Download the September/October 1991 Issue in PDF format - Gear ...

Download the September/October 1991 Issue in PDF format - Gear ...

Download the September/October 1991 Issue in PDF format - Gear ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

at <strong>the</strong> same standard pitch diameter. They<br />

represent a system <strong>in</strong> which <strong>the</strong> action between<br />

gear teeth <strong>in</strong> <strong>the</strong> arc of reces ion (assum<strong>in</strong>g<br />

<strong>the</strong> p<strong>in</strong>ion as <strong>the</strong> driver) is <strong>in</strong>creased<br />

at DO sacrifice of action <strong>in</strong> Ule arc of appreach,<br />

because <strong>the</strong> arc of approach is limited<br />

by <strong>the</strong> undercut anyway. The long and<br />

short addendum system should only be u ed<br />

<strong>in</strong> 'those <strong>in</strong>stances where undercuts and high<br />

base circle diameters limit <strong>the</strong> l<strong>in</strong>e of action.<br />

There is no po<strong>in</strong>t <strong>in</strong> <strong>in</strong>creas<strong>in</strong>g<strong>the</strong> addendum<br />

of one gear at <strong>the</strong> expense of <strong>the</strong> o<strong>the</strong>r <strong>in</strong><br />

cases where <strong>the</strong>re is no undercut It would<br />

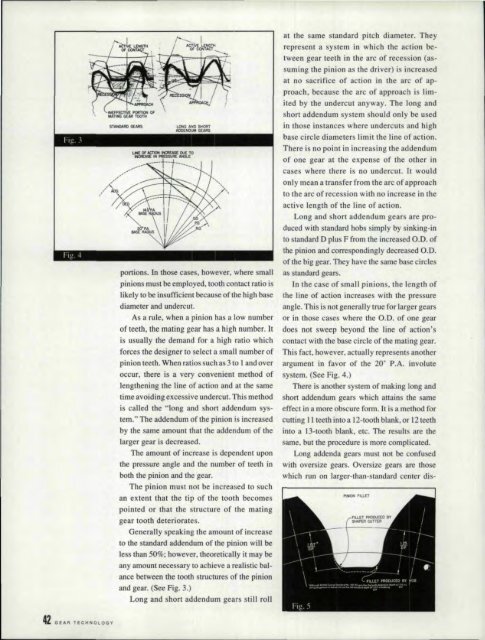

portions. In those case ,:nowever, where small<br />

p<strong>in</strong>ions must be 'employed. tooth contact ratio is<br />

likely to be <strong>in</strong>sufficient<br />

diameter<br />

and undercut.<br />

because of 'Ihe nigh ba e<br />

As a rule, when a p<strong>in</strong>ion 'has a low number<br />

of teeth, <strong>the</strong> mat<strong>in</strong>g gear has a high number,<br />

is usually <strong>the</strong> demand for a high rano which<br />

forces <strong>the</strong> designer<br />

to select a small number of<br />

p<strong>in</strong>ion teeth. When ratios such as 3,to ] and over<br />

OCCUJ, <strong>the</strong>re isa very convenient method of<br />

leng<strong>the</strong>n<strong>in</strong>g<br />

<strong>the</strong> l<strong>in</strong>e of action and at <strong>the</strong> same<br />

time avoid<strong>in</strong>g excessive undercut. This method<br />

is called <strong>the</strong> "long and short addendum system."<br />

The addendum ofrhe p<strong>in</strong>ion is <strong>in</strong>creased<br />

by <strong>the</strong> same amount that <strong>the</strong> addendum of <strong>the</strong><br />

larger gear is decreased.<br />

The amount of <strong>in</strong>crease is dependent upon<br />

<strong>the</strong> pressure angle and <strong>the</strong> number of teeth <strong>in</strong><br />

both <strong>the</strong> p<strong>in</strong>ion and! <strong>the</strong> gear.<br />

The p<strong>in</strong>ion must not be <strong>in</strong>creased to such<br />

an extent that <strong>the</strong> tip of <strong>the</strong> tooth becomes<br />

po<strong>in</strong>ted or that <strong>the</strong> structure of <strong>the</strong> mat<strong>in</strong>g<br />

gear tooth deteriorates.<br />

Generally speak<strong>in</strong>g <strong>the</strong>amount of <strong>in</strong>crease<br />

to <strong>the</strong> standard addendum<br />

less than 50%;. however, <strong>the</strong>oretically<br />

any amount necessary<br />

to achieve a realistic balance<br />

between <strong>the</strong> tooth structures<br />

andgear ..(See Fig. 3.)<br />

It<br />

of <strong>the</strong> p<strong>in</strong>ion will be<br />

it may be<br />

of <strong>the</strong> p<strong>in</strong>ion<br />

Long and short addendum gears still roll<br />

only mean a transfer<br />

from <strong>the</strong> arc of approach<br />

10 <strong>the</strong> arc of recession with no <strong>in</strong>crease <strong>in</strong> <strong>the</strong><br />

active length of <strong>the</strong> I<strong>in</strong>e of action ..<br />

Long and short addendum gears are produced<br />

with standard bobs simply by <strong>in</strong>k<strong>in</strong>g-<strong>in</strong><br />

10 standard D plusF from <strong>the</strong> <strong>in</strong>creased O.D. of<br />

tile p<strong>in</strong>ion and correspond<strong>in</strong>gly decreased a.D.<br />

of <strong>the</strong> big gear. They have <strong>the</strong><br />

as standard gears.<br />

arne base circles<br />

In<strong>the</strong> case of small pillions, <strong>the</strong> length of<br />

<strong>the</strong> l<strong>in</strong>e of action <strong>in</strong>crea es with <strong>the</strong> pressure<br />

angle. This is not generally<br />

or <strong>in</strong> those cases where<br />

true for larger gears<br />

<strong>the</strong> O.D. of one gear<br />

does not sweep beyond tile l<strong>in</strong>e of action's<br />

contact<br />

with <strong>the</strong> base circle of <strong>the</strong> mat<strong>in</strong>g gear.<br />

This fact, however, actually repre ent ano<strong>the</strong>r<br />

nrgument <strong>in</strong> favor of <strong>the</strong> 20· P,A. <strong>in</strong>volute<br />

system. (See Fig. 4.)<br />

There is ano<strong>the</strong>r system of mak<strong>in</strong>g long and<br />

short addendum gears which atta<strong>in</strong>s <strong>the</strong> same<br />

effect <strong>in</strong>a more obscure fOI111. It is a method for<br />

cutt<strong>in</strong>g L1teeth <strong>in</strong>k>a 12-tooth blank, or ] 2 teeth<br />

<strong>in</strong>to a 1.3-tooth blank, etc. The resultsare <strong>the</strong><br />

arne, but <strong>the</strong> procedure is more complicated.<br />

Long addenda gears must not be confused<br />

wlth oversize gears. Oversize gears are those<br />

which run on larger-than-standard center dis-<br />

42 GEAR TECHNOLOGY