Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>KOIKE</strong> <strong>ARONSON</strong>, <strong>Inc</strong>.<br />

Lasertex Z Series Precision CO 2 Laser Cutting Machine<br />

<strong>KOIKE</strong> <strong>ARONSON</strong>, <strong>Inc</strong>.<br />

introduces the most effective way of<br />

high– production laser plate cutting<br />

systems in the world. We have the<br />

model of machine to accommodate<br />

your demand for high accuracy lasercut<br />

parts.

Fanuc Series C2000E<br />

Mild steel cutting capacity: 5/8 in.<br />

Stainless steel cutting capacity: 1/4 in.<br />

(no oxidation)<br />

Fanuc Series C4000E<br />

Mild steel cutting capacity: 3/4 in.<br />

Stainless steel cutting capacity: 1/2 in.<br />

(no oxidation)<br />

Lasertex Z Series Features:<br />

Sigma Box beam delivery<br />

Unmanned operation<br />

HSQ piercing includes AFT<br />

Common line cutting<br />

Superior cut accuracy<br />

Power track<br />

Carriage Pendant Operation<br />

Chiller included<br />

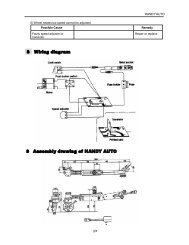

Setting of Cutting Conditions<br />

Setting of Cutting Conditions<br />

Breakthrough design features of the<br />

Lasertex reduce maintenance,<br />

decrease cycle time and improve<br />

production throughput. The Lasertex<br />

series produce highly accurate parts<br />

that can further reduce downstream<br />

production costs by eliminating<br />

special fixtures or allowing parts to<br />

be robotically welded.<br />

For your cutting needs, we

Trumpf TLF 6000 Turbo HQ<br />

Mild steel cutting capacity: 1.1 in.<br />

Stainless steel cutting capacity: 5/8 in. (optional high pressure for 1 in.)<br />

(no oxidation)<br />

Durability and advanced technology<br />

have been built into the Lasertex<br />

ensuring dependable ease of operation.<br />

The Lasertex is the answer for improving<br />

existing production processes and<br />

opening new opportunities to expand<br />

your business.<br />

The Lasertex series of cutting machines<br />

is the ultimate solution for the larger<br />

capacity and higher accuracy demands<br />

of today’s industry. The Lasertex is<br />

designed to address the increasing<br />

demand for reducing the cost of<br />

operating expenses by utilizing<br />

common-line cutting and unmanned<br />

operation.<br />

have the model to choose from!

SIGMA BOX<br />

External beam is fixed on the<br />

traverse carriage; guarantees a<br />

better quality cut!<br />

Resonator<br />

SIGMA BOX<br />

Traverse Carriage<br />

Reflection Mirrors<br />

inside SIGMA BOX<br />

Costs can be reduced significantly by operating the system unattended during<br />

night shift hours. The Lasertex is capable of producing two shifts of operation<br />

for one shift’s labor cost. A dross-free result eliminates the need for secondary<br />

cleaning operations. Common-line cutting reduces remnant scrap costs from<br />

1% to 5%. With unmanned operation, cost of operating the machine is lower<br />

due to decreased cost of power and no operator interference.

*Stable & a Higher Quality beam for a longer time period.<br />

*Longer period between periodic maintenance.<br />

*Longer lifetime of optical components.<br />

Easier maintenance; bellows system is eliminated.<br />

*Operator friendly easy maintenance.<br />

*Higher safety.<br />

*Machine balance is the best. (The resonator moves with traverse carriage).<br />

AFT Nozzle<br />

Conventional<br />

DF Nozzle<br />

●AFT nozzle (Active Flow Technology)<br />

Patent pending<br />

The AFT (Active Flow Technology) nozzle works together with the<br />

release of the HSQ piercing feature. These features allow the<br />

Lasertex to run with improved cut quality, quicker pierce times,<br />

improved unmanned operation results, and significantly increased<br />

life span of the nozzle and lens. The AFT nozzle allows for a higher<br />

standoff while piercing which protects the nozzle and lens from<br />

spatter. It also controls the flow of cutting gas in a way that<br />

minimizes spatter on the material for more consistent cutting while<br />

also improving edge quality and eliminating dross.<br />

●HSQ Piercing (High Speed and High quality)<br />

Patent No. 2875626 and others.<br />

The HSQ (High Speed and Quality) system uses a servomotor to<br />

move the lens’ focal point downward into the material during the<br />

pierce cycle while simultaneously ramping up duty cycles and<br />

frequencies. This process shortens the pierce time and produces<br />

better holes to begin cutting for improved reliability for unmanned<br />

operations.<br />

Pulse HSQ Quick Piercing

OPTIONAL EQUIPMENT AVAILABLE<br />

6Kw offers a fully contouring laser bevel cutting unit.<br />

The rotating unit uses an endless system, and there are no restrictions of NC<br />

programming like gas/plasma cutting machines.<br />

The bevel unit uses an offset system, and the amount of offset is adjusted<br />

automatically from the CNC. The bevel unit uses simplified programming.<br />

Stable bevel cutting can be measured by a built in high-speed automatic focus<br />

device and high speed and high quality HSQ piercing.<br />

Torch collision detection (touch sensor with a buffer mechanism of a nozzle<br />

block base) prevents breakage of equipment.<br />

The plug-in type lens holder makes lens cleaning easy.<br />

I-cutting (straight cutting) and +/- bevel cutting is possible.<br />

Samples<br />

Reduces the daily<br />

maintenance by<br />

cleaning the pinion<br />

with a medium bristled<br />

brush mounted to a<br />

motor.<br />

Stainless steel plate thickness ½”(12mm)<br />

Mild Steel 3/4 in. 30°angle

Fanuc 2Kw and 4Kw resonator<br />

The resonator is a highly reliable design.<br />

Various safety standards, such as European<br />

standards and the FDA standards, are included.<br />

Display functions make maintenance easy.<br />

A reliable external electrode type discharge tube and<br />

solid high frequency power supply.<br />

Improved efficiency provides a more stable output of oscillation.<br />

The oscillation efficiency is improved by high quality high frequency electric discharge excitation.<br />

