reduction of boiler stack particulate emissions and scrubber water ...

reduction of boiler stack particulate emissions and scrubber water ...

reduction of boiler stack particulate emissions and scrubber water ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

INTRODUCTION<br />

Voluntary compliance tests for <strong>particulate</strong> <strong>emissions</strong> were performed in October <strong>of</strong> 1995 at the<br />

Western Sugar Company's Fort Morgan sugar beet processing plant.<br />

The <strong>boiler</strong>house contains two Babcock & Wilcox stoker-fired <strong>boiler</strong>s. The units were placed in<br />

service in 1947 <strong>and</strong>, except for a short time using natural gas, have used Detroit Stoker stokers as<br />

the coal-firing system. Each <strong>boiler</strong> has an American St<strong>and</strong>ard Series 361 fly-ash collector <strong>and</strong> an<br />

in-house (Great Western Sugar Company) designed low-pressure venturi <strong>scrubber</strong>. Exhaust gas<br />

streams from each <strong>boiler</strong> are combined in a common <strong>stack</strong> which has a chevron-type mist<br />

eliminator.<br />

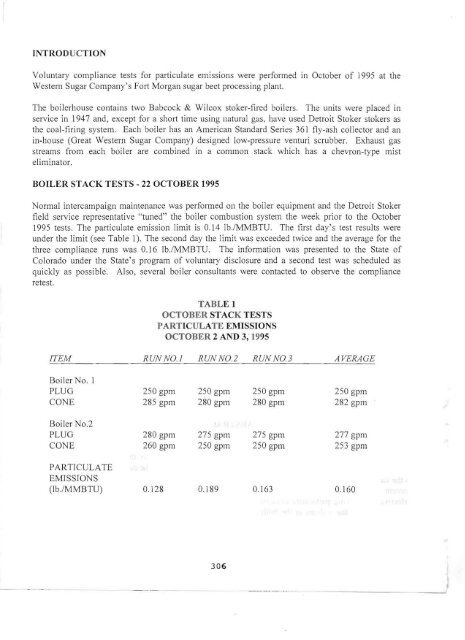

BOILER STACK TESTS - 22 OCTOBER 1995<br />

Normal intercampaign maintenance was performed on the <strong>boiler</strong> equipment <strong>and</strong> the Detroit Stoker<br />

field service representative "tuned" the <strong>boiler</strong> combustion system the week prior to the October<br />

1995 tests. The <strong>particulate</strong> emission limit is 0.14 Ib.lMMBTU. The first day's test results were<br />

under the limit (see Table 1). The second day the limit was exceeded twice <strong>and</strong> the average for the<br />

three compliance runs was 0.16 Ib.lMMBTU. The information was presented to the State <strong>of</strong><br />

Colorado under the State's program <strong>of</strong> voluntary disclosure <strong>and</strong> a second test was scheduled as<br />

quickly as possible. Also, several <strong>boiler</strong> consultants were contacted to observe the compliance<br />

retest.<br />

TABLE 1 <br />

OCTOBER STACK TESTS <br />

PARTICULATE EMISSIONS <br />

OCTOBER 2 AND 3; 1995 <br />

ITEM RUNNO.1 RUNNO.2 RUN NO.3 AVERAGE<br />

Boiler No.1<br />

PLUG<br />

CONE<br />

250 gpm<br />

285 gpm<br />

250 gpm<br />

280 gpm<br />

250 gpm<br />

280 gpm<br />

250 gpm<br />

282 gpm<br />

Boiler No.2<br />

PLUG<br />

CONE<br />

280 gpm<br />

260 gpm<br />

275 gpm<br />

250 gpm<br />

275 gpm<br />

250 gpm<br />

277 gpm<br />

253 gpm<br />

PARTICULATE<br />

EMISSIONS<br />

(lb.lMMBTU)<br />

0.128<br />

0.189<br />

0.163<br />

0.160<br />

306 <br />

- - .... - -