Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

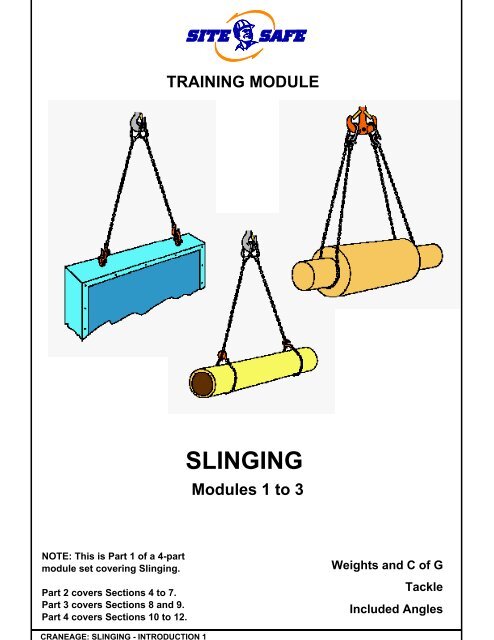

CRANEAGE: SLINGING - INTRODUCTION 1<br />

TRAINING MODULE<br />

SLINGING<br />

Modules 1 to 3<br />

NOTE: This is Part 1 of a 4-part<br />

module set covering Slinging.<br />

Part 2 covers Sections 4 to 7.<br />

Part 3 covers Sections 8 and 9.<br />

Part 4 covers Sections 10 to 12.<br />

Weights and C of G<br />

Tackle<br />

Included Angles

CRANEAGE: SLINGING - INTRODUCTION 1<br />

SLINGING<br />

Modules 1 to 3<br />

This Training Module comes to you courtesy of:<br />

<strong>Site</strong> <strong>Safe</strong> would like to acknowledge Fletcher Construction’s on-going support

CRANEAGE - SLINGING: BASICS PAGE 1<br />

CRANEAGE - SLINGING BASICS<br />

SECTION 1:<br />

WEIGHTS AND CENTRE OF GRAVITY<br />

1.1 Know the Load Weight<br />

1.2 Estimating Weights<br />

1.3 Weights of Common Materials<br />

1.4 Centre of Gravity 1<br />

1.5 Centre of Gravity 2<br />

1.6 Centre of Gravity 3

CRANEAGE - SLINGING: BASICS PAGE 2<br />

GOOD SLINGING PRACTICE<br />

BASIC RULES ... 1<br />

1.1 KNOW THE LOAD WEIGHT.<br />

Lifting any load with gear which is inadequate for the job is just not an<br />

option. Commonsense tells you this is dangerous.<br />

Before carrying out a lift, there are TWO factors which MUST be known:<br />

a) The weight of the object or material being lifted<br />

b) The lifting capacity of the tackle<br />

On the following sheets, are some simple formulas which will allow you to<br />

estimate the weights of most common materials on a construction site.<br />

Details of the lifting capacities of common <strong>slinging</strong> systems are shown in<br />

a separate section (Section 2).

