Asia Pacific version - Sparrows

Asia Pacific version - Sparrows

Asia Pacific version - Sparrows

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

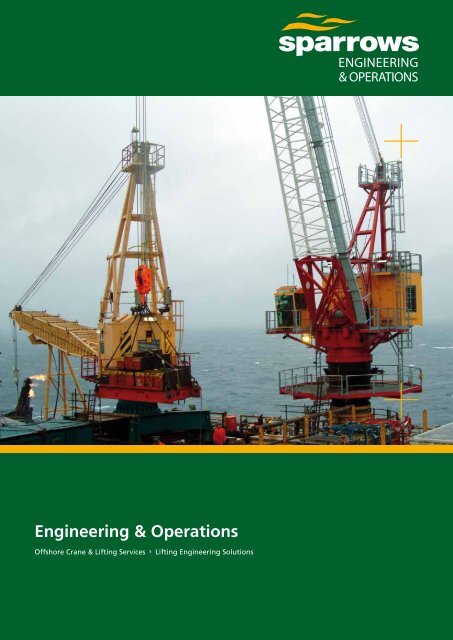

Engineering & Operations<br />

Offshore Crane & Lifting Services › Lifting Engineering Solutions

<strong>Sparrows</strong> Engineering & Operations<br />

provide cost-effective solutions and<br />

operational support to enhance the safety,<br />

reliability and productivity of your offshore<br />

lifting and handling operations.<br />

Our company<br />

Across our global network of<br />

service centres, we deliver a wide<br />

range of services from concept to<br />

completion, through operation<br />

support to decommissioning. Our<br />

design engineers, offshore crews and<br />

onshore support teams have the skill<br />

and experience to quickly identify<br />

the best solution to fit your needs<br />

and maximise your operations.<br />

Our services include:<br />

• y Consultancy, design &<br />

project engineering<br />

• y Crane/lifting equipment<br />

operation, inspection,<br />

maintenance & repair<br />

• y Crane/lifting equipment<br />

management<br />

• y Onshore repair & refurbishment<br />

• y Spare parts and products<br />

• y Loose lifting equipment services<br />

• y Used cranes<br />

Our People<br />

Our engineering and technical<br />

specialists have delivered a variety<br />

of projects in a host of different<br />

industries around the world. As part<br />

of the <strong>Sparrows</strong> group, we work in<br />

multi-disciplined teams, combining<br />

operational experience, engineering<br />

expertise and a pioneering mindset.<br />

Our knowledge sharing forum engages<br />

engineers throughout the group to<br />

exchange innovative methodologies<br />

and concepts, allowing them to take<br />

these ideas and adapt them to suit<br />

varying projects around the world.<br />

Quality<br />

Accredited to ISO 9001, our integrated<br />

systems and procedures are designed to<br />

ensure integrity, efficiency and above all<br />

safety in everything we do.<br />

Our Facilities<br />

Our facilities are strategically<br />

located around the world, equipped<br />

to process a wide range of<br />

fabrication, overhaul, repair and<br />

refurbishment projects. Working<br />

to accredited HSEQ procedures, our<br />

skilled technicians produce quality<br />

results. Our large stock holding<br />

of spare parts and components<br />

guarantees a fast turnaround.<br />

1<br />

1. Bolt Inspection

2<br />

3<br />

2. Overside Lift<br />

3. Pedestal Stress Analysis<br />

4. National OS215 Rental Crane<br />

4<br />

Our Services<br />

Consultancy, Design &<br />

Project Engineering<br />

Led by technical experts with an<br />

unrivalled wealth of knowledge and<br />

experience, our dedicated project<br />

and design engineers create specialist<br />

solutions to fit your needs. From quick<br />

answers to meet small operational<br />

improvements to challenging and<br />

complex lift engineering projects, our<br />

approach is to always offer the best<br />

solution on time and in budget.<br />

This includes:<br />

• y Lifting needs analysis<br />

• y Lifting plans<br />

• y Crane, design, specification<br />

& manufacture<br />

• y Project lifting systems<br />

• y Drilling derrick handling<br />

equipment<br />

• y Platform decommissioning<br />

support<br />

• y Risk assessment<br />

• y Lifting plan preparation & review<br />

• y Lifting studies<br />

• y Equipment specification<br />

• y Detailed equipment design<br />

• y 3D structural analysis<br />

• y 3D finite element analysis<br />

• y Failure Modes Effects &<br />

Criticality Analysis<br />

• y Fatigue & design life review<br />

• y LOLER/NORSOK survey & review<br />

“Our proven<br />

methodologies<br />

improve safety,<br />

extend life, enhance<br />

performance and<br />

yield greater results”

