TM 11-6665-214-10 OPERATOR'S MANUAL

TM 11-6665-214-10 OPERATOR'S MANUAL

TM 11-6665-214-10 OPERATOR'S MANUAL

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>TM</strong> <strong>11</strong>-<strong>6665</strong>-<strong>214</strong>-<strong>10</strong><br />

OPERATOR’S <strong>MANUAL</strong><br />

HEADQUARTERS, DEPAR<strong>TM</strong>ENT OF THE ARMY<br />

1 AUGUST 1986

This publication is required for official use or for<br />

administrative or operational purposes only. Distribution is<br />

limited to US Government Agencies. Other requests for this<br />

document must be referred to Commander, US Army<br />

Communications-Electronics Commend and Fort Monmouth,<br />

ATTN: AMSEL-ME-P, Fort Monmouth, NJ 07703-5007.

<strong>TM</strong> <strong>11</strong>-<strong>6665</strong>-<strong>214</strong>-<strong>10</strong><br />

C1<br />

Change<br />

No. 1<br />

HEADQUARTERS<br />

DEPAR<strong>TM</strong>ENT OF THE ARMY<br />

Washington, DC, 15 May 1988<br />

OPERATOR’S <strong>MANUAL</strong><br />

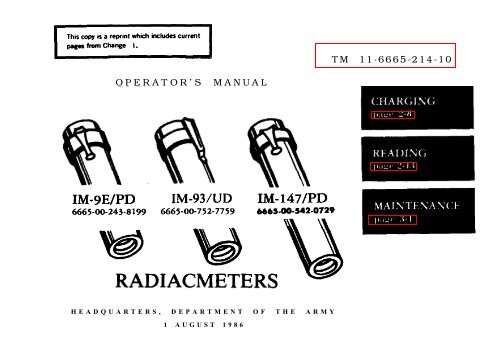

RADIACMETERS lM-9E/PD (NSN <strong>6665</strong>-00-243-8199)<br />

IM-93/UD (NSN <strong>6665</strong>-00-752-7759) AND<br />

IM-147/PD (NSN <strong>6665</strong>-00-542-0729)<br />

<strong>TM</strong> <strong>11</strong>-<strong>6665</strong>-<strong>214</strong>-<strong>10</strong>, 1 August 1986, is changed as follows:<br />

1. Remove old pages and insert new pages as indicated below. New or<br />

changed material is indicated by a vertical bar in the margin of the page.<br />

Added or revised illustrations are indicated by a vertical bar adjacent to the<br />

identification number.

Remove pages<br />

Insert pages<br />

i and ii . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..i and ii<br />

2-3 through 2-6 . . . . . . . . . . . . . . . . . . . . . . . . . ..2-3 through 2-6<br />

2-21 and 2-22 . . . . . . . . . . . . . . . . . . . . . . . . . . . ..2-21 and 2-22<br />

3-1 through 3-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1 through 3-4<br />

A-1/(A-2 blank) . . . . . . . . . . . . . . . . . . . . . . . . . . A-1/(A-2 blank)<br />

B-1 through B-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1 through B-4<br />

2. File this change in front of the publication for reference purposes.<br />

Distribution authorized to the Department of Defense and DOD contractors only<br />

for official use or for administration or operational purposes. This determination<br />

was made on 4 February 1988. Other requests for this document will be<br />

referred to Commander, US Army Communications-Electronics Command and<br />

Fort Monmouth, ATTN: AMSEL-ME-P, Fort Monmouth, NJ 07703-5000.<br />

DESTRUCTION NOTICE – Destroy by any method that will prevent disclosure of<br />

contents or reconstruction of the document.

SEVERE ILLNESS or DEATH may result if you fail to observe the<br />

following safety precautions. Both denatured and isopropyl<br />

alcohols are toxic, volatile, and flammable. Use only in well ventilated<br />

areas away from heat or open flame. Avoid ingestion, prolonged<br />

breathing of vapor, and contact with skin.<br />

DO NOT insert sharp objects into the charging end of the<br />

dosimeter. This will damage the interior of the socket and the<br />

charging contact.<br />

DO NOT blow on the dosimeter. DO NOT use a drying cloth.<br />

The charging end must be moisture- and lint-free.<br />

A/(B blank)

*<strong>TM</strong> <strong>11</strong>-<strong>6665</strong>-<strong>214</strong>-<strong>10</strong><br />