CRANEAGE - SLINGING: ESTIMATING WEIGHTS<br />

PAGE 3<br />

GOOD SLINGING PRACTICE<br />

BASIC RULES ... 1<br />

1.2 KNOW THE LOAD WEIGHT.<br />

L<br />

W<br />

RECTANGLE<br />

This applies for cubes and rectangles of any size.<br />

H<br />

L x W x H x wt./cu.m<br />

L<br />

SOLID CYLINDER<br />

(3.14 ÷ 4) x D x D x L x Wt./Cu.M.<br />

D<br />

D<br />

HEAVY WALL PIPE<br />

(3.14 ÷ 4) x D x D x L x Wt./Cu.M = Solid weight,<br />

MINUS<br />

(3.14 ÷ 4) x d x d x l x Wt./Cu.M = Hole weigh.<br />

Take the "hole" from the "solid" = Pipe weight!<br />

d<br />

C<br />

D<br />

THIN WALL PIPE<br />

Working this out is imagining that you have split the pipe<br />

lengthways, and have rolled it out into a flat sheet.<br />

3.14 x D x L x t x wt./cu.m.<br />

OR<br />

C x L x t x wt./cu.m<br />

t<br />

STEEL SECTIONS<br />

Any steel section can be divided into convenient<br />

sections, and the weight of each worked out. Add<br />

all the totals together, and you have the overall<br />

weight of the complete section.<br />

(This trick can also be used for<br />

any irregular-shaped object.)<br />

1<br />

e.g; an RSJ<br />

is three<br />

rectangles!<br />

2<br />

Wt. of 1 + Wt. of 2 + Wt. of 3 = Total weight.<br />

3

CRANEAGE - SLINGING: ESTIMATING WEIGHTS<br />

PAGE 4<br />

GOOD SLINGING PRACTICE<br />

BASIC RULES ... 1<br />

1.3 KNOW THE LOAD WEIGHT.<br />

A GUIDE TO WEIGHTS.<br />

STEEL BARS<br />

& RODS<br />

Dia.<br />

(mm)<br />

Approx. kg<br />

per metre<br />

WEIGHTS OF<br />

COMMON MATERIALS<br />

Material:<br />

Approx. kg. per<br />

cubic metre<br />

5<br />

0.15<br />

Aluminium<br />

2,645<br />

6<br />

0.22<br />

Asphalt<br />

1,410<br />

8<br />

0.40<br />

Blocks - conc.<br />

1,134<br />

10<br />

0.62<br />

Brick - common<br />

2,005<br />

12<br />

0.90<br />

Cement - loose<br />

1,506<br />

13<br />

1.05<br />

Concrete - plug<br />

2,305<br />

14<br />

1.20<br />

Concrete - reinf.<br />

2,405<br />

16<br />

1.60<br />

Copper<br />

8,950<br />

17<br />

1.80<br />

Earth - dry<br />

1,280<br />

18<br />

2.25<br />

Earth - wet<br />

1,600<br />

20<br />

2.45<br />

Glass sheet<br />

2,565<br />

22<br />

3.00<br />

Granite<br />

2,725<br />

24<br />

3.55<br />

Gravel - dry<br />

1,760<br />

25<br />

3.85<br />

Gravel - wet<br />

1,920<br />

28<br />

4.80<br />

Marble<br />

2,720<br />

30<br />

5.55<br />

Oils<br />

930<br />

32<br />

6.30<br />

Timber - dry<br />

810<br />

35<br />

7.55<br />

Timber - wet<br />

960<br />

40<br />

9.85<br />

Sand - dry<br />

1,730<br />

50<br />

12.50<br />

Sand - wet<br />

1,890<br />

100<br />

61.65<br />

Steel<br />

7,800<br />

150<br />

138.75<br />

Water<br />

1,000

CRANEAGE - SLINGING: ESTIMATING WEIGHTS<br />

PAGE 5<br />

GOOD SLINGING PRACTICE<br />

BASIC RULES ... 1<br />

1.4. KNOW HOW TO FIND THE CENTRE OF GRAVITY ... 1.<br />

Every load has a "centre of gravity".<br />

The "Centre of Gravity" of a load is a point which, if the load could be suspended from it, the<br />

load would be in perfect balance.<br />

In a simple rectanglar or square shape, the C of G is easily found, as the exact centre of the<br />

load. It gets a little more complicated with odd-shaped loads, but the following illustrations<br />

may make it a little easier.<br />

In a simple rectangle, the C of G is in the dead centre of the load, at a point where<br />

all the diagonals (from corner to corner) would intersect. A quick way is to divide<br />

the sides in half - the mid-point is the line of the C of G.<br />

Make sure the hook is over the centre of the load and it will be quite stable.<br />

Half the width will<br />

locate the C of G<br />

horizontally.<br />

=<br />

=<br />

=<br />

=<br />

Half the depth will<br />

locate the C of G<br />

vertically.<br />

=<br />

=<br />

The C of G for a cylinder or pipe is readily<br />

found, by halving the length. The C of G is<br />

on this line, on the centreline of the cylinder<br />

or pipe.<br />

The problems can arise where an irrgular-shaped load has to be<br />

lifted, which may require slings of different length, or the load on<br />

each sling may be markedly different.<br />

How to find the centres of gravity with these loads is covered on<br />

the following sheets.

PAGE 6<br />

GOOD SLINGING PRACTICE<br />

BASIC RULES ... 1<br />

1.5. KNOW HOW TO FIND THE CENTRE OF GRAVITY ... 2.<br />

The "Centre of Gravity" of a load is a point which, if the load could be suspended from it,<br />

the load would be in perfect balance.<br />

The crane hook needs to be directly over the centre of gravity, for the load to be stable.<br />

This load is not stable.<br />

The hook is over the<br />

centre of gravity, but<br />

the C of G is above the<br />

crane hook.<br />

This load is top-heavy,<br />

and could overturn<br />

while being craned.<br />

This load is<br />

stable. The<br />

hook is right<br />

over the<br />

load's centre<br />

of gravity.<br />

WHAT WILL HAPPEN....?<br />

UNSTABLE<br />

Hook is not over<br />

centre of gravity.<br />

The load will shift until the<br />

centre of gravity is under the<br />

hook.<br />

This will make landing the<br />

load very difficult, and could<br />

cause major problems in<br />

craneage.

