Wellbore Quality Characterization for Drilling and Casing Running in ...

Wellbore Quality Characterization for Drilling and Casing Running in ...

Wellbore Quality Characterization for Drilling and Casing Running in ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

SPE DISTINGUISHED LECTURER SERIES<br />

is funded pr<strong>in</strong>cipally<br />

through a grant of the<br />

SPE FOUNDATION<br />

The Society gratefully acknowledges<br />

those companies that support the program<br />

by allow<strong>in</strong>g their professionals<br />

to participate as Lecturers.<br />

And special thanks to The American Institute of M<strong>in</strong><strong>in</strong>g, Metallurgical,<br />

p g g<br />

<strong>and</strong> Petroleum Eng<strong>in</strong>eers (AIME) <strong>for</strong> their contribution to the program.

BP EXPLORATION<br />

<strong>Wellbore</strong> <strong>Quality</strong> <strong>Characterization</strong><br />

<strong>for</strong> <strong>Drill<strong>in</strong>g</strong> <strong>and</strong> <strong>Cas<strong>in</strong>g</strong> <strong>Runn<strong>in</strong>g</strong><br />

<strong>in</strong> Challeng<strong>in</strong>g Wells<br />

Dr. Col<strong>in</strong> Mason<br />

Senior <strong>Drill<strong>in</strong>g</strong> Specialist<br />

Sunbury-on-Thames<br />

United K<strong>in</strong>gdom<br />

Telephone: +44 1932 739518<br />

Email: masoncj@bp.com

Lecture Overview<br />

‣ Introduction<br />

‣ Def<strong>in</strong>ition<br />

‣ Measur<strong>in</strong>g wellbore quality<br />

‣ Manag<strong>in</strong>g wellbore quality<br />

‣ Field case studies<br />

‣ Conclusions

Introduction<br />

‣ "<strong>Wellbore</strong> quality" common oilfield concept<br />

‣ Often associated with directional drill<strong>in</strong>g<br />

‣ Often l<strong>in</strong>ked with per<strong>for</strong>mance improvements<br />

‣ Diverse <strong>in</strong>terpretations <strong>for</strong> each discipl<strong>in</strong>e<br />

‣ No unique def<strong>in</strong>ition exists<br />

‣ No proven method of measurement exist<br />

‣ Context: <strong>Drill<strong>in</strong>g</strong> <strong>and</strong> Completions

<strong>Wellbore</strong> <strong>Quality</strong> Parameters<br />

Attribute<br />

Influenced by<br />

Tortuosity<br />

Directional driller<br />

<strong>Wellbore</strong> spirall<strong>in</strong>g<br />

Directional drill<strong>in</strong>g BHA<br />

Cutt<strong>in</strong>gs bed <strong>Drill<strong>in</strong>g</strong> practices<br />

Ledg<strong>in</strong>g<br />

<strong>Drill<strong>in</strong>g</strong> practices / environment<br />

Lost circulation <strong>Drill<strong>in</strong>g</strong> practices / environment<br />

<strong>Wellbore</strong> breakout<br />

Mud weight / exposure time<br />

Formation damage Mud type / mud properties<br />

Target hole size<br />

Plann<strong>in</strong>g / Learn<strong>in</strong>g<br />

Measurable Chosen methodology

Def<strong>in</strong>ition – <strong>Quality</strong> <strong>Wellbore</strong><br />

‣ Straight wellbore – m<strong>in</strong>imal tortuosity <strong>and</strong><br />

m<strong>in</strong>imal hole spirall<strong>in</strong>g (micro-tortuosity)<br />

‣ Round gauge hole – m<strong>in</strong>imal wellbore break-out,<br />

no wash-outs <strong>and</strong> hole not undergauge<br />

‣ Smooth wellbore – m<strong>in</strong>imal ledg<strong>in</strong>g<br />

‣ Clean hole – m<strong>in</strong>imal residual cutt<strong>in</strong>gs bed<br />

‣ Integrity – no leakage, no <strong>for</strong>mation damage<br />

‣ Fit <strong>for</strong> purpose – cas<strong>in</strong>g or logs will run to depth