Our Services<br />

Crane Operation<br />

Our pool of crane operators provide<br />

support to drilling and maintenance<br />

operations, workovers and other 24-<br />

hour operations. Our thinking behind<br />

the multi-skilled role of the crane<br />

operator/maintainer helps to increase<br />

the availability of resource and add value<br />

to your operations.<br />

Our crane operator training programme<br />

has gone on to become an industry<br />

standard in the UK and internationally<br />

while in the US, <strong>Sparrows</strong> train crane<br />

operators to API standard.<br />

Inspection<br />

The integrity of your crane/lifting<br />

equipment is vital to performing<br />

safe and reliable lifting operations.<br />

Ensuring your equipment is in safe<br />

working order helps to prevent<br />

any nasty or costly surprises when<br />

you least need them. Our experts<br />

undertake regular crane inspection to<br />

a developed scheme, allowing you to<br />

maximise uptime and plan outages<br />

to minimise operational impact.<br />

We offer:<br />

• y Thorough assessment of your<br />

equipment undertaken by<br />

experienced professionals<br />

• y Expert recommendations<br />

to optimise equipment<br />

performance & reliability<br />

• y Solutions to enhance<br />

equipment capacity & heavy<br />

lift preparation<br />

Online Reports<br />

Our unique web based concept provides<br />

clients with immediate access to their<br />

reports whenever and wherever they<br />

need them. Its user friendly design<br />

offers secure log in via the <strong>Sparrows</strong> web<br />

site with an easy-to-read traffic light<br />

summary highlighting urgent to non<br />

essential recommendations. Clients also<br />

have access to the full detailed report<br />

and list of recommendations, which<br />

are kept up-to-date as and when any<br />

remedial work is undertaken.<br />

1<br />

1. Crane Operator<br />

2. Crane Maintainer<br />

2

3<br />

4<br />

3. Slew Ring Bolt Tensioning<br />

4. Boom Refurbishment<br />

5. Managed crane services<br />

5<br />

Maintenance & Repair<br />

<strong>Sparrows</strong> has a team of specialist<br />

maintenance engineers who can run<br />

any equipment through a Failure Modes<br />

Effects and Criticality Analysis study<br />

to determine when inspections and<br />

maintenance need to be undertaken,<br />

ensuring single point failures that would<br />

lead to a dropped load are mitigated.<br />

From here a maintenance strategy is<br />

worked up, complete with a set of<br />

detailed planned maintenance routines.<br />

Whatever the problem, we can mobilise<br />

maintenance technicians within 24<br />

hours who have the knowledge and<br />

experience to deal with any breakdowns.<br />

Crane/Lifting Equipment<br />

Management<br />

The crane management concept was<br />

developed by <strong>Sparrows</strong>. Its simple – we<br />

take complete responsibility for the safe<br />

and continuous operation of your cranes<br />

and lifting equipment. This includes:<br />

• y Dedicated engineering support<br />

• y Annual activity plan and<br />

budget management<br />

• y Maintenance strategy/planned<br />

maintenance routine development<br />

• y Provision of skilled core crew<br />

& additional ad-hoc supply<br />

• y Spares management<br />

• y Competency assurance<br />

• y Transparency & regular reportage<br />

• y KPI performance measure<br />

“Outsource to<br />

the expert”

