Chapter 4.pdf - Zagazig University Staff Home Page

Chapter 4.pdf - Zagazig University Staff Home Page

Chapter 4.pdf - Zagazig University Staff Home Page

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Production Engineering (1)<br />

<strong>Chapter</strong> 4<br />

Dr. Mahmoud M. Atta<br />

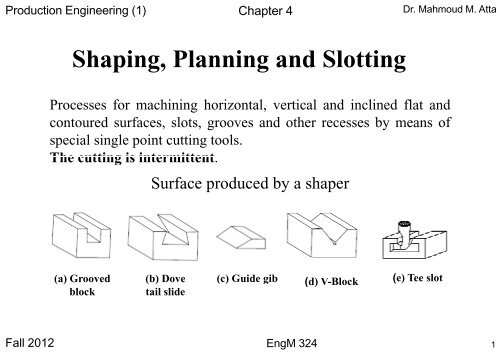

Shaping, Planning and Slotting<br />

Processes for machining horizontal, vertical and inclined flat and<br />

contoured surfaces, slots, grooves and other recesses by meansof<br />

special single point cutting tools.<br />

The cutting is intermittent.<br />

Surface produced by a shaper<br />

(a) Grooved<br />

block<br />

(b) Dove<br />

tail slide<br />

(c) Guide gib<br />

(d) V-Block<br />

(e) Tee slot<br />

Fall 2012 EngM 324<br />

1

Production Engineering (1)<br />

<strong>Chapter</strong> 4<br />

Dr. Mahmoud M. Atta<br />

Difference between the three types<br />

Shaper Planer Slotter<br />

1<br />

The work is stationary and the The tool is stationary and the The work is held stationary and the<br />

tool on the ram is moved back workpiece on the table travels tool on the ram is moved up and<br />

and forth across the work. back and forth under the tool down across the work.<br />

