83365 ClovaGrip Anti-Slip Epoxy - Cloverdale Paint

83365 ClovaGrip Anti-Slip Epoxy - Cloverdale Paint

83365 ClovaGrip Anti-Slip Epoxy - Cloverdale Paint

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

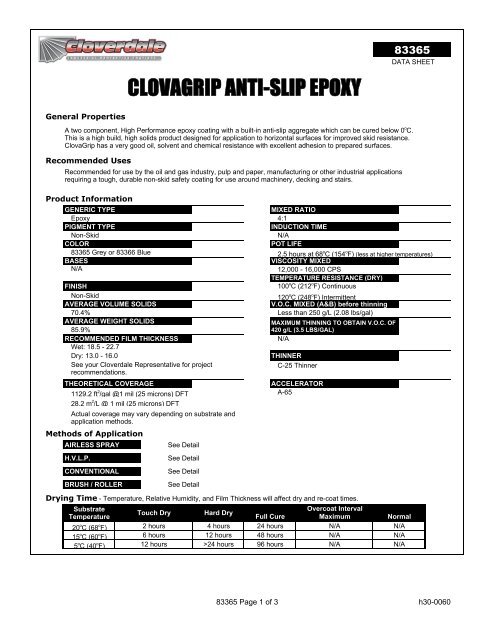

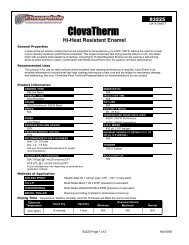

CLOVAGRIP ANTI-SLIP EPOXY<br />

<strong>83365</strong><br />

DATA SHEET<br />

General Properties<br />

A two component, High Performance epoxy coating with a built-in anti-slip aggregate which can be cured below 0 o C.<br />

This is a high build, high solids product designed for application to horizontal surfaces for improved skid resistance.<br />

<strong>ClovaGrip</strong> has a very good oil, solvent and chemical resistance with excellent adhesion to prepared surfaces.<br />

Recommended Uses<br />

Recommended for use by the oil and gas industry, pulp and paper, manufacturing or other industrial applications<br />

requiring a tough, durable non-skid safety coating for use around machinery, decking and stairs.<br />

Product Information<br />

GENERIC TYPE<br />

MIXED RATIO<br />

<strong>Epoxy</strong> 4:1<br />

PIGMENT TYPE<br />

INDUCTION TIME<br />

Non-Skid<br />

N/A<br />

COLOR<br />

POT LIFE<br />

<strong>83365</strong> Grey or 83366 Blue 2.5 hours at 68 o C (154 o F) (less at higher temperatures)<br />

BASES<br />

N/A<br />

VISCOSITY MIXED<br />

12,000 - 16,000 CPS<br />

TEMPERATURE RESISTANCE (DRY)<br />

FINISH<br />

100 o C (212 o F) Continuous<br />

Non-Skid<br />

120 o C (248 o F) Intermittent<br />

AVERAGE VOLUME SOLIDS<br />

V.O.C. MIXED (A&B) before thinning<br />

70.4% Less than 250 g/L (2.08 lbs/gal)<br />

AVERAGE WEIGHT SOLIDS<br />

85.9%<br />

RECOMMENDED FILM THICKNESS<br />

MAXIMUM THINNING TO OBTAIN V.O.C. OF<br />

420 g/L (3.5 LBS/GAL)<br />

N/A<br />

Wet: 18.5 - 22.7<br />

Dry: 13.0 - 16.0<br />

See your <strong>Cloverdale</strong> Representative for project<br />

recommendations.<br />

THINNER<br />

C-25 Thinner<br />

THEORETICAL COVERAGE<br />

ACCELERATOR<br />

1129.2 ft 2 /gal @1 mil (25 microns) DFT A-65<br />

28.2 m 2 /L @ 1 mil (25 microns) DFT<br />

Actual coverage may vary depending on substrate and<br />

application methods.<br />

Methods of Application<br />

AIRLESS SPRAY<br />

H.V.L.P.<br />

CONVENTIONAL<br />

BRUSH / ROLLER<br />

See Detail<br />

See Detail<br />

See Detail<br />

See Detail<br />

Drying Time - Temperature, Relative Humidity, and Film Thickness will affect dry and re-coat times.<br />

