Day 1 - Society of Petroleum Engineers

Day 1 - Society of Petroleum Engineers

Day 1 - Society of Petroleum Engineers

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

26<br />

SPE TODAY<br />

Around the Exhibit Floor<br />

A roundup <strong>of</strong> technology being showcased at this year’s ATCE<br />

Laboratory Focuses on<br />

Downhole Perforating Systems<br />

The Advanced Perforating Flow<br />

Laboratory at Halliburton’s Jet<br />

Research Center conducts tests<br />

to help better understand actual<br />

downhole conditions and perforating<br />

system performance.<br />

The laboratory has been expanded<br />

with new cutting-edge technology and<br />

vessels, which provide customers with<br />

the most accurate information possible<br />

about the effects <strong>of</strong> perforations in<br />

various formations and environments.<br />

The three new vessels include<br />

a 50,000-psi vessel that allows<br />

Halliburton to conduct tests at<br />

pressure higher than any other testing<br />

facility in the industry, a 25,000-psi<br />

vessel that can rotate up to 180° and<br />

enables studies about gravity-related<br />

sanding to better understand the<br />

effects <strong>of</strong> perforating and fracturing<br />

in horizontal wells, and a 25,000-psi<br />

high-temperature vessel that can flow<br />

at temperatures reaching 204°C for<br />

testing <strong>of</strong> perforating capabilities at<br />

high temperatures. Booth 2235.<br />

Satellite Imagery Provides<br />

Sharp Eyes in the Sky<br />

Spatial Energy’s satellite imagery is<br />

available on demand from its archives,<br />

which are composed <strong>of</strong> data from<br />

satellites and aerial providers, its own<br />

speculative collection, and its hosted<br />

content <strong>of</strong> corporate imagery. The<br />

Enterprise Remote Sensing Solutions<br />

system provides one source for a full<br />

range <strong>of</strong> remote sensing services. Its<br />

data is tailored for use with geological,<br />

geophysical, and other energy-specific<br />

desktop applications.<br />

Spatial <strong>of</strong>fers high-resolution and<br />

satellite imagery from all the major<br />

commercial satellites: QuickBird,<br />

WorldView 1 and 2, IKONOS, SPOT,<br />

GeoEye-1, RapidEye, and Pleiades. The<br />

company’s imagery can be viewed,<br />

analyzed, shared, and combined with<br />

other geographic data using leading<br />

desktop and browser applications such<br />

as Google Earth, Global Mapper, ESRI,<br />

and Virtual Earth. Booth 2869.<br />

High-Speed Reaming Systems<br />

Fine Tune Completions<br />

Deep Casing Tools’ Shalerunner is<br />

a high-speed reaming system that<br />

enables landing completions at correct<br />

depth faster and less expensively. It<br />

gives the completion team rotation<br />

at the shoe without rotating the<br />

completion, the company said.<br />

Shalerunner’s design combines highspeed<br />

rotational reaming with low<br />

operation pressure and low flow rates.<br />

The system connects directly to the<br />

completion assembly and can be used<br />

to ream open the hole and land the<br />

completion on depth without any need<br />

for additional wiper trips.<br />

The company’s Turbocaser Express<br />

is the first high-speed, drillable<br />

motor and reamer system, enabling<br />

drilling teams to land casings<br />

and intermediate liners at target<br />

depth. It provides the driller with a<br />

circulation-powered reamer system<br />

to get the casing through difficult hole<br />

sections. Following normal cementing<br />

Halliburton has expanded the Advanced Perforating Flow Laboratory at its Jet<br />

