Download the August/September 1984 Issue in PDF format - Gear ...

Download the August/September 1984 Issue in PDF format - Gear ...

Download the August/September 1984 Issue in PDF format - Gear ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

operation-offers considerable advantage over mach<strong>in</strong><strong>in</strong>g,<br />

because this method. of manufacture (1) reduces material<br />

losses and mach<strong>in</strong><strong>in</strong>g costs and (2)' <strong>in</strong>creases <strong>the</strong> fatigue life<br />

of gears up to 30 percent.<br />

A few companies around <strong>the</strong> world are able to produce<br />

spiral bevel gears by precision forg<strong>in</strong>g, However, <strong>the</strong><br />

development of <strong>the</strong> process for each new gear design requires<br />

considerable trial anderror, Thus, application of<br />

computer techniques to <strong>the</strong> design and. manufacture<br />

(CAD/CAM) of <strong>the</strong> gear forg<strong>in</strong>g dies represents an attractive<br />

alternative. Therefore, <strong>in</strong> this program, methods were<br />

developed to applyexisHng advanced computer aided<br />

design and manufactur<strong>in</strong>g (CAD/CAM) technology (f<strong>in</strong>ite<br />

element, metal form<strong>in</strong>g, and heat transfer analysis) to gear<br />

forg<strong>in</strong>g die design and manufacture. <strong>Gear</strong> forg<strong>in</strong>g dies were<br />

designed and manufactured accord<strong>in</strong>g to <strong>the</strong> data supplied.<br />

by <strong>the</strong> output of <strong>the</strong> CAD procedure; thus, <strong>the</strong> CAD and<br />

CAM processes were <strong>in</strong>tegrated. The results of <strong>the</strong><br />

CAD/CAM techniques were evaluated for a given spiral<br />

bevel. gear/p<strong>in</strong>ion set by design<strong>in</strong>g and manuJactur<strong>in</strong>g <strong>the</strong><br />

forg<strong>in</strong>g dies via CAD/CAM.<br />

In recent years, CAD/CAM techniques have been applied<br />

to. die design and manufacture for forg<strong>in</strong>g rib-web type aircraft<br />

structural parts, track shoes for military vehicles, and<br />

precision turb<strong>in</strong>e and compressor blades. The experience<br />

ga<strong>in</strong>ed <strong>in</strong> all <strong>the</strong>se applications <strong>in</strong>dicates that acerta<strong>in</strong><br />

overall methodology is necessary for CAD/CAM of dies for<br />

precision and/or near net shape forg<strong>in</strong>g. This approach <strong>in</strong>dicates<br />

that <strong>the</strong> necessary <strong>in</strong>puts to <strong>the</strong> CAD/CAM system<br />

are: geometric description of '<strong>the</strong> forg<strong>in</strong>g, data on billet<br />

material under forg<strong>in</strong>g conditions (billet and die temperatures<br />

and rate and amount of de<strong>format</strong>ion)',mction coefficient,<br />

to. quantify <strong>the</strong> friction shear stress at material and die<br />

i.nterface, and forg<strong>in</strong>g conditions [i.e., temperatures, de<strong>format</strong>ion<br />

rates, die lubricants, method of heati<strong>in</strong>g <strong>the</strong> billets,<br />

and suggested number oJ forg<strong>in</strong>g operations) ..<br />

With <strong>the</strong>se <strong>in</strong>put data, a prelim<strong>in</strong>ary design of <strong>the</strong> f<strong>in</strong>ish<br />

forg<strong>in</strong>g die can be made. Next, stresses necessary to f<strong>in</strong>ish<br />

forge <strong>the</strong> part and temperatures <strong>in</strong> <strong>the</strong> forg<strong>in</strong>g and <strong>the</strong> dies<br />

are calculated. The temperature calculations take <strong>in</strong>to ac-<br />

COUJ1t <strong>the</strong> heat generated due '10' de<strong>format</strong>ion and friction,<br />

and <strong>the</strong> heat transfer dur<strong>in</strong>g <strong>the</strong> contact between <strong>the</strong> hot<br />

forg<strong>in</strong>g and <strong>the</strong> cooler dies. Thus, <strong>the</strong> elastic die deflections.<br />

due Ito temperatures and stresses, can be 'estimated and used<br />

to predict <strong>the</strong> small corrections necessary on <strong>the</strong> f<strong>in</strong>ish die<br />

geometry .. The estimation of die geometry correerions is<br />

necessary ror obta<strong>in</strong><strong>in</strong>g dose tolerance forg<strong>in</strong>gs and for<br />

mach<strong>in</strong><strong>in</strong>g <strong>the</strong> f<strong>in</strong>ish dies 'to <strong>the</strong> exact dimensions,<br />

