The Stork PD 4 rotary screen printing/coating system - Stork Prints

The Stork PD 4 rotary screen printing/coating system - Stork Prints

The Stork PD 4 rotary screen printing/coating system - Stork Prints

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

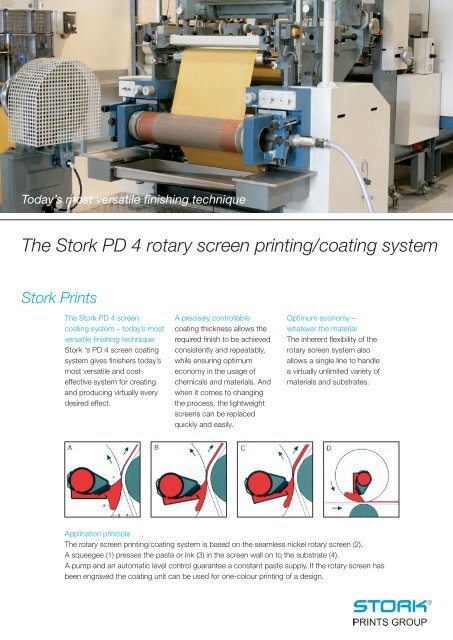

Today’s most versatile finishing technique<br />

<strong>The</strong> <strong>Stork</strong> <strong>PD</strong> 4 <strong>rotary</strong> <strong>screen</strong> <strong>printing</strong>/<strong>coating</strong> <strong>system</strong><br />

<strong>Stork</strong> <strong>Prints</strong><br />

<strong>The</strong> <strong>Stork</strong> <strong>PD</strong> 4 <strong>screen</strong><br />

<strong>coating</strong> <strong>system</strong> – today’s most<br />

versatile finishing technique<br />

<strong>Stork</strong> ‘s <strong>PD</strong> 4 <strong>screen</strong> <strong>coating</strong><br />

<strong>system</strong> gives finishers today’s<br />

most versatile and costeffective<br />

<strong>system</strong> for creating<br />

and producing virtually every<br />

desired effect.<br />

A precisely controllable<br />

<strong>coating</strong> thickness allows the<br />

required finish to be achieved<br />

consistently and repeatably,<br />

while ensuring optimum<br />

economy in the usage of<br />

chemicals and materials. And<br />

when it comes to changing<br />

the process, the lightweight<br />

<strong>screen</strong>s can be replaced<br />

quickly and easily.<br />

Optimum economy –<br />

whatever the material<br />

<strong>The</strong> inherent flexibility of the<br />

<strong>rotary</strong> <strong>screen</strong> <strong>system</strong> also<br />

allows a single line to handle<br />

a virtually unlimited variety of<br />

materials and substrates.<br />

Application principle<br />

<strong>The</strong> <strong>rotary</strong> <strong>screen</strong> <strong>printing</strong>/<strong>coating</strong> <strong>system</strong> is based on the seamless nickel <strong>rotary</strong> <strong>screen</strong> (2).<br />

A squeegee (1) presses the paste or ink (3) in the <strong>screen</strong> wall on to the substrate (4).<br />

A pump and an automatic level control guarantee a constant paste supply. If the <strong>rotary</strong> <strong>screen</strong> has<br />

been engraved the <strong>coating</strong> unit can be used for one-colour <strong>printing</strong> of a design.

Coating/<strong>printing</strong> System<br />

Coating/<strong>printing</strong> <strong>system</strong><br />

1 Control platform in front of the <strong>coating</strong> unit.<br />

2 An infeed web tension control with a set of pulling rollers.<br />

3 Screen suspension. <strong>The</strong> <strong>screen</strong> is mechanically secured and pneumatically tensioned.<br />

4 Squeegee suspension. <strong>The</strong> squeegee pressure can be set manually independently for both sides.<br />

5 Pneumatically operated counter pressure roller.<br />

6 A squeegee holder that also functions as a distribution pipe for the <strong>printing</strong>/<strong>coating</strong> paste.<br />

<strong>The</strong> stainless steel squeegee blade is attached to it.<br />

7 Whisper blade with stainless steel squeegee blade and necessary adjustment facilities.<br />

8 Standard <strong>coating</strong>/<strong>printing</strong> widths: 600 – 900 – 1200 – 1700 – 2200 – 2600 mm.<br />

Suitable for following applications<br />

Substrate: Paper, foil, non-woven.<br />

Printing <strong>coating</strong>: PVC resigns, ink, foam, PU, large pigments, solvent inks.<br />

<strong>The</strong> data in this brochure was valid at the time of publishing, and is subject to<br />

change without notice. <strong>Stork</strong> reserves the right to modify its products at any<br />

time without further obligation.<br />

<strong>Stork</strong> <strong>Prints</strong><br />

P.O. Box 67<br />

5830 AB Boxmeer<br />

<strong>The</strong> Netherlands<br />

Tel. +31 485 59 95 55<br />

Fax. +31 485 59 95 56<br />

info.storkprints@stork.com<br />

www.storkprints.com<br />

10135 0508