Download the November/December 2001 Issue in PDF format

Download the November/December 2001 Issue in PDF format

Download the November/December 2001 Issue in PDF format

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

GEAR<br />

HONINGI<br />

Properties of Tooth Surfaces due to<br />

Gear Hon<strong>in</strong>q with Electroplated Tools<br />

ICarslen MalrzeneU and Hans Kurt TOnshofl<br />

Introduction<br />

In recent years, <strong>the</strong> demands for load<br />

capacity and fatigue life of gears constantly<br />

<strong>in</strong>creased while weight and volume<br />

had 10 be reduced. To achieve rho e<br />

aims. rno t of today's gear wheels are<br />

heal treated oiooth surfaces will have<br />

high wear resi lance. A a con equence<br />

or heal treatment, distortion unavoidably<br />

occurs. With <strong>the</strong> high geometrical accuracy<br />

and quality required for gears, a Il<br />

hard mach<strong>in</strong><strong>in</strong>g proce s is needed that<br />

generate, favorable properties on <strong>the</strong><br />

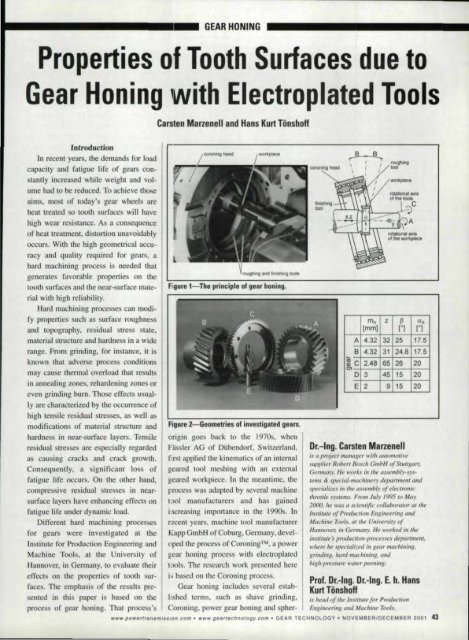

tooth surface and <strong>the</strong> near-surface mate- Figure I-<strong>the</strong> pT<strong>in</strong>cip'le ot gear hon<strong>in</strong>g l •<br />

.rial with high reliability.<br />

Hard mach<strong>in</strong><strong>in</strong>g proce se can modify<br />

properties such as surface roughness<br />

and topography. residual stress slate<br />

material structure and hardness <strong>in</strong> a wide<br />

range. From gr<strong>in</strong>d<strong>in</strong>g. for <strong>in</strong>stance. it is<br />

known that adverse process conditions<br />

may cause <strong>the</strong>rmal overload that re ults<br />

<strong>in</strong> anneal<strong>in</strong>g zones. reharden<strong>in</strong>g zones. or<br />

even gr<strong>in</strong>d<strong>in</strong>g bum. Tho e effects usually<br />

are characterized by <strong>the</strong> occurrence of<br />

hardness <strong>in</strong> near-surface layers. Tensile<br />

re idual stresses are especially<br />

regarded<br />

as caus<strong>in</strong>g crack and crack growth.<br />

Consequently, a significant loss of<br />

fatigue life occurs. On <strong>the</strong> o<strong>the</strong>r hand,<br />

compressive re idual stresses <strong>in</strong> nearsurface<br />

layer have enhanc<strong>in</strong>g effects on<br />

fatigue life under dynamic load.<br />

Different hard macil<strong>in</strong><strong>in</strong>g processes<br />

for gears were <strong>in</strong>vestigated at <strong>the</strong><br />

Institute for Production Eng<strong>in</strong>eer<strong>in</strong>g and<br />

Mach<strong>in</strong>e Tools, at <strong>the</strong> University of<br />

Hannover, <strong>in</strong> Germany, 10 evaluate <strong>the</strong>ir<br />

effects on <strong>the</strong> properties of tooth sur-<br />

r-:;;;;;;;;;;;;:;:::;:;::;::;::;:::;::;:::;;:;;::;;;-----------I<br />

hi~gh tensile residual stresses, as well as<br />

modifications of material structure and Figure,2"""""Geomehieso. <strong>in</strong>vestigated gars ..<br />

orig<strong>in</strong> goes back to jhe 1970s, when<br />

Fassler AG of Dabendorf, Switzerland,<br />

fJrst applied <strong>the</strong> k<strong>in</strong>ematics of an <strong>in</strong>ternal<br />

geared 1001 mesh<strong>in</strong>g with an external<br />

geared workpiece. In <strong>the</strong> meantime, <strong>the</strong><br />

process was adapted by several mach<strong>in</strong>e<br />

tool manufacturers and has ga<strong>in</strong>ed<br />

hcreas<strong>in</strong>g importance <strong>in</strong> tile 1990 .In<br />

recent years, mach<strong>in</strong>e tool manufacturer<br />

Kapp GmbH of Coburg. Germany. developed<br />

<strong>the</strong> process ofCoronillg, a power<br />

gear hon<strong>in</strong>g process with electroplated<br />

tools. The research work presented here<br />

i,based on <strong>the</strong> Coron<strong>in</strong>g process.<br />

...<br />

Or.-Ing'. Carsten<br />

mn z ~ an<br />

~mmI I"} (OJ<br />

A 4.32 32 25 17.5<br />

B 4.32 31 24.8 17.5<br />

I'll<br />

III C 2.48 65 26 20<br />

01<br />

10 3 45 15 20<br />

IE 2 9' 15 .20<br />

M,arzeneU<br />

is a projeet manager with automotive<br />

supplier Robrrt Bosch. GmbH of Stuttgart,<br />

Germany. He works <strong>in</strong> <strong>the</strong> assembly-systems<br />

& special-mach<strong>in</strong>ery department fIIUJ<br />

specializes <strong>in</strong> <strong>the</strong> assembly of electronic<br />

throttle systems. From July 1995 10 May<br />

2000. he II'(U (I scientific collaborator {It thl!<br />

Institute of Production Eng<strong>in</strong>eer<strong>in</strong>g and<br />

Mac/l<strong>in</strong>e Tool. at <strong>the</strong> University of<br />

Hannover; ill GemlllllY. He worked ill rile<br />

<strong>in</strong>stitute's production-processes department.<br />

where he sperializrd ill gear mach<strong>in</strong><strong>in</strong>g,<br />

gr<strong>in</strong>d<strong>in</strong>g. hard marh<strong>in</strong><strong>in</strong>g, and<br />

high-pressure water peen<strong>in</strong>g.<br />

Prof. O'rAng ..10r,~I:ng.E. h. Hans<br />

face. The emphasis of <strong>the</strong> result presented<br />

<strong>in</strong> tills paper L based 011 <strong>the</strong> lished terms, such as shave gr<strong>in</strong>d<strong>in</strong>g. is Ireatj of <strong>the</strong> Institute for Production<br />

Gear hon<strong>in</strong>g <strong>in</strong>cludes several estab-<br />

Kurt Ti<strong>in</strong>shofl<br />

proces of gear hon<strong>in</strong>g. That process's Coronmg, power gear hon<strong>in</strong>g and spher- Eng<strong>in</strong>eer<strong>in</strong>g Wid Mllclrille Tools .<br />

..... "'.powertrlltlsmfss'on.com •.. w ....g.eart·9chnology com' GEAR TECHNOLOGY' NOVEM'BERIDECEMBER <strong>2001</strong> 43,<br />

I<br />

I<br />

I