Prelimer suspended solids can be separated. - ASSBT Proceedings

Prelimer suspended solids can be separated. - ASSBT Proceedings

Prelimer suspended solids can be separated. - ASSBT Proceedings

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Note that with the high speed pump the filtrate recovered is nearly doubled when<br />

filtration is ahead of the pump. 1t will also <strong>be</strong> seen that four times as much susp nded<br />

<strong>solids</strong> were removed. This is surely strong evidence of degradation of the fragile floc<br />

particles by the shear ofthe high speed centrifugal ptunp. With the variable spe d pump<br />

signifi<strong>can</strong>t improvement is shown. Still, the filtrate volume is 28% greater <strong>be</strong>fore the<br />

pump, and the <strong>solids</strong> removal is 50 percent greater. The evidence indicates that the<br />

gentlest possible handling ofthe effluent is imperative.<br />

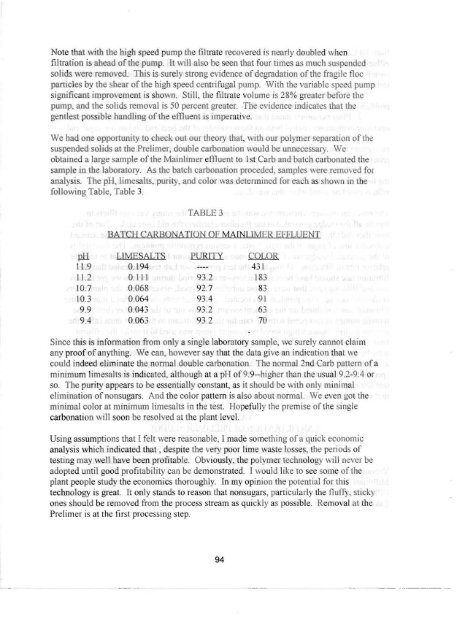

We had one opportunity to check out our theory that, with OUT polymer separation of the<br />

<strong>suspended</strong> <strong>solids</strong> at the <strong>Prelimer</strong>, double carbonation would <strong>be</strong> unnecessary. We<br />

obtained a large sample ofthe Mainlimer effi uent to 1 st Carb and batch carbonated tl e<br />

sample in the laboratory. As the batch carbonation pro ceded, samples wer removed for<br />

analysis. The pH, Iimesalts. purity. and color was detenn ined for each as shown in the<br />

following Table, Table 3.<br />

TABLE 3<br />

BATCH CARBONATION OF MAfNLIMER EFFLUENT<br />

pH UMESALTS PURITY COLQR<br />

11.9 0. 194 43 L<br />

11 .2 0. 11 ] 93.2 183<br />

10.7 0. 068 92.7 83<br />

10.3 0.064 93.4 91<br />

9.9 0.043 93.2 63<br />

9.4 0.063 93.2 70<br />

Since this is infonnation from only a single laboratory sample, we surely <strong>can</strong>not claim<br />

any proof of anything. We <strong>can</strong>, however say that the data give an indication that we<br />

could indeed eliminate the normal double carbonation. The nonnal 2nd Carb pattern of a<br />

minimum limesalts is indicated, although at a pH of 9.9--higher than the usual 9.2-9.4 or<br />

so. The purity a-ppears to <strong>be</strong> essentially constant, as it should <strong>be</strong> with onJy minimal<br />

elimination ofnonsugars. And the color pattern is also about normal. We e en got the<br />

minimal color at minimum limesalts in the test. Hopefully the premise ofthe single<br />

carbonation will soon <strong>be</strong> resolved at the plant level.<br />

Using assumptions that I felt were reasonable, I made something ofa quick economic<br />

analysis which indicated that, despite the very poor lime waste losses, the periods of<br />

testing may well have <strong>be</strong>en profitable. Obviously, the polymer technology will never <strong>be</strong><br />

adopted until good profitability <strong>can</strong> <strong>be</strong> demonstrated. 1 would li ke to see some of the<br />

plant people study the economjcs thoroughly. In my opinion tie potential for this<br />

technology is great. It only stands to reason that nonsugars, particularly the fluffy, stick),<br />

ones should <strong>be</strong> removed from the process stream as quickly as possible. Removal at the<br />

<strong>Prelimer</strong> is at the first processing step.<br />

94