A glowing future.pdf - British Stainless Steel Association

A glowing future.pdf - British Stainless Steel Association

A glowing future.pdf - British Stainless Steel Association

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Stainless</strong> <strong>Steel</strong>: A <strong>glowing</strong> <strong>future</strong> in<br />

Construction by Paul Snelgrove<br />

the Puerta de Europa twin towers in Madrid, among<br />

others. The choice of stainless steel is due to its natural<br />

corrosion-resistant properties, ease of fabrication,<br />

resistance to surface damage, and to the variety of<br />

available surface finishes. The Eurostar Terminal at<br />

Waterloo, London, in the UK, uses stainless steel for<br />

roofing panels, gutters and supports, to meet long-life<br />

design criteria of 125 years with a first maintenance<br />

requirement of 25 years. <strong>Stainless</strong> steel surfaces are<br />

generally easy to keep clean, although they do require<br />

some attention to maintain their original beauty. On<br />

buildings, depending on the grade of steel and where<br />

it is used, cleaning need only take place, on average,<br />

once every six to twelve months.<br />

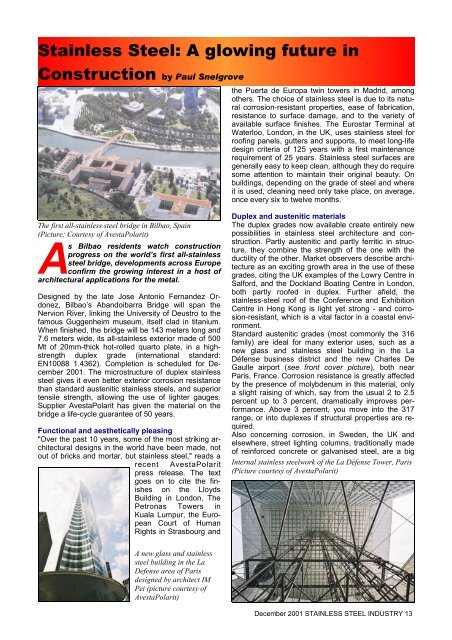

The first all-stainless steel bridge in Bilbao, Spain<br />

(Picture: Courtesy of AvestaPolarit)<br />

A<br />

s Bilbao residents watch construction<br />

progress on the world’s first all-stainless<br />

steel bridge, developments across Europe<br />

confirm the growing interest in a host of<br />

architectural applications for the metal.<br />

Designed by the late Jose Antonio Fernandez Ordonez,<br />

Bilbao’s Abandoibarra Bridge will span the<br />

Nervion River, linking the University of Deustro to the<br />

famous Guggenheim museum, itself clad in titanium.<br />

When finished, the bridge will be 143 meters long and<br />

7.6 meters wide, its all-stainless exterior made of 500<br />

Mt of 20mm-thick hot-rolled quarto plate, in a highstrength<br />

duplex grade (international standard:<br />

EN10088 1.4362). Completion is scheduled for December<br />

2001. The microstructure of duplex stainless<br />

steel gives it even better exterior corrosion resistance<br />

than standard austenitic stainless steels, and superior<br />

tensile strength, allowing the use of lighter gauges.<br />

Supplier AvestaPolarit has given the material on the<br />

bridge a life-cycle guarantee of 50 years.<br />

Functional and aesthetically pleasing<br />

"Over the past 10 years, some of the most striking architectural<br />

designs in the world have been made, not<br />

out of bricks and mortar, but stainless steel," reads a<br />

recent AvestaPolarit<br />

press release. The text<br />

goes on to cite the finishes<br />

on the Lloyds<br />

Building in London, The<br />

Petronas Towers in<br />

Kuala Lumpur, the European<br />

Court of Human<br />

Rights in Strasbourg and<br />

Duplex and austenitic materials<br />

The duplex grades now available create entirely new<br />

possibilities in stainless steel architecture and construction.<br />

Partly austenitic and partly ferritic in structure,<br />

they combine the strength of the one with the<br />

ductility of the other. Market observers describe architecture<br />

as an exciting growth area in the use of these<br />

grades, citing the UK examples of the Lowry Centre in<br />

Salford, and the Dockland Boating Centre in London,<br />

both partly roofed in duplex. Further afield, the<br />

stainless-steel roof of the Conference and Exhibition<br />

Centre in Hong Kong is light yet strong - and corrosion-resistant,<br />

which is a vital factor in a coastal environment.<br />

Standard austenitic grades (most commonly the 316<br />

family) are ideal for many exterior uses, such as a<br />

new glass and stainless steel building in the La<br />

Défense business district and the new Charles De<br />

Gaulle airport (see front cover picture), both near<br />

Paris, France. Corrosion resistance is greatly affected<br />

by the presence of molybdenum in this material, only<br />

a slight raising of which, say from the usual 2 to 2.5<br />

percent up to 3 percent, dramatically improves performance.<br />

Above 3 percent, you move into the 317<br />

range, or into duplexes if structural properties are required.<br />

Also concerning corrosion, in Sweden, the UK and<br />

elsewhere, street lighting columns, traditionally made<br />

of reinforced concrete or galvanised steel, are a big<br />

Internal stainless steelwork of the La Défense Tower, Paris<br />

(Picture courtesy of AvestaPolarit)<br />

A new glass and stainless<br />

steel building in the La<br />

Defense area of Paris<br />

designed by architect IM<br />

Pei (picture courtesy of<br />

AvestaPolarit)<br />

December 2001 STAINLESS STEEL INDUSTRY 13

issue today for many city councils. Concrete can crack<br />

and drop off as the inner metal reinforcement rusts<br />

and expands, while steel columns corrode both below<br />

ground and above ground when water seeps inside<br />

posts and damages the galvanising. In the UK alone,<br />

it is estimated that about 3 million outdoor lampposts<br />

will need replacing in the next ten years. Many are urgent.<br />

The industry is promoting the proposition of<br />

stainless steel columns that should last 70 years at<br />

the very least.<br />