TECHNICAL <strong>MANUAL</strong><br />

HEADQUARTERS<br />

DEPAR<strong>TM</strong>ENT OF THE ARMY<br />

No. <strong>11</strong>-<strong>6665</strong>-<strong>214</strong>-<strong>10</strong> Washington, DC, 1 August 1986<br />

OPERATOR’S <strong>MANUAL</strong><br />

RADIACMETERS lM-9E/PD (NSN <strong>6665</strong>-00-243-8199)<br />

lM-93/UD (<strong>6665</strong>-00-752-7759) AND<br />

lM-147/PD (<strong>6665</strong>-00-542-0729)<br />

REPORTING ERRORS AND RECOMMENDING IMPROVEMENTS<br />

You can help improve this manual. If you find any mistakes or if<br />

you know of a way to improve the procedures, please let us know.<br />

Mail your letter or DA Form 2028 (Recommended Changes to<br />

Publications and Blank Forms), direct to: Commander, US Army<br />

Communications-Electronics Command and Fort Monmouth,<br />

ATTN: AMSEL-ME-MP, Fort Monmouth, New Jersey<br />

07703-5000.<br />

In either case, a reply will be furnished direct to you.<br />

*This manual supersedes <strong>TM</strong> <strong>11</strong>-<strong>6665</strong>-<strong>214</strong>-<strong>10</strong>, 27 November 1962, including all changes.<br />

Change 1<br />

i

TABLE OF CONTENTS<br />

CHAPTER 1. INTRODUCTION<br />

Section I. General Information . . . . . . . . . . . . . . . . . . . . . . . . . . .<br />

II. Equipment Description and Data . . . . . . . . . . . . . . .<br />

III. Technical Principles of Operation . . . . . . . . . . . . . . .<br />

CHAPTER 2. OPERATING INSTRUCTIONS<br />

Section I. Description and Use of Operator’s Controls<br />

and Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .<br />

II. Preventive Maintenance Checks and Services<br />

(PMCS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .<br />

III. Operation Under Usual Conditions . . . . . . . . . . . . . .<br />

IV. Operation Under Unusual Conditions . . . . . . . . . . . .<br />

CHAPTER 3. MAINTENANCE INSTRUCTIONS<br />

Section I. Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .<br />

II. Maintenance Procedures . . . . . . . . . . . . . . . . . . . . . . .<br />

APPENDIX A. REFERENCES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .<br />

B. EXPENDABLE/DURABLE SUPPLIES AND<br />

MATERIALS LISTS . . . . . . . . . . . . . . . . . . . . . . . . . .<br />

ii<br />

Page<br />

1-1<br />

1-4<br />

1-8<br />

2-1<br />

2-3<br />

2-8<br />

2-22<br />

3-1<br />

3-2<br />

A-1<br />

B-1

1-1. SCOPE<br />

CHAPTER 1<br />

INTRODUCTION<br />

Section I. GENERAL INFORMATION<br />

a. This manual describes Radiacmeters IM-9E/PD, IM-93/UD and<br />

IM-147/PD. It guides you, the operator, as you operate and maintain this<br />

equipment.<br />

b. Throughout this manual, Radiacmeters IM-9E/PD, IM-93/UD, and<br />

IM-147/PD are also called dosimeters. Don’t be confused by these terms,<br />

a dosimeter is a radiacmeter.<br />

c. The IM-93/UD and IM-147/PD Radiacmeters are used to detect and<br />

measure large-scale radiation, e.g., a nuclear contaminated area. The<br />

IM-9E/PD Radiacmeter is used to detect and measure small-scale radiation,<br />

e.g., a laboratory environment.<br />

1-1

1-2. MAINTENANCE FORMS, RECORDS AND REPORTS<br />

a. Reports of Maintenance and Unsatisfactory Equipment. Department of the<br />

Army forms and procedures used for equipment maintenance will be those prescribed<br />

by DA Pam 738-750 as contained in Maintenance Management Update.<br />

b. Report of Packaging and Handling Deficiencies. Fill out and forward SF 364<br />

(Report of Discrepancy (ROD)) as prescribed in AR 735-<strong>11</strong>-2/DLAR 4140.55/<br />