2<br />

Used for shaping much smaller<br />

jobs<br />

Meant for much larger jobs.<br />

Jobs as large as 6 metre wide and<br />

twice as long can be machined.<br />

It is used for making slots in<br />

smaller jobs.<br />

3 Is a light machine It is a heavy duty machine. Slotting is light machine<br />

4<br />

Can employ light cuts and finer<br />

Can employ heavier cuts and<br />

Can employ light cuts and finer<br />

feed.<br />

coarse feed.<br />

feed.<br />

5<br />

Uses one cutting tool at a time<br />

Several tools can cut<br />

simultaneously.<br />

Shaper uses one cutting tool at a<br />

time<br />

6<br />

Driven using quick- return link<br />

mechanism<br />

The drive on the planer table is<br />

either by gears or by hydraulic<br />

means<br />

The rams are either crank-driven<br />

or hydraulically driven.<br />

7<br />

It is less rigid and less robust<br />

Better rigidity that give more<br />

accuracy on machined surfaces.<br />

It is less rigid and less robust<br />

Fall 2012 EngM 324<br />

2

Production Engineering (1)<br />

<strong>Chapter</strong> 4<br />

Dr. Mahmoud M. Atta<br />

a) Shaping b) Planning c) Slotting<br />

Fall 2012 EngM 324<br />

3

Production Engineering (1)<br />

<strong>Chapter</strong> 4<br />

Dr. Mahmoud M. Atta<br />

Shaping<br />

Specification of shaper<br />

1. Maximum ram stroke (mm)<br />

2. Work table surface (W*L)<br />

3. No. of stroke per min (st/min)<br />

4. Motor power (KW)<br />

(1) The column<br />

(2) the motor<br />

(3) the ram<br />

(4) the table<br />

(5) The tool head<br />

(6) clapper box<br />

(7) The slot with the clamp.<br />

(8) The tool slide and feed screw handle.<br />

(9) Ratchet and pawl mechanism<br />

(10) the elevating screw of the table.<br />

(11) Support bracket<br />

(12) The levers for setting (st/min)<br />

Fall 2012 EngM 324<br />

4

Production Engineering (1)<br />

<strong>Chapter</strong> 4<br />

Dr. Mahmoud M. Atta<br />

Fall 2012 EngM 324<br />

5

Production Engineering (1)<br />

<strong>Chapter</strong> 4<br />

Dr. Mahmoud M. Atta<br />

Specification of planer<br />

1. Max. Workpiece dimension (W*L)<br />

2. Table speed (m/min)<br />

3. Vertical tool feed per stroke (mm)<br />

4. Table motor power (KW)<br />

Planer<br />

Fall 2012 EngM 324<br />

6

Production Engineering (1)<br />

<strong>Chapter</strong> 4<br />

Dr. Mahmoud M. Atta<br />

Specification of slotter<br />

1. Maximum ram stroke (mm)<br />

2. Work table diameter (mm)<br />

3. Max distance between tool post<br />

to bed (mm)<br />

4. Max distance between ram guide<br />

and work table (mm)<br />

5. Motor power (KW)<br />

Slotter<br />

Fall 2012 EngM 324<br />

7

Production Engineering (1)<br />

<strong>Chapter</strong> 4<br />

Dr. Mahmoud M. Atta<br />

Quick-return mechanisms<br />

These types of machine tool are of rectilinear cutting motion<br />

therefore, the rotary motion of the drive is converted into<br />

reciprocating motion.<br />

The metal is removed in the forward cutting stroke, while the<br />

return stroke goes idle and no metal is removed during this<br />

period.<br />

The cutting mechanism is so designed that it moves at a<br />

comparatively slower speed during forward cutting stroke,<br />

whereas during the return stroke it allow the ram to move at a<br />

faster speed to reduce the idle return time.<br />

This mechanism is known as quick return mechanism.<br />

Fall 2012 EngM 324<br />

8

Production Engineering (1)<br />

<strong>Chapter</strong> 4<br />

Dr. Mahmoud M. Atta<br />

The reciprocating movement of the ram and the quick return<br />

mechanism of the machine are generally obtained dby anyone<br />

of the following methods:<br />

1. Lever rocker arm mechanism (shaper).<br />

2. Slider crank mechanism (slotter).<br />

3. With worth quick return mechanism (shaper and slotter).<br />

4. Hydraulic system ( all the 3 types).<br />

5. Variable speed reversible motor (slotter and planer).<br />

6. Rack and pinion mechanism (planer).<br />

Fall 2012 EngM 324<br />

9

Production Engineering (1)<br />

<strong>Chapter</strong> 4<br />

Dr. Mahmoud M. Atta<br />

Hydraulic system<br />

Its advantages;<br />

1. Greater flexibility of speed (infinite variable)<br />

2. Smoother in operation<br />

3. Ability to slip in case of overload, thus eliminating tool and<br />