Substrate<br />

Temperature<br />

Touch Dry<br />

Hard Dry<br />

20 o C (68 o F) 2 hours 4 hours<br />

15 o C (60 o F)<br />

6 hours 12 hours<br />

5 o C (40 o F)<br />

12 hours<br />

>24 hours<br />

Overcoat Interval<br />

Full Cure<br />

Maximum<br />

24 hours N/A<br />

48 hours<br />

N/A<br />

96 hours N/A<br />

Normal<br />

N/A<br />

N/A<br />

N/A<br />

<strong>83365</strong> Page 1 of 3 h30-0060

Surface Preparation:<br />

<strong>83365</strong><br />

Surface must be clean, dry, and free of contamination such as oils, grease, wax, loose rust or mill scale.<br />

An SSPC SP-6 Commercial Sandblast is recommended as a preparation for bare steel whether applying<br />

directly or using 83021 ClovaPrime 21 as a primer. Porous surfaces such as concrete and wood should be<br />

primed using 83021 ClovaPrime 21. New concrete should be wet cured for at least three days and allowed<br />

to dry with good ventilation for an additional 30 days.<br />

Methods of Application:<br />

<strong>ClovaGrip</strong> performs best when applied over a primer. Pre-mix base component with a mechanical mixer<br />

such as a pneumatic drill motor with a jiffy mixing blade. Make sure that all aggregate is lifted off bottom of<br />

the container and is uniformly dispersed. Pour the entire contents of the 83360(B) Activator into base<br />

material. Mix hardener for approximately 3 to 5 minutes until material assumes a uniform color and<br />

appearance. Working pot life is 2.5 hours at 70 o C. Pot life is extended at lower temperatures and<br />

decreases at higher temperatures. A-65 accelerator can be used in this product to speed up curing,<br />

however the pot life will be shorter.<br />

Spray:<br />

Spray application will result in a uniform appearance with good non-slip characteristics. A specialized<br />

mastic type spray equipment is required. A 5-gallon bottom outlet pressure tank equipped with a double<br />

regulator and air driven agitator, and 1" I.D. outlet pipe. A 25 feet of 3/8" female connectors at each end. A<br />

25 feet of 3/4" material hose with 3/4" female connectors at each end. A Binks Model 7E2 spray gun<br />

equipped with 1/4" (#45) fluid nozzle and a 1/4" internal air cap or a Binks Model 52-2012 (4 foot) pole gun<br />

equipped with the same fluid nozzle and air nozzle.<br />

Minimum air supply required is 20 CFM at 90 lbs. pressure. Recommended pressure is 15-20 psi on<br />

material and 20-25 psi on atomization. Always keep atomization air pressure higher than pot pressure.<br />

Keep agitator running slowly. Good coverage and film thickness will be obtained working at 18" or 24"<br />

distance from surface. Overlap strokes about 50%. Make sure of wet application. Very little abrasive<br />

rebound will be noticed at 15 psi; however, it will be more noticeable at higher pressures. When<br />

temperature is above 80oF, it is advisable to flush the spray equipment's with C-25 every hour or so in<br />

order to prevent the possibility of any material setting up and plugging the equipment.<br />

Trowel:<br />

Roller:<br />

Trowelled applications provide excellent non-slip characteristics with a rough, textured surface. Use a<br />

flexible blade plasterer's finishing trowel approximately 4 inches by 12 inches. Use smooth edges, not<br />

notched. Pour a "ribbon" on the surface approximately 2' long and 6" wide. Hold trowel at 45 degree angle<br />

to surface to spread with sweeping motion. Reverse angle of trowel for opposite stroke. pull material<br />

toward you. To cover corners, etc., pull straight strokes using material on the trowel. Trowel across welds<br />

to avoid an excessively thick application.<br />

Rolled applications provide the most aggressive non-slip characteristics with an irregular, ridged profile.<br />

Use a phenolic roller. It is important that the rolled profile expose the maximum amount of non-slip<br />

aggregate. If aggregate is not properly exposed, the coating may become slippery when wet. Pour a<br />