NAVMATINST 4355.73B/AFR 400-54/MCO 4430.3H.<br />

c. Discrepancy in Shipment Report (DISREP) (SF 361). Fill out and forward<br />

Discrepancy in Shipment Report (DISREP) (SF 361) as prescribed in AR 55-38/<br />

NAVSUPINST 46<strong>10</strong>.33C/AFR 75-18/MCO P46<strong>10</strong> .19D/DLAR 4500.15.<br />

1-3. Reporting Equipment Improvement Recommendations (EIR)<br />

If your radiacmeter needs improvement, let us know. Send us an EIR. You, the user,<br />

are the only one who can tell us what you don’t like about the design. Put it on an SF<br />

368 (Quality Deficiency Report). Mail it to: Commander, US Army<br />

Communications-Electronics Command and Fort Monmouth, ATTN: AMSEL-<br />

PA-MA-D, Fort Monmouth, New Jersey 07703-5023. We’ll send you a reply.<br />

1-2

1-4. DESTRUCTION OF ARMY ELECTRONIC MATERIEL TO PREVENT ENEMY<br />

USE<br />

Evacuation, rather than destruction, is first priority, whenever possible. Destruction,<br />

when necessary, will be accomplished only upon the order of the<br />

Commander.<br />

Each using organization and/or installation having custody of radiacmeters<br />

should have a Standard operating procedure (SOP) for radiacmeter destruction.<br />

This demolition plan should be suitably flexible to cover any situation.<br />

Destruction method should consider troop availability, materials required,<br />

time needed, etc. Some of the methods used for destruction are smashing,<br />

exploding, and burning (with manual) after demolition.<br />

1-3

Section II. EQUIPMENT DESCRIPTION AND DATA<br />

1-5. EQUIPMENT CHARACTERISTICS, CAPABILITIES, AND FEATURES<br />

The dosimeter:<br />

● detects and<br />

measures cumulative<br />

exposure to shortduration<br />

high or low intensity X-ray and gamma-ray radiation.<br />

● can be clipped to the<br />

user’s pocket or,<br />

can be attached to some<br />

object in the area that is<br />

to be measured for total<br />

radiation exposure.<br />

1-4

1-6. DIFFERENCES BETWEEN MODELS<br />

a. Physical characteristics<br />

IM-9E/PD<br />

IM-93/UD<br />

IM-147/PD<br />

1-5

1-6. DIFFERENCES BETWEEN MODELS - Continued<br />

b. Technical characteristics<br />

NOTE<br />

The terms RAD/millirad and<br />

ROENTGEN/milliroentgen are being<br />

phased out and replaced by the new term,<br />

GRAY/centigray. One centigray equals<br />

one RAD/ROENTGEN.<br />

Dosimeter<br />

Total dosage and scale range<br />

IM-9E/PD . . . . . . . . . . . . . . . . . . . . . . . . . . . 0-200 millirads, in increments of <strong>10</strong><br />

IM-93/UD . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0-600 RADS, in increments of 20<br />

IM-147/PD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 0-50 RADS, in increments of 2<br />

1-6<br />

NOTE<br />

The IM-9E/PD is used only in a<br />

laboratory environment. The IM-93/UD<br />

and IM-147/PD are used in the field.

1-6. DIFFERENCES BETWEEN MODELS - Continued<br />

Maximum acceptable leakage (in radiation-free area)<br />

IM-9E/PD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 millirads/day (24-hours)<br />

IM-93/UD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 RADS/day (24-hours)<br />

IM-147/PD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 RAD/day (24-hours)<br />

NOTE<br />

All leakage is cumulative. If you wait two days, for example, you<br />

may double the maximum. (Example: IM-9E/PD, 2 days = 8<br />

millirads.)<br />

Temperature range<br />

IM-9E/PD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . –65ºto+132ºF<br />

IM-93/UD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . –40ºto+150ºF<br />

IM-147/PD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . –40ºto+150ºF<br />

1-7. EQUIPMENT DATA<br />

Type of radiation detected . . . . . . . . . . . . . . . . . . . . . . . . . . . . X- and gamma-ray<br />

Type of detector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. ionization chamber<br />

Type of indicator . . . . . . . . . . . . . . . . . . . . . . . image (shadow) of electrometer<br />

fiber (quartz) on calibrated scale<br />

1-7

1-7. EQUIPMENT DATA - Continued<br />

Calibration accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ±<strong>10</strong>% of true dose<br />