CRANEAGE - SLINGING: ESTIMATING WEIGHTS<br />

PAGE 7<br />

GOOD SLINGING PRACTICE<br />

BASIC RULES ... 1<br />

1.6. KNOW HOW TO FIND THE CENTRE OF GRAVITY ... 3.<br />

A load that is not centred will swing as soon as it is lifted.<br />

This puts a greater stress on one sling, and can be dangerous.<br />

It becomes important to set the slings so the hook is right<br />

over the centre of gravity of the load, and this requires<br />

a bit of calculation.<br />

METHOD 1.<br />

In this case, the load is formed of two<br />

rectangles. The centre of gravity for each<br />

rectangle can easily be found, and the weight<br />

of the section estimated.<br />

Section 1 = 800kg; C of G = CG1.<br />

Section 2 = 1,200kg; C of G = CG2.<br />

Combined weight = 2,000kg.<br />

The larger section is (1200/2000), or 60% of<br />

the total load.<br />

Draw a line from CG1 to CG2, and measure it.<br />

Say it is 2.400 metres.<br />

60% of 2.400 m is 1.584 metres.<br />

The combined centre of gravity is then<br />

1.584 m from CG1. This is shown as CG3.<br />

The hook needs to be located over this point.<br />

800kg<br />

1 584<br />

CG1<br />

CG3<br />

2 400<br />

1200kg<br />

CG2<br />

METHOD 2<br />

Sometimes it seems possible to calculate<br />

the sling load stress on each side of a<br />

non-symmetrical load as shown, by using<br />

the normal sling formula and applying it<br />

twice: once for one side, and again for the<br />

other side, using two different lengths of<br />

sling and different heights.<br />

1 920<br />

1600 kg<br />

Heavily<br />

loaded<br />

sling<br />

This method is not accurate,<br />

especially with extreme load<br />

distribution such as a heavy<br />

steel structure on one end and<br />

light steel framing on the other<br />

end.<br />

400 kg<br />

CG1<br />

2 400<br />

CG2

CRANEAGE - SLINGING: BASICS PAGE 8<br />

CRANEAGE - SLINGING BASICS<br />

SECTION 2:<br />

KNOW YOUR TACKLE<br />

2.1 Know the Tackle Capacity<br />

2.2 The Riggers Chart - 1<br />

2.3 The Riggers Chart - 2<br />

2.4 Shackle Care<br />

2.5 Crane Hook Care<br />

2.6 Wedge Sockets<br />

2.7 Web Slinging Rights and Wrongs<br />

2.8 Web Slinging Capacity Details<br />

2.9 Blocks & Tackle 1<br />

2.10 Blocks & Tackle 2<br />

2.11 Blocks & Tackle 3

GOOD SLINGING PRACTICE<br />

BASIC RULES ... 2<br />

2.1 KNOW THE TACKLE CAPACITY<br />

Lifting any load with tackle which is inadequate for the job is just not an option.<br />

Commonsense tells you this is dangerous.<br />

Before carrying out any lift, there are TWO factors which MUST be known:<br />

The weight of the load, and<br />

The lifting capacity of the tackle.<br />

On the following sheets are some simple formulas which will show how to select the<br />

correct tackle for the job.<br />

Sheets 2.2 and 2.3 are quick-reference sheets for the common slings and shackles,<br />

with following sheets providing more detail, with information for checks of equipment,<br />

