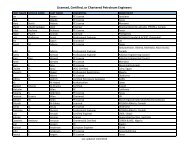

The Use of Risk Analysis in Design

The Use of Risk Analysis in Design

The Use of Risk Analysis in Design

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

SPE-121065<br />

<strong>The</strong> <strong>Use</strong> <strong>of</strong> <strong>Risk</strong> <strong>Analysis</strong> <strong>in</strong><br />

<strong>Design</strong><br />

Safety Aspects Related to the<br />

<strong>Design</strong> and Operation <strong>of</strong> a FPSO<br />

Lars Tronstad, StatoilHydro

Contents<br />

• Introduction<br />

• Challenges with FPSOs<br />

• <strong>Risk</strong> analysis <strong>in</strong> design<br />

• Safety Aspects<br />

• Asgard FPSO experience

Challenges with FPSOs<br />

Position<strong>in</strong>g<br />

Safety - Technical<br />

Telemetry<br />

Green l<strong>in</strong>e<br />

Tank atmosphere<br />

Safety - Operation<br />

Stability<br />

Area surveilance<br />

Stern <strong>of</strong>ftake<br />

Swivel<br />

Pitch/roll<br />

Green sea<br />

Cargo operation<br />

Sea chests<br />

Cargo system<br />

Pumps<br />

Pump room<br />

Hull design<br />

Ballast system<br />

Valves<br />

L<strong>in</strong>es<br />

Turret<br />

Cargo system<br />

Flexible risers<br />

Anchor<strong>in</strong>g

Asgard FPSO data<br />

•Length: 278 m<br />

•Breadth: 45 m<br />

•Displacement: 184.300<br />

tonnes<br />

•Storage cap.: 910.000 bbl<br />

•Process cap.: 200.000 bbl/d<br />

•On stream: May 1999<br />

•Estimated produc<strong>in</strong>g life: 20<br />

yrs

Barents sea<br />

Norwegian Sea<br />

Tromsøflaket<br />

Harstad<br />

• Outside Mid-<br />

Norway<br />

Asgard field<br />

• Location <strong>of</strong> Asgard<br />

Stjørdal<br />

Bergen<br />

Stavanger<br />

North Sea

Asgard - Schematic Field Layout<br />

S3<br />

MORVIN<br />

Morv<strong>in</strong> 10.5”<br />

20.1 km w/DEH<br />

Morv<strong>in</strong> 5” -15<br />

km Gas <strong>in</strong>jection<br />

FLOWLINE<br />

BUNDLE AS03 :<br />

G-101, I-101, I-102<br />

F-103<br />

F<br />

E<br />

F-201<br />

TEMPLATE LEGEND:<br />

Oil Production<br />

Gas Production<br />

K-102<br />

STIFS<br />

G<br />

I<br />

G-201<br />

I-201<br />

E-201<br />

E-102<br />

AS03<br />

AS02<br />

12" Condensate<br />

l<strong>in</strong>e from Krist<strong>in</strong><br />

(P-211)<br />

FLOWLINE<br />

BUNDLE:<br />

E-101,F-101,<br />

F-102<br />

Gas Injection<br />

H<br />

HEATING<br />

MEDIUM<br />

MANIFOLD<br />

Umbilical Junction<br />

K<br />

H-201<br />

H-101<br />

H-102<br />

L-102<br />

L-101<br />

L-201<br />

J<br />

K-201<br />

K-101<br />

L<br />

A<br />

B<br />

O-201<br />

J-201<br />

J-102<br />

J-101<br />

AB-103<br />

AB-102<br />

AB-101<br />

42" GAS EXPORT<br />

LINE TO KÅRSTØ.<br />

O<br />

M<br />

N-201<br />

M-101<br />

M-201<br />

P-101<br />

BC-101<br />

EXPORT<br />

RISER<br />

BASE<br />

Åsgard T<br />

P-102<br />

N<br />

Norne Gas<br />

Export -<br />

16"<br />

~126 km<br />

N-101<br />

N-102<br />

C<br />

Norne & Heidrun<br />

Gas Export Pipel<strong>in</strong>es<br />

P<br />

Mikkel 3,5" MEG l<strong>in</strong>e<br />

+<br />

Mikkel Umbilical<br />

ca. 63 km<br />

Q-101<br />

Q-102<br />