Charging voltage (for zero reference) . . . . . . . . . . . . . . . . . 180 volts maximum<br />

Section Ill. TECHNICAL PRINCIPLES OF OPERATION<br />

CAP (WITH WINDOW) . . . . . . . . Keeps out dirt and moisture. Dosimeter<br />

will operate with or without cap.<br />

WIRE ELEMENT . . . . . . . . . . . . . . . Voltage applied from charger attracts<br />

quartz fiber, moving fiber toward zero<br />

on calibrated scale.<br />

QUARTZ FIBER . . . . . . . . . . . . . . . . Indicates charge. Light entering charging<br />

end causes fiber to cast hairline<br />

shadow onto calibrated reticle scale.<br />

EYEPIECE . . . . . . . . . . . . . . . . . . . . . . Operator views dosage scale through<br />

here.<br />

DOSAGE SCALE . . . . . . . . . . . . . . . Operator views hairline on scale and<br />

(Calibrated Reticle)<br />

reads dosage.<br />

LENSES . . . . . . . . . . . . . . . . . . . . . . . . Magnify image of quartz fiber.<br />

ELECTRODE . . . . . . . . . . . . . . . . . . . Connects dosimeter to charger, which<br />

supplies voltage to wire element.<br />

1-8<br />

NOTE<br />

If cap is lost or defective, you can use<br />

cellophane tape or any clear material.

1-9/(1-<strong>10</strong> blank)

CHAPTER 2<br />

OPERATING INSTRUCTIONS<br />

Section I. DESCRIPTION AND USE OF OPERATOR’S CONTROLS AND INDICATORS<br />

CALIBRATED RETICLE SCALE - Indicates accumulated radiation dose when<br />

viewed through eyepiece.<br />

NOTE<br />

Scale MUST be held HORIZONTAL to<br />

obtain accurate readings.<br />

2-1

2-2<br />

1. Airtight, sealed assembly<br />

2. Aluminum barrel<br />

3. Pocket clip, steel<br />

4. Plastic protective cap

Section II. PREVENTIVE MAINTENANCE CHECKS AND SERVICES (PMCS)<br />

2-1. GENERAL<br />

a. ALWAYS<br />

● keep in mind the CAUTIONS and WARNINGS.<br />

b. BEFORE you operate<br />

● perform your before (B) PMCS.<br />

c. WHILE you operate<br />

● perform your during (D) PMCS.<br />

d. AFTER you operate<br />

● perform your after (A) PMCS.<br />

2-3

e. PERIODICALLY<br />

● check the last date entered on the DA label 80 located on your dosimeter.<br />

Your dosimeter must be sent to the nearest US Army Area<br />

Calibration and Repair Center (ACRC) nucleonic laboratory for<br />

inspection and certification (I&C) service - once a year for active (in<br />

use) dosimeters; once every 5 years for contingency (standby) dosimeters.<br />

2-2. PMCS TABLE<br />

Your Preventive Maintenance Checks and Services table lists the inspections<br />

and care of your dosimeter required to keep it in good operating condition.<br />