and the use of blocks and tackle.<br />

WLL 2.5T<br />

SWL 5.0 T

CRANEAGE - SLINGING: BASICS PAGE 10<br />

GOOD SLINGING PRACTICE<br />

BASIC RULES ... 2 - QUICK REFERENCE CHART 1<br />

POLYESTER ROUND SLINGS:<br />

LISTED CAPACITIES<br />

INDICATIVE ONLY.<br />

One stitch row = 1 tonne<br />

Vertical<br />

Choke<br />

Parallel<br />

Basket<br />

Basket<br />

90°<br />

All lifting tackle has the<br />

SWL or WLL marked.<br />

Slings must NOT be used<br />

beyond their 6-month<br />

inspection date.<br />

1.0<br />

2.0<br />

3.0<br />

4.0<br />

5.0<br />

6.0<br />

0.8<br />

1.6<br />

2.4<br />

3.2<br />

4.0<br />

4.8<br />

2.0<br />

4.0<br />

6.0<br />

8.0<br />

10.0<br />

12.0<br />

1.4<br />

2.8<br />

4.2<br />

5.6<br />

7.0<br />

8.1<br />

Nip angle<br />

must NOT<br />

exceed 120°,<br />

square or<br />

round reeved<br />

(choked).<br />

120°<br />

8.0<br />

6.4<br />

16.0<br />

11.2<br />

CHAIN SLINGS<br />

Grade 80, Lifting chain only.<br />

Chain<br />

dia. mm<br />

Single<br />

Vertical<br />

Single<br />

Reeved<br />

2-, 3- and 4- legged Slings<br />

Straight<br />

Reeved<br />

10 mm 3.2<br />

13 mm 5.4<br />

16 mm 8.0<br />

19 mm<br />

23 mm<br />

Rope<br />

dia. mm<br />

13 mm 2.0<br />

16 mm 3.0<br />

19 mm<br />

22 mm<br />

24 mm<br />

11.5<br />

16.9<br />

WIRE ROPE SLINGS<br />

Single<br />

Vertical<br />

4.3<br />

5.7<br />

6.8<br />

2.6<br />

4.3<br />

6.4<br />

9.2<br />

13.5<br />

Single<br />

Reeved<br />

1.6<br />

2.4<br />

3.4<br />

4.6<br />

5.4<br />

0° - 90° 90°-120°<br />

2.8<br />

4.2<br />

6.0<br />

8.0<br />

9.5<br />

Grade 1770, Fibre core<br />

2-, 3- and 4- legged Slings<br />

Straight<br />

2.0<br />

3.0<br />

4.3<br />

5.7<br />

6.8<br />

2.2<br />

3.4<br />

4.8<br />

6.4<br />

7.6<br />

Reeved<br />

26 mm 8.0 6.4 11.0 8.0 8.8 6.4<br />

28 mm 9.3 7.4 13.0 9.3 10.4 7.4<br />

4.5<br />

32 mm 12.1 9.7 16.9 12.1 13.5 9.7<br />

7.6<br />

11.3<br />

16.2<br />

23.9<br />

3.2<br />

5.4<br />

8.0<br />

11.5<br />

16.9<br />

0° - 90° 90°-120°<br />

7 mm 1.5 1.2 2.1 1.5<br />

1.7 1.2<br />

3.6<br />

6.0<br />

9.0<br />

12.9<br />

19.1<br />

2.6<br />

4.3<br />

6.4<br />

9.2<br />

13.5<br />

1.6<br />

2.4<br />

3.4<br />

4.6<br />

5.4

CRANEAGE - SLINGING: BASICS PAGE 11<br />

GOOD SLINGING PRACTICE<br />

BASIC RULES ... 2<br />

2.3. QUICK REFERENCE CHART 2<br />

BOW SHACKLES<br />

High Tensile<br />

Screw pin type.<br />

Size mm 10 11 13 16 19 22 25 28 32 35 38 45<br />

Pin Ø mm 11 13 16 19 22 25 28 32 35 38 42 50<br />

SWL<br />

1.0 1.5 2.0 3.25 4.15 6.5 8.0 9.5 12.0 13.5 17.0 25.0<br />

SWIFTLIFT PINS<br />

Min. 20MPa concrete.<br />

3 x depth = dist. from edge<br />

Pin length. mm<br />

SWL<br />

35 50 55 65 75 85 90 95 120<br />

0.47 0.88 1.17 1.51 1.88 2.1 2.42 2.92 4.16<br />

170<br />

5.00<br />

EFFECT OF INCLUDED ANGLE<br />

ON SLING LOADS<br />

WEIGHTS OF CONSTRUCTION<br />

MATERIALS<br />

0.5 t 0.5 t<br />

Load<br />

in<br />

tonnes<br />

30°<br />

60°<br />

0.52<br />

0.58<br />

Brick<br />

Concrete (wet)<br />

Concrete (& precast)<br />

Sand / Gravel (wet)<br />

Steel<br />

Timber<br />

Water<br />

T /Cu.M.<br />

2.01<br />

2.40<br />

2.41<br />

1.92<br />

7.85<br />

0.610<br />

1.00<br />

90°<br />

0.7<br />

120°<br />

1.0<br />

150° 2.0<br />

170°<br />

1 tonne load<br />

6.0<br />

CONCRETE WEIGHTS<br />

0.5 cu.m. skip<br />

1.4 t<br />

1.0 cu.m. skip<br />

2.7 t<br />

2.0 cu.m. skip<br />

5.6 t<br />

HOLLOW CORE FLOORING<br />

200 thk series<br />

