BALAJI TECHNOLOGIES - always yours

BALAJI TECHNOLOGIES - always yours

BALAJI TECHNOLOGIES - always yours

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Issue #: [Date]<br />

Dolor Sit Amet<br />

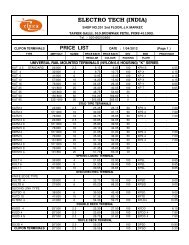

PYROLYSIS PRODUCT DETAILS OF A<br />

12-TON PLANT<br />

Carbon black is left in the reactor at the end of the process tha t is collected and zipped<br />

into the bags automatically with the help of a small machine. This forms<br />

30% to 35% percent of the total output. The collection of carbon black<br />

does not require more tha n one man supervising the collection and<br />

zipping process. Carbon from the reactor is removed in a n efficient<br />

manner to the extent that there is no carbon pollution on the site.<br />

Steel wire that is also left in the reactor at the end is magnetically removed. Wire forms 10-<br />

15% of the tota l output. However, we ca n a rra nge a wire-snatching machine that is used to<br />

pull the wire out from the tires right before the tires are fed into the<br />

reactor. Most clients opt for the wire-snatching machine because if the<br />

wire is removed from the tires before the pyrolysis, it is sold at a very high<br />

price in the market as compared to the price at which it is sold a fter the<br />

pyrolysis. It is easily sellable in the loca l ma rket.<br />

OTHER GASES<br />

Apart from the primary a nd secondary products obta ined from the pyrolysis of tires about<br />

8% of other ga ses are a lso produced those are non – condensable. If you choose to set-up<br />

more than one pyrolysis plants then we set them up in a ma nner where these gases are<br />

directed into the second reactor for another thermo-chemical rea ction to take place without<br />

any external heating required. This saves on costs involved with heating the rea ctor.