2-4 Change 1

Item<br />

No.<br />

Table 2-1. Operator Preventive Maintenance Checks and Services<br />

1 ●<br />

Interval<br />

●<br />

NOTE: Perform checks in order listed -<br />

B-before D-during A-after M-monthly<br />

Item to be<br />

Inspected<br />

Excessive<br />

standby<br />

leakage<br />

Procedure<br />

Check for and have<br />

repaired or adjusted,<br />

as necessary.<br />

NOTE<br />

Dosimeters should normally<br />

be held in a charged<br />

(standby) condition prior<br />

to use/mission. If dosimeters<br />

are not held in<br />

standby, perform leakage<br />

test (para 3-2) prior to use.<br />

Read the dosimeter after<br />

removing it from standby.<br />

Compare its reading to<br />

dosimeters in standby. If<br />

reading is much higher<br />

than other dosimeter readings,<br />

perform leakage test<br />

(para 3-2).<br />

Equipment<br />

is Not<br />

Ready/<br />

Available If:<br />

Dosimeter is<br />

unable to pass<br />

leakage test.<br />

Change 1 2-5

Table 2-1. Operator Preventive Maintenance<br />

Checks and Services - Continued<br />

NOTE: Perform checks in order listed -<br />

B-before D-during A-after M-monthly<br />

Item<br />

No.<br />

2<br />

Interval<br />

Item to be<br />

Inspected<br />

Ability to<br />

charge.<br />

Procedure<br />

Check for and have<br />

repaired or adjusted,<br />

as necessary.<br />

Charge dosimeter to 0.<br />

Equipment<br />

is Not<br />

Ready/<br />

Available If:<br />

Unable to<br />

charge<br />

dosimeter<br />

to 0.<br />

NOTE<br />

For dosimeters held in<br />

standby, perform steps 1<br />

and 2 only, and return to<br />

standby.<br />

2-6 Change 1

Table 2-1. Operator Preventive Maintenance<br />

Checks and Services -Continued<br />

NOTE: Perform checks in order listed -<br />

B-before D-during A-after M-monthly<br />

Procedure<br />

Equipment<br />

Interval Check for and have is Not<br />

Item Item to be repaired or adjusted, Ready/<br />

No. B D A M Inspected as necessary.<br />

Available If:<br />

3 ●<br />

Excessive Read dosimeter during use<br />

leakage to record exposure. When<br />

large, unexplained readings<br />

are recorded, perform<br />

leakage test (para 3-2) to<br />

verify dosimeter operation.<br />

4 ● Recharge After use, recharge dosimfor<br />

standby eter to 0 and place in<br />

standby.<br />

2-7

Section III. OPERATION UNDER USUAL CONDITIONS<br />

2-3. CHARGING THE DOSIMETER<br />

NOTE<br />

The radiacmeter detector charger, PP-1578A/PD, is not supplied<br />

with the dosimeter but is needed for use with it. If a radiacmeter<br />

detector charger is not available, a field emergency dosimeter<br />

charger should be used.<br />

2-8

2-3. CHARGING THE DOSIMETER - Continued<br />

a. Charge the dosimeter:<br />

● before use.<br />

● if it becomes discharged because of leakage or exposure to radiation.<br />

● only in a dust- and radiation-free environment.<br />

b. After charging, DO NOT subject the dosimeter to:<br />

● severe shock.<br />

● excessive dampness.<br />

● high temperatures.<br />

c. Charging procedure using the PP-1578A/UD. (See TB SIG 226-8 for<br />

detailed instructions.)<br />

(1) Prepare charger for use.<br />

● remove from carrying case.<br />

● unscrew dust cap and lift it off the charging pedestal.<br />

● check to see that charging pedestal is clean and dry and, if necessary,<br />

clean it. Use detergent and distilled water, and AIR DRY only.<br />

2-9

2-3. CHARGING THE DOSIMETER - Continued<br />

(2) Remove protective cap from charging end of dosimeter.<br />

(3) Place dosimeter in position on charger and press straight down.<br />

(4) Charge dosimeter to zero by rotating charging knob while looking<br />

through dosimeter eyepiece. To bring the hairline to zero, turn clockwise/<br />

increasing the charge. If hairline drops below “0”, then turn counterclockwise/decreasing<br />