0.32 t / m<br />

300 thk series<br />

0.42 t / m

CRANEAGE - SLINGING: BASICS PAGE 12<br />

GOOD SLINGING PRACTICE<br />

BASIC RULES ... 2<br />

2.4. CARE OF SHACKLES<br />

Shackle size is usually given<br />

as the pin diameter, not the<br />

bow diameter.<br />

NEVER use a bolt in place<br />

of a proper shackle pin. A<br />

bolt is made of the wrong<br />

(weaker) metal.<br />

Tie the pin to prevent it<br />

coming undone with<br />

twitching wire through the<br />

eye and around the<br />

opposite part of the bow.<br />

WLL 2.5 T<br />

Where possible, use a<br />

shackle with the pin on the<br />

hook, and not upside-down.<br />

A rope being pulled across a<br />

pin could cause it to come<br />

undone.<br />

ALWAYS use a shackle for<br />

vertical lifts only. If you have<br />

to use a shackle with two<br />

chokers spread at a wide<br />

angle, go UP a size in rating.<br />

CHECK for wear on the<br />

shackle bow. Any more<br />

than a 10% reduction in the<br />

bow material - throw the<br />

shackle out.<br />

CHECK FOR:<br />

Damaged threads<br />

Nicks or flat spots on pin<br />

Worn or damaged shoulder<br />

Bending in the pin<br />

Opening or closing-up of<br />

the bow gap<br />

Flat spots on bow<br />

Wear on bow<br />

Eyes out of alignment<br />

WLL 2.5 T<br />

A pin should have ONE thread showing<br />

when tight.<br />

Any more or any less - the shackle has<br />

distorted and should be scrapped.

CRANEAGE - SLINGING: BASICS PAGE 13<br />

GOOD SLINGING PRACTICE<br />

BASIC RULES ... 2<br />

2.5. CRANE HOOK CHECK AREAS<br />

CHECK<br />

the swivel<br />

is working<br />

smoothly<br />

CHECK<br />

for signs<br />

of cracks<br />

and<br />

twisting<br />

CHECK for<br />

wear and<br />

cracks<br />

CHECK for<br />

wear and<br />

deformation<br />

CHECK for<br />

signs<br />

of the throat<br />

opening up<br />

CHECK<br />

the<br />

safety<br />

latch<br />

CHECK<br />

the hook<br />

rating<br />

is clearly<br />

shown<br />

CHECK<br />

for<br />

twisting<br />

ANY sign of a defect means the<br />

hook could be dangerous if used.<br />

DO NOT risk using it - have it<br />

checked over by our experts. Tag it<br />

as being "FAULTY".<br />

Other suspicious signs to check for:<br />

- Discolouration through heat.<br />

- Any signs of welding.<br />

- Any sign of the hook rating being altered or obscured.<br />

- Any sign of the hook having contact with power (arced areas)<br />

- Any deformations, even hammer marks, on the hook.<br />

YOU MAY BE THE ONE UNDER THE HOOK IF IT FAILS.<br />

YOU DON'T GET SECOND CHANCES.

CRANEAGE - SLINGING: BASICS PAGE 14<br />

GOOD SLINGING PRACTICE<br />

BASIC RULES ... 2<br />

2.6. WEDGE SOCKET CHECKS<br />

The wedge socket<br />

MUST be attached with<br />

the load line pulling in a<br />

straight line from the<br />

pin.<br />

RIGHT!<br />

WRONG!!<br />

METHODS OF SECURING THE DEAD END<br />

Always pull sufficient rope through the socket.<br />

The dead end is clamped to the<br />

load line - NOT too tight, or the<br />

load line may be damaged.<br />

Always allow a little slack.<br />

After loading the socket, the<br />

dogging clamp should be<br />

released and some slack<br />

forced into the dead end,<br />

otherwise the dogging clamp<br />

takes all the load until it fails.<br />

(A)<br />

Saddle on live end<br />

This is a common method -<br />

clamp a short length of line<br />

to the dead end.<br />

(B)<br />

Take care if<br />

considering this<br />

method - the loop<br />

can often snag on<br />

projecting materials.<br />

(C)