ThE! overall procedure described above has been applied<br />

to CAD/CAM of spiral bevel gears as Phase I of this<br />

project.<br />

The second part of <strong>the</strong> project (Phase ]I) <strong>in</strong>volved Computer<br />

Aided Manufactur<strong>in</strong>g (CAM) of <strong>the</strong> forg<strong>in</strong>g dies (from<br />

rough bi1let) and demonstration of <strong>the</strong> effectiveness of<br />

CAD/CAM hy forg<strong>in</strong>g 20 spiral bevel gear sets. Phase<br />

m-AppJication of CAD/CAM techniques to actual production<br />

of bevel gears (spiral or straight)-has not yet<br />

started.<br />

Five Tasks Carried Out<br />

Five separate tasks were carried out under Phase I of '<strong>the</strong><br />

work preform design, tool design, manufactur<strong>in</strong>g of forg<strong>in</strong>g<br />

dies, forg<strong>in</strong>g trials, and f<strong>in</strong>ish<strong>in</strong>g and dimensional check<strong>in</strong>g<br />

of forged gears,<br />

One of <strong>the</strong> most important aspects of <strong>the</strong> forg<strong>in</strong>g process<br />

is <strong>the</strong> proper design of preform<strong>in</strong>g (or block<strong>in</strong>g) operations.<br />

The follow<strong>in</strong>g features were considered <strong>in</strong> <strong>the</strong> design of <strong>the</strong><br />

preform of <strong>the</strong> spiral bevel gear considered <strong>in</strong> this project.<br />

ASSUf\e Defect free Metal Ro,wa:nd Adequate Die Fill<strong>in</strong>g.<br />

Adequate metal distribution is necessary <strong>in</strong> <strong>the</strong> blocker<br />

design Itoavoid forg<strong>in</strong>g defects, such as cold shuts and folds ..<br />

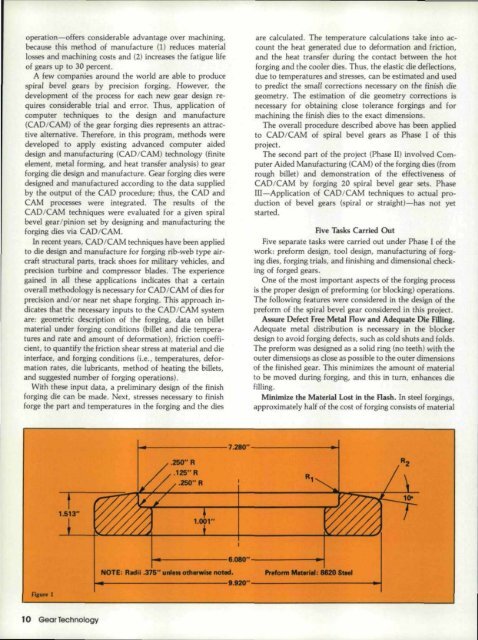

The preform was designed as a solid r<strong>in</strong>g (no teeth) with <strong>the</strong><br />

outer dimensious as dose as possible to <strong>the</strong> outer dimensions<br />

of <strong>the</strong> f<strong>in</strong>ished gear. This m<strong>in</strong>imlzes <strong>the</strong> amount of material<br />

to be moved dur<strong>in</strong>g forg<strong>in</strong>g, and this <strong>in</strong> turn, enhances die<br />

fiU<strong>in</strong>g.<br />

M<strong>in</strong>imize <strong>the</strong> Material Lost <strong>in</strong> <strong>the</strong> Rash. In steel forg<strong>in</strong>gs,<br />

approximately half of <strong>the</strong> cost of forg<strong>in</strong>g consists of material<br />

~----------------7~'--------------~~<br />

.260"R<br />

1. '"<br />

fIaure I<br />

...----------I.08O"'-----------...-t<br />

NOTE: R_III .37&" unl.. oth__ nobd.<br />

~~--------------------------a~'--------------------------~~