the charge to zero.<br />

(5) Remove dosimeter from charger and reinstall protective cap on<br />

charging end.<br />

(6) Reinstall dust cap on charging pedestal of charger.<br />

(7) Return charger to carrying case, and fasten flap.<br />

2-<strong>10</strong>

2-3. CHARGING THE DOSIMETER - Continued<br />

NOTE<br />

For detailed charger<br />

operation and maintenance,<br />

see TB SIG 226-8.<br />

PP-1578A/UD<br />

2-<strong>11</strong>

2-3. CHARGING THE DOSIMETER - Continued<br />

d. Charging procedure using field emergency charger.<br />

(1) Remove protective cap from charging end of dosimeter.<br />

(2) Push plug (PL-55) into charging end of dosimeter.<br />

(3) Look through dosimeter eyepiece<br />

and charge dosimeter to 0.<br />

(4)<br />

(5)<br />

Remove plug from charging<br />

end of dosimeter.<br />

Reinstall protective cap on<br />

charging end of dosimeter.<br />

2-12

2-4. USING THE DOSIMETER<br />

Either:<br />

● clip your dosimeter to<br />

your clothing (shirt<br />

pocket is ideal).<br />

or<br />

● attach your dosimeter<br />

to any object (tree,<br />

tent, rock, etc.) in<br />

the area you wish to<br />

check.<br />

2-5. READING YOUR DOSIMETER<br />

NOTE<br />

Always hold dosimeter level to ground. If<br />

you lie down, tilt your head to read the<br />

dosimeter, or hold the dosimeter at an<br />

angle, you’ll get inaccurate readings.<br />

2-13

2-5. READING YOUR DOSIMETER - Continued<br />

● look towards a light<br />

source through the<br />

eyepiece lens of the<br />

dosimeter.<br />

2-14

2-5. READING YOUR DOSIMETER - Continued<br />

● rotate the dosimeter until the calibrated scale is horizontal.<br />

NOTE<br />

Always hold dosimeter level to ground. If you lie down, tilt your<br />

head to read the dosimeter, or hold the dosimeter at an angle,<br />

you’ll get inaccurate readings.<br />

2-15

● note the position of the shadow<br />

(hairline) on the calibrated<br />

(reticle) scale.<br />

● determine the amount of radiation<br />

detected.<br />

2-6. DETERMINING THE RADIATION DOSAGE<br />

To figure out how much radiation you were exposed to, just subtract your<br />

initial reading (taken before you use the dosimeter) from your final reading<br />

(taken after a certain exposure time, i.e., month, day, hour, etc.).<br />

2-16

234-544 - 89 - 2<br />

2-6. DETERMINING THE RADIATION DOSAGE - Continued<br />

NOTE<br />

In some instances, you will have to estimate your readings, as in<br />

the previous example where the shadow (hairline) fell between<br />

two markings. Since each marking equals 20 RADs, the values<br />

between the <strong>10</strong>0 RAD mark and the first mark following has a<br />

range from <strong>10</strong>1 to <strong>11</strong>9. Because the shadow falls approximately in<br />

the middle, the value is about <strong>11</strong>0 RADs.<br />

2-17

Example readings for each model:<br />

2-18

. IM-147/PD<br />

INITIAL<br />

FINAL<br />

2-19

c. IM-9E/PD<br />

INITIAL<br />

FINAL<br />

2-20

2-7. ADMINISTRATIVE STORAGE<br />

a. Check <strong>TM</strong> 740-90-1 for general information about the requirements<br />

and procedures for administrative storage.<br />

b. Although this general information does apply to dosimeters, you must<br />

also follow some additional procedures for proper storage of dosimeters.<br />

Before storing, charge dosimeters to zero. After removing from storage,<br />

check to see that the dosimeters are fully charged at zero; if not, charge to<br />

zero.<br />

c. Before the dosimeter is placed into administrative storage (1 to 45<br />

days), it should be cleaned, charged, and packed in a paperboard carton.<br />

Place the packaged dosimeter in a sheltered area away from any known<br />

radiation source.<br />

2-8. PACKAGING-PACKING REQUIREMENTS<br />

Inspect the dosimeter for damage that may have occurred during shipment.<br />

Change 1 2-21

Section IV. OPERATION UNDER UNUSUAL CONDITIONS<br />

2-9. NUCLEAR, BIOLOGICAL, AND CHEMICAL (NBC) DECONTAMINATION<br />

PROCEDURES<br />

See paragraph 3-4c for decontamination instructions.<br />

2-22

CHAPTER 3<br />

MAINTENANCE INSTRUCTIONS<br />

Section I. TROUBLESHOOTING<br />

This manual does not list all possible malfunctions that may occur, or all<br />

tests or inspections, and corrective actions. If a malfunction is not listed,<br />

notify your supervisor.<br />

Malfunction, Test or Inspection, Corrective Action<br />

Leakage rate exceeds acceptable values (para 1-6b).<br />

Check electrical leakage rate, recharge, and clean.<br />

If the leakage rate exceeds the acceptable standards, clean the<br />

charging end of the dosimeter. Recheck the leakage rate. If the<br />

leakage is still higher than the values in paragraph 1-6b, the dosimeter is<br />

defective and should be turned in for a replacement. Perform leakage<br />

test according to steps in paragraph 3-2.<br />

Change 1 3-1

Section II. MAINTENANCE PROCEDURES<br />

3-1. INTRODUCTION<br />

Maintenance on your dosimeter consists of cleaning, decontaminating, testing,<br />

