Barrier Coating (pdf) - Stora Enso

Barrier Coating (pdf) - Stora Enso

Barrier Coating (pdf) - Stora Enso

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

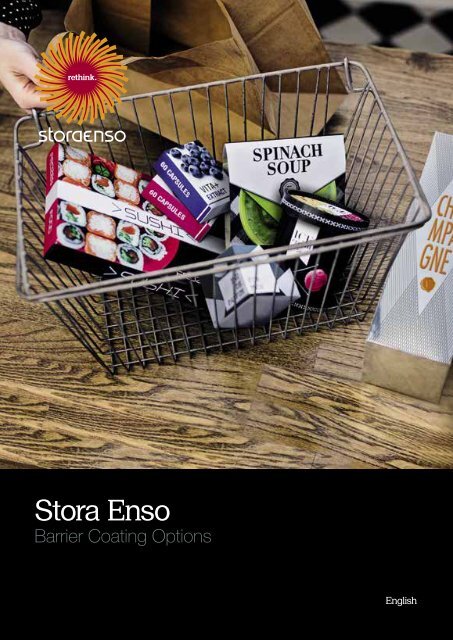

<strong>Stora</strong> <strong>Enso</strong><br />

<strong>Barrier</strong> <strong>Coating</strong> Options<br />

English

Replacing fossil-based<br />

materials with<br />

renewable materials<br />

There are no longer any excuses to opt for anything but a renewable<br />

packaging material. Even in demanding end uses such as food and<br />

liquid, renewable fibre-based materials can provide the same protection,<br />

performance and product experience.<br />

More efficient, smaller carbon footprint<br />

In most cases, the use of fibre-based materials enables more<br />

ingenious packaging solutions and clear improvements in<br />

end-to-end efficiency and carbon footprint. We understand<br />

that renewable packaging must perform in all shapes, sizes,<br />

forms and temperatures. By using proper barrier coatings,<br />

performance is guaranteed. This brochure introduces the<br />

most common barrier coatings and the insights behind<br />

them.<br />

<strong>Barrier</strong> coating really makes sense<br />

<strong>Barrier</strong> coating is the main element in efforts to optimise<br />

protection, odour control and prolongation of shelf life.<br />

<strong>Stora</strong> <strong>Enso</strong> has years of expertise in coatings and has<br />

developed responsible solutions for all conceivable end<br />

uses. <strong>Stora</strong> <strong>Enso</strong> provides the largest variety of polymer<br />

coatings. Humidity control, sealing properties, airtightness,<br />

light protection, oxygen permeability, aroma barrier, heat<br />

resistance, peelability, grease-proofing – name your need,<br />

we have a solution. All produced in a sustainable manner,<br />

and in some cases also allowing composting. Board and<br />

paper are normally recycled and the recycled fibres can be<br />

reused while separated coating materials can be recovered<br />

as energy.<br />

Combining economy and performance<br />

<strong>Barrier</strong> coating options cover a wide range of end use<br />

applications. The products have been designed to combine<br />

economy and outstanding performance, whereby excellent<br />

printing and conversion properties are provided and effective<br />

recycling is facilitated. This has resulted in designs that<br />

strike the perfect balance between product protection and<br />

aesthetic appeal.<br />

For many applications, board and paper can be coated<br />

with biopolymers. Biopolymers are produced from raw<br />

materials, deriving from natural crops or from fossil sources.<br />

Biopolymer-coated paperboard breaks down to humus<br />

and CO 2<br />

in industrial composting. In recycling schemes,<br />

biodegradable products can be either recycled or collected<br />

among other compostable materials.<br />

<strong>Barrier</strong> coatings are made of high-quality polymers, which<br />

are applied on the board surface. The coating layer improves<br />

convertibility and creates effective barriers for a wide variety<br />

of products, including perishable foodstuffs. Extrusioncoating<br />

technology enables the use of only a thin layer of<br />

polymer, while still providing the needed barrier.