Benefits – <strong>Quality</strong> <strong>Wellbore</strong><br />

‣ Improved weight transfer – better ROP<br />

‣ Good hole clean<strong>in</strong>g – gauge g<br />

hole<br />

‣ Lower vibration – constant drill<strong>in</strong>g parameters<br />

‣ Trouble-free trips & cas<strong>in</strong>g runs – gauge g<br />

hole<br />

‣ Better log quality – gauge, non-spiralled hole<br />

‣ Competent cement bond – gauge hole<br />

‣ Reduced torque <strong>and</strong> drag – low tortuosity

Influences: Subsurface Environment<br />

Geology <strong>in</strong>fluences wellbore quality<br />

‣ Pore Pressure / Fracture Gradient<br />

‣ Geothermal Gradient<br />

‣ Formation Types<br />

‣ Rock Strength<br />

‣ Stress Orientation<br />

‣ Fractures / Fault<strong>in</strong>g<br />

‣ Life of field issues – depletion

Influences: <strong>Wellbore</strong> Placement<br />

‣ Wellpath selection<br />

‣ Tortuosity (planned versus actual)<br />

0<br />

M13<br />

M04<br />

TVD<br />

BRT (ft)<br />

5,000<br />

M17<br />

M10<br />

F18<br />

F19<br />

M12<br />

M08<br />

F20<br />

M07<br />

M01<br />

F21<br />

M18<br />

M06<br />

M15z<br />

M03 M02<br />

M09<br />

M15<br />

M05<br />

M14<br />

M11<br />

M16<br />

10,000000<br />

0 5,000 10,000 15,000 20,000 25,000 30,000 35,000 40,000<br />

Equivalent Departure (ft)

Influences: Mud System<br />

In this application an OBM is needed to stabilise a shale

Influences: Directional <strong>Drill<strong>in</strong>g</strong> Tools<br />

Rotary Steerable Tool<br />

Long<br />

gauge<br />

PDC<br />

bit<br />

Steerable Motor<br />

Tricone Bit

Hole Spirall<strong>in</strong>g – Introduction<br />

‣ Hole spirall<strong>in</strong>g exists <strong>in</strong> most wells<br />

‣ Pitch, amplitude, drift, gauge – key parameters<br />

‣ Negatively impacts drill<strong>in</strong>g <strong>and</strong> completion operations<br />

‣ Usually can be detected from logs<br />

‣ Effects more pronounced <strong>in</strong> horizontal / ERD wells<br />

‣ Long gauge bits – tend to help reduce spirall<strong>in</strong>g

Hole Spirall<strong>in</strong>g – Imag<strong>in</strong>g

Hole Spirall<strong>in</strong>g – Image Log<br />

Image Log<br />

shows<br />

Spiral<br />

Hole from<br />

PDM <strong>and</strong><br />

RSS<br />

(Cannot be<br />

seen <strong>in</strong><br />

Survey)

Limitation of MWD Survey Tools<br />

MWD survey tool crosses the trough or valley of a spiral hole.<br />

Incl<strong>in</strong>ation <strong>and</strong> direction of the drift is be<strong>in</strong>g measured.<br />

This effect is called “micro-tortuosity”

Problems associated with a Spiralled Hole<br />

Reduced Drift<br />

Higher friction <strong>for</strong>ces, higher T&D<br />

Lower ROP, poor weight transfer<br />

<strong>Cas<strong>in</strong>g</strong> hangs up<br />

Ambiguous log response<br />

Cutt<strong>in</strong>gs Bed Traps<br />

Poor hole clean<strong>in</strong>g<br />

Backream<strong>in</strong>g <strong>and</strong> short trips<br />

Stuck pipe<br />

Poor cement job<br />

Unstable bit<br />

Higher vibration<br />

More tool failures<br />

Shortened bit life<br />

More trips

Spirall<strong>in</strong>g results from Unstable Bit<br />

Conf<strong>in</strong>ed by<br />

high-side<br />

troughs<br />

Conf<strong>in</strong>ed by<br />

low-side<br />

peaks<br />

How Spirall<strong>in</strong>g is Created

Measur<strong>in</strong>g <strong>Wellbore</strong> <strong>Quality</strong><br />