and troubleshooting. You will extend the useful life of your dosimeter<br />

by carefully following these procedures.<br />

3-2. LEAKAGE TEST<br />

Your dosimeter’s charge will gradually leak off, even though the dosimeter<br />

is not exposed to X- or gamma-rays. This leakage, if excessive, will cause an<br />

improper reading on the dosimeter.<br />

3-2<br />

NOTE<br />

If your dosimeter has not been charged for more than one month<br />

(or has been stored uncharged) or for an unknown length of time<br />

and is then fully charged, excessive leakage may occur due to<br />

INSULATION SOAK-IN (penetration of part of the charge into<br />

the insulation). Do not perform a leakage rate check on the dosimeter<br />

until it has been charged-to-zero each day for five consecutive<br />

days. Ignore the daily leakage.

3-2. LEAKAGE TEST - Continued<br />

The leakage rate should not exceed 2% of full-scale reading per day (see para<br />

1-6b for maximum acceptable leakage specs). Check the leakage rate as<br />

follows:<br />

a. Charge the dosimeter using Radiacmeter Charger PP-1578A/PD to read<br />

0 on the calibrated scale.<br />

b. Store the dosimeter in a radiation-free area for a 24-hour period.<br />

c. Note the reading on the calibrated scale of the dosimeter. This reading<br />

represents the leakage rate in either RADS/ROENTGENS or millirads/<br />

milliroentgens per day.<br />

NOTE<br />

If one day’s leakage rate is difficult to determine, the charged<br />

dosimeter may be allowed to sit for several days until a readable<br />

value is obtained. To determine the average daily leakage rate,<br />

divide this value by the number of days the charged dosimeter sat.<br />

Change 1 3-3

3-2. LEAKAGE TEST - Continued<br />

d. If the leakage rate exceeds the maximum acceptable rate (para l-6b),<br />

clean the charging end of the dosimeter.<br />

e. Recheck the leakage rate. If it is still greater than the values in paragraph 1-6b,<br />

the dosimeter is defective and must be turned in for a replacement.<br />

3-3. REPAIR<br />

There is no repair authorized at operator level. If your radiacmeter is defective,<br />

refer it to your unit commander for possible evacuation to higher level<br />

of maintenance.<br />

3-4. CLEANING AND DECONTAMINATING<br />

a. Materials required<br />

The following materials are required for maintenance of the dosimeter:<br />

(1) Denatured alcohol (NSN 68<strong>10</strong>-00-201-0906)<br />

or<br />

isopropyl alcohol (NSN 68<strong>10</strong>-00-753-4993).<br />

3-4 Change 1

3-4. CLEANING AND DECONTAMINATING - Continued<br />

WARNING<br />

SEVERE ILLNESS or DEATH may result if you fail to observe the<br />

following safety precautions. Both denatured and isopropyl<br />

alcohols are toxic, volatile, and flammable. Use only in well ventilated<br />

areas away from heat or open flame. Avoid ingestion, prolonged<br />

breathing of vapor, and contact with skin.<br />

(2) Detergent (commercial type).<br />

b. Cleaning<br />

CAUTION<br />

DO NOT insert sharp objects into the charging end of the<br />

dosimeter. This will damage the interior of the socket and the<br />

charging contact.<br />

3-5

3-4. CLEANING AND DECONTAMINATING - Continued<br />

To clean the socket in the charging end of the dosimeter, proceed as follows:<br />

● remove the protective cap from charging end.<br />

3-6<br />

● carefully wash<br />

the open end<br />

of the dosimeter<br />

with a<br />

few drops of<br />

alcohol.

3-4. CLEANING AND DECONTAMINATING - Continued<br />

● thoroughly dry the dosimeter by<br />

waving it in the air.<br />

CAUTION<br />

DO NOT blow on the dosimeter. DO NOT use a drying cloth.<br />

The charging end must be moisture- and lint-free.<br />

234-544 0 - 89 - 3<br />

3-7

3-4. CLEANING AND DECONTAMINATING - Continued<br />

● reinstall the protective cap on<br />

charging end.<br />

NOTE<br />

If the protective cap<br />

any similar material.<br />

is lost or defective, use cellophane tape or<br />

3-8

3-4. CLEANING AND DECONTAMINATING - Continued<br />

c. Decontaminating<br />

To decontaminate the dosimeter, proceed as follows:<br />

● prepare a solution of detergent<br />

and clean water.<br />

● wash the dosimeter<br />

in the solution.<br />

thoroughly in<br />

3-9

3-4. CLEANING AND DECONTAMINATING - Continued<br />

● rinse the dosimeter<br />

in clear water.<br />

3-<strong>10</strong>

3-4. CLEANING AND DECONTAMINATING - Continued<br />

● remove protective cap (1), wash both ends of dosimeter with alcohol<br />

(2), AIR DRY (3), then reinstall protective cap (4).<br />

3-<strong>11</strong>

3-5. TESTING<br />

Perform leakage testing (para 3-2) to ensure dosimeter is operational after<br />

