Download the September/October 1991 Issue in PDF format - Gear ...

Download the September/October 1991 Issue in PDF format - Gear ...

Download the September/October 1991 Issue in PDF format - Gear ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

2) Workpieces whose critical Ioeat<strong>in</strong>g<br />

elements have not been identified and qualified<br />

to a compatible capability level will<br />

cause <strong>the</strong> statisticalevaluation to fail. Bore<br />

geom.etry variation impact lead, <strong>in</strong>volute,<br />

and radial runout error.<br />

3) Little bore geometry error means less<br />

lead, <strong>in</strong>volate, and radial ranout variation.<br />

4) Little axial face runout error means less<br />

lead, <strong>in</strong>volute. and radial ranout error. Fig.<br />

S iljustrates <strong>the</strong> effect o,f face wobble <strong>in</strong><br />

determ<strong>in</strong><strong>in</strong>g lead variation.<br />

5) Greater bore geometry error means less<br />

contact between <strong>the</strong> mach<strong>in</strong>e workhold<strong>in</strong>g<br />

fixtur,e and <strong>the</strong> actual bore of <strong>the</strong> gear ..<br />

6) Less contact berweea mach<strong>in</strong>e workhold<strong>in</strong>g<br />

and <strong>the</strong> actual. bore of gear means greater<br />

lead, <strong>in</strong>volute, and radiel runout variation.<br />

7) Less random variation of number and magnitude<br />

of bare geemetry errors from part to part<br />

and throughout a given sample of parts means<br />

lead, <strong>in</strong>volute, and radi~ runout variation shall<br />

be :<strong>in</strong>."statistical control."<br />

8) A greater random variation of number<br />

and magnitude o[l:>o·]',etI,eometry errors from<br />

part to part and throughout a. given sample<br />

~f parts .. means lead, <strong>in</strong>volute, and radial<br />

runout variation shall be less "staristicalty<br />

capable."<br />

For <strong>in</strong>spection workpiece/workhol.d<strong>in</strong>g<br />

repeatabijity <strong>the</strong> e <strong>in</strong>herent variable can<br />

be implied from <strong>the</strong> foUow<strong>in</strong>g statements:<br />

1) At best, <strong>in</strong>spection workhold<strong>in</strong>g "approximates"<br />

<strong>the</strong> mach<strong>in</strong>e workhold<strong>in</strong>g axis<br />

of rotation,<br />

2), There is always a difference between mach<strong>in</strong>e<br />

work:hoId<strong>in</strong>gand<br />

<strong>in</strong>spection workhold<strong>in</strong>g,<br />

which means that me axis of workpiece<br />

rotation<br />

and <strong>the</strong> axis of <strong>in</strong> pection rotation cannot<br />

be identical.<br />

3) Greater random variation of number and<br />

magnitude of bore geometry errors f:rom<br />

part 'to part and threughout a given sample<br />

of parts meansgreater difference between<br />

ma~h<strong>in</strong>e workholdmg and <strong>in</strong>spection<br />

workhold<strong>in</strong>g,<br />

which means lead, <strong>in</strong>volllte, and<br />

radial runout variation will be less "stati.sti·<br />

cally capable. ".<br />

4) Inspection mach<strong>in</strong>e software, designed<br />

1.0 draw <strong>the</strong> average trace of leads on feur<br />

teeth 90° apart and u <strong>in</strong>g <strong>the</strong> sum-of-leastquares<br />

method, can show random mead<br />

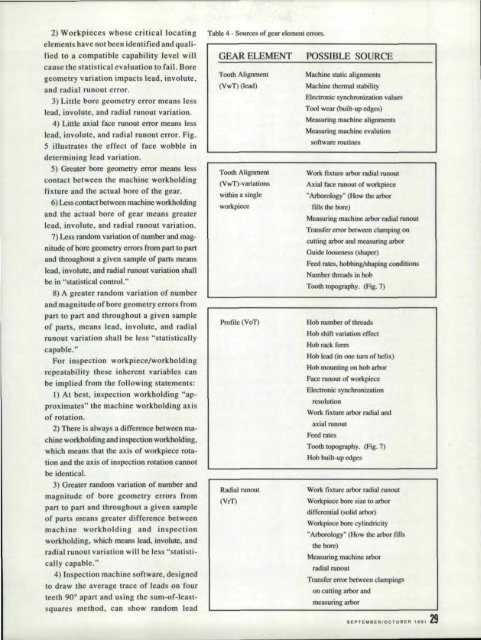

Table 4 - Sources of geal' element errors.<br />

GEAR ELEMENT<br />

rossrat.s SOURCE<br />

TootIJ Aligmnent<br />

Mach<strong>in</strong>e tatle ali.gnmenls<br />

(VwT)Oead)<br />

Mach<strong>in</strong>e <strong>the</strong>nnal ~tability<br />

Electronic sync'ltronizalionvalues<br />

'(':00] wear (built.up edge )<br />

Measur<strong>in</strong>g m.ach<strong>in</strong>e align_ments<br />

Measur<strong>in</strong>g mach<strong>in</strong>e evalution<br />

'Software rout<strong>in</strong>es<br />

Tooth Alignment<br />

(VwT)-variatioru<br />

Work fixture arbor radiali runmU<br />

Axial face runout of workpiece<br />

wilhill a s<strong>in</strong>gle<br />

"Arborology" (How <strong>the</strong> arbor<br />

workpiece<br />

fills <strong>the</strong> bore)<br />

Measur<strong>in</strong>g macl:t<strong>in</strong>earbor radiaJ runout<br />

Transfer error between clamp<strong>in</strong>g on<br />

cutt<strong>in</strong>g arbor and :measur<strong>in</strong>g .arbor<br />

Guide looseness (sha,per)<br />

Feed rates, hobb<strong>in</strong>g/slt ;p<strong>in</strong>g condition<br />

Number threads '<strong>in</strong> hob<br />

Tooth topography. (Fig. 7)<br />

Profile (VoT)<br />

Hob number ofllueads<br />

Hob shift variation effeci<br />

Hob rack form<br />

Hob lead (<strong>in</strong> one tum of helix)<br />

Hob moulll<strong>in</strong>g on hob arbor<br />

Face runout of workpiece<br />

Electronic sync'iuonization<br />

resolution<br />

Work futturearbor radialland<br />

3xiaII1IInOui<br />

Feed rates<br />

Tooth topography. (Fig. 7)<br />

Hob buill-UP edges<br />

Radial runout<br />

Work fixture arbor radial runout<br />

(Vff)<br />

Workpieoebore size 10 arbor<br />

differential (solid arbes)<br />

Workpiece bore cyl<strong>in</strong>dricity<br />

"Arbomlogy" (How tile arbor fills<br />

<strong>the</strong> bore)<br />

Measur<strong>in</strong>g mach<strong>in</strong>e arbor<br />

radial nmaut<br />

Transfer error between elamp<strong>in</strong>gs<br />

on cutt<strong>in</strong>g arborand<br />

measurillgarbor<br />

SEPTEIoIBIERIOCTOBEF! III' 29