‣ Explicit methods – physical measurements<br />

– <strong>in</strong>dividual measures possible<br />

– difficult to <strong>in</strong>terpret <strong>in</strong> terms of wellbore quality<br />

– specific examples illustrated<br />

‣ Implicit methods – <strong>in</strong>direct measurements<br />

– measure responses to wellbore quality<br />

– Illustrated by analogy <strong>and</strong> applications

Measur<strong>in</strong>g <strong>Wellbore</strong> <strong>Quality</strong><br />

Explicit Methods<br />

‣ Drift – caliper logs<br />

‣ Surface f<strong>in</strong>ish – <strong>in</strong>ferred from image logs<br />

‣ Micro-tortuosity / spirall<strong>in</strong>g – pitch, amplitude<br />

‣ Tortuosity / doglegs – statistical analysis<br />

‣ Pseudo measure – directional difficulty <strong>in</strong>dex

Caliper Logs – <strong>Drill<strong>in</strong>g</strong> vs. Trip-Out<br />

12<br />

11.5<br />

Colville<br />

HRZ<br />

Kuparuk Kuparuk C Miluveach K<strong>in</strong>gak<br />

Colville<br />

11<br />

10.5<br />

Diamete er (<strong>in</strong>s.)<br />

10<br />

95 9.5<br />

9<br />

8.5<br />

8<br />

7.5<br />

Caliper dur<strong>in</strong>g <strong>Drill<strong>in</strong>g</strong><br />

Caliper dur<strong>in</strong>g Trip-Out<br />

7<br />

16,000 16,500 17,000 17,500 18,000 18,500 19,000<br />

Measured Depth (ft)

Measur<strong>in</strong>g <strong>Wellbore</strong> <strong>Quality</strong><br />

Implicit Methods<br />

‣ Require a methodology / philosophy<br />

‣ Identify appropriate response variable<br />

‣ In<strong>for</strong>mation to characterize responses<br />

‣ Analysis <strong>and</strong> <strong>in</strong>terpretation<br />

‣ Scor<strong>in</strong>g / rank<strong>in</strong>g process

Head Trauma Injury Assessment<br />

Scenario<br />

‣ Patient arrives at Emergency Room<br />

‣ Apparent Head Injury<br />

‣ Immediate assessment of bra<strong>in</strong> function needed<br />

‣ No immediate visual assessment possible<br />

– no useful explicit measure<br />

‣ How does the physician carry out the evaluation?<br />

‣ Responses to stimuli are carried out<br />

– implicit measures

Head Trauma Injury Assessment<br />

Three responses<br />

determ<strong>in</strong>e<br />

overall severity<br />

of head trauma<br />

GCS ≥ 13 Mild Bra<strong>in</strong> Injury<br />

GCS = Glasgow Coma Scale<br />

9 ≤ GCS ≤ 12 Moderate Bra<strong>in</strong> Injury<br />

3 ≤ GCS ≤ 8 Severe Bra<strong>in</strong> Injury

The <strong>Wellbore</strong> <strong>Quality</strong> Scorecard (WQS)<br />

Methodology<br />

‣ Technique based on head trauma assessment<br />

‣ <strong>Wellbore</strong> quality <strong>in</strong>ferred from response variables<br />

– drill<strong>in</strong>g, tripp<strong>in</strong>g-out <strong>and</strong> cas<strong>in</strong>g runn<strong>in</strong>g<br />

‣ Primary response variables are T&D parameters<br />

‣ Surface logg<strong>in</strong>g data used to characterize responses<br />

‣ Trend analysis pr<strong>in</strong>cipal evaluation tool<br />

‣ Extent <strong>and</strong> <strong>in</strong>tensity of data variations evaluated