R-201<br />

R-102<br />

R-101<br />

Q-201<br />

P-201<br />

R<br />

S-101<br />

S-102<br />

Preferred<br />

Rig Head<strong>in</strong>g<br />

B-401<br />

Heidrun Gas<br />

Export - 16"<br />

~ 40 km<br />

Q<br />

S-201<br />

S<br />

HALTENPIPE, 16"<br />

HEIDRUN FIBRE CABLE<br />

Y-103<br />

X-101<br />

Mikkel A located<br />

28930 m south and<br />

2165 m east <strong>of</strong> the<br />

Midgard Z template.<br />

Q-202<br />

ÅSGARD<br />

Fibre Cable<br />

B-401, Field<br />

Jo<strong>in</strong>t with<br />

Heidrun Fibre<br />

Cable.<br />

Y-102<br />

Y-101<br />

10" Gas <strong>in</strong>jection<br />

to Tyrihans.<br />

X-201<br />

MIKKEL<br />

225 o<br />

Mikkel A<br />

S2<br />

FSM<br />

X<br />

10" ROV<br />

valves<br />

Y-102<br />

Template<br />

slot<br />

position<br />

S1<br />

Yttergryta<br />

20" ROV<br />

valve<br />

Y-201<br />

Y-103<br />

Y<br />

Y-101<br />

S4<br />

10" ROV<br />

valves<br />

18" Mikkel<br />

LINE TO<br />

"Z"<br />

Mikkel 36891 Bmeter<br />

Z<br />

Z-201

Heidrun<br />

Asgard<br />

Midgard<br />

Draugen<br />

42”<br />

Tjeldbergodden<br />

Statfjord<br />

Frigg<br />

Gullfaks<br />

Troll<br />

Kollsnes<br />

Norway<br />

Heimdal<br />

Kårstø<br />

Sleipner<br />

Draupner<br />

St. Fergus<br />

Ek<strong>of</strong>isk<br />

UK<br />

Eur<br />

opipe<br />

Norpipe<br />

Zeepipe Norfra<br />

Zeebrügge<br />

Dunkerque<br />

Emden<br />

Etzel<br />

Germany

Asgard Field

Layout - Mar<strong>in</strong>e loads

FPSO - Turret loads<br />

Jumper<br />

• Load overview:<br />

– Turret weight<br />

– Moor<strong>in</strong>g loads<br />

EV<br />

Stigerør oppheng<br />

Ankerv<strong>in</strong>sj<br />

Swivel<br />

– Riser loads<br />

– Boyancy load<br />

Ship<br />

Turret<br />

Bear<strong>in</strong>gs<br />

– Dynamic loads<br />

– “Added mass” with<br />

Bunn<br />

vessel motion<br />

Anchorl<strong>in</strong>e<br />

Riser<br />

Fairleads

Flexible Risers - Critical<br />

Areas<br />

End connection<br />

area (C<strong>of</strong>lon)<br />

Crack growth<br />

Fatigue<br />

Bend stiffener<br />

area (armour)<br />

Boyancy elements<br />

Hydrolysis<br />

Riser base<br />

Sag bend<br />

area (Rilsan)

FPSO - Load Calculator<br />

Input: Updated light ship condition, loads from anchor l<strong>in</strong>es, risers, variable weights, tank levels,<br />

draught for and aft, w<strong>in</strong>d loads<br />

Output: Stability data, stability marg<strong>in</strong>s, hull bend<strong>in</strong>g moment and shear loads with limit curves

Wave impacts - Lessons<br />

•High forecastle<br />

•Strong w<strong>in</strong>dows<br />

•Solid design fwd

“Green sea” protection<br />

Panels<br />

Cargo deck (tank top)

"Green sea"<br />

panels<br />

Protection panels design:<br />

• prevent green sea damages<br />

• ma<strong>in</strong>ta<strong>in</strong> good ventilation<br />

• m<strong>in</strong>imize explosion risk<br />

• CFD analyses

Gas dispersion and Explosion<br />

modell<strong>in</strong>g<br />

- All areas modelled for optimized layout!

Subsea gas plume –<br />

Buoyancy?<br />

355 kg/s subsea riser rupture (5 m/s w<strong>in</strong>d 15 deg. on port side)