2<br />

3<br />

1. <strong>Sparrows</strong> Hydraulic Technician<br />

2. Refurbished National Crane<br />

3. Boom Refurbishment<br />

4. Crane Boom Spray Paint<br />

4<br />

Onshore Repairs &<br />

Refurbishment<br />

Our facilities are built to undertake<br />

fast and efficient turn around of<br />

your refurbishment or repair projects.<br />

Equipped with overhead cranes, the<br />

latest fabrication and manufacturing<br />

equipment and tools, we deliver<br />

a wide range of projects to our<br />

customers around the world, from the<br />

manufacture of small machined crane<br />

components to the fabrication and<br />

assembly of boom sections and whole<br />

cranes. These can be to OEM standard<br />

or to specific customer requests.<br />

Our experienced engineers and<br />

technicians work to a high standard<br />

of quality and are able to deliver<br />

innovative and cost effective<br />

solutions to meet your needs.<br />

Services we provide through<br />

our onshore facilities:<br />

• y Disassembly, inspection<br />

and rebuild of mechanical<br />

assemblies such as gearboxes,<br />

hook blocks and winches<br />

• y Fabrication of structural<br />

components such as booms<br />

and “A” frames<br />

• y Manufacture of replacement<br />

machined components<br />

required in the rebuild of<br />

mechanical assemblies<br />

• y Shot blasting and painting to<br />

offshore standards of steelwork<br />

from small components to<br />

complete crane booms<br />

Authorised Paccar Braden/<br />

Cargo Service Centres<br />

Paccar Winch Division is the industry<br />

leader in the design and manufacture<br />

of winch, hoist and drive systems.<br />

As an official distributor and service<br />

centre for the Braden Planetary and<br />

Cargo Gearmatic range, <strong>Sparrows</strong><br />

deliver a wide range of services and<br />

technical expertise within the Gulf<br />

of Mexico, UAE & Persian Gulf.<br />

We offer:<br />

• y Purpose-built, high capacity<br />

winch testing facilities<br />

• y Sophisticated data<br />

recording system<br />

• y Large inventory of OEM parts<br />

• y Skilled & fully trained technicians<br />

• y Service & technical support<br />

• y After sales care

Spare Parts & Products<br />

Spares Supply<br />

Products<br />

<strong>Sparrows</strong> offer an independent and<br />

impartial approach to spares supply,<br />

with the freedom to specify the most<br />

appropriate and cost effective option<br />

to suit your needs. An extensive stock<br />

holding of critical spares ensures that<br />

you have immediate access to parts<br />

when you need them most, helping you<br />

avoid delays and minimising downtime.<br />

We have significant buying power with<br />

our suppliers, allowing you to benefit<br />

from faster lead times and better prices.<br />

Our services include:<br />

• y Spares management<br />

• y Re-engineering and replacement<br />

of obsolete components<br />

• y OEM spares for American Aero,<br />

Titan, Houston Systems, Bucyrus<br />

Erie Marine Cranes<br />

We also have several strategic<br />

partnerships with technology and<br />

component suppliers in the lifting<br />

and access support industries,<br />

with agreements in place that<br />

enable us to deliver a fast response<br />

at competitive prices:<br />

• y Stahl Crane Systems – Ex<br />

explosion proof hoists<br />

• y AADI – Mipeg – load<br />

monitoring systems<br />

• y LSI Load Monitoring Systems<br />

• y Paccar Braden Planetary<br />

gear winches<br />

• y Orlaco – boom tip cameras<br />

• y Latchways PLC – cable<br />

based fall arrest systems<br />

• y Reflex Marine – FROG Marine<br />

personnel transfer capsule<br />

PMS 554 PMS 556<br />

PMS 421<br />

• y Outreach – powered access &<br />

tubular handling equipment<br />

1<br />

2<br />

1. LSI Sensor<br />

2. Spares Supply<br />

3. Latchways Fall Arrest System<br />

3

4<br />

5<br />

4. Rigging Loft Inventory Check<br />

5. Rigging Loft Equipment Inspection<br />

6. National OS215 FAT<br />

6<br />

Loose Lifting<br />

Equipment Services<br />

Regular inspection or replacement of<br />

lifting equipment is the only assured<br />