Example – Torque Trend Data<br />

35<br />

30<br />

25<br />

Very low open hole friction factor<br />

<strong>in</strong>dicative of good drill<strong>in</strong>g practices<br />

also OBM used so good lubricity<br />

hole quality considered excellent<br />

Narrow<br />

b<strong>and</strong>width<br />

Torque<br />

(kft.lb)<br />

20<br />

15<br />

10<br />

FF = 0.17/0.11<br />

Surface Torque<br />

Bit Torque<br />

5<br />

0<br />

1,000 2,000 3,000 4,000 5,000 6,000 7,000 8,000 9,000<br />

Measured Depth (m)

<strong>Wellbore</strong> <strong>Quality</strong> Scorecard – Guidel<strong>in</strong>es<br />

<strong>Drill<strong>in</strong>g</strong> Response (5 po<strong>in</strong>ts)<br />

Severe drill<strong>in</strong>g problems<br />

- stuck pipe<br />

- near stuck pipe <strong>in</strong>cident<br />

Score<br />

Transient drill<strong>in</strong>g problems<br />

- poor hole clean<strong>in</strong>g with high cutt<strong>in</strong>gs bed<br />

2<br />

- severe pack-off<br />

2<br />

- severe loss circulation<br />

2<br />

- erratic torque <strong>and</strong> drag response<br />

3<br />

Torque <strong>and</strong> drag response<br />

- all parameters follow smooth trend<br />

- lower than expected torque <strong>and</strong> drag<br />

F<strong>in</strong>al Trip-out Response (7 po<strong>in</strong>ts)<br />

0<br />

1<br />

4<br />

5<br />

Score<br />

Stuck pipe 0<br />

Residual cutt<strong>in</strong>gs bed / differential stick<strong>in</strong>g<br />

- section length with overpulls > 100 klbs<br />

- section length with overpulls > 50 klbs<br />

Ledges<br />

- isolated overpulls > 100 klbs<br />

- isolated overpulls > 50 klbs<br />

1<br />

2<br />

3<br />

4<br />

<strong>Cas<strong>in</strong>g</strong> <strong>Runn<strong>in</strong>g</strong> Response (8 po<strong>in</strong>ts)<br />

Severe cas<strong>in</strong>g runn<strong>in</strong>g problems<br />

- stuck cas<strong>in</strong>g<br />

- cas<strong>in</strong>g pulled due to downhole problems<br />

Score<br />

Differential stick<strong>in</strong>g environment<br />

- static friction > 100 klbs on connections 1<br />

- static friction > 50 klbs on connections 2<br />

Intervention needed dur<strong>in</strong>g cas<strong>in</strong>g run<br />

- unplanned rotation needed<br />

3<br />

- unplanned circulation needed<br />

4<br />

- jo<strong>in</strong>ts wiped to reduce drag 5<br />

<strong>Cas<strong>in</strong>g</strong> run without significant problems<br />

- elevated but smooth drag levels<br />

6<br />

- achieved expected drag levels<br />

7<br />

- better than expected drag levels 8<br />

Transient tripp<strong>in</strong>g-out problems<br />

- loss circulation<br />

5<br />

- unplanned circulation<br />

5<br />

- unplanned ream<strong>in</strong>g <strong>and</strong> back-ream<strong>in</strong>g 5<br />

Drag response<br />

- smooth drag levels measured throughout<br />

- better than expected drag levels recorded<br />

0<br />

0<br />

6<br />

7

<strong>Wellbore</strong> <strong>Quality</strong> Scores – Interpretation<br />

‣ WQS is recorded as a response mnemonic<br />

– D4T5C5 (<strong>Drill<strong>in</strong>g</strong> 4; Tripp<strong>in</strong>g-out 5; <strong>Cas<strong>in</strong>g</strong> <strong>Runn<strong>in</strong>g</strong> 5)<br />

‣ WQS = sum of each response score<br />

0 < WQS ≤ 2 stuck pipe or stuck cas<strong>in</strong>g<br />

2 < WQS ≤ 6 low quality wellbore<br />

6 < WQS ≤ 10 medium wellbore quality<br />

10 < WQS ≤ 14 high wellbore quality<br />

14 < WQS < 20 excellent wellbore quality<br />

WQS = 20<br />

“The Perfect <strong>Wellbore</strong>!”

