Brian Roland

Brian Roland

Brian Roland

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

A Reality about Reliability<br />

<strong>Brian</strong> <strong>Roland</strong><br />

Project Manager, Interiors Engineering<br />

Continental Airlines<br />

February 13, 2003

A Reality about Reliability<br />

US airlines are required to have a<br />

Reliability Program in accordance to FAR<br />

121.373:<br />

Continuing Analysis and Surveillance.<br />

(a) Each certificate holder shall establish and maintain<br />

a system for the continuing analysis and surveillance of<br />

the performance and effectiveness of its inspection<br />

program and the program covering other maintenance,<br />

preventive maintenance, and alterations and for the<br />

correction of any deficiency in those programs….

Reliability versus Availability<br />

• Reliability<br />

– Useful in evaluating component performance<br />

and maintenance requirements<br />

• Availability (ARINC 628 Part 8)<br />

– Useful for evaluating a systems effectiveness at<br />

providing the intended service to the passenger

What is Reliability?<br />

By technical definition:<br />

The probability that an item will perform a<br />

required function without failure under<br />

stated conditions for a stated period of time

Operational Indicators<br />

• Inverse of failure rate (failures/hour)<br />

• MTBUR - Mean Time Between Unscheduled<br />

Removals<br />

– Total hours / number of unscheduled removals<br />

– Removal is an interruption of continual usage<br />

• MTBF - Mean Time Between Failure<br />

– Confirmed failure

Longevity Indicators<br />

• MTTF - Mean Time To Failure<br />

– Average time a unit remains serviceable until<br />

failure

IFE Reliability<br />

• Focus is on IFE components rather than<br />

entire system performance<br />

– Does the component work and for how long?<br />

• IFE is made up of components chained in a<br />

series - any break in the chain can be critical

Reliability over Availability<br />

• At Continental, availability is rarely used to<br />

measure IFE performance<br />

• Even with poor component reliability,<br />

availability can be 100%

Example<br />

Scenario for Tape Player<br />

Time span<br />

30 days<br />

Fleet size<br />

71 aircraft<br />

Number of units/aircraft 3<br />

Number of unscheduled removals 39

Calculating Usage<br />

Aircraft Utilization 3 flight-segments per day<br />

4 hours per segment<br />

Usage<br />

= 71 aircraft X 3 flight-segments/day X 30 days<br />

= 6390 aircraft flight-segments<br />

X 3 components/aircraft<br />

= 19,170 component flight-segments<br />

X 4 hours per segment<br />

= 76,680 component flight-hours

MTBUR Result<br />

• In terms of Reliability for 30-day period:<br />

MTBUR =<br />

76,680 component flight-hours<br />

39 unscheduled removals<br />

= 1966 Hours<br />

• MTBF Target is 4500 hours

But in Terms of Availability…<br />

• Result = 100% because of redundancies<br />

• Source Availability (ARINC 628P8)<br />

“Sources are only to be considered unavailable<br />

if a failure impacts the ability of a passenger to<br />

use the IFE system for its intended function.”