machine damage<br />

4. Possibility of changing speeds and feeds during operation.<br />

5. Providing a constant speed all over the stroke.<br />

Fall 2012 EngM 324<br />

10

Production Engineering (1)<br />

<strong>Chapter</strong> 4<br />

Dr. Mahmoud M. Atta<br />

Rack and pinion mechanism<br />

Fall 2012 EngM 324<br />

11

Production Engineering (1)<br />

<strong>Chapter</strong> 4<br />

Dr. Mahmoud M. Atta<br />

Lever rocker arm mechanism<br />

1. Speed adjustment 3. Stroke position adjustment<br />

2. Stroke length adjustment 4. Quick return action<br />

Fall 2012 EngM 324<br />

12

Production Engineering (1)<br />

<strong>Chapter</strong> 4<br />

Dr. Mahmoud M. Atta<br />

Quick return action<br />

Cutting ration =<br />

Time for cutting stroke<br />

Time for return stroke<br />

= t C<br />

t R<br />

=<br />

Angle of cutting stroke<br />

Angle of return stroke<br />

θ C<br />

=<br />

θ<br />

= 1 m<br />

θ R<br />

The length of the stroke is reduced the quick return<br />

The length of the stroke is reduced the quick return<br />

action (inverse proportional).<br />

Fall 2012 EngM 324<br />

13

Production Engineering (1)<br />

<strong>Chapter</strong> 4<br />

Dr. Mahmoud M. Atta<br />

Feed Mechanism<br />

1. Driving disc<br />

2. Driving pin<br />

3. Connecting link<br />

4. The pawl carrier<br />

5. Pawl<br />

6. The ratchet wheel<br />

How to reverse the direction of the machine table and to make<br />

the feeding rate zero.<br />

Fall 2012 EngM 324<br />

14

Production Engineering (1)<br />

<strong>Chapter</strong> 4<br />

Dr. Mahmoud M. Atta<br />

Tool mounting<br />

Tool head<br />

Back block<br />

Tool post<br />

Fall 2012 EngM 324<br />

15

Production Engineering (1)<br />

<strong>Chapter</strong> 4<br />

Dr. Mahmoud M. Atta<br />

Work holding devices<br />

Fall 2012 EngM 324<br />

16

Production Engineering (1)<br />

<strong>Chapter</strong> 4<br />

Dr. Mahmoud M. Atta<br />

Machining time<br />

W.<br />

i<br />

NL( 1+<br />

m)<br />

T m =<br />

V c =<br />

f . N<br />

1000<br />

N<br />

1000<br />

V<br />

= Vc =<br />

VR<br />

* m<br />

2.<br />

L s<br />

V is the average cutting speed<br />

V c is the mean cutting speed<br />

V R is the mean return speed<br />

W = w + w 1 + w 2<br />

m is the inverse of the cutting ratio<br />

Fall 2012 EngM 324<br />

17

Production Engineering (1)<br />

<strong>Chapter</strong> 4<br />

Dr. Mahmoud M. Atta<br />

Example<br />

It is required to machine three slots, in a workpiece, of 20 mm. wide<br />

and 30 mm. height by ashaping machine. The stroke length is 450<br />

mm. the shaper makes 30 stroke/min with feed rate 0.25 mm/stroke<br />

and cutting angle 210º. Take the depth of cut equal 5 mm.<br />

Calculate:<br />

1) Average cutting and return speeds.<br />

2) The machining time.<br />

3) How can the feed adjusted if the shaper table cross slide lead<br />

screw has 5 mm. pitch and tooth wheel of 75 teeth.<br />

Fall 2012 EngM 324<br />

18

JAZAN UNIVERSITY<br />

COLLEGE OF ENGINEERING<br />

MECHANICAL ENGINEEING DEPARTMENT<br />

PRODUCTION ENGINEERING (1) (ENGM324)<br />

SHEET 3<br />

1. Mention, with neat sketch, the different surfaces produced with shaper.<br />

2. Make a comparison between shaping, planning and slotting processes.<br />

3. Discuss 3 different methods used to produce quick return action in shaper,<br />

planer or sloter.<br />

4. What is the advantage of the hydraulic system when used as quick return<br />

mechanism?<br />

5. Show how to adjust the stroke length and stroke position in lever rocker arm<br />

mechanism<br />

6. Describe the quick return action in Lever rocker arm mechanism.<br />

7. Describe the feed mechanism in shaper and show how to reverse the feed<br />

direction.<br />

8. Show how to produce the inclined surfaces in shaper.<br />

9. It is required to reduce the height of a workpiece of 200 mm. wide with 7<br />

mm. by a shaping machine. The stroke length is 450 mm. the shaper makes<br />

30 stroke/min with feed rate 0.6 mm/stroke and cutting angle 210º. Take the<br />

max. depth of cut equal 5 mm. Calculate:<br />

• Average cutting and return speeds.<br />

• The machining time.<br />

• How can the feed adjusted if the shaper table cross slide lead screw<br />

has 5 mm. pitch and tooth wheel of 75 teeth.