CRANEAGE - SLINGING: BASICS PAGE 15<br />

GOOD SLINGING PRACTICE<br />

BASIC RULES ... 2<br />

2.7. WEB SLINGING<br />

SWL 10 T WITH 6M SLINGS<br />

Lifting Beam<br />

10,000kg LOAD<br />

RIGHT!!<br />

This is the correct way<br />

to sling precast using<br />

mesh or nylon slings.<br />

Note the slings are<br />

vertical and the full<br />

width of the sling is<br />

taking the load.<br />

The greater the included angle,<br />

the greater the risk.<br />

10,000kg LOAD<br />

WRONG!!<br />

This is a common - and risky - method<br />

of <strong>slinging</strong>. The only thing preventing<br />

the slings being pulled together, is<br />

friction between the webbing and the<br />

load.<br />

The entire load is being<br />

borne by a thin edge of the<br />

sling. Failure is certain.<br />

Side force:<br />

2 900 kg @ 60° incl. angle<br />

5 000 kg @ 90° incl. angle<br />

The sling will<br />

tear at this point.<br />

FACTORS INVOLVED:<br />

1. Load is applied to the sling edge only. It<br />

must be shared by the entire sling width.<br />

2. The slings are being pulled in together<br />

by the weight of the load (Side force).<br />

3. If slipping starts, the slings will be destroyed<br />

by both abrasive friction, and heat.<br />

4. Once slipping starts, it cannot be halted.

CRANEAGE - SLINGING: BASICS PAGE 16<br />

GOOD SLINGING PRACTICE<br />

BASIC RULES ... 2<br />

2.8. WEB SLINGING<br />

FLAT EYE<br />

Used where<br />

minimum<br />

clearance is<br />

required<br />

for passing under<br />

load, and for use<br />

with lifting beams.<br />

REDUCED<br />

EYE<br />

For use with<br />

small hooks.<br />

REDUCED AND<br />

REVERSED<br />

EYE<br />

For choker lift,<br />

giving square lift<br />

to the load on the<br />

same plane as<br />

the webbing.<br />

METAL DEE<br />

(Plain and Choker)<br />

Best suited to lifts<br />

where the eye is<br />

subject to heavy<br />

wear.<br />

SAFE WORKING CAPACITY (S.W.L.) IN TONNES<br />

Slings as above<br />

Endless Slings<br />

Sling<br />

Width:<br />

No. of<br />

Plys<br />

38mm<br />

One<br />

Two<br />

0.75<br />

1.50<br />

0.60<br />

1.20<br />

1.05<br />

2.10<br />

1.50<br />

3.00<br />

1.50<br />

3.00<br />

1.20<br />

2.40<br />

2.10<br />

4.20<br />

3.00<br />

6.00<br />

50mm<br />

One<br />

Two<br />

1.00<br />

2.00<br />

0.80<br />

1.60<br />

1.40<br />

2.80<br />

2.00<br />

4.00<br />

2.00<br />

4.00<br />

1.60<br />

3.20<br />

2.80<br />

5.60<br />

4.00<br />

8.00<br />

75mm<br />

One<br />

Two<br />

1.50<br />

3.00<br />

1.20<br />

2.40<br />

2.10<br />

4.20<br />

3.00<br />

6.00<br />

3.00<br />

6.00<br />

2.40<br />

4.80<br />

4.20<br />

8.40<br />

6.00<br />

12.00<br />

100mm<br />

One<br />

Two<br />

2.00<br />

4.00<br />

1.60<br />

3.20<br />

2.80<br />

5.60<br />

4.00<br />

8.00<br />

4.00<br />

8.00<br />

3.20<br />

6.40<br />

5.60<br />

11.20<br />

8.00<br />

16.00<br />

150mm<br />

One<br />

Two<br />

3.00<br />

6.00<br />

2.40<br />

4.80<br />

4.20<br />

8.40<br />

6.00<br />

12.00<br />

6.00<br />

12.00<br />

4.80<br />

9.60<br />

8.40<br />

16.80<br />

12.00<br />

24.00<br />

200mm<br />

One<br />

Two<br />

4.00<br />

8.00<br />

3.20<br />

6.40<br />

5.60<br />

11.20<br />

8.00<br />

16.00<br />

8.00<br />

16.00<br />

6.40<br />

12.80<br />

11.20<br />

22.40<br />

16.00<br />

32.00<br />

300mm<br />

One<br />

Two<br />

6.00<br />

12.00<br />

4.80<br />

9.60<br />

8.40<br />

16.80<br />

12.00<br />

24.00<br />

Special endless slings<br />

available to specific design.

CRANEAGE - SLINGING: BASICS PAGE 17<br />

GOOD SLINGING PRACTICE<br />

BASIC RULES ... 2<br />

2.9. BLOCKS AND TACKLE ... 1<br />

A load of 500 kg is<br />

going to need a force of<br />

500 kg to shift it. Those<br />

TWO loads will be<br />

applied to the block<br />

rigging.<br />

Load on block rigging:<br />

(500 kg + 500 kg) = 1,000 kg!<br />

500 kg<br />

A snatch block is rated by<br />

the maximum line pull.<br />

Therefore, a 500 kg snatch<br />

block will have a 1,000 kg<br />

capacity hook.<br />

500 kg<br />

Load: 500kg<br />

The greater the included angle between the load rope and the pulling rope, the less the<br />

force on the block rigging.<br />

Yes, this is the opposite to slings, and can be confusing, BUT it is very important to<br />

remember the difference, and WHY that difference works.<br />

920 kg 705 kg 500 kg<br />

500 kg<br />

500 kg 500 kg<br />

500 kg 500 kg<br />

500 kg<br />

45° 90° 135°<br />

In a vertical,lift, the combined force of both the load AND the lifting force are applied to<br />

the block. If the load was being pulled at 180° - in effect a straight rope - the block<br />

would take NO load. The load on the block then decreases, as the included angle<br />

increases.<br />

The following sheet shows how these forces can be worked out, for a number of<br />

angles. All you need to do, is MULTIPLY the load by the factor shown for the nearest<br />

angle between the load line and lead line ("pulling" line).