Technical structure<br />

Piscuit pouch picture will be here!<br />

Polymer coating<br />

Board<br />

PE <strong>Coating</strong>s<br />

Polyolefin barriers, such as LDPE and HDPE polymers,<br />

provide excellent humidity protection. <strong>Stora</strong> <strong>Enso</strong> also<br />

offers Green PE coating, which is made of renewable raw<br />

materials. PE coatings are available on one or both sides<br />

depending on end use.<br />

Typical end uses: PE-coated packages and cups for<br />

beverages, frozen food, ice cream and yoghurt. HDPEcoated<br />

packages for moisture-sensitive dry foods.<br />

PET <strong>Coating</strong>s<br />

PET provides barriers and performs other functions. Black<br />

or white PET coatings that provide heat resistance act as<br />

an excellent grease barrier and possess solid WVTR (water<br />

vapour transmission rate) properties.<br />

Typical end uses: Ovenable trays, reheatable product<br />

packages and bakery products.<br />

Light<br />

barrier<br />

White PET <strong>Coating</strong><br />

<strong>Barrier</strong> Performance:<br />

1 Moderate 2 Good 3 Very good 4 Excellent<br />

LDPE <strong>Coating</strong><br />

Moisture<br />

Sealability<br />

4<br />

3<br />

2<br />

1<br />

0<br />

Oxygen<br />

Heat<br />

resistance<br />

Grease<br />

Light<br />

barrier<br />

HDPE <strong>Coating</strong><br />

Moisture<br />

Sealability<br />

4<br />

3<br />

2<br />

1<br />

0<br />

Oxygen<br />

Heat<br />

resistance<br />

Black PET <strong>Coating</strong><br />

Grease<br />

Biodegradable <strong>Coating</strong><br />

Biodegradable coatings are tailor-made polymers offering<br />

humidity, oxygen and grease barriers and sealability.<br />

Biopolymers are based on raw materials that come from<br />

natural crops or from fossil sources, or combinations of<br />

these. Our biodegradable coatings are compostable.<br />

Typical end uses: Drinking cups, plates, trays and cartons<br />

for fresh foods, salads, sandwiches and dairy products.<br />

Light<br />

barrier<br />

Moisture<br />

Sealability<br />

4<br />

3<br />

2<br />

1<br />

0<br />

Oxygen<br />

Heat<br />

resistance<br />

Grease<br />

Light<br />

barrier<br />

Moisture<br />

Sealability<br />

4<br />

3<br />

2<br />

1<br />

0<br />

Oxygen<br />

Heat<br />

resistance<br />

Grease<br />

High <strong>Barrier</strong> <strong>Coating</strong> (Barr)<br />

Our patented <strong>Enso</strong>barr high-barrier coating consists of<br />

a multilayer EVOH and PE polymer structure. It provides<br />

excellent oxygen, humidity and aroma protection. The highbarrier<br />

coated boards and papers are also greaseproof.<br />

Typical end uses: Various delicate foods, including<br />

chocolate, cereals and dairy products. Dry foods, such<br />

as sweets, savoury and processed snacks, coffee and<br />

tea, milk and cocoa powders. Liquid products, such as<br />

juices, soft drinks, green tea, water, soups, desserts and<br />

wines. Non-food products, such as liquid detergents and<br />

fabric softeners.<br />

Light<br />

barrier<br />

Biodegradable <strong>Coating</strong><br />

Moisture<br />

Sealability<br />

4<br />

3<br />

2<br />

1<br />

0<br />

Oxygen<br />

Heat<br />

resistance<br />

Grease<br />

Light<br />

barrier<br />

High <strong>Barrier</strong> <strong>Coating</strong><br />

Moisture<br />

Sealability<br />

4<br />

3<br />

2<br />

1<br />

0<br />

Oxygen<br />

Heat<br />

resistance<br />

Grease<br />

Airtight<br />

Freezable<br />

Microwavable<br />

Ovenable<br />

Recyclable<br />

Guide to abbreviations<br />

LDPE Low-density polyethylene<br />

HDPE High-density polyethylene<br />

PET<br />

EVOH<br />

Polyethylene terephthalate<br />

Ethylene vinyl alcohol

Fibre-based solutions for<br />

a more responsible tomorrow<br />

Packaging frequently plays an important strategic role in<br />

the products’ market presence and lifecycle. Increasingly<br />

often, packaging should also enhance the sustainability<br />

aspirations of the manufacturer. <strong>Stora</strong> <strong>Enso</strong>’s fibre-based<br />