Availability Flying at 100%<br />

• Redundant components<br />

• Alternate programming<br />

• Manual play overriding automatic mode<br />

• Open seats with operative in-seat IFE

The Burdens of Breakdowns<br />

• Disruption and/or degradation of inflight<br />

service<br />

• Intervention required by flight crews<br />

• Maintenance costs and spares<br />

• Delays<br />

• Loss of revenue and loyalty<br />

• Customer compensation

IFE Reliability Management<br />

Concerted effort between Supplier and Airline<br />

– Maintenance reporting failures<br />

– Reliability analyzing failure modes and trends<br />

– Engineering determining root causes and<br />

implementing corrective action plans<br />

– Purchasing coordinating repair and action plan

Collecting Reliability Data<br />

Failure reporting is key:<br />

– Aircraft log pages and data collection<br />

• Details of conditions experienced is critical<br />

– Component tear down reports<br />

– Communication between supplier and airline

Measuring Reliability<br />

Invokes various statistical data analysis to<br />

assemble a proper perspective of reliability<br />

– Trend analysis<br />

– Growth analysis<br />

– Failure mode analysis<br />

– Times-to-failure analysis

IFE Problem Children<br />

• Tape Player<br />

• Monitor<br />

• Passenger Control Unit (PCU)<br />

• System Control Unit (SCU)<br />

• Audio

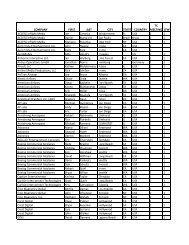

Log Page Analysis<br />

120<br />

737 NG IFE Log Pages<br />

30%<br />

100<br />

# L/P, (737NG, TTL 480)<br />

25%<br />

Nbr of Log Pages<br />

80<br />

60<br />

40<br />

% L/P (737NG)<br />

20%<br />

15%<br />

10%<br />

Percentage of Log<br />

Pages<br />

20<br />

5%<br />

0<br />

TAPE PLR MONITOR SCU PCU SEB PRAM ARU MUX<br />

# L/P, (737NG, TTL 480) 119 98 69 95 22 9 8 5<br />

% L/P (737NG) 25% 20% 14% 20% 5% 2% 2% 1%<br />

Category<br />

0%

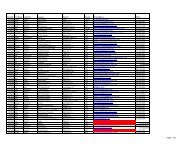

Trend Analysis<br />

737NG TAPE PLAYER<br />

MTBUR or MTBF, Hours<br />

20000<br />

18000<br />

16000<br />

14000<br />

12000<br />

10000<br />

8000<br />

6000<br />

4000<br />

2000<br />

0<br />

12 month MTBF<br />

12 month MTBUR<br />

12 month NTF %<br />

100<br />

80<br />

60<br />

40<br />

20<br />

0<br />

5/99<br />

7/99<br />

9/99<br />

11/99<br />

1/00<br />

3/00<br />

5/00<br />

7/00<br />

9/00<br />

11/00<br />

01/01<br />

03/01<br />

05/01<br />

07/01<br />

09/01<br />

11/01<br />

01/02<br />

03/02<br />

05/02<br />

07/02<br />

09/02<br />

11/02<br />

NFF, %

Failure Mode Analysis<br />

50%<br />

Tape Player Failure Type Comparison<br />

Percent of Failures<br />

45%<br />

40%<br />

35%<br />

30%<br />

25%<br />

20%<br />

15%<br />

10%<br />

5%<br />

06-12/00 01-05/01<br />

0%<br />

INOP TAPE STUCK DAMAGE TAPES BAD PICTURE<br />

06-12/00 41% 20% 6% 5%<br />

01-05/01 32% 32% 13% 4%<br />

Failure Type

Typical Tape Path in Player

Demise of the Hi-8:<br />

Repair Breakdown<br />

NFF/Cln (10 REP ORDERS)<br />

REMOVE BAD TAPE (29)<br />

Tear Down N/A (13)<br />

Cassette Components Related (69)<br />

Eating Tape / Tape Stuck in / Tape Jam<br />

NFF/Cln (10 REP<br />

ORDERS)<br />

8%<br />

REMOVE BAD TAPE (29)<br />

24%<br />

Cassette Components<br />

Related (69)<br />

57%<br />

Tear Down N/A (13)<br />

11%

Failure Analysis Summary<br />

• Determine the root cause of failure/removal<br />

• Analyze repair breakdowns<br />

• Develop fault tree<br />

• Identify failure trends<br />

– Mechanical wear, deterioration, damage<br />

– Software fault<br />

– Environment – heat, humidity, contaminants

The VCC Environment

Improving IFE Reliability<br />

• Identify root cause of failures and implement fix<br />

• Increase spares and allocation<br />

• Modify software and/or hardware<br />

• Implement proper maintenance & equipment<br />

cleaning programs<br />

• Train personnel on better handling<br />

• Improve environment around IFE equipment

A Reality about Reliability<br />

• Reliability is a valuable measurement of IFE<br />

performance<br />

– Requires detailed failure reporting, complex data<br />

analysis, and an effective corrective action program<br />

• Redundancies allow availability to run at 100%<br />

• Design better “fly-to-fail” components while<br />

keeping cost of ownership down

THANKS!!