CRANEAGE - SLINGING: BASICS PAGE 18<br />

GOOD SLINGING PRACTICE<br />

BASIC RULES ... 2<br />

2.10. BLOCKS AND TACKLE ... 2<br />

TABLE OF MULTIPLICATION FACTORS FOR<br />

SNATCH BLOCK LOADS<br />

Angle between<br />

Lead and Load<br />

Lines<br />

Multiplication<br />

Factor<br />

10°<br />

20°<br />

30°<br />

1.99<br />

1.97<br />

1.93<br />

Lifting<br />

force<br />

Load<br />

40°<br />

1.87<br />

Angle:<br />

50°<br />

1.81<br />

60°<br />

1.73<br />

70°<br />

1.64<br />

80°<br />

1.53<br />

90°<br />

1.41<br />

100°<br />

1.29<br />

110°<br />

1.15<br />

120°<br />

1.00<br />

130°<br />

0.84<br />

140°<br />

0.68<br />

150°<br />

0.52<br />

160°<br />

0.35<br />

170°<br />

0.17<br />

180°<br />

0.00<br />

Examples:<br />

A load of 645 kg is to be shifted using a snatch block. The angle between the lead line<br />

and the load line is 80°. What force will be applied to the snatch block rigging?<br />

= (645 x 1.53) = 986.85 kg , say 987 kg.<br />

A load of 362 kg is to be shifted, with the angle between lines at 75°. What is the force<br />

applied to the block rigging?<br />

Here, you take a factor half-way between the 70° and 80° factors and use that.<br />

= (362 x 1.59) = 575.58 kg, say 576 kg.

CRANEAGE - SLINGING: BASICS PAGE 19<br />

GOOD SLINGING PRACTICE<br />

BASIC RULES ... 2<br />

2.11. BLOCKS AND TACKLE ... 3<br />

"What is meant by mechanical advantage?"<br />

"Mechanical advantage" is a term to describe how<br />

any machine multiplies the force applied to it in order<br />

to lift or move a load.<br />

With a block and tackle, using a rope through several<br />

pulleys or sheaves, a large load can be lifted or<br />

moved with only a small effort.<br />

Diag. 1<br />

The top fixed sheaves, which do not travel up or<br />

down, serve no other purpose than to change the<br />

direction of the rope. The sheaves on the travelling<br />

block - the lower block - will create a mechanical<br />

advantage of 2:1 on each sheave.<br />

(Not counted)<br />

2<br />

3<br />

1<br />

4<br />

To calculate the mechanical advantage of a block<br />

system, simply count the number of lines supporting the<br />

load - except for the lead line (the one you pull on) when<br />

it comes down over the top block.<br />

Diagram 1 at right shows this set-up.<br />

Mechanical advantage is 4:1, which means that, to lift a<br />

load of 400 kg, an effort of only 100 kg is required on the<br />

lead line.<br />

However, if the lead line comes up to the<br />

winch or lifting force, it is counted as a<br />

supporting line, and the mechanical<br />

advantage in this case - as shown in<br />

Diagram 2 - becomes 5:1, which means<br />

that, for the same 400 kg load, only 80 kg<br />

of effort is required.<br />

Diag. 2<br />

1<br />

4 5<br />

2<br />

3

CRANEAGE - SLINGING: BASICS PAGE 20<br />

CRANEAGE - SLINGING BASICS<br />

SECTION 3:<br />

KNOW ABOUT INCLUDED ANGLES<br />

3.1 Know about the "Included Angle"<br />

3.2 Effect of Included Angle on Sling Loads<br />

3.3 Load Angle Factors<br />

3.4 Finding the Included Angle

CRANEAGE - SLINGING: BASICS PAGE 21<br />

GOOD SLINGING PRACTICE<br />

BASIC RULES ... 3<br />

3.1. KNOW WHAT THE "INCLUDED ANGLE" IS ALL ABOUT.<br />

You know the weight of the load to be lifted.<br />

You have estimated the load's centre of gravity.<br />

You know what loads the slings can carry.<br />

You have information on the different types of slings.<br />

You are all set to lift, then. Right?<br />

No!<br />

There is still one very important factor to take into account - the "Included Angle" of<br />

the slings.<br />

Having the angle of the slings is so important that it gets a section all of its own.<br />

