Download the November/December 1990 Issue in PDF format

Download the November/December 1990 Issue in PDF format

Download the November/December 1990 Issue in PDF format

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Bought<br />

BRIDLES<br />

B CKlES<br />

CLOTHI G<br />

B.ITS<br />

* BOOKS<br />

HIGH<br />

Western<br />

& SoIJ:<br />

N'OON<br />

BELTS<br />

BOLOS<br />

CHAPS<br />

SPURS<br />

* SADDlES<br />

Collectibles<br />

(213) 202-9010 by appo<strong>in</strong>tment (111)'<br />

(213) 202·1340 (fax)<br />

CIRClE .A-5 ON IREADER REPLVCARD<br />

EDITORIAL<br />

STAFF<br />

PUBUSHER &EDITOR·IN-CHIEF<br />

Michae~ Goldste<strong>in</strong><br />

ASSOCIATE PUBLISHER. &:<br />

MANAGING EDITOR<br />

Peg Short<br />

SENIOR EDITOR<br />

Nancy Bartels<br />

ART DlRECI'OR<br />

Jean Sykes<br />

ADVERTISING SAlES .MANAGER<br />

Patricia FLam<br />

SALES COORDINATOR<br />

Mary Michelson<br />

(lRCUlATION<br />

Pamela Nolan<br />

Debbie Donigian<br />

RANDALL PUBLISHING STAFF<br />

PRESIDENT<br />

Michael Goldste<strong>in</strong><br />

VICE PRESIDENT<br />

Richard GoldsWn<br />

VICE PRESIDENT/GEN.<br />

Peg Short<br />

ACCOUNTING<br />

Laura K<strong>in</strong>nan.e<br />

ART CONSULTANT<br />

Marsha Goldste<strong>in</strong>.<br />

MGR.<br />

RAND.ALL PUBLlSHlNC CO., INC.<br />

1401 Lunt Avenue<br />

P.O .. Hox 1426<br />

Elk Grove, [L 60007<br />

(708) 437-6604<br />

2 'Geonec'hnolog:y<br />

CIRCLE A.o ON READER REPLYCARD<br />

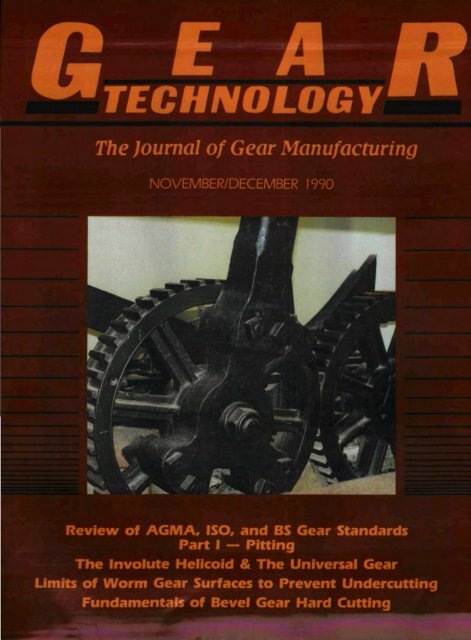

OUR COVER<br />

'Sun and Planet" mechanism develop.ed<br />

by James Watt to modify his steam<br />

eng<strong>in</strong>e to achieve rotary motion. In this<br />

system a cog wheel is attached' to <strong>the</strong><br />

connect<strong>in</strong>g rod ,and <strong>the</strong>n married to<br />

ano<strong>the</strong>r, usually smaller, cogwheel<br />

jo<strong>in</strong>ed to a flywheel. The mach<strong>in</strong>e<br />

shown was manufactured around 1787<br />

by Boulton & Watt. Itis at <strong>the</strong> Science<br />

Museum <strong>in</strong> Ed<strong>in</strong>burgh:. Scotland'. Our<br />

thanks to Mr. Richard' E Beale of<br />

Brisbane, Australia, for use of <strong>the</strong><br />

photos and <strong>in</strong><strong>format</strong>ion Or! this early<br />

steam eng<strong>in</strong>e.

The Journal 01Gear Manufactur<strong>in</strong>g<br />

CONTENTS<br />

FEATURES<br />

.A .REVIEW OF A:CNA, ISO, AND BS GEAR STANDAR~S •<br />

.P'ART 1 - PITTINC<br />

Doug Wall:on, YUloIIen Shl, Stan Taylor,<br />

University of B<strong>in</strong>n<strong>in</strong>gnam, Birm<strong>in</strong>gham. England<br />

10<br />

THE INVOLUTE HEUOOm AND THE UNIVERSAL GEAR<br />

Leonard J. Smith. Inv<strong>in</strong>cible 'Gear Co., Livonia, M]<br />

18<br />

UMITATION OF WORM AND' WORM CEAR SURFA:CES<br />

TO AVOID UNDERCUITING •••<br />

Vadim Kill, Purdue University, Hammond, IN<br />

30<br />

ED.lTORIAL 7<br />

VIEWPOINT 9<br />

BACK, TO BAJiICS • " '.<br />

,F1JNDAMENTALS OF BEVEL 'GEAR HARD CUTnNG<br />

Yogi, Sharma. Philadelphia Gear Co., K<strong>in</strong>g of Prussia. PA<br />

36<br />

CLASS[FJEDS 46<br />

<strong>November</strong>J<strong>December</strong>, <strong>1990</strong>_' V_o_I._7_, _N_o_. _6<br />

IN'ovemoer/Decem'ber 199Qi 3

Know<strong>in</strong>g<br />

it's Ground<br />

on a<br />

••<br />

BHS-HOFLER ...<br />

Unsurpassed <strong>in</strong> quality and speed<br />

- with capability to gr<strong>in</strong>d tooth<br />

modifications required for today's<br />

and tomorrow's needs.<br />

In a world of ever grow<strong>in</strong>g competition<br />

and demand for Quality, only<br />

<strong>the</strong> best will survive. Therefore<br />

modernize your gear production<br />

now where you need it most of all<br />

- <strong>in</strong> <strong>the</strong> gear gr<strong>in</strong>d<strong>in</strong>g room.<br />

BHS-HOFLER offers gear gr<strong>in</strong>d<strong>in</strong>g<br />

mach<strong>in</strong>es <strong>in</strong> 14 sizes for gears<br />

from 1" to 160" <strong>in</strong> diameter -<br />

manual- or CNC-technology.<br />

- For <strong>the</strong> first time ever:<br />

precision pallet load<strong>in</strong>g system.<br />

- Newly developed NC-dressable<br />

gr<strong>in</strong>d<strong>in</strong>g wheels.<br />

Call or write<br />

for more <strong>in</strong><strong>format</strong>ion:<br />

BHS-HOFLER CORP.<br />

P. O.Box 127<br />

Sky Manor Road<br />

Pittstown, NJ 08867<br />

j}fj!J<br />

147<br />

.. II<br />

Telephone: 908-996-6922<br />

Teletax; 908-996-6977<br />

Telex: 380576<br />

* ..• A reference list with more than 500 satisfied<br />

customers world-wide is available for <strong>the</strong><br />

ask<strong>in</strong>g who's who <strong>in</strong> <strong>the</strong> gear <strong>in</strong>dustry.<br />

CIRClE<br />

A-7 ON READER REPLYCARD

~BS;lhiliujil<br />

The IKashifuji KN 1150CNC<br />

Gear Hobber. High aocuracy<br />

assured through Irigidconstruction.<br />

Full 5 axis eNe controls plus<br />

hob rotation. Exce'ls over a wide<br />

range ,of high speedl hobb<strong>in</strong>g<br />

applications. Small foot Ipr<strong>in</strong>t.<br />

Easy and fast changeover<br />

accommodates vary<strong>in</strong>gllproduction lots.<br />

Handl'es gear sizesfrom 3f4" to40~<br />

High production capacity<br />

with fast auto loaders ..<br />

Kashifuji KN·150eNe Gear Hobbers.<br />

Contad. Kashifuil Product Manager,<br />

Midwest Branch,<br />

Cosa Corporation<br />

1,680 S. Uvernois,<br />

IRochester" M148063<br />

Tel. 313--652·7404<br />

Fax. 313·652-1450:.<br />

COSACORPORATION"<br />

MACHINETOOLDIVISION<br />

17 P,hilips Pal'lkway, Montvale" NJ 07645 Tel. 2011-3911-0700 Fax. 2011-391-4261<br />

C'IRCLE A~e ON IREADER IREPlY CARD

. . _, f' actU r<strong>in</strong>g<br />

S'Plen-<br />

. ala, nU<br />

- p~\&\QI\. • G- e'3' r 'IVI<br />

"e.t.\-t '10' , '<br />

TOtal QUallY .<br />

- - rn. 'Start<br />

IFro ,-<br />

Part blank and<br />

gear cutt<strong>in</strong>g tools,<br />

play .cl'hical lroles ill<br />

'q,lJality contnll.<br />

,oller optional soltware<br />

packages fur <strong>in</strong>spect<strong>in</strong>g<br />

gear blanks for<br />

circular geometry and g,eer<br />

cutt<strong>in</strong>g tools, such as hobs,<br />

shaperlshaver cutters,<br />

and broaches.<br />

Gear Test<strong>in</strong>g us<strong>in</strong>g Gener:aUve Metrology techniques,<br />

is enhanced by computerized autemallon<br />

andanalys[s. Ti'ue <strong>in</strong>dex, lead,<br />

and <strong>in</strong>volute test<strong>in</strong>g are performed<br />

Index<br />

Process control' 'can be<br />

implemented by analyz<strong>in</strong>g<br />

data collected<br />

l<strong>in</strong> gear test<strong>in</strong>g., We<br />

offer SPC software,<br />

'to evaluate x-bar, R.<br />

histogram, and<br />

tooth surface<br />

topological<br />

studles,<br />

31n2-4ac 'Gear A,nalyzer Is,<br />

one of a family of our gear<br />

and 'gearClfttlng tool! analyzers.<br />

For a free'full·color brochure<br />

describ<strong>in</strong>g our Gear analyzers,<br />

write or call MI& M IPrecision<br />

Systems, 300 Progress Rd.,<br />

Wesl Carrollton, OH 45449\<br />

513f859cS273,fAX 5131859-4452.<br />

CIRCI.!E A.!9 ON<br />

REAOE.R REPLY CAiRO<br />

M&M PAsc,s"aN<br />

_SYSTEMS<br />

AN ACME-CLEVELAND<br />

COMPANY

- PART IIII<br />

Beg<strong>in</strong>n<strong>in</strong>g with our ne.xt issue', som.e of.<strong>the</strong> pr.omised changes <strong>in</strong> fo.rmat f.or Gear<br />