way to reduce the risk of potential<br />

failure and accident. The integrity of<br />

your equipment can only be guaranteed<br />

with a dedicated management system in<br />

place. <strong>Sparrows</strong> have long experience of<br />

providing loose lifting equipment services<br />

and have built up a considerable stock of<br />

certified equipment for hire:<br />

• y Rigging loft containers fully<br />

equipped for transportation and<br />

subsequent control of rigging gear<br />

• y Lifting equipment – chain,<br />

lever, wire rope and pneumatic<br />

hoists, beam clamps and<br />

trolleys, sheave blocks<br />

• y Working at height equipment –<br />

inertia reels, harnesses, lanyards<br />

• y Accessories – slings (wire<br />

and fabric), shackles,<br />

eyebolts, crane pendants<br />

• y Lifting Equipment Examiners to<br />

inspect fixed lifting equipment<br />

(runway beams, padeyes, etc.)<br />

Used Cranes<br />

<strong>Sparrows</strong> refurbish used cranes for<br />

re-sale or hire from our regional<br />

service centres. Used cranes can<br />

often be the most economically<br />

viable solution when considering<br />

equipment replacement offshore.<br />

Our range of hydraulic cranes tend<br />

to be over 15 years old with known<br />

service records, refurbished to the<br />

manufacturers original specification<br />

or with customised upgrades<br />

to enhance performance.<br />

<strong>Sparrows</strong> own the intellectual property<br />

rights to Bucyrus Erie Marine Cranes.<br />

Manufactured originally to the API 2C<br />

standard, we also stock and supply all<br />

spare parts & components to support<br />

these cranes.<br />

Regular models in our fleet include:<br />

• y National<br />

• y Bucyrus Erie Marine Cranes<br />

• y Linkbelt<br />

• y Unit Mariner<br />

• y American Aero<br />

• y Titan<br />

“Temporary<br />

crane solutions”

MEMBER<br />

Worldwide locations<br />

UK › Netherlands › Angola › Nigeria › Azerbaijan › UAE › Singapore › Indonesia › Australia › USA › Mexico<br />

Global Service Support<br />

As part of the <strong>Sparrows</strong> group, we deliver<br />

a wide range of effective lifting, handling<br />

and fluid power solutions from any of our<br />

service centres around the world.<br />

• y Crane manufacturing<br />

• y Crane rental<br />

• y Training<br />

• y Pipe & cable handling<br />

• y Fluid power solutions<br />

“Global support<br />

delivered locally”<br />

For more information visit<br />

www.sparrowsgroup.com<br />

IMR 506024

Europe/West Africa<br />

Regional Headquarters<br />

Seton House, Murcar Industrial Estate,<br />

Denmore Road, Bridge of Don, Aberdeen,<br />

UK AB23 8JW<br />

T: +44 (0)1224 704868<br />

F: +44 (0)1224 825191<br />

E: engops.europe@sparrowsgroup.com<br />

E: engops.africa@sparrowsgroup.com<br />

US<br />

Regional Headquarters<br />

10235 West Little York, Suite 100, Houston,<br />

Texas, 77040, USA<br />

T: +1 832 467 7300<br />

F: +1 832 467 7390<br />

E: engops.us@sparrowsgroup.com<br />

Caspian<br />

Regional Headquarters<br />

Natavan Residences & Office Centre Millennium,<br />

Room 401B, 3 Tbilisi Avenue,<br />

AZ1065, Baku, Azerbaijan<br />

T: +994 (0)12 4970922<br />

F: +994 (0)12 5104137<br />

E: engops.caspian@sparrowsgroup.com<br />

Middle East<br />

Regional Headquarters<br />

6th Street, 6th Zone, Corniche Road,<br />

Mussafah Industrial Area, PO Box 4015,<br />

Abu Dhabi, UAE<br />

T: +971 (0)2 554 4401<br />

F: +971 (0)2 554 4607<br />

E: engops.me@sparrowsgroup.com<br />

<strong>Asia</strong> <strong>Pacific</strong><br />

Regional Headquarters<br />

9 Gul Circle, Singapore, 629565, Singapore<br />

T: +65 655 88 058<br />

F: +65 655 88 057<br />

E: engops.asia@sparrowsgroup.com<br />

Indonesia Operations<br />

Ground Floor, Radiant Utama Building, JL, Kapten Tendean No 24,<br />

Mampang Prapatan, Jakarta Seletan, Indonesia, 12720<br />

T: +62 21 719 0974<br />

F: +62 21 719 0975<br />

E: engops.asia@sparrowsgroup.com<br />

Australia<br />

Regional Headquarters<br />

82 Chisholm Crescent, Kewdale, Perth<br />

WA 6105, Australia<br />

T: +61 (0)8 9359 2355<br />

F: +61 (0)8 9359 4530<br />

E: engops.au@sparrowsgroup.com<br />

www.sparrowsgroup.com