"ribbon" on the surface approximately 2' long and 6" wide. Roll material in one direction only, in slow<br />

straight strokes pulling material toward you with a moderate amount of pressure. Do not over-roll too many<br />

times or press down too heavily. Be careful that material does not build up too thickly along welds (roll<br />

across welds, not along them). Material applied too thickly may not properly cure. Higher temperatures<br />

will shorten drying time and conversely, lower temperature and high relative humidity will lengthen drying<br />

time. Exterior applications must be protected from rain for at least 12 to 24 hours after application<br />

according to the humidity. Protect from heavy or extended exposure to water, oil, and chemicals for 5 to 7<br />

days during final cure.<br />

<strong>83365</strong> Page 2 of 3 h30-0060

Recommended Primer<br />

STEEL Self prime or use 83021 ClovaPrime 21<br />

<strong>83365</strong><br />

CONCRETE<br />

GALVANIZED<br />

ALUMINUM<br />

Self prime or use 83021 ClovaPrime 21<br />

N/A<br />

N/A<br />

Typical Resistance (Non-Immersion)<br />

WEATHER<br />

Excellent<br />

SALT WATER<br />

Excellent<br />

ACIDS<br />

Good<br />

MOISTURE<br />

Excellent<br />

FRESH WATER<br />

Excellent<br />

ALKALIS<br />

Excellent<br />

SOLVENTS<br />

Good ABRASION Excellent OIL<br />

Good<br />

Limitations<br />

Not recommended for immersion service. Darker colors will chalk and lose considerable gloss on exposure<br />

to sunlight. This will not affect product performance. Discoloration is expected with higher temperature<br />

exposure. For best results apply when substrate temperature is above 10 o C (50 o F), and at a minimum of<br />

3 o C (5 o F) above the dew point. Do not apply when the relative humidity is above 85%.<br />

Mixing Instructions<br />

Pre-mix base component with a mechanical mixer such as a pneumatic drill motor with a jiffy mixing blade.<br />

Make sure that all aggregate is lifted off bottom of the container and is uniformly dispersed. Pour the entire<br />

contents of 83360(B) Activator into base material. Mix hardener for approximately 3 to 5 minutes until<br />

material assumes a uniform color and appearance.<br />

Safety Precautions<br />

This product is for industrial use only. Refer to Material Safety Data Sheet for proper health and safety information.<br />

Storage and Handling<br />

FLASH POINT<br />

PRODUCT WEIGHT<br />

STORAGE<br />

PACKAGE SIZE<br />

-7 o C (19 o F) TCC<br />

18.17 lbs/gal (container extra)<br />

Cool, dry, secure location. See your <strong>Cloverdale</strong> <strong>Paint</strong> Representative.<br />

1 gallon and 5 gallon kits.<br />

Some package sizes or colors may be by special order only. Please check with your <strong>Cloverdale</strong> Representative when ordering.<br />

Warranty Disclaimer<br />

<strong>Cloverdale</strong> <strong>Paint</strong> manufactures quality products. In the event that this product is defective or in any way unsuitable for the application for which it is sold, <strong>Cloverdale</strong> <strong>Paint</strong> Inc.<br />

will replace the product free of charge. The warranty provided by this data sheet is the only warranty or guarantee of quality made in respect of this product by <strong>Cloverdale</strong><br />

<strong>Paint</strong> Inc. By purchasing this product the customer accepts this warranty in lieu of all others, and waives all claims to any other remedy arising from any warranty or guarantee<br />

of quality, whether such warranty or guarantee of quality was made expressly to the customer or implied by any applicable law.<br />

<strong>Cloverdale</strong> <strong>Paint</strong> Inc<br />

6950 King George Boulevard, Surrey, British Columbia, Canada V3W 4Z1<br />

Web Site: www.cloverdalepaint.com Email: helpdesk@cloverdalepaint.com<br />

Phone: 604 596 6261 Fax: 604 597 2677<br />

h30-0060v3<br />

27-Jan-11<br />

<strong>83365</strong> Page 3 of 3 h30-0060