Research Center. Photo courtesy <strong>of</strong> Halliburton.<br />

operations, the whole system can be<br />

drilled through in minutes with the<br />

next bottomhole assembly, targeting<br />

the next zone. Booth 3158.<br />

System Tests Instruments, Tools,<br />

Electronics for Harsh Conditions<br />

Qualmark’s Typhoon Inferno is a highly<br />

accelerated life test (HALT) system<br />

configured for testing the durability<br />

<strong>of</strong> instruments, tools, and electronics<br />

that will face harsh environments such<br />

as those encountered during oil and<br />

gas exploration.<br />

The Inferno can accommodate<br />

extreme temperatures ranging from<br />

−100 to +250°C, shock and vibration<br />

<strong>of</strong> more than 60 G rms , and multiaxis<br />

vibration with 6° <strong>of</strong> freedom vibration,<br />

all in a matter <strong>of</strong> minutes. Rapidly<br />

exposing products to such extremes<br />

reveals design and manufacturing flaws<br />

that are missed by traditional reliability<br />

testing methods. Booth 708.<br />

PetroLook E&P S<strong>of</strong>tware<br />

Unlocks Power <strong>of</strong> Data<br />

Aclaro S<strong>of</strong>tworks’ PetroLook<br />

applications provide a gateway to<br />

upstream data through a simple<br />

interface to browse and analyze<br />

information from any part <strong>of</strong> a<br />

company. Users can compare data<br />

between different operations and track<br />

changes to data over time.<br />

The s<strong>of</strong>tware is a Web-based<br />

business intelligence system built<br />

specifically to meet the needs <strong>of</strong> the oil<br />

and gas industry.<br />

PetroLook provides a common<br />

interface to a company’s multiple<br />

systems to provide a rich pool <strong>of</strong> data<br />

for informed decision making. It has<br />

been designed to allow comprehensive<br />

data analysis, accessing multiple<br />

data operations such as accounting<br />

reserves, daily field production, land<br />

economics, budgeting, and marketing<br />

data. Once analyzed, the system<br />

provides an array <strong>of</strong> reporting options<br />

to share results.<br />

PetroLook Reserves is a full<br />

reserves management system by<br />

which company reserves data from<br />

multiple sources can be compiled and<br />

rolled up to calculate total reserves,<br />

reconcile differences, book changes,<br />

and generate internal and external<br />

reports. As a PetroLook component,<br />

the reserves module makes use <strong>of</strong> the<br />

application’s underlying architecture,<br />

including Web-based navigation,<br />

versioning, a security model, and<br />

comprehensive reporting and charting.<br />

PetroLook’s Portfolio Advisor<br />

system is a full-featured portfolio<br />

optimization solution and is the first<br />

and only exploration and production<br />

(E&P) s<strong>of</strong>tware product that <strong>of</strong>fers<br />

true constrained multiobjective<br />

optimization, the company said. The<br />

key advantage <strong>of</strong> the portfolio advisor<br />

is a technical breakthrough that<br />

allows full constraint handling during<br />

optimization. Booth 3151.<br />

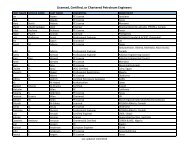

Sigma 3 Adds Companies<br />

To Boost Data Services<br />

Symphony Technology Group’s<br />

Sigma 3 Integrated Reservoir Solutions<br />

recently acquired Colorado-based<br />

APEX <strong>Petroleum</strong> Engineering, APEX<br />

HiPoint, and HiPoint Reservoir Imaging.<br />

The moves are part <strong>of</strong> its strategy<br />

to improve reservoir understanding,<br />

optimize production, define risk, and<br />

enhance return on investments<br />

for its clients.<br />

APEX <strong>Petroleum</strong> Engineering<br />

provides consultation for hydraulic<br />

fracturing engineering such as<br />

onsite treatment supervision and<br />

quality control, drilling, operations,<br />

and well completions engineering.<br />

APEX HiPoint provides real-time<br />

microseismic fracture mapping,<br />

wellbore seismic imaging, and reservoir<br />

characterization technologies and<br />

services. HiPoint Reservoir Imaging<br />

provides microseismic and borehole<br />

seismic data-processing analysis<br />

and interpretation.<br />

The new affiliates are recognized<br />

leaders in their respective fields,<br />

and the combination <strong>of</strong> their assets<br />

with the Sigma 3 Earth modeling,<br />

reservoir geophysics, geohazards and<br />

geopressure, and continuous fracture<br />

modeling capabilities creates a more<br />

integrated package for Sigma 3 .<br />

Booth 1863.<br />

3D Programs Address<br />

Development Uncertainties<br />

ION’s ResSCAN 3D programs<br />

encompass multiple industry<br />

disciplines to address two key<br />

uncertainties in unconventional<br />

reservoirs: characterizing reservoir<br />

quality and well completion for<br />

optimal production. The programs<br />

are developed and managed by ION’s<br />

GeoVentures group and are imaged<br />

by ION’s GX Technology group using<br />

advanced data processing techniques.<br />

Relying on upfront geological,<br />

petrophysical, and rock physics<br />

analysis, ResSCAN programs establish<br />

what seismic attributes, from 3D single<br />

or multicomponent seismic data,<br />

provide the most predictive expression<br />

<strong>of</strong> key reservoir properties for a<br />

given shale play and, most important,<br />

affect an operator’s drilling and well<br />

completion engineering decisions<br />

and parameters.<br />

Five 3D programs encompassing<br />

more than 900 square miles are<br />

currently in various stages <strong>of</strong> the<br />

ResSCAN workflow. All <strong>of</strong> these<br />

programs incorporate multicomponent<br />

acquisition, employ GX Technology’s<br />

data processing technologies and<br />

techniques, and rely on quantitative<br />

interpretation to derive highly<br />

optimized seismic attributes. These<br />

customized attributes are obtained<br />

from careful data processing followed<br />

typically by seismic inversion and<br />

shear-wave splitting analysis.<br />

With this approach, a high resolution<br />

estimate <strong>of</strong> formation density and<br />

natural fracture intensity can be<br />

determined, which generally cannot<br />

be accurately estimated with P-wave<br />

(single component) data alone.<br />

Booth 129.<br />

Sigma 3 recently acquired HiPoint Reservoir Imaging, which provides microseismic<br />

and borehole seismic data-processing analysis. Photo courtesy <strong>of</strong> Sigma 3 .