boards and speciality papers offer superior printing and<br />

finishing quality, reliability in filling lines through better rigidity,<br />

sustainability of high standards and versatile solutions for a<br />

virtually endless array of end uses. Optimal integration of<br />

fibre-based material and barrier coating ensures package<br />

performance, high visual quality, material savings, simple<br />

conversion, waste reduction and easy recycling.<br />

For brand owners, renewable packaging enables better<br />

brand extension – with improvements in both graphics and<br />

environmental properties. Our true ambition is to enhance<br />

the co operation with our partners, aiming to promote the<br />

efficiency and sustainability of fibre-based packaging.<br />

Standard barrier coating offering<br />

Cup and tray grades PE 2PE Bio Barr White PET Black PET<br />

Cupforma Natura<br />

Cupforma Prime<br />

Cupforma Dairy<br />

Cupforma Premium Lite<br />

Cupforma Special<br />

Trayforma Performance<br />

Trayforma Special<br />

General packaging grades PE 2PE Green PE Barr Metallised PET-film<br />

CKB<br />

<strong>Enso</strong>coat<br />

Performa Bright<br />

Performa Cream<br />

Performa Natura<br />

Performa White<br />

Tambrite<br />

Liquid packaging board 2PE Barr<br />

Natura<br />

Speciality paper grades<br />

Different speciality<br />

paper grades<br />

Barr<br />

Ask for other available coating options from your local sales representative.<br />

Also available in various packaging solutions such as Primeforma for cold-cut packages and DeLight for various trayformed packaging<br />

in different sizes, forms and lidding options.

Disposable tray lifecycle assessment<br />

One of the main performance indicators of good packaging<br />

is its responsibility. One way of measuring this is the carbon<br />

footprint. In 2010, the FutuPack Eko study was carried out<br />

in Finland. The study proved that when used in a package<br />

for cold cuts, Primeforma board produces a considerably<br />

smaller carbon footprint than packages made entirely of<br />

plastic. You can see the full results in the graph on the right.<br />

The smaller carbon footprint is just one factor. The Primeforma<br />

board is also well suited to existing packaging lines, while<br />

also providing superior brand extension through high-quality<br />

print performance.<br />

These advantages for fibre-based packaging can only<br />

be achieved through excellence in barrier-coating tech -<br />

nology. Innovative products like DeLight and Primeforma,<br />

enforced with proper barrier coatings, open up new opportunities<br />

for food packaging even in the most demanding<br />

applications.<br />

Responsible production value chain<br />

<strong>Stora</strong> <strong>Enso</strong>’s production facilities are integrated, meaning<br />

that both pulp and board are produced at the same site.<br />

This allows complete environmental management of the<br />

production value chain. The high percentage of bio energy<br />

used on site ensures a low carbon footprint for paper and<br />

board products.<br />

Since paperboards are so versatile and light, they facilitate<br />

many space-saving designs, which ultimately result in<br />

economical transportation and storage. In addition, more<br />

information can be printed directly onto the surface of the<br />

board, so no extra labels are needed.<br />

Carbon footprint, packaging production<br />

(without waste management)<br />

Primeforma<br />

+<br />

Plastic film<br />

(PP, PE, EVOH) 150 g<br />

PP/PA<br />

+<br />

Plastic film<br />

(PP, PE, EVOH) 150 g<br />

APET<br />

+<br />

Plastic film <br />

(PE, EVOH, PET) 150 g<br />

112<br />

124<br />

184<br />

SOURCE: FUTUPAK EKO2010 STUDY<br />

0 50 100 150 200<br />

CO 2<br />

-eq kg/t ham<br />

Recycled board and paper fibres have good strength<br />

properties and can be recycled for a number of paper and<br />

board grades. In the recovery of polymer-coated boards<br />

and papers, the plastic can be used for energy production,<br />

replacing fossil fuels, or recycled when appropriate.<br />

Fibre-based solutions<br />

– building a more<br />

responsible tomorrow

Redesigning the Future<br />

with Renewable Packaging<br />

Chocolate &<br />

Confectionery<br />

Cigarette<br />

Cosmetics &<br />

Luxury<br />

Cups<br />

Drinks, Wines<br />

& Spirits<br />

Food<br />

<strong>Stora</strong> <strong>Enso</strong> Renewable Packaging<br />

Consumer Board<br />

Tel. +358 2046 121<br />

Fax +358 2046 24716<br />

www.storaenso.com/sales<br />

Graphical<br />

Liquid<br />

Pharmaceuticals<br />

Product Information:<br />

www.storaenso.com/consumerboard<br />

www.storaenso.com/specialitypapers<br />

03.2013 Printed on <strong>Enso</strong>coat 2S 220 g/m 2 , a renewable fibre-based board material.