Case Study – Horizontal Well Norway<br />

26” conductor<br />

@ 486m<br />

13-3/8” shoe<br />

@ 1,521m<br />

Size<br />

<strong>in</strong>s.<br />

Weight<br />

ppf<br />

Grade<br />

Connection<br />

Type<br />

26" 267 X-65<br />

XLC-S<br />

13-3/8" 3/8" 72 P-110<br />

D<strong>in</strong>o Vam<br />

9-5/8"<br />

53.5 5 P-110<br />

New Vam<br />

5½" 32.6 Q-125<br />

Vam Top<br />

Top<br />

TVD RKB<br />

Surface<br />

Surface<br />

Surface<br />

Bottom<br />

TVD RKB<br />

Bottom<br />

MD RKB<br />

478 m 478 m<br />

1443 m 1521 m<br />

2654 m 3200 m<br />

2554 m MD 2516 m 5398 m<br />

5½” TOL<br />

@ 2,554m<br />

Drill 2,198m 8½” horizontal section<br />

Run 2,844m 5½” thick wall l<strong>in</strong>er<br />

9-5/8" shoe<br />

@ 3,200m<br />

5½” shoe<br />

@ 5,398m

Case Study – <strong>Drill<strong>in</strong>g</strong> Response (D3)<br />

50<br />

1,000<br />

Erratic Torque Response<br />

45<br />

BHA 8: RSS + PDC Bit<br />

Vibration problems <strong>in</strong> chalk reservoir<br />

900<br />

40<br />

BHA 9: RSS + PDC Bit<br />

FF=0.20/0.15<br />

800<br />

Str<strong>in</strong>g RPM<br />

35<br />

700<br />

orque (kNm)<br />

Surface T<br />

30<br />

25<br />

20<br />

600<br />

500<br />

400<br />

Str<strong>in</strong>g RPM<br />

15<br />

300<br />

10<br />

200<br />

5<br />

100<br />

0<br />

0<br />

3,100 3,300 3,500 3,700 3,900 4,100 4,300 4,500 4,700 4,900 5,100 5,300 5,500<br />

Measured Depth (m)

Case Study – Tripp<strong>in</strong>g-out Response (T2)<br />

300<br />

Surface Torqu ue (kNm)<br />

250<br />

200<br />

150<br />

BHA 9: Hookload<br />

BHA 9: Surface Torque<br />

Pick-Up: FF=0.15/0.20<br />

Mud Type: OBM<br />

Weight = 1.50 SG<br />

PV = 36 cP<br />

YP = 21 lbf/100ft²<br />

9-5/8" Shoe<br />

@ 3,200m<br />

Elevated Drag<br />

4,400-4,600m<br />

TD @<br />

5,398m<br />

Elevated Drag<br />

5,200-5,400m<br />

Hooklo oad (tonnes) /<br />

100<br />

50<br />

Ream<strong>in</strong>g/Back-ream<strong>in</strong>g<br />

needed to reduce drag<br />

0<br />

0 500 1,000 1,500 2,000 2,500 3,000 3,500 4,000 4,500 5,000 5,500<br />

Measured Depth (m)

Case Study – L<strong>in</strong>er <strong>Runn<strong>in</strong>g</strong> Response (C3)<br />

Ho ookload (tonne es) / Torque (k kNm)<br />

250<br />

200<br />

150<br />

100<br />

67m<br />

453m<br />

2,252m<br />

69m<br />

2,557m<br />

8¼" Reamer Shoe<br />

5" 18.0# Q125 H-125 L<strong>in</strong>er<br />

5" 26.7# Q125 Vam Top HT<br />

5½" 32.6# Q125 Vam Top HT<br />

7" 32.0# P110 Vam Top HT<br />

5½" 26.4# DP 5½" FH<br />

Surface Torque<br />

Hookload<br />

Slack-Off: FF=0.12/0.45<br />

Mud Type: OBM<br />

Weight = 1.50 SG<br />

PV = 35 cP<br />

YP = 19 lbf/100ft²<br />

9-5/8" Shoe<br />

@ 3,200m<br />

Severe Slip stick effect<br />

when runn<strong>in</strong>g l<strong>in</strong>er<br />

L<strong>in</strong>er Shoe<br />

@ 5,398m<br />

50<br />

8¼" solid centraliser on 5" cas<strong>in</strong>g<br />

8" solid centraliser on 5½" cas<strong>in</strong>g<br />

8¼" solid centraliser on 7" cas<strong>in</strong>g<br />

0<br />

0 500 1,000 1,500 2,000 2,500 3,000 3,500 4,000 4,500 5,000 5,500<br />

Measured Depth (m)

