase flow). Control and mitigation methods for flow assurance risks must be<br />

both cost-effective and practical, and standard technologies may become non-optimal solutions in extreme<br />

environments, etc. Innovative technologies (active heating, multiphase boosting, kinetic inhibition) and<br />

non-conventional methods for non-conventional problems are more and more common to find the optimal<br />

strategy to assure deliverability in extreme environmental conditions.<br />

1040–1100 hours C<strong>of</strong>fee Break/Poster Presentation<br />

1100–1240 hours Session 5: Online Production Monitoring Systems and Optimisation and<br />

Debottlenecking in Flow System<br />

Session Chairs: Hua Guan, M-I Swaco; Morten Stenhaug, Schlumberger<br />

This session intends to encourage the sharing <strong>of</strong> experiences and best practices in the areas <strong>of</strong> real-time<br />

monitoring, optimisation, and debottlenecking <strong>of</strong> production systems. With the advancement in data<br />

acquisition and modelling, fields are increasingly monitored online, for example, the implementation <strong>of</strong> smart<br />

wells, virtual metering, integrated production system modelling and many predictive tools allow the wells<br />

and facilities to be monitored in real time; potential problems are identified with early warnings; subsequent<br />

proactive actions can be made such as debottlenecking, re-routing <strong>of</strong> wells, changing operation parameters<br />

(e.g. pressure); and opportunities for production optimisation are identified. This session welcomes abstracts<br />

covering the development <strong>of</strong> technologies and field case histories addressing flow assurance issues such as<br />

slugging, hydrate, rheology, gas well unloading, flow improvers, drag reducers, and back pressure.<br />

1240–1330 hours Luncheon<br />

1330–1510 hours Session 6: Chemical Treatment–Economical and Environmental Aspects<br />

Session Chairs: Ardian Nengkoda, <strong>Petroleum</strong> Development Oman;<br />

Ghada Bassioni, The <strong>Petroleum</strong> Institute/Ain Shams University, Egypt<br />

Global oilfield chemical demand will rise 8.6 percent annually through 2014, driven by a recovery in the oil<br />

and gas industry (EOR and unconventional production) and higher oil and gas prices. Naturally, crude oil<br />

and gas are emerging from the well with a considerable range and variation <strong>of</strong> both physical properties and<br />

chemical constituents. Some organic and inorganic deposits, emulsions, corrosion products, however, have<br />

a negative impact on quality, safety, the ability <strong>of</strong> a well to continue to produce and the ability <strong>of</strong> the refinery<br />

to handle the output and consequently on cost. Application <strong>of</strong> chemicals becomes essential in terms <strong>of</strong> flow<br />

assurance risk mitigation, however:<br />

• Chemicals can be rather expensive (OPEX)<br />

• Applying chemicals can be labour intensive<br />

• Chemicals <strong>of</strong>ten have a negative impact on the environment when disposed<br />

Best practices suggest for the above reasons that chemicals should only be applied as necessarily needed.<br />

Moreover, in order to select the most effective chemical the problem at hand has to be fully identified. This<br />

session will discuss chemical treatment practices, case studies, the life cycle starting with laboratory testing<br />

through performance monitoring, effective treatment processes (dehydration, produced water treatment,<br />

reservoir souring mitigation) and compliance to the environment.<br />

1510–1530 hours C<strong>of</strong>fee Break/Poster Presentation<br />

1530–1615 hours Breakout Session<br />

1615–1630 hours Report-Back Findings/Day 2 Wrap-Up<br />

<strong>Workshop</strong> Venue<br />

Amwaj Rotana Hotel<br />

Jumeirah Beach Residence<br />

P.O. Box 86834, Dubai, UAE<br />

T: +971.4.428.2000<br />

F: +971.4.434.3666<br />

Website: www.rotana.com<br />

<strong>Workshop</strong> Guidelines<br />

Format<br />

Two (2) days <strong>of</strong> informal discussions prompted by<br />

selected keynote presentations and discussions.<br />

<strong>Workshop</strong>s maximize the exchange <strong>of</strong> ideas among<br />

attendees and presenters through brief technical<br />

presentations followed by extended break-out<br />

sessions and Q&A periods. The majority <strong>of</strong> the<br />

presentations are in the form <strong>of</strong> case studies,<br />

highlighting engineering achievements and lessons<br />

learned.<br />

Documentation<br />

Proceedings from the workshop will not be<br />

published; therefore, formal papers and handouts<br />

are not requested <strong>of</strong> speakers or panel members.<br />

A URL containing released copied <strong>of</strong> the workshop<br />

presentations will be available to attendees within<br />

4–6 weeks following the workshop.<br />

Poster Session<br />

The Steering Committee encourages registrations<br />

from pr<strong>of</strong>essionals who are able to prepare and<br />

present a poster on a relevant project. For further<br />

details kindly contact Norvie Tungcul, event manager<br />

at ntungcul@spe.org<br />

Attendance<br />

Registrations will be accepted on a first-come firstserve<br />

basis. The Steering Committee encourages<br />

attendance from those who can contribute to the<br />

workshop most effectively either in discussions<br />

or with posters. A mix <strong>of</strong> attendees in terms <strong>of</strong><br />

