Supercast Joco 1205 - EPMS Supplies

Supercast Joco 1205 - EPMS Supplies

Supercast Joco 1205 - EPMS Supplies

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

constructive solutions<br />

<br />

<br />

<br />

<br />

<br />

<strong>Supercast</strong> <strong>Joco</strong> 10 injection system has been specially<br />

developed to provide increased water tight integrity for<br />

construction joints in water excluding and retaining<br />

structures, i.e. basements and water tanks.<br />

<br />

Re-injectable making it a very economic system<br />

Remains active while concreting<br />

No drilling or damage to the concrete required for<br />

injection process<br />

Installation is quick and straightforward<br />

Can be installed in wet conditions<br />

<br />

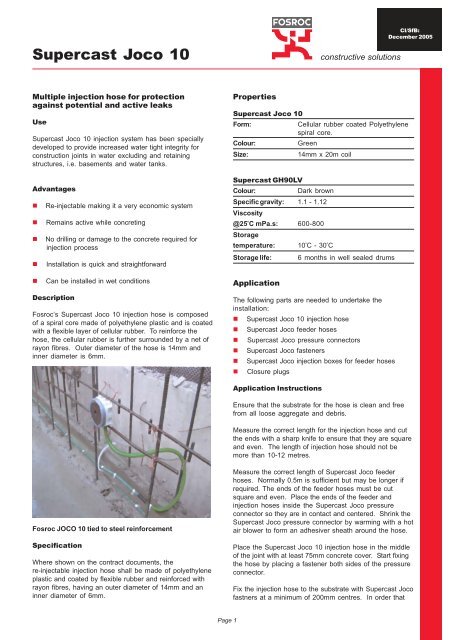

Fosroc’s <strong>Supercast</strong> <strong>Joco</strong> 10 injection hose is composed<br />

of a spiral core made of polyethylene plastic and is coated<br />

with a flexible layer of cellular rubber. To reinforce the<br />

hose, the cellular rubber is further surrounded by a net of<br />

rayon fibres. Outer diameter of the hose is 14mm and<br />

inner diameter is 6mm.<br />

<br />

<br />

Form:<br />

Cellular rubber coated Polyethylene<br />

spiral core.<br />

Colour:<br />

Size:<br />

<br />

Colour:<br />

Green<br />

14mm x 20m coil<br />

Dark brown<br />

Specific gravity: 1.1 - 1.12<br />

Viscosity<br />

@25 o C mPa.s: 600-800<br />

Storage<br />

temperature: 10 o C - 30 o C<br />

Storage life:<br />

<br />

6 months in well sealed drums<br />

The following parts are needed to undertake the<br />

installation:<br />

<strong>Supercast</strong> <strong>Joco</strong> 10 injection hose<br />

<strong>Supercast</strong> <strong>Joco</strong> feeder hoses<br />

<strong>Supercast</strong> <strong>Joco</strong> pressure connectors<br />

<strong>Supercast</strong> <strong>Joco</strong> fasteners<br />

<strong>Supercast</strong> <strong>Joco</strong> injection boxes for feeder hoses<br />

Closure plugs<br />

<br />

Ensure that the substrate for the hose is clean and free<br />

from all loose aggregate and debris.<br />

Measure the correct length for the injection hose and cut<br />

the ends with a sharp knife to ensure that they are square<br />

and even. The length of injection hose should not be<br />

more than 10-12 metres.<br />

Fosroc JOCO 10 tied to steel reinforcement<br />

<br />

Where shown on the contract documents, the<br />

re-injectable injection hose shall be made of polyethylene<br />

plastic and coated by flexible rubber and reinforced with<br />

rayon fibres, having an outer diameter of 14mm and an<br />

inner diameter of 6mm.<br />

Measure the correct length of <strong>Supercast</strong> <strong>Joco</strong> feeder<br />

hoses. Normally 0.5m is sufficient but may be longer if<br />

required. The ends of the feeder hoses must be cut<br />

square and even. Place the ends of the feeder and<br />

injection hoses inside the <strong>Supercast</strong> <strong>Joco</strong> pressure<br />

connector so they are in contact and centered. Shrink the<br />

<strong>Supercast</strong> <strong>Joco</strong> pressure connector by warming with a hot<br />

air blower to form an adhesiver sheath around the hose.<br />

Place the <strong>Supercast</strong> <strong>Joco</strong> 10 injection hose in the middle<br />

of the joint with at least 75mm concrete cover. Start fixing<br />

the hose by placing a fastener both sides of the pressure<br />

connector.<br />

Fix the injection hose to the substrate with <strong>Supercast</strong> <strong>Joco</strong><br />

fastners at a minimum of 200mm centres. In order that<br />

Page 1

the hose functions correctly, it is essential that it does not<br />

float in the fresh concrete during the casting. For fixing the<br />

<strong>Supercast</strong> <strong>Joco</strong> fastners use a nail gun with steel nails or<br />

other suitable materials.<br />

<br />

There are no known health hazards associated with<br />

<strong>Supercast</strong> <strong>Joco</strong> 10.<br />

At the connections, overlap injection hoses by 50mm.<br />

Injection hoses must not be one upon another or in any<br />

contact with each other to prevent cross flow during<br />

injection.<br />

Place the <strong>Supercast</strong> <strong>Joco</strong> feeder hoses into the <strong>Supercast</strong><br />

<strong>Joco</strong> injection box which should be secured to the steel<br />

reinforcement in order to achieve a flush finish to the final<br />

wall face.<br />

Label the <strong>Supercast</strong> <strong>Joco</strong> feeder hoses with reference<br />

numbers and record these on the contract drawings.<br />

<br />

Multiple injection application<br />

Fosroc’s <strong>Supercast</strong> GH90LV is a single component<br />

Polyurethane resin system suitable for the sealing of<br />

cracks in concrete structures. The resin may be flushed<br />

out of the hose with water, allowing the injection process<br />

to be carried out several times.<br />

Pump the resin through the <strong>Supercast</strong> <strong>Joco</strong> 10<br />

hose until it appears at the other end, plug this end<br />

with a ‘closure plug’, then continue pumping unitl the<br />

crack is full of resin.<br />

After conclusion of resin injection, remove ‘closure<br />

plug’ and flush out hose by pumping water through it<br />

at a maximum pressure of 2bar.<br />

<br />

The <strong>Supercast</strong> <strong>Joco</strong> 10 hose is then ready for future<br />

injection, if required.<br />

<br />

The concrete must be fully cured, this is normally<br />

achieved at 28 days, prior to commencement of injection.<br />

<br />

Important note<br />

Fosroc products are guaranteed against defective materials and manufacture and are sold subject to its standard Conditions for the<br />

Supply of Goods and Services, copies of which may be obtained on request. Whilst Fosroc endeavours to ensure that any advice,<br />

recommendation, specification of information it may give is accurate and correct, it cannot, because it has no direct or continuous control<br />

over where or how its products are applied, accept any liability either directly or indirectly arising from the use of its products, whether or<br />

not in accordance with any advice, specification, recommendation of information given by it.<br />

Drayton Manor Business Park<br />

Coleshill Road, Tamworth,<br />

Staffordshire B78 3TL. UK<br />

<br />

telephone: fax: email:<br />

+44 0 (1827) 262222 +44 0 (1827) 262444 uk@fosroc.com<br />

Page 2<br />

Certificate number FM 610