Technology will beg<strong>in</strong> show<strong>in</strong>g up <strong>in</strong> <strong>the</strong>se pages. As part of our commitment to pro-<br />

- vide you with important <strong>in</strong><strong>format</strong>ion about <strong>the</strong> gear and gear products <strong>in</strong>dustry,<br />

weare expand<strong>in</strong>g our coverage. In addition to cont<strong>in</strong>u<strong>in</strong>g to publish some af<strong>the</strong> best results<br />

,ofgear research and development throughout <strong>the</strong> world, we will be add<strong>in</strong>g special columns<br />

cover<strong>in</strong>g vital aspects of <strong>the</strong> gear<strong>in</strong>g bus<strong>in</strong>ess.<br />

In our Shop Floorcolumn, several well-known gear<strong>in</strong>g professionals will discuss practical<br />

design and manufactur<strong>in</strong>g problems that appear <strong>in</strong> <strong>the</strong> work place. We <strong>in</strong>vite you to<br />

submit your questions to this panel of experts.<br />

Management Maners will cover some of <strong>the</strong> challenges of runn<strong>in</strong>g a gear design or<br />

manufacturi ng busl n ss<strong>in</strong> t he 90s. We willi cover such matters asdo<strong>in</strong>g bus<strong>in</strong>ess overseas,<br />

tra<strong>in</strong><strong>in</strong>g, employee problems, product liability, market<strong>in</strong>g for your company, and o<strong>the</strong>r<br />

items of concern to gear shops, both large and small.<br />

Along with <strong>the</strong>se additions to our<br />

editorial l<strong>in</strong>e-up, wewilll conl<strong>in</strong>ueto provide<br />

several art ides on gear design,<br />

manufactur<strong>in</strong>g, and research <strong>in</strong> every<br />

issue. Thls is one part of<strong>the</strong> magaz<strong>in</strong>e that<br />

will not change. While we are undergo<strong>in</strong>g<br />

a facelift, we have not lost sight of <strong>the</strong> fact<br />

that provid<strong>in</strong>g <strong>the</strong> latest <strong>in</strong><strong>format</strong>ion about<br />

gear rnanufacturtng, research, and development<br />

is our primary goal<br />

Along with <strong>the</strong>se editorial improvem<br />

nts, we shan be mak<strong>in</strong>g some<br />

cosmetic changes to ,Gear 7:echnology.<br />

Look for some new 'type faces, headl<strong>in</strong>e<br />

styles, and design elements to appear<br />

beg<strong>in</strong>n<strong>in</strong>g with next issue. Our goal with<br />

<strong>the</strong>se changes is to make <strong>the</strong> magaz<strong>in</strong>e<br />

more contemporary, more readable, and<br />

more useful to our readers.<br />

Perhaps <strong>the</strong> most readily apparent<br />

change 1.0 Gear Technology will be on<br />

our cover. W:ith some regret, we have<br />

reached <strong>the</strong> end ofour seriesof gear draw<strong>in</strong>gs<br />

by Leonardod'a V<strong>in</strong>ci. In <strong>the</strong> course or<br />

nearly seven years of publish<strong>in</strong>g, we have<br />

used most of <strong>the</strong> artist's gear-related<br />

draw<strong>in</strong>gs, and commission<strong>in</strong>g new ones is. beyond <strong>the</strong> power of our editorial and art staff.<br />

Instead, we will be featunngfour-color art on our covers. If you or youlr company have<br />

photos of gea rs, gears <strong>in</strong> motion, or gear cutti ng that you! h<strong>in</strong>k would rnakea good cover<br />

for Gear Technology, please send <strong>the</strong>m to our art department for consideration. We will<br />

credit you or vour company as <strong>the</strong> source, and <strong>the</strong> artwork wil!1be returned to you after<br />

<strong>the</strong> magaz<strong>in</strong>e is pr<strong>in</strong>ted.<br />

Our goal <strong>in</strong>execut<strong>in</strong>g <strong>the</strong>se changes to Gear r:echnologyis to keep up with <strong>the</strong> chang<strong>in</strong>g<br />

needs and <strong>in</strong>terests of you, om readers. As you strive to rema<strong>in</strong> competitive and keep<br />

up with <strong>the</strong> chang<strong>in</strong>g bus<strong>in</strong>ess climate, we ~-<br />