Completed <strong>Wellbore</strong> <strong>Quality</strong> Scorecard<br />

Horizontal Well Offshore Norway<br />

WQS<br />

<strong>Drill<strong>in</strong>g</strong> Response (max 5 po<strong>in</strong>ts)<br />

Persistent erratic torque response observed. Observation is <strong>in</strong>dicative of vibration problems<br />

typically seen <strong>in</strong> the chalk reservoir. Vibrations are considered a transient problem <strong>and</strong> should<br />

not significantly impact overall wellbore quality.<br />

Average rotary friction factors of 0.20/0.15 are typical of field-wide torque behaviour.<br />

F<strong>in</strong>al Trip-out Of Hole Response (max 7 po<strong>in</strong>ts)<br />

Elevated drag levels <strong>in</strong> excess of 50klbs are observed from 4,300 to 4,600m <strong>and</strong> from 5,200 to<br />

5,400m <strong>in</strong>dicat<strong>in</strong>g a possible hole clean<strong>in</strong>g problem. Overpulls also occur at chalk / shale<br />

transition zones. A <strong>for</strong>m of slip-stick stick axial drag is also present when tripp<strong>in</strong>g-out through the<br />

open hole section.<br />

Average pick-up friction factors of 0.15/0.20 are typical of field-wide experience.<br />

L<strong>in</strong>er <strong>Runn<strong>in</strong>g</strong> Response (max 8 po<strong>in</strong>ts) 3<br />

L<strong>in</strong>er runn<strong>in</strong>g <strong>in</strong> open hole is far from smooth; significant axial slip-stick stick events observed which<br />

<strong>in</strong>crease <strong>in</strong> <strong>in</strong>tensity with depth. Str<strong>in</strong>g has to be worked significantly over last 600m. Str<strong>in</strong>g<br />

also had to be torqued to overcome tight spots / ledges.<br />

Slack-off friction factors of 0.12/0.45 are <strong>in</strong> l<strong>in</strong>e with field-wide experience.<br />

WQS (D3T2C3)<br />

A score of 8 corresponds to a medium quality wellbore.<br />

3<br />

2<br />

8

Cost vs. <strong>Wellbore</strong> <strong>Quality</strong> Relationship<br />

Field data suggests<br />

Low WQS ⇒<br />

very high D&C costs<br />

ToohighWQS⇒<br />

⇒<br />

higher D&C costs<br />

Well Cost<br />

THE PERFE ECT WELLBORE E!<br />

Optimum WQS ⇒<br />

lowest D&C costs<br />

Tra<strong>in</strong><br />

Wreck<br />

Low<br />

<strong>Quality</strong><br />

Medium<br />

<strong>Quality</strong><br />

High<br />

<strong>Quality</strong><br />

Excellent<br />

<strong>Quality</strong><br />

0 2 4 6 8 10 12 14 16 18 20<br />

WQS

<strong>Wellbore</strong> <strong>Quality</strong> Scorecard<br />

Learn<strong>in</strong>gs<br />

‣ A low WQS does not always equate to poor per<strong>for</strong>mance<br />

‣ A low WQS can be due to degree of difficulty of drill<strong>in</strong>g<br />

<strong>and</strong> cas<strong>in</strong>g runn<strong>in</strong>g <strong>in</strong> that field<br />

‣ Poorly designed cas<strong>in</strong>g run can result <strong>in</strong> failure<br />

‣ Implications of scor<strong>in</strong>g wellbore quality need to be<br />

understood by operators / service companies<br />

‣ <strong>Wellbore</strong> <strong>Quality</strong> has to be managed at field level<br />

‣ Need to underst<strong>and</strong> Cost vs. <strong>Wellbore</strong> <strong>Quality</strong> relationship