Layout - Segregation

Fire walls/deck<br />

Fire wall/deck

Escape tunnel<br />

Escape tunnel

Escape tunnel

Turret / Swivel area<br />

•Risers<br />

<strong>in</strong>side guide<br />

tubes<br />

• Riser ESV<br />

fireprotecti<br />

on<br />

– 2 hrs jet fire<br />

• Open layout<br />

ESV

Material handl<strong>in</strong>g<br />

• Laydown areas<br />

• Storage areas<br />

• Crane operations<br />

• Crash barriers<br />

• Lift<strong>in</strong>g restrictions

Vessel motions<br />

20m high waves – Large difference <strong>in</strong> heave; semi/fpso

Weather limitations<br />

Helideck:<br />

• Heave<br />

•Pitch<br />

•Roll<br />

• Night flights

Sea fasten<strong>in</strong>g

Offload<strong>in</strong>g

Offload<strong>in</strong>g arrangement<br />

• 20” hose<br />

• 8000 m 3 /h

Offload<strong>in</strong>g arrangement

Offload<strong>in</strong>g arrangement<br />

Challenges:<br />

• Work<strong>in</strong>g<br />

env. issues<br />

• Simpler<br />

handl<strong>in</strong>g<br />

needed

Preferred system

Shuttle tanker – Collision<br />

• Flare stack location<br />

• Aft arrangement<br />

• Tandem operation<br />

risk

Shuttle Tanker Collision aft

Collision aft – Flare stack

• Alarm zones<br />

• Longer <strong>of</strong>fload<strong>in</strong>g hose<br />

• Strict requirements to the shuttle<br />

tankers<br />

Collision avoidance<br />

FPSO<br />

Shuttle tanker<br />

ESD I<br />

ESD II

Collision avoidance<br />

• Strict technical and operative<br />

requirements to the shuttle tankers:<br />

– All shuttle tankers DP2-class<br />

– Several DP reference systems<br />

– Early warn<strong>in</strong>g systems - manual takeover<br />

– At least two DP operators at all times<br />

– DP operator competence<br />

requirements<br />

– Simulator tra<strong>in</strong><strong>in</strong>g for tandem load<strong>in</strong>g

…Long list <strong>of</strong> risk/safety<br />

analyses:<br />

–Concept <strong>Risk</strong> & Emergency Preparedness <strong>Analysis</strong><br />

–<strong>Design</strong> Accidental Load Specification<br />

–Leaks <strong>in</strong>side guide tubes<br />

–FMECA <strong>of</strong> riser system<br />

–Gas dispersion study<br />

–Explosion evaluation report<br />

–Fire risk assessment<br />

–<strong>Risk</strong> related to material handl<strong>in</strong>g<br />

–Qualitative assessment <strong>of</strong> escape and evac.<br />

–Safety eval. <strong>of</strong> essential diesel eng<strong>in</strong>es<br />

–Safety eval. <strong>of</strong> compass thrusters<br />

–Safety review <strong>of</strong> emergency power system<br />

–<strong>Risk</strong> analysis <strong>of</strong> pedestal cranes<br />

–Qualitative analysis <strong>of</strong> ballast system<br />

–Tank explosion frequency assessment<br />

–Quantitative fire and explosion study <strong>of</strong> oil storage systems<br />

–Reliability analysis <strong>of</strong> <strong>in</strong>strumented overpressure protection for cargo tanks<br />

–Passive fire protection optimization<br />

–DP-operations <strong>of</strong> tankers <strong>of</strong>fload<strong>in</strong>g Asgard<br />

–Technical and operational requirements to shuttle tankers serv<strong>in</strong>g Asgard<br />

–Environmental Impact Assessment<br />

–Emergency Preparedness <strong>Analysis</strong><br />

–Quantitative <strong>Risk</strong> Assessment, QRA<br />

–Total <strong>Risk</strong> Assessment, TRA

Safe <strong>Design</strong> - Summary<br />

•Good segregation between HC areas and safe areas<br />

•LQ, evacuation means and HVAC <strong>in</strong>take upw<strong>in</strong>d<br />

•Escape tunnel along the whole ship<br />

•Process area segregated from cargo deck by plated<br />

H-0 deck<br />

•No high pressure HC equipment on cargo deck

Safe <strong>Design</strong> - Summary (contd.)<br />

•Water ballast tanks around the cargo tanks, double<br />

barrier (double hull)<br />

•Open layout <strong>in</strong> modules; reduced explosion risk<br />

•<strong>Design</strong> the aft for shuttle tanker collision<br />

•Include measures for collision avoidance<br />

•Large helideck

Safe <strong>Design</strong> – Summary<br />

(contd.)<br />

•Ship movements must be considered for all material<br />

handl<strong>in</strong>g and storage<br />

•Dropped/ sw<strong>in</strong>g<strong>in</strong>g load barriers<br />

•Lift<strong>in</strong>g above pressurized equipment prohibited<br />

•One must expect green sea <strong>in</strong> bad weather condition;<br />

Personnel should not be present at cargo deck <strong>in</strong><br />

such conditions

FPSO - Experience<br />

transfer<br />

• Workgroup between the FPSO<br />

operators <strong>in</strong> Norwegian and UK:<br />

– Improve FPSO operation and design for<br />

future projects<br />

– Web-site: http://fpso.olf.no/lesson<br />

• OGP: “Guidel<strong>in</strong>e for Manag<strong>in</strong>g<br />

Mar<strong>in</strong>e <strong>Risk</strong>s Associated with<br />

FPSOs”

Conclusions<br />

• Assess risk and safety<br />

– Early<br />

– In all phases<br />

• Gather experience<br />

• Identify all hazards<br />

• Def<strong>in</strong>e safety strategies and<br />

standards<br />

• Follow up with control and<br />

documentation

Conclusions<br />

• <strong>The</strong>re are challenges with<br />

FPSOs, but if properly<br />

designed and operated,<br />

a FPSO is a very safe<br />

concept!

Thank You<br />

for listen<strong>in</strong>g!<br />

Questions?