want to keep <strong>in</strong> step with you and con- ~ , . ..<br />

~~~r::of~~ :el~~~~~~r::i~s:~r' ;~f:~~:~e .• -~. -- . -~ -<br />

Michael Goldste<strong>in</strong>,<br />

IEditor/Publish<br />

IT'S YOUR MOVE<br />

GIEAR TECHNOLOGY always<br />

wants 10 be responsive to its<br />

readers. Please send us your<br />

reactions to th changes <strong>in</strong> our<br />

magaz<strong>in</strong>e. If you have ideas for<br />

additional or different columns,<br />

cover art, quesuons for our columnists,<br />

or just would like <strong>the</strong><br />

opportunity to respond to<br />

someth<strong>in</strong>g you've r ad <strong>in</strong> our<br />

pages, pleas let us know. A<br />

phone call or I tter to our<br />

ed itorial offices is always<br />

welcome.<br />

We also cont<strong>in</strong>ue to rema<strong>in</strong> on<br />

<strong>the</strong> lookout (or articles on all<br />

aspens or gear manufacture and<br />

design. These articles rema<strong>in</strong> rhe<br />

heart of our magaz<strong>in</strong>e. PI ase<br />

consider shar<strong>in</strong>g any article you<br />

have writ! n with us. Call or<br />

write for a copy or our editorial<br />

guidel<strong>in</strong> s.<br />

<strong>November</strong>jDecem'berl,990 7

Great American Geannakers<br />

deserve World Class f<strong>in</strong>ish<strong>in</strong>g<br />

equipment too!<br />

That's why we feature<br />

CIMA KANZAKI 'Gear Shavers.<br />

MODEL 'GSF 400<br />

eNe,6<br />

Built tough to withstand rigorous gearmak<strong>in</strong>g<br />

conditions, C~MA KANZAKI comb<strong>in</strong>es heavy<br />

duty construction with ground and hardened<br />

slides for maximum system rigidity. The<br />

result. .. accuracy levels to ± .00004" on<br />

workpieces up to 18" O.D. Additional<br />

standard features like Vickers hydraulics, a<br />

Trahan central lubrication system and a 20<br />

gpm coolant system complete <strong>the</strong> ClMA<br />

KANZAKI gear shaver ... designed and built.<br />

to deliver years of trouble-free operation.<br />

Comb<strong>in</strong>ed with <strong>the</strong> 4, 5 or 6 axis CNC<br />

control of your choice, <strong>the</strong> CIMA KANZAKlI<br />

Gear f<strong>in</strong>ish<strong>in</strong>g system provides unparalleled<br />

operat<strong>in</strong>g flexibility, faster set-ups for greater<br />

productivity and an easy DNC <strong>in</strong>terface for<br />

improved management<strong>in</strong>fonnation.<br />

And .... CIMA KANZAKlI models can be equipped with<br />

semi- or tully-automatic tool changers and automated load/<br />

unload systems for <strong>in</strong> l<strong>in</strong>e (cell) applications.<br />

CIMA KANZAK~ is proud to serve Great American<br />

Gearmakers with equipment that REDUCES CYCLE<br />

TIMES, IMPROVES or MONITORS QUALITY and<br />

INCREASES SHOP PROFIT ABILITY. And, we support<br />

equipment with unparalleled spare parts & service<br />

capability ... if it's ever required.<br />

Ask our sales representative forfur<strong>the</strong>r details or contact<br />

CIMA-USA,lDivision of' GDPM Inc., 50] Southlake Blvd.,<br />

Richmond, VA 23236. Phone (804) 794-9764,<br />

FAX (804) 794-6187. Telex 6844252.<br />

Global Technology with a U.S..Base<br />

CIRCLE A-lOON<br />

READER REPLYCARD

VIEWPOINT<br />

THE LEADER IN<br />

GEAR<br />

DEBURRING<br />

Dear<br />

Editor:<br />

Yourartide on <strong>the</strong> ]TCs Report to <strong>the</strong> President on<br />

<strong>the</strong> condition of <strong>the</strong> U.S. gear <strong>in</strong>dustry (Sept.lOcL<br />

issue) was most <strong>in</strong>terest<strong>in</strong>g, I am wonder<strong>in</strong>g if <strong>the</strong><br />

total report neglected to mention that some of our<br />

Lnability to export gears is due to our reluctance to<br />

provide metric countries with <strong>the</strong> metric module-based<br />

gears that overseas customers demand,<br />

I also hope your readers are apprised of <strong>the</strong> fact<br />

that those <strong>in</strong>volved <strong>in</strong> furnish<strong>in</strong>g gears to <strong>the</strong> U. S.<br />

government as contractors will have to provide<br />

metric-dimensioned gears after 1992.<br />

S<strong>in</strong>cerely,<br />

Valerie Anto<strong>in</strong>e<br />

Executive Director<br />

U.S. Metric Association, Inc.<br />

EDITOR'S NOTE: The relevent portion of <strong>the</strong> Omnibus<br />

Trade and Competitiveness Act of 1988 reads as<br />

follows:<br />

"... It is <strong>the</strong>refore <strong>the</strong> declared policy of <strong>the</strong> United<br />

States {l)to designate <strong>the</strong> metric system of measurement<br />

as <strong>the</strong> preferred system of weights and measures<br />

for U.S. trade and commerce: (2) to require that each<br />

Federal. agency, by a date certa<strong>in</strong> and to <strong>the</strong> extent<br />

ecnomically feasible by <strong>the</strong> end, of <strong>the</strong> fiscal year 1992,<br />

use <strong>the</strong> metric system of measurement <strong>in</strong> its procurements"<br />

grants, and o<strong>the</strong>r bus<strong>in</strong>ess-related ,a.ctivilties,<br />

except to <strong>the</strong> extent that such use is impractical or is<br />

likely to cause significant <strong>in</strong>efficiences or loss of<br />

markets to U.S. firms ... "<br />

Readers should also note that <strong>in</strong> a july 30 letter to<br />

Secretary of Commerce Robert A. Mosbacher, NASA<br />

<strong>in</strong>formed <strong>the</strong> secretary that "Effective with <strong>the</strong> start of<br />

<strong>the</strong> new fiscal year, October 1, <strong>1990</strong>', aU Requests for<br />

Proposals for new NASA flight programs will require<br />

use of <strong>the</strong> metric system of measurement." A memo .<br />

dated July 20, <strong>1990</strong>, which sets NASA policy on<br />

metric conversion states: "Ongo<strong>in</strong>g programs may<br />

cont<strong>in</strong>ue use of <strong>the</strong> conventional <strong>in</strong>ch-pound system<br />

basel<strong>in</strong>e for hardware design, but must plan to accommodate<br />

<strong>the</strong> metric hardware that will result from this<br />

transition. "<br />

Letters for this column should be addressed to Letters<br />

to <strong>the</strong> Editor, GEAR TECHNOLOGY, P.Q. Box 1426,<br />

Elk Grove Vill'age, IL 60009. Letters sent to this column<br />

become .<strong>the</strong> property of GEAR TECHNOLOGY.<br />

Names wi1l be withheld upon request, however, no<br />

anonymous letters will' be published.<br />

"ZERO-SETUP'<br />

• Rad<strong>in</strong> Modell 24-Universal' gear chamfer<strong>in</strong>g/deburr<strong>in</strong>g<br />

mach<strong>in</strong>e - 2 models.<br />

'. Ehm<strong>in</strong>ates costly manual mach<strong>in</strong>e setup.<br />

• C.N.C. controlled - 8 or 10 axis.<br />

• Part program storage -1000 pip.<br />

• Program load<strong>in</strong>gl - M.D.I. or Disc.<br />

• S<strong>in</strong>gle or doubl'ehead mach<strong>in</strong>es.<br />

1817 - 18th Ave.<br />

Rockford. IlL 611104<br />

8115~39S~1010 IFAX.S15-398-11047<br />

DEALERS WELOOME!<br />

CIRCLE A-lION<br />

0,<br />

G~ GRINO FACLIlY· COMPlETE GEI

AGMA, ISO, and B,SGear Stan'dard's<br />

P,artI Pitt<strong>in</strong>g Resistance Rati,ngs<br />

Doug Walton, Yuwen Shi, Stan Taylor,<br />

Mechanical Eng<strong>in</strong>eer<strong>in</strong>g Department<br />

University of Birm<strong>in</strong>gham, Birm<strong>in</strong>gham, U.K.<br />

Summary:<br />

A study of AGMA 218, <strong>the</strong> draft ISO standard 6336, and<br />

5S 436: 1986 methods for rat<strong>in</strong>g gear tooth strength and surface<br />

durability for metallic spur and helical gears is<br />

presented. A comparison of <strong>the</strong> standards ma<strong>in</strong>ly focuses on<br />

fundamental formulae and <strong>in</strong>fluence factors, such as <strong>the</strong><br />

load distribution factor, geometry factor, and o<strong>the</strong>rs. No attempt<br />

is made to qualify or judge <strong>the</strong> standards o<strong>the</strong>r than<br />

to comment on <strong>the</strong> facilities or lack of <strong>the</strong>m <strong>in</strong> each standard<br />

reviewed. In Part I a comparison of pitt<strong>in</strong>g resistance rat<strong>in</strong>gs<br />

is made, and <strong>in</strong> <strong>the</strong> subsequent issue, Part IIwill deal with<br />

bend<strong>in</strong>g stress rat<strong>in</strong>gs and comparisons of designs.<br />

Introduction<br />

Standard spur and helical gears are usually designed to<br />

specific standards to meet <strong>the</strong> requirements of proportions,<br />

manufactur<strong>in</strong>g accuracy, and load rat<strong>in</strong>g. The load rat<strong>in</strong>g is<br />

<strong>the</strong> most important issue discussed <strong>in</strong> AGMA (American<br />

Gear Manufacturers Association), ISO (International Standards<br />

Organization), DIN Deutsche lndustrie Norrnen) and<br />

BSI (British Standards Institution) gear standards. The standards<br />

written by <strong>the</strong>se organizations are widely used for gear<br />

design throughout <strong>the</strong> worJd and also fonn <strong>the</strong> basis of<br />

"m<strong>in</strong>ority" gear standards. Ch<strong>in</strong>a, for example, issues a gear<br />

design standard based on ISO. European gear standards are<br />

now becom<strong>in</strong>g very similar. The new BS and <strong>the</strong> draft ISO<br />

standard share much <strong>in</strong> common with DIN. This paper considers<br />

BS 436:1986, <strong>the</strong> draft ISO standard 6336, and AGMA<br />

218.01. S<strong>in</strong>ce this review was written, AGMA <strong>in</strong>troduced<br />

AGMA.2001-B88, although this new standard is not considered<br />

here. However, <strong>the</strong> trend toward a universal standard<br />

cont<strong>in</strong>ues, with AGMA 2001 publish<strong>in</strong>g rat<strong>in</strong>g factors, some<br />

