Corporate responsibility report 2005 - Tata Steel

Corporate responsibility report 2005 - Tata Steel

Corporate responsibility report 2005 - Tata Steel

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

How do we protect the environment?<br />

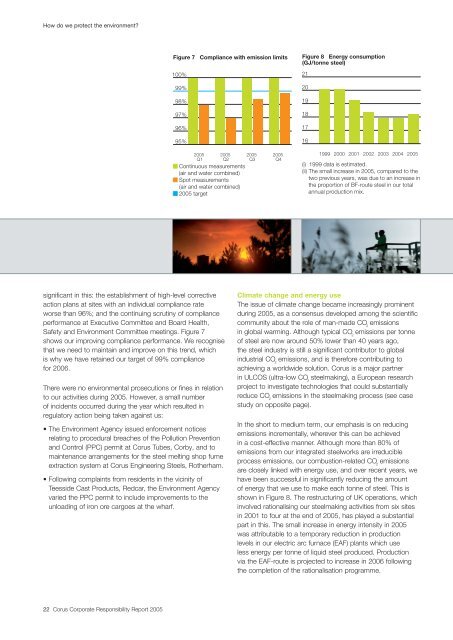

Figure 7 Compliance with emission limits<br />

100%<br />

99%<br />

98%<br />

97%<br />

96%<br />

95%<br />

Figure 8 Energy consumption<br />

(GJ/tonne steel)<br />

21<br />

20<br />

19<br />

18<br />

17<br />

16<br />

<strong>2005</strong><br />

Q1<br />

<strong>2005</strong><br />

Q2<br />

■ Continuous measurements<br />

(air and water combined)<br />

■ Spot measurements<br />

(air and water combined)<br />

■ <strong>2005</strong> target<br />

<strong>2005</strong><br />

Q3<br />

<strong>2005</strong><br />

Q4<br />

1999<br />

2000<br />

2001 2002 2003 2004 <strong>2005</strong><br />

(i) 1999 data is estimated.<br />

(ii) The small increase in <strong>2005</strong>, compared to the<br />

two previous years, was due to an increase in<br />

the proportion of BF-route steel in our total<br />

annual production mix.<br />

significant in this: the establishment of high-level corrective<br />

action plans at sites with an individual compliance rate<br />

worse than 96%; and the continuing scrutiny of compliance<br />

performance at Executive Committee and Board Health,<br />

Safety and Environment Committee meetings. Figure 7<br />

shows our improving compliance performance. We recognise<br />

that we need to maintain and improve on this trend, which<br />

is why we have retained our target of 99% compliance<br />

for 2006.<br />

There were no environmental prosecutions or fines in relation<br />

to our activities during <strong>2005</strong>. However, a small number<br />

of incidents occurred during the year which resulted in<br />

regulatory action being taken against us:<br />

• The Environment Agency issued enforcement notices<br />

relating to procedural breaches of the Pollution Prevention<br />

and Control (PPC) permit at Corus Tubes, Corby, and to<br />

maintenance arrangements for the steel melting shop fume<br />

extraction system at Corus Engineering <strong>Steel</strong>s, Rotherham.<br />

• Following complaints from residents in the vicinity of<br />

Teesside Cast Products, Redcar, the Environment Agency<br />

varied the PPC permit to include improvements to the<br />

unloading of iron ore cargoes at the wharf.<br />

Climate change and energy use<br />

The issue of climate change became increasingly prominent<br />

during <strong>2005</strong>, as a consensus developed among the scientific<br />

community about the role of man-made CO 2<br />

emissions<br />

in global warming. Although typical CO 2<br />

emissions per tonne<br />

of steel are now around 50% lower than 40 years ago,<br />

the steel industry is still a significant contributor to global<br />

industrial CO 2<br />

emissions, and is therefore contributing to<br />

achieving a worldwide solution. Corus is a major partner<br />

in ULCOS (ultra-low CO 2<br />

steelmaking), a European research<br />

project to investigate technologies that could substantially<br />

reduce CO 2<br />

emissions in the steelmaking process (see case<br />

study on opposite page).<br />

In the short to medium term, our emphasis is on reducing<br />

emissions incrementally, wherever this can be achieved<br />

in a cost-effective manner. Although more than 80% of<br />

emissions from our integrated steelworks are irreducible<br />

process emissions, our combustion-related CO 2<br />

emissions<br />

are closely linked with energy use, and over recent years, we<br />

have been successful in significantly reducing the amount<br />

of energy that we use to make each tonne of steel. This is<br />

shown in Figure 8. The restructuring of UK operations, which<br />

involved rationalising our steelmaking activities from six sites<br />

in 2001 to four at the end of <strong>2005</strong>, has played a substantial<br />

part in this. The small increase in energy intensity in <strong>2005</strong><br />

was attributable to a temporary reduction in production<br />

levels in our electric arc furnace (EAF) plants which use<br />

less energy per tonne of liquid steel produced. Production<br />

via the EAF-route is projected to increase in 2006 following<br />

the completion of the rationalisation programme.<br />

22 Corus <strong>Corporate</strong> Responsibility Report <strong>2005</strong>