cleaning or decontaminating.<br />

3-12

APPENDIX A<br />

REFERENCES<br />

The following is a list of all the references you will need as an operator of<br />

Radiacmeters IM-9E/PD, IM-93/UD, and IM-147/PD:<br />

Consolidated Index of Army Publications<br />

and Blank Forms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . DA Pam 25-30<br />

The Army Maintenance Management<br />

System (TAMMS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . DA Pam 738-750<br />

Chargers, Radiac Detector PP-1578/PD and<br />

PP-1578A/PD (NSN 6625-00-542-<strong>11</strong>77) . . . . . . . . . . . . . . TB SIG 226-8<br />

Field Expedient for charging Radiacmeters<br />

IM-93/UD and IM-147/PD . . . . . . . . . . . . . . . . . . . . . . . . . . . TB SIG 226-9<br />

Change 1 A-1/(A-2 blank)

APPENDIX B<br />

EXPENDABLE/DURABLE SUPPLIES AND MATERIALS LIST<br />

Section I. INTRODUCTION<br />

B-1. Scope<br />

This appendix lists expendable supplies and materials you will need to operate<br />

and maintain Radiacmeters IM-9E/PD, IM93/UD and lM-147/PD. These items are<br />

authorized to you by CTA 50-970, Expendable Items (Except Medical, Class V,<br />

Repair Parts, and Heraldic Items).<br />

B-2. Explanation of Columns<br />

a. Column 1 — Item Number. This number is assigned to the entry in the<br />

Change 1 B-1

listing and is referenced in the narrative instructions to identify the material (e.g.,<br />

“Use cleaning compound, item 5, App. D").<br />

b. Column 2 — Level. This column identifies the lowest level of maintenance<br />

that requires the listed item.<br />

C - Operator/Crew<br />

O - Organizational Maintenance<br />

F - Direct Support Maintenance<br />

H - General Support Maintenance<br />

c. Column 3 — National Stock Number. This is the National stock number<br />

assigned to the item; use it to request or requisition the item.<br />

d. Column 4 — Description. Indicates the Federal item name and, if required, a<br />

description to identify the item. The last line for each item indicates the part<br />

number followed by the Federal Supply Code for Manufacturer (FSCM) in parentheses,<br />

if applicable.<br />

B-2

e. Column 5 — Unit of Measure (U/M). Indicates the measure used in performing<br />

the actual maintenance function. This measure is expressed by a twocharacter<br />

alphabetical abbreviation (e.g., ea, in, pr). If the unit of measure differs<br />

from the unit of issue, requisition the lowest unit of issue that will satisfy your<br />

requirements.<br />

B-3

SECTION II<br />

EXPENDABLE/DURABLE SUPPLIES AND MATERIALS LIST<br />

This appendix lists expendable supplies and materials you will need to<br />

operate and maintain your dosimeter.<br />

Item Maintenance<br />

Number Level<br />

1 C<br />

2 C<br />

3 C<br />

NSN Description U/M<br />

68<strong>10</strong>-00-201-0906 Alcohol, denatured QT<br />

68<strong>10</strong>-00-753-4993 Alcohol, isopropyl QT<br />

— Detergent, commercial —<br />

B-4 Change 1

By Order of the Secretary of the Army:<br />

Official:<br />

CARL E. VUONO<br />

General, United States Army<br />

Chief of Staff<br />

R.L. DILWORTH<br />

Brigadier General, United States Army<br />

The Adjutant General<br />

DISTRIBUTION •<br />

To be distributed in accordance with DA Form<br />

12-36 literature requirements for IM-147/PD.<br />

U.S. GOVERNMENT PRINTING OFFICE : 1989 - 234-544

THE METRIC SYSTEM AND EQUIVALENTS

PIN: 019508-001