of which are similar to <strong>the</strong> draft ISO standard.<br />

This article is <strong>in</strong>tended for designers who will appreciate a<br />

review of this complex subject ..Many designers <strong>in</strong> <strong>the</strong> USA<br />

will still use AGMA 218 because <strong>the</strong>y are familiar with it, and<br />

will, we suspect, cont<strong>in</strong>ue to do so for some time ..(This situation<br />

also exists <strong>in</strong> <strong>the</strong> UK with respect to <strong>the</strong> old and new<br />

British Standards on gear rat<strong>in</strong>gs.) It will take <strong>the</strong> authors<br />

some time before <strong>the</strong>y have enough experience <strong>in</strong> <strong>the</strong> use of<br />

AGMA 2001 and have been able to validate it aga<strong>in</strong>st real<br />

designs and o<strong>the</strong>r rat<strong>in</strong>g standards. While <strong>the</strong>re are marked<br />

similarities between <strong>the</strong> old and new AGMA formulas for pitt<br />

0 Gear Technology<br />

t<strong>in</strong>g resistance and bend<strong>in</strong>g strength rat<strong>in</strong>gs, we have ma<strong>in</strong>ly<br />

excluded any reference to AGMA 2001.<br />

Although, <strong>the</strong>oretically, any standard will produce a gear<br />

pair which is satisfactory, it is no longer enough to accept any<br />

standard when o<strong>the</strong>r procedures might produce more competitive<br />

designs. On <strong>the</strong> o<strong>the</strong>r hand, if <strong>the</strong> design calls for<br />

special operat<strong>in</strong>g conditions, such as shock loads or flexible<br />

drives, it may be advantageous for <strong>the</strong> designer to address a<br />

standard which deals more closely with <strong>the</strong>se conditions, In<br />

addition, <strong>the</strong> customer may specify <strong>the</strong> code to be used. A<br />

work<strong>in</strong>g knowledge of more than one standard is desirable,<br />

particularly if <strong>the</strong> product is aimed at<strong>in</strong>ternational markets.<br />

An understand<strong>in</strong>g of <strong>the</strong> differences between gear standards<br />

is, <strong>the</strong>refore, important. It should be po<strong>in</strong>ted out, however,<br />

that <strong>in</strong> a review of gear standards it is impossible to cover<br />

every aspect of each code. ISO 6336 Parts 1 to 4, for example,<br />

conta<strong>in</strong> over 90 figures and over 20 tables.<br />

Standards for Spur and Helical Gears<br />

The old British Standard, BS 436:1940, (I} <strong>in</strong> use for nearly<br />

fifty years, was a revision of <strong>the</strong> orig<strong>in</strong>al Specification for<br />

Mach<strong>in</strong>e Cut Gears first issued <strong>in</strong> 1932. Dur<strong>in</strong>g its long existence,<br />

<strong>the</strong> rat<strong>in</strong>g method rema<strong>in</strong>ed <strong>the</strong> same with only m<strong>in</strong>or<br />

revisions. Though obsolescent, it is still used extensively<br />

throughout Brita<strong>in</strong> and elsewhere, ma<strong>in</strong>ly because it is easy<br />

to use. The standard rates gears on <strong>the</strong> basis of bend<strong>in</strong>g<br />

strength and contact stresses, which are referred to as wear<br />

(mean<strong>in</strong>g non-abrasive wear). The tooth root bend<strong>in</strong>g<br />

strength is based on <strong>the</strong> Lewis equation, (2) consider<strong>in</strong>g both<br />

tangential and radial loads. The effect of stress concentrations<br />

at <strong>the</strong> root is not taken <strong>in</strong>to account directly, but allowances<br />

are made <strong>in</strong> <strong>the</strong> use of <strong>the</strong> allowable bend<strong>in</strong>g strength of <strong>the</strong><br />

gear material, values for which are supplied <strong>in</strong> <strong>the</strong> standard.<br />

The bend<strong>in</strong>g strength is also factored for runn<strong>in</strong>g speed and<br />

life. Contact stresses are based on a modified Hertz equation<br />

with allowances for speed, runn<strong>in</strong>g time, and geometry. The<br />

latter item is taken <strong>in</strong>to consideration by a zone factor, which<br />

accounts for <strong>the</strong> <strong>in</strong>fluence on <strong>the</strong> Hertzian stress of tooth flank<br />

curvature at <strong>the</strong> pitch po<strong>in</strong>t, and converts <strong>the</strong> tangential load<br />

to a normal force. No serious attempt was made to keep this<br />

standard up to date on newer gear materials and processes to<br />

predict <strong>the</strong> higher performances be<strong>in</strong>g achieved <strong>in</strong> practice.<br />

Ano<strong>the</strong>r serious deficiency is that no account was made for<br />

surface f<strong>in</strong>ish or uneven load distribution.

BS 436:1940<br />

d Pitch diameters of p<strong>in</strong>ion and wheel<br />

Ee Equivalent Young's modulus<br />

F Face width<br />

k Constant <strong>in</strong> Hertz contact stress formula<br />

K Pitch Eactor<br />

n, N P<strong>in</strong>ion and wheel runn<strong>in</strong>g speed<br />

P DiametraJ pitch<br />

R Gear ratio<br />

Rr Relative radius of curvature<br />

s Maximum contact stress set <strong>in</strong> <strong>the</strong> surface layers of<br />

<strong>the</strong> gear cyl<strong>in</strong>ders<br />

Sc Surface stress factor<br />

T Number of teeth on wheel<br />

Xc Speed factor for contact. stress<br />

Z Zone factor<br />

at Transverse pressure angle at reference cyl<strong>in</strong>der<br />

atw Transverse pressure angle at pitch cyl<strong>in</strong>der<br />

I3b Base helical angle<br />

AGMA218.01<br />

C.. Application faetar for pitt<strong>in</strong>g resistance<br />

C c Curvature factor at pitch l<strong>in</strong>e<br />

CI Surface condition factor<br />

C H Hardness ratio factor<br />

CL life factor for pitt<strong>in</strong>g resistance<br />

em Load distribution factor for pitt<strong>in</strong>g resistance<br />

NOMENCLATURE<br />

c;, Elastic coefficient<br />

C R Reliability factor for pitt<strong>in</strong>g resistance<br />

C, Size factor for pitt<strong>in</strong>g resistance<br />

CT Temperature factor for pitt<strong>in</strong>g resistance<br />

c,.. Dynamic factor for pitt<strong>in</strong>g resistance<br />

Cx Contact height factor<br />

---<br />

Smith(3) described B5 436 as "an. average experience<br />

method, wherebygear manufacturers and users collaborate<br />

to provide extremely empirical rules of thumb based on<br />

operat<strong>in</strong>g experience. Permissible loads are specified for<br />

'typical' manufacturir1g accuracies of a given class with<br />

'typical.' load<strong>in</strong>g cycles and corrections for speed, etc."<br />

Although <strong>the</strong> standard did not take <strong>in</strong>to account factors<br />

known to <strong>in</strong>fluence bend<strong>in</strong>g and contact stresses, such as application<br />

conditions (i.e., <strong>the</strong> load fluctuations caused by external<br />

sources), system dynamics and gear accuracy and <strong>the</strong><br />

benefits of surface harden<strong>in</strong>g, <strong>the</strong> standard served its users<br />

well.<br />

The orig<strong>in</strong>al AGMA standard was issued <strong>in</strong>1926, and <strong>the</strong><br />

first draft of AGMA 218.01,(4) used. <strong>in</strong> this review, was<br />

drafted <strong>in</strong> 1973 and approved for publication <strong>in</strong> 1982. AGMA<br />

218 also rates gearson <strong>the</strong> basis of bend<strong>in</strong>g strength and surface<br />

contact stresses, (referred to as surface durability or pitt<strong>in</strong>g)<br />

but also <strong>in</strong>troduces a. number of o<strong>the</strong>r factors <strong>in</strong> <strong>the</strong><br />

rat<strong>in</strong>g equations. For example, <strong>in</strong>fluence factors are used to<br />

take <strong>in</strong>to account load distribution across <strong>the</strong> face width,<br />

quality of<strong>the</strong>bcansmission drive, and transmission accuracy<br />

relat<strong>in</strong>g to manufacture, Considerable knowledge and judgment<br />

is required to determ<strong>in</strong>e values for <strong>the</strong>se factors.<br />

Compared to <strong>the</strong> old British Standard, AGMA 218 is considerably<br />

mare comprehensive. Rat<strong>in</strong>gs for pitt<strong>in</strong>g resistance<br />

are based on '<strong>the</strong> Hertzian equation for contact pressure betw'een<br />

curved surfaces, which is modified for <strong>the</strong> ,effectof load<br />

shar<strong>in</strong>g between adjacent teeth. The Lewis equation has been<br />

madified to account far ,effects, such as stress concentrations,<br />

at <strong>the</strong> tooth root, compressive stresses result<strong>in</strong>g from <strong>the</strong><br />

Cv, Helical overlap factor<br />

d Operat<strong>in</strong>g pitch diameter of p<strong>in</strong>ion<br />

F Net facewidth of <strong>the</strong> narrowest number<br />

I Geometry factor for pitt<strong>in</strong>g resistance<br />

mN Load shar<strong>in</strong>g ratio<br />

np P<strong>in</strong>ion runn<strong>in</strong>g speed<br />

P 1I Diarnetral pitch<br />

Sac Allowable contact stress number<br />

85436: 1986 and ISO/DIS 6336<br />

b Face width<br />

d 1 Reference diameter of p<strong>in</strong>ion<br />

KA Application factor<br />

KHa Transverse load factor for contact stress<br />

K H ,9 Face load factor for contact stress<br />

Kv Dynamic factor<br />

n1 P<strong>in</strong>ion runn<strong>in</strong>g speed<br />

SHmm M<strong>in</strong>imum demanded safety factor on contact stress<br />

ZM (BS only material quality factor for contact stress)<br />

ZN life factor for contact stress<br />

Zx Size factor for contact stress<br />

ZE Elasticity factor for contact stress<br />

ZH Zone factor for contact stress<br />