The included angle is the angle<br />

between the two legs of a sling system.<br />

The greater the included angle<br />

between sling legs, the less load can<br />

be lifted.<br />

If a single sling is taking a load<br />

vertically, the load on that sling is<br />

equal to the load weight. That's<br />

quite simple, and certainly<br />

sounds logical.<br />

1,000 kg<br />

It may sound odd, but if a sling<br />

has an angle between the sling<br />

legs of 150°, each sling leg will<br />

have a load equal to twice the<br />

total load weight.<br />

For a load of 1,000 kg, each sling<br />

will have a load of 2,000 kg.<br />

Sling load =<br />

2,000 kg<br />

1,000 kg<br />

Incl. angle =<br />

150°<br />

Should that angle increase to<br />

170°, each leg will be subject to<br />

a load that is six times the total<br />

load weight.<br />

For a load of 1,000 kg, each sling<br />

will be loaded with 6,000 kg.<br />

Sling load =<br />

6,000 kg<br />

1,000 kg<br />

Incl. angle =<br />

170°

CRANEAGE - SLINGING: BASICS PAGE 22<br />

GOOD SLINGING PRACTICE<br />

BASIC RULES ... 3<br />

3.2. THE EFFECT OF THE "INCLUDED ANGLE" ON SLING LOADS.<br />

30°<br />

520<br />

520<br />

60°<br />

580<br />

580<br />

90°<br />

700 700<br />

120°<br />

1000<br />

1000<br />

2000<br />

150°<br />

2000<br />

6000<br />

170°<br />

6000<br />

1000 kg load<br />

This shows the effect of increasing the included angle in slings.You<br />

will see that, with an included angle of 170°, the load on each sling<br />

is six times the actual weight being lifted.<br />

Do NOT exceed the 120° included angle which provides each sling<br />

with the same weight as the actual load.

Vert<br />

CRANEAGE - SLINGING: BASICS PAGE 23<br />

GOOD SLINGING PRACTICE<br />

BASIC RULES ... 3<br />

3.3. INCLUDED ANGLE FACTORS ON SLING LOADS.<br />

12,000<br />

11,000<br />

10,000<br />

This simple graph shows the dramatic increase in loading of<br />

slings as the included angle increases.<br />

It can be seen that an included angle of less than 120°<br />

is the best option.<br />

(BASED ON TWO SLINGS LIFTING A LOAD OF 2,000 KG.)<br />

9,000<br />

8,000<br />

7,000<br />

6,000<br />

5,000<br />

4,000<br />

3,000<br />

2,000<br />

1,000<br />

10 0<br />

20 0<br />

30 0<br />

40 0<br />

50 0<br />

60 0<br />

70 0<br />

80 0<br />

90 0<br />

INCLUDED ANGLE<br />

100 0<br />

110 0<br />

120 0<br />

130 0<br />

140 0<br />

150 0<br />

160 0<br />

170 0<br />

SLING<br />

LOAD<br />

IN KGs<br />

Actual load<br />

on sling<br />

1,154<br />

C L<br />

60°<br />

Angle off<br />

horizontal:<br />

Included<br />

angle of<br />

sling:<br />

Sling<br />

included<br />

angle:<br />

Load<br />

angle<br />

factor:<br />

1,414<br />

2,000<br />

2,924<br />

5,714<br />

11,490<br />

2,000 kg load<br />

45°<br />

30°<br />

20°<br />

10°<br />

5°<br />

60°<br />

90°<br />

120°<br />

140°<br />

160°<br />

170°<br />

170° 11,490<br />

160°<br />

150°<br />

140°<br />

130°<br />

120°<br />

110°<br />

100°<br />

90°<br />

80°<br />

70°<br />

60°<br />

50°<br />

40°<br />

30°<br />

20°<br />

10°<br />

5,714<br />

3,861<br />

2,924<br />

2,364<br />

2,000<br />

1,742<br />

1,555<br />

1,414<br />

1,305<br />

1,221<br />

1,155<br />

1,104<br />

1,064<br />

1,035<br />

1,015<br />

1,004

PAGE 24<br />

GOOD SLINGING PRACTICE<br />

BASIC RULES ... 3<br />

3.4. FINDING THE INCLUDED ANGLE.<br />

How do you work out or measure the "included angle" in a set of slings?<br />

As you will now be aware, an included angle of more than 120° is not an option. The<br />

stresses on the sling start to increase dramatically once the angle of 120° is exceeded.<br />

It is a <strong>good</strong> <strong>practice</strong> to keep the sling included angle at a maximum of 60°.<br />

60° is obtained when (L) - the distance between sling attachments - is<br />

EQUAL to (S) - the sling length.<br />

90° is obtained when L is 1.4 times S.<br />

120° is obtained when L is 1.7 times S.<br />

Included<br />

Angle:<br />

S<br />

L