Manag<strong>in</strong>g <strong>Wellbore</strong> <strong>Quality</strong><br />

<strong>Drill<strong>in</strong>g</strong> Practices<br />

‣ Operat<strong>in</strong>g Parameters (WOB, RPM, Flow Rate)<br />

‣ Connection practices<br />

‣ Hole clean<strong>in</strong>g practices<br />

‣ Mud weight management<br />

‣ Manag<strong>in</strong>g pack-offs<br />

‣ Vibration management<br />

‣ ECD management

Manag<strong>in</strong>g <strong>Wellbore</strong> <strong>Quality</strong><br />

Tripp<strong>in</strong>g / <strong>Cas<strong>in</strong>g</strong> <strong>Runn<strong>in</strong>g</strong> Practices<br />

‣ Surge <strong>and</strong> Swab Pressure Cycles<br />

– can result <strong>in</strong> rock fatigue<br />

‣ Manag<strong>in</strong>g g<br />

Downhole Problems<br />

– cutt<strong>in</strong>gs bed, ledg<strong>in</strong>g, pack-offs, overpulls<br />

‣ Circulation Losses<br />

– especially dur<strong>in</strong>g cas<strong>in</strong>g runn<strong>in</strong>g

Enhanc<strong>in</strong>g <strong>Wellbore</strong> <strong>Quality</strong><br />

Emerg<strong>in</strong>g Technologies<br />

‣ Cont<strong>in</strong>uous Circulation System<br />

– reduces swab <strong>and</strong> surge cycles <strong>in</strong> well<br />

‣ ECD Reduction<br />

– reduces downhole annular pressures<br />

‣ Fracture Gradient Enhancement<br />

– strengthens wellbore by <strong>for</strong>m<strong>in</strong>g stress cage

<strong>Wellbore</strong> <strong>Quality</strong> <strong>Characterization</strong><br />

Conclusions<br />

‣ <strong>Characterization</strong> important concept<br />

‣ Can reflect degree of difficulty<br />

‣ Most value <strong>for</strong> horizontal <strong>and</strong> ERD wells<br />

‣ Industry st<strong>and</strong>ard def<strong>in</strong>ition needed<br />

‣ Measurement protocol biggest challenge<br />

‣ <strong>Wellbore</strong> quality scorecard promis<strong>in</strong>g technique<br />

‣ Software needed: efficiency, clarity & consistency<br />

‣ <strong>Wellbore</strong> quality enhanc<strong>in</strong>g technology exists

Additional Slides

Hole Spirall<strong>in</strong>g – Inferred from Logs<br />

Log Evidence: Caliper vs. Neutron Porosity vs. Sonic DT

Image Log – 8½” Section

Image Logs – 6-1/8” Hole Spirall<strong>in</strong>g

Image Logs – 6-1/8” Hole Spirall<strong>in</strong>g

<strong>Wellbore</strong> <strong>Quality</strong> vs. Tub<strong>in</strong>g Life<br />

‣ Slant drill<strong>in</strong>g Canada<br />

‣ Heavy Oil Reservoir<br />

‣ Pad <strong>Drill<strong>in</strong>g</strong><br />

‣ 600m TVD

Canada – High DLS Slant Well<br />

Tub<strong>in</strong>g Wear vs. DLS/hole angle <strong>for</strong> high-DLS well<br />

Well on production <strong>for</strong> 2½ months be<strong>for</strong>e failure

Canada – Low DLS Slant Well<br />

Tub<strong>in</strong>g Wear vs. DLS/hole angle <strong>for</strong> low-DLS well<br />

Well on production <strong>for</strong> 21 months be<strong>for</strong>e failure