ZL,ZR,ZV Lubricant <strong>in</strong>fluence. roughness, and speed factor for<br />

pitt<strong>in</strong>g<br />

Zw Work-harden<strong>in</strong>g factor for contact stress<br />

Z, Contact ratio factor for contact stress<br />

Zfj Helix angle factor<br />

at Transverse pressure angle at reference cyl<strong>in</strong>der<br />

atw Transverse pressure angle at pitch cyl<strong>in</strong>der<br />

(3b Base helix angle<br />

'O'Hlim Basic endurance limit for contact stress<br />

uHP Permissible contact stress<br />

radial. component of <strong>the</strong> gear load, load distribution due to<br />

misalignment between mesh<strong>in</strong>g teeth, andload shar<strong>in</strong>g. The<br />

'Critical bend<strong>in</strong>g stress is assumed to occur at <strong>the</strong> tooth fillet<br />

but, as <strong>in</strong> <strong>the</strong> old British Standard, <strong>the</strong> effect of blank<br />

geometry (e.g., rimand web size and how <strong>the</strong> relative size of<br />

<strong>the</strong>se effects stresses at <strong>the</strong>tooth root) is not considered.<br />

The 150 standard, ISO 6336,

scuff<strong>in</strong>g ..The basic equations are modified by apply<strong>in</strong>g. <strong>in</strong>fluence<br />

factors as <strong>in</strong> A:GMA. These procedures demand a<br />

realistic appraisal of all <strong>in</strong>fluence factors, particularly those<br />

for <strong>the</strong> allowable stress, <strong>the</strong> probability of failure, and <strong>the</strong> appropriate<br />

safety factor. ISO also offers three different<br />

methods for determ<strong>in</strong><strong>in</strong>g bend<strong>in</strong>g and contact stresses and<br />

<strong>the</strong>ir <strong>in</strong>fluence factors, depend<strong>in</strong>g on <strong>the</strong> application and accuracy<br />

required. S<strong>in</strong>ce <strong>the</strong> latest German standard, DIN 3990:<br />

1987, (6) is substantially similar to ISO 6336,. a detailed discussionof<br />

DIN is excluded.<br />

The new British standard, BS 436:1986,(7) is similar to<br />

ISO / DIS 6336 and is a complete revision of <strong>the</strong> old standard.<br />

It is, however, much more user friendly than [SO. Like <strong>the</strong><br />

o<strong>the</strong>r standards, <strong>the</strong> new British standard uses modified Lewis<br />

and Hertz equations, us<strong>in</strong>g correction factors, such as <strong>the</strong><br />

dynamic factor to account for load fluctuations aris<strong>in</strong>g from<br />

manufactur<strong>in</strong>g errors, and a load distribution factor to take<br />

<strong>in</strong>to account <strong>the</strong> <strong>in</strong>crease <strong>in</strong> local load due to non-uniform<br />

load<strong>in</strong>g aris<strong>in</strong>g from conditions such as shaft stiffness and, <strong>in</strong><br />

<strong>the</strong> case of helical gears, helix error. The correction factors are<br />

<strong>the</strong> same or are similar to those used. by ISO. Geometry factors<br />

<strong>in</strong> <strong>the</strong> new BS 436 are similar to those <strong>in</strong> ISO (method B)<br />

willIe o<strong>the</strong>r methods <strong>in</strong> ISO use different approaches for<br />

geometry factors ..The new British standard, however, draws<br />

on a considerable amount of previously published research<br />

and uses additional parameters, like materia] quality factors,<br />

not allowed for by ISO or AGMA. This standard does not<br />

work on "typical" figures for each rat<strong>in</strong>g factor as <strong>in</strong> <strong>the</strong> old<br />

standard, but uses researched data to predict load <strong>in</strong>creases<br />

caused by deflections, alignment tolerances, and helix<br />

modifications. Throughout this review, <strong>the</strong> term.BS refers to<br />

<strong>the</strong> new standard, except where stated.<br />

In <strong>the</strong> stress analysis procedures of BSand ]50, bend<strong>in</strong>g<br />

and contact stresses are classified <strong>in</strong>to three groups: 1)<br />

Nom<strong>in</strong>al or basic stresses, which

COMPLE,TEWITIH ,A,LLlE,NBRADLlE,V PLe<br />

C'ONTRO!l ,A,ND CRT O'PERATOR IINTEIRFACE<br />

Ea'Syto use canned cycles <strong>in</strong>olude: Variable Hob Speeds"<br />

Variable axial a'nd radial feed rates~ Hob, shift <strong>in</strong>ct:ements<br />

and ft:equency. Dwell times, 'S<strong>in</strong>gle, dou.ble and r:adiaJ'cut<br />

cycles, Axial cycle work<strong>in</strong>g' limits, - and muoh' more!<br />

Specific p,arameters are f<strong>in</strong>,e tuned throug,h simple' M.D.!. <strong>in</strong>put.<br />

Call or write today..<br />

FAX. 203 :271110487 BOX 400' W. JOHNSON AVE. CHESHIRE, CT. 06410<br />

CIRCLE A-13 ONI READER REPLY CARD

mation is required and some, like generat<strong>in</strong>g <strong>the</strong> tooth layout<br />

to give <strong>the</strong> necessary geometry data, may be difficult to<br />

obta<strong>in</strong>.<br />

3) Each standard has its own def<strong>in</strong>itions for <strong>the</strong> <strong>in</strong>fluence<br />

factors, but factors bear<strong>in</strong>g <strong>the</strong> same names do not necessarily<br />

have <strong>the</strong> same effects. This makes direct comparisons of <strong>in</strong>fluence<br />

factors difficult. For example, although AGMA and<br />

ISO both <strong>in</strong>troduce a service factor, <strong>the</strong> values cannot be<br />

compared directly.<br />

The terms used <strong>in</strong> each standwdare listed <strong>in</strong> <strong>the</strong><br />

nomenclature .<br />

The power rat<strong>in</strong>g for contact stressesgiven by BS436: 1940<br />

XcScZFNT<br />

126000KP<br />

Equation 1can be rewritten as<br />

____ n Fd2 Rr_Xe<br />

0.8 s2<br />

126000 d k Ee<br />

For AGMA 218.01 <strong>the</strong> transmissible power based on pitt<strong>in</strong>g is<br />

n Fd<br />

e 2<br />

..<br />

126000<br />

The as 436:1986 power rat<strong>in</strong>g is<br />

b d 1<br />

2 n1 u 1<br />

126000 u+1 ZH 2 Z~<br />

and for ISO lOIS 6336 <strong>the</strong> power is<br />

bdlnl U 1<br />

126000 u+I zi Z; z3<br />

where<br />

UHP = (O"H1irn ZN). z, ZR Zv Zw z, (7)<br />

SHm<strong>in</strong><br />

From Equations 2-7 it may be seen that for a given gear<br />

ratio <strong>the</strong> transmissible power is proportional to <strong>the</strong> square<br />

of <strong>the</strong> p<strong>in</strong>ion pitch circle diameter and permissible contact<br />

stresses. Therefore, to <strong>in</strong>crease gear power capacity <strong>in</strong> terms<br />

of surface durabilty, it is more effective to <strong>in</strong>crease <strong>the</strong> p<strong>in</strong>ion<br />

peD or permissible surface stresses than to <strong>in</strong>crease <strong>the</strong> gear<br />

pair facewidth.<br />

The pitt<strong>in</strong>g resistance related factors above may be<br />

grouped <strong>in</strong>to common and non-common factors. Common<br />

factors are those which have <strong>the</strong> same mean<strong>in</strong>gs <strong>in</strong> all <strong>the</strong><br />

standards, (not all <strong>the</strong>se factors appear <strong>in</strong> <strong>the</strong> standards) and<br />

<strong>the</strong>i:r values can becompared directly. For example, <strong>the</strong><br />

dynamic factor whichallows for <strong>in</strong>ternally generated gear<br />

tooth loads <strong>in</strong>duced by non-conjugate mesh<strong>in</strong>g action of <strong>the</strong><br />

gear teeth, appears <strong>in</strong> all <strong>the</strong> standardsexcept <strong>the</strong> old BS, and<br />

values can be compared directly. Non-common factors,<br />

such as <strong>the</strong> geometry factor,are those which are only<br />

equivalent to each o<strong>the</strong>r <strong>in</strong> <strong>the</strong> sense of hav<strong>in</strong>g <strong>the</strong> same eEl'4<br />

Gear feehnology<br />

1<br />

1<br />

(1)<br />

(2)<br />

(3)<br />

fects on <strong>the</strong> rat<strong>in</strong>g results, although specific values cannot<br />

be compared.<br />

Table 1classifies all <strong>the</strong> contact stress <strong>in</strong>fluence factors <strong>in</strong>to<br />

ei<strong>the</strong>r common or non-common groups where it can be seen<br />

that <strong>the</strong> old British Standard had few parameters for comparison<br />

with o<strong>the</strong>r standards. The similarity between BSand<br />

ISO isalso apparent. A comparison between <strong>the</strong> <strong>in</strong>fl'uence<br />

factors given <strong>in</strong>each standard is made <strong>in</strong> <strong>the</strong> follow<strong>in</strong>g<br />

paragraphs.<br />

1) Application factors. An application factor is used <strong>in</strong><br />

AGMA, ISO,. and BS to evaluate external <strong>in</strong>fluences tend<strong>in</strong>g<br />

to apply a greater load to <strong>the</strong> gear teeth than that based on<br />

steady runn<strong>in</strong>g conditions. Typical external <strong>in</strong>fluences are<br />

<strong>the</strong> drive characteristics (e..g., smoothness and load fluctuations)<br />

of <strong>the</strong> prime mover and of <strong>the</strong> driven mach<strong>in</strong>e ..Values<br />

suggested <strong>in</strong> ISO correspond to those for <strong>the</strong> overload factor<br />

<strong>in</strong> AGMA 215. While no data appears <strong>in</strong>.AGMA 218,<br />

<strong>the</strong>se factors may be found <strong>in</strong> related AGMA application<br />

standards. BS gives more detailed conditions than ISO,<br />

although values are similar.<br />

2) Dynamic factors. As discussed above, <strong>the</strong> application<br />

factor is used to handle dynamic loads unrelated to tooth accuracy.<br />

The effect of dynamic load related gear tooth accuracy<br />

is <strong>the</strong>n evaluated by <strong>the</strong> Inclusion of a dynamic factor<br />