geographic origin, companies and disciplines will be<br />

encouraged.<br />

<strong>Workshop</strong> Deliverables<br />

The Steering Committee will appoint a “scribe”<br />

to record the discussions and to produce the<br />

full workshop report for SPE. This report will<br />

be circulated to all attendees as the workshop<br />

deliverable within 4–6 weeks following the workshop.<br />

The copyright <strong>of</strong> the report is with SPE.<br />

Commercialism<br />

In keeping with ATW objectives and the SPE<br />

mission, commercialism in posters or presentations<br />

will not be permitted. Company logos must be<br />

limited to the title slide and used only to indicate the<br />

affiliation <strong>of</strong> the presenter and other involved in the<br />

work.<br />

Attendance Certificate<br />

All attendees will receive an attendance certificate<br />

attesting to their participation in the workshop.<br />

This certificate will be provided in exchange for a<br />

completed workshop questionnaire.<br />

Continuing Education Units<br />

Attendees at this workshop qualify for SPE<br />

Continuing Education Units (CEU) at the rate <strong>of</strong> 0.1<br />

CEU per hour <strong>of</strong> the <strong>Workshop</strong>.<br />

PLEASE USE INSIDE FORM FOR REGISTRATION

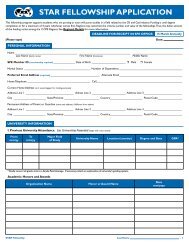

REGISTRATION FORM<br />

Flow Assurance and Production Chemistry: Finding Integrated Solutions Across the Value Chain<br />

20–21 November 2012, Amwaj Rotana Hotel, Dubai, UAE<br />

Important: Attendance is limited and is not guaranteed. Early registration is recommended. Please print or type in black ink.<br />

Registration Fee MUST be paid in advance for attending the Applied Technology <strong>Workshop</strong>.<br />

First Name/Forename__________________________________________________ Middle Name___________________________________________________<br />

Last/Family Name________________________________________________________________________________________ SPE Member? ❒ Yes ❒ No<br />

Member No.__________________________________________ Job Title_____________________________________________________________________<br />

Company/Organisation_______________________________________________________________________________________________________________<br />

Street or P.O. Box Number_____________________________________________________________________ City___________________________________<br />

State/Province___________________________________ Zip/Postal Code___________________________ Country___________________________________<br />

Telephone____________________________________________ Facsimile<br />

Email (required)____________________________________________________________________________________________________________________<br />

Applied Technology<br />

WORKSHOP<br />

<strong>Workshop</strong> Fee: Before 5 October 2012 ❒ USD 1,150 for SPE Members ❒ USD 1,350 for Nonmembers<br />

After 5 October 2012 ❒ USD 1,850 for SPE Members ❒ USD 2,050 for Nonmembers<br />

Applied Technology <strong>Workshop</strong> Fee includes: Technical sessions, c<strong>of</strong>fee breaks, luncheons, welcome cocktail reception and dinner (if applicable).<br />

Accommodation is NOT included in the workshop registration fee.<br />

IMPORTANT: All SPE Middle East rates are net <strong>of</strong> taxes. The fees in this form do not include any local or withholding taxes. All such taxes will be added to<br />

the invoice.<br />

Do you wish to present a poster? (subject to selection) ❒ Yes ❒ No<br />

Do you wish to be considered a Discussion Leader? (subject to selection) ❒ Yes ❒ No<br />

If yes, please indicate which subject you would like to present on:<br />

Credit Card (Check One): ❒ American Express ❒ MasterCard ❒ Visa<br />

NO REFUNDS will be granted on cancellations on or after 13 November 2010.<br />

Card Number (will be billed through <strong>Society</strong> <strong>of</strong> <strong>Petroleum</strong> <strong>Engineers</strong>) Expiration Date (mm/yy) Security Code<br />

Name <strong>of</strong> Credit Card Holder (printed) _________________________________________________________________________________________________<br />

Signature (required)___________________________________________________________________________ Date_______________________________<br />

Please inform us <strong>of</strong> mobility or special dietary needs_____________________________________________________________________________________<br />

Payment by Bank Transfer: IMPORTANT - For reference: Please quote “12ADU7” and name <strong>of</strong> delegate<br />

Make Payment to: HSBC Bank Middle East Ltd, Jebel Ali Branch, P.O. Box 66, Dubai, UAE<br />

Account Name: SPE Middle East DMCC Account Number: 036-217131-100 Swift Code: BBMEAEAD<br />

IBAN Code: 180200000036217131100<br />

Cancellation and Refund Policy:<br />

• A processing fee <strong>of</strong> USD 100 will be charged for cancellations received before the registration deadline 5 November 2012.<br />

• For cancellations received after the registration deadline, 5 November 2012, 25% refund will be made to the registrant.<br />

• No refund on cancellations received within seven (7) days prior to the workshop dates, i.e. on or after 13 November 2012.<br />

• No refund will be issued if a registrant fails to attend the workshop.<br />

Not an SPE Member?<br />

Join SPE when you register and<br />

save money by paying the lower<br />

member registration fee.<br />

A portion <strong>of</strong> your dues is<br />

allocated to a JPT subscription<br />

and is not deductible or refundable.<br />

Visa:<br />

SPE Middle East, North Africa, and India will assist in providing a visa invitation letter, upon request in writing, to confirmed registrants after receiving full payment <strong>of</strong> registration<br />

fees. Visa invitation letters take five days to issue from the date <strong>of</strong> request and it is the course attendee’s responsibility to obtain their own visa. SPE cannot issue the visa nor can we<br />

guarantee it will be obtained.<br />

For questions or additional information contact: Norvie Tungcul at ntungcul@spe.org.<br />

To submit your registration online, please visit the event’s website at: www.spe.org/events/12adu7.<br />

Alternatively, you can email this form to: formsdubai@spe.org, or fax it to: +971.4.451.3164.<br />

12ADU7