<strong>Drill<strong>in</strong>g</strong> 12¼” Section – Azerbaijan Well<br />

45 900<br />

40<br />

35<br />

Surface Torque - BHA 7<br />

Surface Torque - BHA6<br />

On-Bottom: FF=0.25/0.30<br />

Off-Bottom: FF=0.25/0.30<br />

Surface RPM<br />

Mud Type: SOBM<br />

Weight = 1.60 SG<br />

PV = 40 cP<br />

YP = 29 lbf/100ft²<br />

800<br />

700<br />

Surface To orque (kft.lb)<br />

30<br />

25<br />

20<br />

15<br />

WOB = 20 klbs<br />

Bit Torque = 5 kft.lb<br />

Flow Rate = 1,000 GPM<br />

600<br />

500<br />

400<br />

300<br />

Str<strong>in</strong>g RPM<br />

10<br />

200<br />

5<br />

100<br />

0<br />

0<br />

1,000 1,500 2,000 2,500 3,000 3,500 4,000 4,500 5,000<br />

Measured Depth (m)

Tripp<strong>in</strong>g-out 12¼” Hole – Azerbaijan Well<br />

500<br />

450<br />

400<br />

Hookload<br />

Pick-Up: FF=0.20/0.20<br />

350<br />

Hooklo oad (klbs)<br />

300<br />

250<br />

200<br />

150<br />

100<br />

50<br />

0<br />

0 500 1,000 1,500 2,000 2,500 3,000 3,500 4,000 4,500 5,000<br />

Measured Depth (m)

<strong>Runn<strong>in</strong>g</strong> 9-5/8” <strong>Cas<strong>in</strong>g</strong> – Azerbaijan Well<br />

800 8<br />

13-3/8" Shoe<br />

@ 1,560m<br />

12-1/4" TD<br />

@ 4,415m<br />

Hooklo oad (klbs)<br />

700<br />

600<br />

500<br />

400<br />

300<br />

Hookload<br />

Static Up Drag<br />

Static Down Drag<br />

Pick-Up Trend<br />

Slack-Off Trend<br />

Slack-Off: FF=0.20/0.30<br />

Block Velocity<br />

Mud Type: SOBM<br />

Weight = 1.60 SG<br />

PV = 37 cP<br />

YP = 26 lbf/100ft²<br />

7<br />

6<br />

5<br />

4<br />

3<br />

Block Veloc city (m/s)<br />

200<br />

2<br />

100<br />

1<br />

0<br />

0<br />

0 500 1,000 1,500 2,000 2,500 3,000 3,500 4,000 4,500 5,000<br />

Measured Depth (m)

WQS – Azerbaijan Well

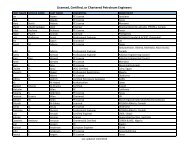

WQS: Wytch Farm ERD Wells<br />

0<br />

M13<br />

M04<br />

5,000<br />

M16<br />

M11<br />

M15<br />

M05<br />

M14<br />

M09<br />

M03 M02<br />

M18<br />

M06<br />

M15z<br />

M01<br />

F21<br />

F19<br />

M12<br />

M08<br />

F20<br />

M07<br />

M17<br />

M10<br />

F18<br />

10,000<br />

0 5,000 10,000 15,000 20,000 25,000 30,000 35,000 40,000<br />

Equivalent Departure (ft)<br />

TVD BRT (ft)

Wytch Farm – Torques 12¼” Section<br />

40<br />

Surface To orque (kft.lb)<br />

35<br />

30<br />

25<br />

20<br />

15<br />

M05<br />

M09<br />

M11<br />

M14<br />

M16<br />

10<br />

5<br />

0<br />

0 1,000 2,000 3,000 4,000 5,000 6,000 7,000 8,000 9,000<br />

Measured Depth (m)

Wytch Farm – 9-5/8” <strong>Cas<strong>in</strong>g</strong> Runs<br />

60<br />

40 M09<br />

M11<br />

20<br />

M14<br />

M16<br />

Str<strong>in</strong>g We eight (klbs)<br />

0<br />

-20<br />

-40<br />

-60<br />

-80<br />

-100<br />

0 1,000 2,000 3,000 4,000 5,000 6,000 7,000 8,000 9,000 10,000<br />

Measured Depth (m)

Wytch Farm ERD Wells – WQS Summary<br />

Comments on high h WQS<br />

‣ Good learn<strong>in</strong>g curve<br />

‣ Cont<strong>in</strong>uous ERD drill<strong>in</strong>g program