which accounts for effects ·of gear set mass elastic effects<br />

and transmission errors. AGMA modified <strong>the</strong> experimental<br />

work of Wellauer(14l to obta<strong>in</strong> dynamic factors as a function<br />

of transmission error. These accuracy levels can under certa<strong>in</strong><br />

manufactur<strong>in</strong>g conditions be <strong>the</strong> same as <strong>the</strong> gear quality<br />

numbers given <strong>in</strong> AGMA 390. (15)<br />

ISO dynamic factors are based on Buck<strong>in</strong>gham's <strong>in</strong>crementalload<br />

method U6J and work by Weber and Banaschek.(l7J<br />

ISO (analytical) method B presents a calculation procedure<br />

for <strong>the</strong> ma<strong>in</strong> resonance speed and divides <strong>the</strong> runn<strong>in</strong>g speed<br />

<strong>in</strong>to three sectors. The dynamic factor corresponds to each<br />

of <strong>the</strong>se speed sectors and may help designers to adjust <strong>the</strong><br />

operat<strong>in</strong>g speed or alter <strong>the</strong> design to avoid critical speeds ..<br />

ISO method C is only applicable to gears with accuracy<br />

numbers of 3 to 10 and cannot be used for gears operat<strong>in</strong>g at<br />

or near <strong>the</strong> ma<strong>in</strong>. resonance speed. The dynamic factor <strong>in</strong> <strong>the</strong><br />

BS is very dose to [SO method C. In <strong>the</strong> old BS, dynamic ef-<br />

£ects were not considered. The speed factor used <strong>in</strong> <strong>the</strong> old BS<br />

is not to be confused with dynamic loads, but was <strong>in</strong>tended<br />

to allow f·or load reversals and <strong>the</strong>ir eHed on fatigue dur<strong>in</strong>g<br />

<strong>the</strong> life of <strong>the</strong> gear.<br />

It has been customary fer AGMA to put <strong>the</strong> dynamic factor<br />

<strong>in</strong> <strong>the</strong> denom<strong>in</strong>ator of <strong>the</strong> rat<strong>in</strong>g formula, whereas ISO<br />

and BS apply it to <strong>the</strong> numerator. Never<strong>the</strong>less, <strong>the</strong> dynamic<br />

factor is def<strong>in</strong>ed as a multiplier of <strong>the</strong> transmitted load <strong>in</strong> all<br />

<strong>the</strong> standards, although some believe that <strong>the</strong> effect should<br />

be additive. (18)<br />

3) Load distribution factors. A load distribution factor is<br />

used <strong>in</strong> <strong>the</strong> rat<strong>in</strong>g equations to reflect <strong>the</strong> non-uniform load<br />

distribution along <strong>the</strong> contact l<strong>in</strong>es caused by deflections,<br />

alignment, and helix modifications (<strong>in</strong>clud<strong>in</strong>g crown<strong>in</strong>g and<br />

end relief), and profile and pitch deviations ..The evaluation<br />

procedure for this factor is ra<strong>the</strong>r complex, siace many<br />

variables are <strong>in</strong>volved, and some of <strong>the</strong>m, such as <strong>the</strong> component<br />

of <strong>the</strong> gear system alignment and manufactur<strong>in</strong>g<br />

errors, are difficult to determ<strong>in</strong>e.

TABLE 1 COMPARISON OF PITTING RESISTANCE INFLUENCE FACTORS<br />

BS436:1940 AGMA21B BS 436:1986 150/0[56336<br />

Geometry<br />

R~·8<br />

u 1 u 1<br />

I<br />

Factors- - -- --- --<br />

d u + 1 Z"; Z2 u+1 Z].Z2 Z2<br />

• H , Ii<br />

Elasticity<br />

(k~}O.5 C p ZE ZE<br />

Factors"<br />

Size<br />

Factors"<br />

1 1<br />

- C s - -<br />

Z2~<br />

Z;<br />

Lubrication 1 ]<br />

Film - C~·5C T ZLZVZR ZtZVZR<br />

Factors"<br />

Application<br />

Factors]<br />

Dynamic<br />

Factors]<br />

- C a KA KA<br />

1 1<br />

- Cv<br />

- -<br />

Kv<br />

Ky<br />

Load 1 1<br />

Distribution<br />

Factorst<br />

- Cm<br />

KHaKHIl'<br />

KH ..KHIl<br />

Work<br />

Harden<strong>in</strong>g - CH Zw Zw<br />

Eactors]<br />

Life<br />

Factorst<br />

Reliability<br />

Factors]<br />

-<br />

CL ZN ZN<br />

- CR SHlim SHm<strong>in</strong><br />

Material<br />

Quality - - ZM -<br />

Factor]<br />

Speed<br />

Factor]<br />

t denotes common and .. non-common factors<br />

'""--<br />

In AGMA <strong>the</strong> load distributi.on factor is <strong>the</strong> product of <strong>the</strong><br />

face and 'transverse load distnbution ~fa.ctors.The face or<br />

Iongituil<strong>in</strong>aJ (as described <strong>in</strong> <strong>the</strong> ISO and BS) load distribution<br />

factor accounts for <strong>the</strong> non-uniform load across <strong>the</strong> face<br />

of <strong>the</strong> gear. while <strong>the</strong> transverse load factor reflects <strong>the</strong> effect<br />

of non-uniform distribution of load down <strong>the</strong> tooth flank due<br />

to profile, pitch deviations. and tooth modifications.<br />

Although AGlv1Auses this factor to allow for <strong>the</strong> effect of <strong>the</strong><br />

non-unilorm distribution of load among <strong>the</strong> teeth.which share<br />

<strong>the</strong> t.otalload, no specific wonnanon is given <strong>in</strong> <strong>the</strong> standard.<br />

The AGMA standard assumes that if <strong>the</strong> gears are accurately<br />

manufactured, <strong>the</strong> value of <strong>the</strong> transverse load distribution<br />

factor can be 'taken as unity. AGMA provides both empirical<br />

and analytical methods to.determ<strong>in</strong>e <strong>the</strong> face load distribution<br />

factor ..The empirical method is recommended for norma1,relatively<br />

stiff gear .a.ssemblies,and only a m<strong>in</strong>imum<br />

amount of <strong>in</strong><strong>format</strong>ion is required. The second method is<br />

based. on elastic and non-elastic lead mismatch and needs <strong>in</strong><strong>format</strong>ion<br />

about design. manufacture. and mount<strong>in</strong>g and is.<br />

<strong>the</strong>oretically, suitable tor any ge.ar design ..<br />

Xc - - -<br />

The ISO load distribution factor is also <strong>the</strong> product of <strong>the</strong><br />

transverseand longitud<strong>in</strong>a] load factors. Three differentappreaches<br />

have been made by ISO to detenn<strong>in</strong>e <strong>the</strong><br />

longitud<strong>in</strong>al load factor ..Method B is a f<strong>in</strong>al proof rat<strong>in</strong>g<br />

calculation method based on known manufactur<strong>in</strong>gerrors.<br />

Method C is a prelim<strong>in</strong>ary rat<strong>in</strong>g method and uses assumed<br />

values of manufactur<strong>in</strong>g errors with<strong>in</strong> limits of prescribed<br />

tolerances. Method 0 is even more simplified than method<br />

C. The transverse load factor isa function of longitud<strong>in</strong>al load<br />

factor, contact ratio, pitch tolerance, and mean load <strong>in</strong>tensity.<br />

Procedures for calculat<strong>in</strong>g <strong>the</strong> load distribution factors<br />

<strong>in</strong> ISO are <strong>the</strong> most complex and are still under revision . Load<br />

distribution factors <strong>in</strong> <strong>the</strong> BSemploy virtually <strong>the</strong> same procedure<br />

as method C <strong>in</strong> 150,. except for a diffef'ence <strong>in</strong> determ<strong>in</strong><strong>in</strong>g<br />

total misalignment. ISO gives .five approximation<br />

methods for this. while <strong>the</strong> BS only gives one.<br />

4) Life factors. Life factors take <strong>in</strong>to. account <strong>the</strong> effects ot<br />

<strong>in</strong>crements <strong>in</strong> permissible stresses if a limited number of load<br />

cycles is demanded, Among AGMA, ISO,. and BS,.<strong>the</strong> most<br />

dist<strong>in</strong>ct diHel'ence lies <strong>in</strong> <strong>the</strong> def<strong>in</strong>ition. of endurance limits.<br />

<strong>November</strong>/<strong>December</strong> <strong>1990</strong> 1.5

AGMA 218 sets 10 7 load cycles as <strong>the</strong> endurance limit for<br />

hoth bend<strong>in</strong>g and pitt<strong>in</strong>g, while ISO and BS def<strong>in</strong>e limits of<br />

2x10P, 5x10 7 , and l09cyc1es for contact stresses ..Although<br />

<strong>the</strong>re is no life factor <strong>in</strong> <strong>the</strong> old BS, a procedure to calculate<br />

variable duty cycles by determm<strong>in</strong>g an equivalent runn<strong>in</strong>g<br />

time was provided. BS 436:1986 also has a procedure to deal<br />

with variable duty cycles, while this aspect of gear runn<strong>in</strong>g<br />

is not considered by ISO.<br />

5) Material quality factor. Among <strong>the</strong> four standards, only<br />

<strong>the</strong> BS <strong>in</strong>troduces material facto.rs <strong>in</strong> its bend<strong>in</strong>g and contact<br />

stress rat<strong>in</strong>gs <strong>in</strong> an attempt to allow for <strong>the</strong> higher permissible<br />

stresses to be obta<strong>in</strong>ed from us<strong>in</strong>g higher quality materials.<br />

6) Size factors ..Size factors are used <strong>in</strong> all. except '<strong>the</strong> old<br />

BS, to take <strong>in</strong>to account <strong>the</strong> <strong>in</strong>fluence of tooth size on surface<br />

fatigue strength . Values are usually taken as unity because no<br />

fur<strong>the</strong>r <strong>in</strong><strong>format</strong>ion is provided <strong>in</strong> any of <strong>the</strong> standards.<br />

7) Work-harden<strong>in</strong>g factors. When <strong>the</strong> p<strong>in</strong>ion material is<br />

substantially harder than <strong>the</strong> wheel, <strong>the</strong> effects of cold work<br />

harden<strong>in</strong>g and <strong>in</strong>ternal stress changes <strong>in</strong> <strong>the</strong> softer wheel<br />

material may occur, <strong>in</strong> which case <strong>the</strong> surface contact stresses<br />

will be reduced. These effects have been considered by<br />

