Homework #4 - Classes

Homework #4 - Classes

Homework #4 - Classes

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

IE 368: Facility Design and Operations Management<br />

Winter 2012<br />

<strong>Homework</strong> <strong>#4</strong>: Production System Design Concepts<br />

Due Date: Tuesday, February 7 th , 2012<br />

(NOTE: To obtain full credit in this homework, make sure to show all your work in each<br />

problem.)<br />

1. Suppose jobs arrive to a workstation at a rate of 20 jobs per hour.<br />

a. If the workstation processes a single job at a time with an average process time per<br />

job of 2.5 minutes, what is the utilization of the workstation?<br />

b. If the workstation processes two jobs at a time with an average process time per job<br />

of 5 minutes, what is the utilization of the workstation?<br />

c. If the workstation processes two jobs at a time with an average process time per job<br />

of 2.5 minutes, what is the utilization of the workstation?<br />

d. If the workstation processes two jobs at a time with an average process time for<br />

server 1 (or machine 1) in the workstation of 2.5 minutes, and 5 minutes for server 2<br />

(or machine 2), what is the utilization of the workstation?<br />

2. Consider a workstation with 11 machines (in parallel), each with an average effective process<br />

time of one hour with CV e2 = 5 . Each machine costs $10,000. Orders arrive at a rate of 10<br />

per hour with CV a2 = 1 and must be filled. The maximum allowable average time-in-system<br />

is two hours. Currently, it is a little more than three hours. Analyze the following options for<br />

decreasing response time and make a recommendation.<br />

a. Add another machine to the workstation at a cost of $10,000.<br />

b. Modify the existing machines (all eleven) to make them faster. Assume the<br />

coefficient of variation for the shorter effective processing times does not change.<br />

The cost will be $8,500 and the new t = 0. 96 hours.<br />

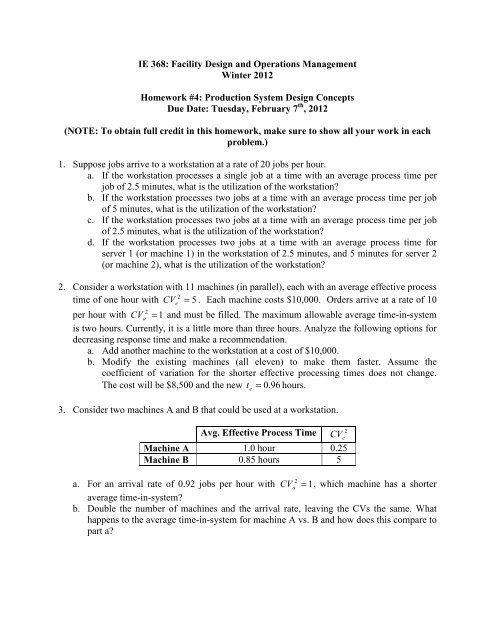

3. Consider two machines A and B that could be used at a workstation.<br />

Avg. Effective Process Time<br />

2<br />

CV<br />

e<br />

Machine A 1.0 hour 0.25<br />

Machine B 0.85 hours 5<br />

e<br />

a. For an arrival rate of 0.92 jobs per hour with CV<br />

a2 = 1, which machine has a shorter<br />

average time-in-system?<br />

b. Double the number of machines and the arrival rate, leaving the CVs the same. What<br />

happens to the average time-in-system for machine A vs. B and how does this compare to<br />

part a?

4. Consider two machines (i.e., A and B) that are used at workstations 1 and 2, respectively,<br />

arranged in series. Each workstation has a single machine.<br />

Avg. Effective Process Time<br />

2<br />

CV<br />

e<br />

Machine A 1.0 hour 0.25<br />

Machine B 0.85 hours 5<br />

For an arrival rate of 0.92 jobs per hour with CV<br />

a2 = 1, calculate the total system WIP and<br />

TIS if:<br />

a. The workstations are visited in the sequence 12.<br />

b. The workstations are visited in the sequence 21.<br />

5. Suppose in problem 4 that the sequence is 21, but now there are two machines at each<br />

workstation with a single queue feeding both machines at each workstation. The average<br />

effective processing times are double the values in problem 4, but the CVs are the same.<br />

Estimate total system WIP and TIS.<br />

6. Using the concepts of t<br />

e<br />

, ta<br />

, CVe<br />

, CVa<br />

, explain the results of the following activities on TIQ.<br />

a. Reducing the repair times at a workstation when it goes down during job processing.<br />

b. Reducing the frequency of failures at a workstation through preventive maintenance.<br />

c. Maintaining an inventory of different types of finished products to permit a similar<br />

production schedule each day.<br />

d. Producing small lots on a workstation with large setup times.<br />

e. Accepting orders for a new product (in addition to existing production) that differs (has<br />

larger times) in effective process time.

IE 368: Facility Design and Operations Management<br />

<strong>Homework</strong> <strong>#4</strong>: Production System Design Concepts<br />

Due Date: Tuesday, February 7 th , 2012<br />

Name: _______________________________________________<br />

1a) Utilization: __________________ %<br />

1b) Utilization: __________________ %<br />

1c) Utilization: __________________ %<br />

1d) Utilization: __________________ %<br />

RESULTS<br />

2a) TIS = _________________ hrs Meets requirements?: YES NO<br />

2b) TIS = _________________ hrs Meets requirements?: YES NO<br />

3a) Machine A TIS: _________________ hrs<br />

Machine B TIS: _________________ hrs<br />

3b) Machine A TIS: _________________ hrs<br />

Machine B TIS: _________________ hrs<br />

4a) Total TIS: _________________ hrs<br />

Total WIP: _________________ jobs<br />

4b) Total TIS: _________________ hrs<br />

Total WIP: _________________ jobs<br />

5) Total TIS: _________________ hrs<br />

Total WIP: _________________ jobs<br />

6) Explain your answers on your workspace.