Better pulse output characteristic by the solid high frequency power supply causes high quality cutting<br />

generated from a stable beam.<br />

Outstanding CNC control functions.<br />

The laser resonator is under direct CNC control.<br />

High speed and high precision processing are made possible directly from the control.<br />

Plate cutting conditions are efficiently set by CNC control.<br />

Trumpf 6Kw resonator<br />

The lightweight and compact CO 2 laser resonation system uniformly<br />

absorbs thermal expansion inside the resonator. The symmetrical design<br />

prevents distortions formed by heat.<br />

The turbo blower uses an oil free magnetic bearing making the laser gas<br />

circulation stable with a high quality output. Less vibration means a high<br />

quality beam output for a longer period.<br />

Resonator cooling is an important factor for the maintenance and stability<br />

of high output and beam quality. Cooling circuits are separated into a<br />

copper system and an aluminum system that provides technically effective<br />

temperature control, as well as an anti-corrosion measure.<br />

High beam stability is made possible by the symmetry<br />

mirror holding frame inside Resonator. Heat distribution<br />

makes the expansion pressure equal to all parts of the<br />

frame, so that no shift of the beam is distorted by heat<br />

transformation.

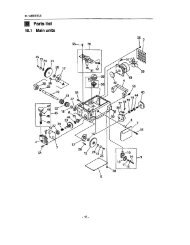

E<br />

A<br />

B<br />

Specifications to change without notice<br />

C<br />

LASERTEX SYSTEM DIMENSIONS<br />

“A” “B” “C” “D” “E”<br />

Model Cutting Width Rail Width Overall Width Machine Length Machine Height<br />

LT-3560 <strong>Inc</strong>hes<br />

mm<br />

138<br />

3500<br />

177<br />

4500<br />

236<br />

6000<br />

92<br />

2330<br />

101<br />

2500<br />

LT-4060 <strong>Inc</strong>hes<br />

mm<br />

157<br />

4000<br />

197<br />

5000<br />

254<br />

6450<br />

92<br />

2330<br />

101<br />

2500<br />

LT-4560 <strong>Inc</strong>hes<br />

mm<br />

177<br />

4500<br />

216.5<br />

5500<br />

276<br />

7000<br />

92<br />

2330<br />

101<br />

2500<br />

LT-5060 <strong>Inc</strong>hes<br />

mm<br />

197<br />

5000<br />

236<br />

6000<br />

295<br />

7500<br />

92<br />

2330<br />

101<br />

2500<br />

Model Cutting Width Rail Width Overall Width Machine Length Machine Height<br />

LT-3540<br />

<strong>Inc</strong>hes<br />

mm<br />

<strong>Inc</strong>hes<br />

mm<br />

<strong>Inc</strong>hes<br />

mm<br />

<strong>Inc</strong>hes<br />

mm<br />

138<br />

3500<br />

177<br />

4500<br />

197<br />

5000<br />

216.5<br />

5500<br />

236<br />

6000<br />

218<br />

6000<br />

238<br />

6450<br />

258<br />

7000<br />

277<br />

7500<br />

92<br />

2330<br />

92<br />

2330<br />

92<br />

2330<br />

92<br />

2330<br />

101<br />

2500<br />

101<br />

2500<br />

101<br />

2500<br />

101<br />

2500<br />

LT-4040<br />

157<br />

4000<br />

LT-4540<br />

177<br />

4500<br />

LT-5040<br />

197<br />

5000<br />

Model Cutting Width Rail Width Overall Width Machine Length Machine Height<br />

LT-2120<br />

LT-2620<br />

LT-3120<br />

LT-3620<br />

<strong>Inc</strong>hes<br />

mm<br />

<strong>Inc</strong>hes<br />

mm<br />

<strong>Inc</strong>hes<br />

mm<br />

<strong>Inc</strong>hes<br />

mm<br />

83<br />

2100<br />

102<br />

2600<br />

122<br />

4500<br />

142<br />

5000<br />

119<br />

3000<br />

138<br />

3500<br />

158<br />

4000<br />

178<br />

4500<br />

157<br />

4000<br />

179<br />

4550<br />

236<br />

6000<br />

256<br />

6500<br />

64<br />

1630<br />

64<br />

1630<br />

64<br />

1630<br />

64<br />

1630<br />

86<br />

2189<br />

86<br />

2189<br />

86<br />

2189<br />

86<br />

2189<br />

<strong>KOIKE</strong> <strong>ARONSON</strong>, <strong>Inc</strong>.<br />

Visit us at: www.koike.com<br />

Main Office:<br />

635 W. Main St.<br />

P.O. Box 307<br />

Arcade, NY 14009<br />

Fax 585-457-3517<br />

Phone: 585-492-2400<br />

Houston Sales Center:<br />

1285 North Post Oak<br />

Suite 150<br />

Houston, TX 77055<br />

Fax 713-957-4852<br />

Phone: 713-682-9645<br />

N o 209917