AGMA, ISO., and BS by <strong>in</strong>troduc<strong>in</strong>g a hardness ratio or<br />

work-harden<strong>in</strong>g factor, In AGMA, <strong>the</strong> hardness ratio factor<br />

is a function of <strong>the</strong> gear ratio and p<strong>in</strong>ion and wheel hardness,<br />

but AGMA only applies this factor to <strong>the</strong> wheel rat<strong>in</strong>g. A<br />

guidance diagram is given by BS for determ<strong>in</strong><strong>in</strong>g <strong>the</strong> workharden<strong>in</strong>g<br />

factor, based on surf ace roughness and haJdness,<br />

The ISO work-harden<strong>in</strong>g factor is only related to wheel<br />

hardness ..<br />

.8) Permissible stresses. Permissible bend<strong>in</strong>g and contact<br />

stresses are given <strong>in</strong> <strong>the</strong> old BS for a limited number of<br />

materials listed <strong>in</strong>.<strong>the</strong> standard. It is usually agreed that <strong>the</strong><br />

values are generally too pessimistic for snrface-hardened<br />

gears. Allowable bend<strong>in</strong>g and contact stresses, based on<br />

laboratory and field experience for each material and heat<br />

treatment condition, are provided <strong>in</strong> AGMA. For most of <strong>the</strong><br />

steels <strong>the</strong> allowable bend<strong>in</strong>g and contact stress numbers are<br />

functions only of material hardness ..<br />

In both BS and ISO <strong>the</strong> pennissible bend<strong>in</strong>g / contact stress'<br />

is based. on <strong>the</strong> bend<strong>in</strong>g/surface fatigue endurance limit for<br />

<strong>the</strong> material, tak<strong>in</strong>g <strong>in</strong>to account <strong>the</strong> required life and runn<strong>in</strong>g<br />

conditions. Accord<strong>in</strong>g to <strong>the</strong> BS, for most gear materials <strong>the</strong><br />

bend<strong>in</strong>g/contact endurance limit depends only on hardness<br />

without differentiat<strong>in</strong>g between materials and heat<br />

treatments. InISO,. bend<strong>in</strong>g/ contactendurance limit is determ<strong>in</strong>ed<br />

ei<strong>the</strong>r based on experimental data for test gears of <strong>the</strong><br />

same material or on prepared, polished specimens. Values are<br />

provided <strong>in</strong> <strong>the</strong> ISO standard for a wide range of steels and<br />

heat treatments.<br />

For surface-hardened gears, <strong>the</strong> BS bend<strong>in</strong>g endurance<br />

limit is based on residual stresses and <strong>the</strong> ultimate tensile<br />

strength of <strong>the</strong> gear material. Detenn<strong>in</strong><strong>in</strong>g <strong>the</strong> residual stresses<br />

and tensile strength of surface-hardened gears is, however,<br />

difficult cast<strong>in</strong>g some doubt as to <strong>the</strong> ease with which this<br />

method can be used.<br />

9) Factors of safety and reliability. So far <strong>the</strong>re is no accepted<br />

method of relat<strong>in</strong>g gear reliability to safety factors consider<strong>in</strong>g<br />

<strong>the</strong> effect of material quality and gear accuracy. The<br />

AGMA reliability factor accounts for <strong>the</strong> effect of <strong>the</strong> normal<br />

statistical distribution of failures from <strong>the</strong> allowable stresses<br />

16 GearTechnology<br />

and can be chosen accord<strong>in</strong>g to <strong>the</strong> reliability required. BS<br />

and ISO leave <strong>the</strong> user to specify a value for this factor.<br />

M<strong>in</strong>imum demanded safety factors for bend<strong>in</strong>g strength and<br />

contact stress are recommended by both ISO and BS to reflect<br />

<strong>the</strong> confidence <strong>in</strong> <strong>the</strong> actual operat<strong>in</strong>g conditions and material<br />

properties, but <strong>the</strong> values for <strong>the</strong>se factors are different. The<br />

safety factor for bend<strong>in</strong>g strength <strong>in</strong> <strong>the</strong> old BS is def<strong>in</strong>ed as<br />

<strong>the</strong> ratio of ultimate tensile strength to <strong>the</strong> product of <strong>the</strong><br />

speed factor and bend<strong>in</strong>g stress factor.<br />

10) Non-common geometry factors. Geometry factors account<br />

for <strong>the</strong> <strong>in</strong>fluence of <strong>the</strong> helix angle, contact ratio, and<br />

tooth flank curvature at <strong>the</strong> pitch po<strong>in</strong>t on gear load capacity.<br />

Ignor<strong>in</strong>g <strong>the</strong> experimental exponent of 0.8, <strong>the</strong> geometry factor<br />

for <strong>the</strong> old BS can be written<br />

R<br />

R+l<br />

cosat cosatw<br />

2coS~b<br />

For <strong>the</strong> BS and ISO <strong>the</strong> geometry<br />

factor is<br />

(·8)<br />

1 casal smatw<br />

--=<br />

(9)<br />

2 cost3b cosa tw<br />

The similarity between Equations 8 and 9 is not apparent<br />

when expressed <strong>in</strong> <strong>the</strong> way given <strong>in</strong> <strong>the</strong> standards. (See<br />

Geometry Factors, Table 1.)<br />

The AGMA geometry Iactor.T, for contact stress is<br />

ccCxq<br />

mN<br />

(10)<br />

where C, is <strong>the</strong> curvature factor at <strong>the</strong> pitch l<strong>in</strong>e and is a<br />

function of <strong>the</strong> gear ratio and pressure angle,

218 does not consider lubrication, it does take tooth surface<br />

roughness and temperature effects <strong>in</strong>to account by <strong>in</strong>troduc<strong>in</strong>g<br />

a surface condition and a temperature factor. In <strong>the</strong> old<br />

BS, lubrication was ignored aJtoge<strong>the</strong>r. Tooth scuff<strong>in</strong>g.<br />

which is covered by ISOand DIN <strong>in</strong> separa.te parts, attempts<br />

to predict <strong>the</strong> t'emperatuN at which scuff<strong>in</strong>g will occur, This<br />

is not dealt with by any of <strong>the</strong> o<strong>the</strong>r standards and,<br />

<strong>the</strong>refore, no comparisons can be made, although scuff<strong>in</strong>g<br />

does appear <strong>in</strong> <strong>the</strong> new AGMA standard.<br />

ReferentleS:<br />

1. BR111SH STANDARDS INSTITUTION. "Spedlication for '<br />

MaCh<strong>in</strong>e Cut Gears. A. Helical and Straight Spur." BS<br />

436;1:940. London, 1973.<br />

2. LEWIS. W. Eng<strong>in</strong>eeisOubofPhiladeJ.phla. Proceed<strong>in</strong>8$ Vol.<br />

X,1893.<br />

3. SMfJ11, ~.D. Gears and Their Vibrations. The Maanillan<br />

Press Ltd, London, 1983.<br />

4. MLERICAN GEAR MANUFACTIJRERS ASSOClATION.<br />

-A:GMA Standard For Rat<strong>in</strong>g <strong>the</strong> Pitt<strong>in</strong>g Resistance and Bend<strong>in</strong>g<br />

Strength of Spur and Helical Involute Gear Teeth."AG1vfA<br />

218.01, 1982.<br />

5. ORGANIZATION FOR INTERNATIONAL STAND'AR-<br />

DIZAnON. "Calculation of Load Capacity of Spur and<br />

Helical Gears .."ISO/DlS 6336:1983, Part H, Belgium, 1983.<br />

6. DEUTSCHE lNDUSTRlE NOR1Vl:EN. "Grundlagen fur die<br />

Tragfahigkeitsberechnung von Gerad - uad Sdtragslimradem,"<br />

DIN 3990': Part 1-5,1986.<br />

7. BRITISH STANDARDS rNSTITUTION. "Spur and H.elical<br />

Gears. Pt. 3. Method for Calculation .of Contact and Root<br />

Bend<strong>in</strong>g Stress limitations for Metallic Invelute Gear." B5 436:<br />

1986. London, 1986.<br />

8. M1ERICAN GEAR J\.IfANUFAcruRERS ASSOCIATION.<br />

"1nfonnation Sheet for Surface Durability (Pitt<strong>in</strong>g) of Spur,<br />

Helical, Hen<strong>in</strong>gbone, and Bevel Gear Teeth." AGMA215.m,<br />

1966.<br />

9. AMERICAN GEAR MANUFACTIJRERS ASSOCilA110N.<br />

"In<strong>format</strong>ion Sheet .forStrength of Spur, Helica], Herr<strong>in</strong>gbone,<br />

and Bevel Gear Teeth." AGMA22S.01. 1967.<br />

10, HOFMANN, D.A. 'The Imporlance .of1111 New Standards BS<br />

436 (1986) and DIN 3990 (1986) f,orGear Design <strong>in</strong> <strong>the</strong> UK."<br />

Mar<strong>in</strong>e Gear<strong>in</strong>g and Revision of Bririsfl Standards. The ~<br />

stitute of Mar<strong>in</strong>e ElIg<strong>in</strong>eers. Mar<strong>in</strong>e Management (Hold<strong>in</strong>gs)<br />

Ltd,1987.<br />

11. RvlWALLE,D'.E.,O.A. LABATHandN. HUr'otINSON. ~A<br />

Review of Riec~nt Cear Ratiqg Dev lopmenl ,]501 AGMA<br />

Comparison Study." ASME Paper ao.C2/DET~25. 1980.<br />

iz. tMWAlLE, D.E., O.A. LABATH. "Differences Between<br />

M<br />

AGMA.and[s()Rat<strong>in</strong>gSystem. AG1vfAP per219.lS,l981.<br />

13. CASTELLANI, G. and V.P. CAS:rELU. "Rat<strong>in</strong>g Gear<br />

Strength." ASME Paper8(}Q/DET-88, 1981.<br />

14. WiELLAUER.,E.J. "Ana1ys:isof FactorsUsecHorRaI<strong>in</strong>g Helical<br />

Gears." ASME PaperS9-A-Ul, 1959.<br />

15. GEA.R HANDBOOK. Vol 1. Gear Classification, Material,<br />

and Measur<strong>in</strong>g Methods for Unassernb.led Gears. AGMA.390',<br />

Wash<strong>in</strong>gton D.C.<br />

16. BUCKINGHAM,E. "Dyn~ic Load on Gear 'Jeeth." ASME<br />

Research Publications. New York, 1931, also <strong>in</strong> Analytical<br />

Mechanics of Gears, PI' 426-452, Dover, 1963.<br />

17. WEBER C. and K.. BANASOfiEK."F.ormanderung und Pl'o~<br />

fiIrucknahme bel Gerad-undScheagveeaahnten." Radem,<br />

Schriftenreihe Anl:riebstechnik, No. 11, 1955.<br />

lB. DUDLEY, D.W.. Handbook of Practical Gear Des.ign.<br />

McGraw-HiIlBook Company, New York, 1984,<br />

UII5,-- ecify GI 'I/FH:USA<br />

C.JlJide, Ski¥i'ng hobs.<br />

Meet<strong>in</strong>g pr,ecise AGMlAto'lerances quickly and<br />

,eonsistenUy lis probably what determ<strong>in</strong>es your<br />

bonorn Il<strong>in</strong>e" tool GMI-FHUSA ,carbide skiv<strong>in</strong>gl ho'bs<br />

take ~hehassle out of m<strong>in</strong>ish<strong>in</strong>g operat,ions with:<br />

• Predictab'le pelitormance<br />

• Long servioe Ilife'<br />

• Off-<strong>the</strong> -Shelf delivery of standard sizes<br />

• Competitive, pric<strong>in</strong>g<br />

As'K your GMI·FHUSA re,presentative for a Q,uotation<br />

andl copies ot our ,quality documentation.<br />

AGMA 12<br />

+<br />

'0011,(708) '986~'1858 Fax ,(1,08)~986~0756<br />

CIRCLE A.-14 ON<br />

READER REPlY CAIRO

The Involute Helicoid<br />

and<br />

The Universal Gear<br />

Leonard J. Smith<br />

tnv<strong>in</strong>cible Gear Co., Livonia, MI.<br />

lntroduction<br />

A universal gear is one generated. by<br />

a common ra.ck on a cyl<strong>in</strong>drical, conical,<br />

or planar surface, and whose teeth<br />

can be oriented parallel or skewed.<br />

centered. or offset with r1!Speetto its<br />

axes. Mat<strong>in</strong>g gear axes can he parallel or<br />

crossed. non-<strong>in</strong>tersect<strong>in</strong>g or i.ntersect<strong>in</strong>.g,<br />

skewed or parallel. and can have<br />

any angular orientation .. (See fig. 1.)<br />

The tape!!'gear is a universal gear. It provides<br />

unique geometric properties and<br />

a range of applications unmatched by<br />

any o<strong>the</strong>r motion transmission element.<br />

(See Fig. 2.) The tapergearcan be produced<br />

by any rack-type too] generator<br />

or hobb<strong>in</strong>g mach<strong>in</strong>e which has a means<br />

of tilt<strong>in</strong>g <strong>the</strong> cutter or work axis andIor<br />

c~rd<strong>in</strong>at<strong>in</strong>g simultaneous traverse and<br />

<strong>in</strong>feed motions.<br />

Traditionally this has entailed <strong>the</strong> U~<br />

of proprietary or special mach<strong>in</strong>es -<br />

however, with <strong>the</strong> advent of numerical<br />

control for axis synchronization, conventional<br />

mach<strong>in</strong>es can be employed,<br />

These are <strong>the</strong> same mach<strong>in</strong>es used tor<br />

spur and helical gear generation.<br />

The taper gear provides features not<br />

atta<strong>in</strong>able with any o<strong>the</strong>r type of gear.<br />

It raeritseensideration for what it can<br />

do, and it may well be <strong>the</strong> answer to a<br />

problem which heretofore has eluded<br />

satisfactory resolution. .<br />

Application<br />

The tapa-gear has many familiar applications;<br />

for example, <strong>the</strong> gear shaper<br />

cutter. where <strong>the</strong> taper is employed to<br />

provide a relieved cutt<strong>in</strong>g edge. (See Fig<br />

3.) Ano<strong>the</strong>r familiar application is <strong>the</strong><br />

rack-and-p<strong>in</strong>ion automotive steer<strong>in</strong>g<br />

mechanism where a taper is used to<br />

1B Gear Technology<br />

elim<strong>in</strong>ate backlash by axial adjustment.<br />

In mar<strong>in</strong>e eng<strong>in</strong>e prop drives a tapered<br />

gear is meshed witha. cyl<strong>in</strong>drical spur or<br />

helical p<strong>in</strong>ion to provide an angular<br />

takeoff and/or to enable an optimum<br />

placement for <strong>the</strong> eng<strong>in</strong>e . The taper gear<br />

also allows several unusual gear meshes<br />

<strong>in</strong><strong>the</strong> mechanism of a well-known aircraft<br />

gun and provides a lightweight<br />

reliable design <strong>in</strong> a m<strong>in</strong>imum envelope.<br />

Taper gears have found. a niche <strong>in</strong><br />

many commercial, and military applic.ations,<br />

but have not been widely embraced<br />

by <strong>the</strong> general gear <strong>in</strong>dustry,<br />

because of a requirement for special<br />

mach<strong>in</strong>es, and because of lack of <strong>in</strong><strong>format</strong>ion<br />

<strong>in</strong><strong>the</strong> literature.<br />

The taper gear concept providesa<br />

powerful tool to <strong>the</strong> geometer. and it is<br />

hoped this article will encourage <strong>the</strong> expansion<br />

of fundamental gear <strong>the</strong>ory to,<br />

<strong>in</strong>clude this versatile mach<strong>in</strong>eelement <strong>in</strong>.<br />

<strong>the</strong> basic gear<strong>in</strong>g literature for widespreadevaluaticn,<br />

The lnvolute Heliooid<br />

The <strong>in</strong>volute helicoid which is conjugate<br />

to a straight-sided rack, when<br />

converted Ito a complex <strong>in</strong>volute helicoid<br />

by <strong>the</strong> addition of a.taper, provides<br />

<strong>the</strong> basis of a universal gear system.<br />

The spur gear is <strong>the</strong> simplest form<br />

embody<strong>in</strong>g <strong>in</strong>volute tooth surfaces.<br />

(See Fig. 4.) The helical gear adds ill helical<br />

twist to <strong>the</strong> surface which results <strong>in</strong><br />

a simple <strong>in</strong>volute helicoid ..(See Fig. 5.)<br />

The <strong>in</strong>volute helicoid has three major<br />

characteristics: <strong>the</strong> <strong>in</strong>volute <strong>in</strong> any<br />

transverse section,a helix <strong>in</strong> any cyl<strong>in</strong>drical<br />

section, and anaxvolute <strong>in</strong> any<br />

axial section.<br />

Apply<strong>in</strong>g a taper to cyl<strong>in</strong>drical spur<br />

<strong>in</strong>volute gears provides an additional<br />

degree of freedom and results <strong>in</strong> a complex,<br />

<strong>in</strong>volute helicoid surface on <strong>the</strong><br />

tooth flanks. Opposite flanks will have<br />

equal, but opposite hands of helix. and<br />

a common lead. (See Fig. 6.) The 'cyl<strong>in</strong> w<br />

drical spur gear thus may be oonsidered<br />

a. special case of <strong>the</strong> <strong>in</strong>volute helicoid<br />

with zero taper. just as <strong>the</strong> cyl<strong>in</strong>drical<br />

spur gear may be considered a special<br />

case of <strong>the</strong> <strong>in</strong>volute helicoid with zero<br />

helix; i.e., <strong>in</strong>f<strong>in</strong>ite Iead,<br />

Apply<strong>in</strong>g a taper to a cyl<strong>in</strong>drical helical<br />

gear also provides an additional<br />

degree of freedom to a gear which is InitiaUya<br />

simple <strong>in</strong>volute helicoid with<br />

equal and parallel helices of <strong>the</strong> same<br />

hand and common lead, and results <strong>in</strong><br />

a. complex <strong>in</strong>volute helicoid of compound<br />

structure.<br />

The helix resultant of <strong>the</strong> taper is additive<br />

to <strong>the</strong> orig<strong>in</strong>al helix. on one flank<br />

and is reductive to <strong>the</strong> helix on <strong>the</strong> opposite<br />

flank. There are: thus two, ,entirely<br />

different helix angles and differ<strong>in</strong>g leads<br />

on opposite flanks. Relative magnitudes<br />

of helix andtaper determ<strong>in</strong>e whe<strong>the</strong>r<br />

AUTHOR:<br />

lEONARD J. SMITH is 'Vic~president of<br />

<strong>the</strong> lrJ'o<strong>in</strong>dble Gear Co. With over a halfcentury<br />

0/ experience <strong>in</strong> precision<br />

metrology and metalwork<strong>in</strong>g, he has<br />

pioneered developments il1 mach <strong>in</strong>e design,<br />

numerical control, adaptive control, servomechanisms,<br />

electricaI discharge<br />

mach<strong>in</strong><strong>in</strong>g, abrasive mach<strong>in</strong><strong>in</strong>g, eng<strong>in</strong>eer.<br />

<strong>in</strong>g reprographics and archiv<strong>in</strong>g, and com·<br />

puter <strong>in</strong>tegratio1'!. He .Ms been active <strong>in</strong><br />

AGMA, ASME, SME, ASME-GRI, and<br />

o<strong>the</strong>r t.echnica.lassociations.

PARALLEL<br />

Spur-<br />

Hel ileal<br />

Taper<br />

INITERSECT ING<br />

Bevel<br />

T,apeol'<br />

NON-~NTE:RSECTING<br />

HVpoid<br />

Worm<br />

Taper<br />

Fig. 1-Axes Orientation<br />

Fig. 4 - Spur Gear Toath - Zero Hel ieoid<br />

..,..,<br />

'" I ,<br />

/ I ,<br />

I I \<br />

I \<br />

I<br />

F"1I.2-<br />

Taper Gear Tooth<br />

fig. 5 - Helical Gear Tooth - Simple Helicoid<br />

AXVOLUTE<br />

INVOLUTE<br />

Fig . .}- Shaper Cutter<br />

:Fig.6-SpurTaperGearTOOlh<br />

- Compi x Helicold<br />

Novem'berjDecem'berl,990 19

<strong>the</strong> flank hands are <strong>the</strong> same or opposUe.<br />

Myriad possibilities are available for<br />

unlike profiles and leads for each flank,<br />

<strong>in</strong>clud<strong>in</strong>g provid<strong>in</strong>g a spur flank on one<br />

side and a helix on <strong>the</strong> o<strong>the</strong>r. Buttress<br />

profiles and one way ratchet<strong>in</strong>g as well<br />

as back stopp<strong>in</strong>g are possible.<br />

The axvolute is <strong>the</strong> key to <strong>the</strong> univer~<br />

sality of <strong>the</strong> taper gear, s<strong>in</strong>ce it provides<br />

a three-dimensional cam or crowned<br />

surface allow<strong>in</strong>g complete freedom of<br />

mesh conditions.<br />

Comparison<br />

The superficial resemblanceof <strong>the</strong><br />

taper gear toa bevel gear is mislead<strong>in</strong>g.<br />

They are two dist<strong>in</strong>ct entities.<br />

BEVEL GEAR. The bevel gear isgenerated<br />

from a conical surface. Its tooth<br />

surfaces converge to a common .apex.<br />

Each transverse section represents a<br />

geometric reduction <strong>in</strong> a. progression<br />

from back to front. Each section represents<br />

a diHe.rent diametral pitCh, and by<br />

custom is referenced at <strong>the</strong> back cone.<br />

(See Fig. 7..)The face 'Width is restricted<br />

by <strong>the</strong> parameters of number of teeth<br />

and cone angie •.s<strong>in</strong>ce <strong>the</strong> width ,of <strong>the</strong><br />

rutt<strong>in</strong>g tool tip at I<strong>the</strong>frQnt face becomes<br />

a limit factor .. Conjugate bevel gears<br />

must have <strong>the</strong> same diametral pitch at<br />

<strong>the</strong>ir back cones, must be flush<br />

matched, have complementarycone<br />

angles equal to <strong>the</strong> sum of <strong>the</strong> :shaft<br />

angle, and have a common apex. Tooth<br />