<strong>Stainless</strong> steel seeks acceptance as a structural<br />

material<br />

Explaining that the industry is working hard to increase<br />

the structural use of stainless steel, experts<br />

affirm that the physical forming of a stainless steel<br />

tube enhances the material's mechanical properties<br />

(work-hardening), making it actually stronger than carbon<br />

steel. The result requires no coating, painting or<br />

maintenance, so stainless steel can be doubly advantageous<br />

as a strong, lightweight structural member.<br />

Already widely used in door- and window-frames, the<br />

metal can be folded and shaped into elaborate sections,<br />

and ground or brushed for an attractive finish. In<br />

The exterior at North Greenwhich Station (picture courtesy<br />

of EuroInox)<br />

addition, the advantages of stainless steel in terms of<br />

fire resistance are not yet fully exploited, and further<br />

research is needed to assess the material's true potential<br />

here.<br />

Extensive R&D, centred on the behaviour of stainless<br />

steel members and connections, has been carried out<br />

in Europe since 1991. The work culminated in the<br />

publication of the ENV for Eurocode 3 Design of <strong>Steel</strong><br />

Structures - Supplementary Rules for <strong>Stainless</strong> <strong>Steel</strong>s<br />

(EC3: Part 1.4). These rules were, however, adapted<br />

from carbon steel rules. Since the load-bearing capacity<br />

of stainless steel members differs from that of carbon<br />

steel members, further research was required to<br />

define a new design approach and maximise the costeffectiveness<br />

of stainless steel’s desirable properties<br />

in structural uses. A recently completed, partially ECfunded,<br />

three-year research project, involving major<br />

producers and other organisations from six European<br />

countries, is now being followed up by a valorisation<br />

project that updates the old design manual for<br />

stainless steel. The project will also ensure wide dissemination<br />

of the latest findings (partly through electronic<br />

media) among architects and structural engineers.<br />

Wall cladding at Souhwark<br />

station (picture courtesy of<br />

EuroInox)<br />

<strong>Stainless</strong> steel for architects<br />

"Handrails and parapets<br />

were rare 20 years ago,<br />

but have become almost<br />

standard nowadays," explains<br />

Thomas Pauly of<br />

Euro-Inox, the European<br />

stainless steel market<br />

development association.<br />

"Interior cladding is a big<br />

growth area as well, being<br />

easily maintained and<br />

attractive. The extension<br />

to London’s Jubilee Line<br />

subway, for example,<br />

uses it extensively," he<br />

adds. Architects tend to<br />

worry about fingerprint<br />

soiling, but very robust embossed<br />

and pattern-rolled finishes exist which are less<br />

sensitive to fingerprints. These are much used for elevators<br />

and escalators in stations, hotels and airports.<br />

"<strong>Stainless</strong> steel has both practical and decorative<br />

merits and elevators and escalators are amongst the<br />

biggest markets for flat products," says Mr. Pauly.<br />

<strong>Stainless</strong> steel facades in architecture go back to the<br />

1950s. The electricity substation at the Elephant and<br />

Castle traffic circle in London dates from that time<br />

and, despite pollution, is still in fine condition. “Now<br />

we can make stainless steel facades at the same cost<br />

as with other materials, so there is huge development<br />

potential,” Mr. Pauly points out. <strong>Stainless</strong> steel roofing<br />

has been around for 30 years, but is set to grow.<br />

There is an obvious trend towards metallic materials<br />

on buildings, especially for decorative purposes, and a<br />

swing back from the “disposable architecture” philosophy<br />

to greater construction quality and durability.<br />

“With stainless steel you don’t get corrosion, even under<br />

difficult circumstances, and whatever you combine<br />

it with it won’t corrode, so its durability is exceptional,”<br />

says Mr. Pauly. Ecologists like it, too, since stainless<br />

steel is neutral to the environment and does not result<br />

in noxious substances getting into the water table.<br />

Switzerland, Austria and parts of France and Germany<br />

have a long tradition of metallic roofing, and the<br />

architects in these Alpine areas readily use stainless<br />

steel. There are two approaches. One is the welded<br />

stainless steel roof, which is a 100-percent watertight<br />

solution, useable on a flat roof, and the other is the<br />

conventional standing seam roof, which can be built<br />

by any roofing contractor. “This is now a very large,<br />

potential market throughout Europe, which we are trying<br />

hard to promote,” underlines Mr. Pauly.<br />

<strong>Stainless</strong> steel in tunnel and road applications<br />

Tunnel linings are an interesting growth area. Alpine<br />

countries use it a lot, often in short tunnels, which can<br />

use up to 300 metric tons of stainless steel. An interesting<br />

projection could be made from this about the<br />

quantities of stainless steel involved in the new tunnel<br />

just agreed between France and Italy, which will be<br />

one of the longest in Europe. The most popular grade<br />

for tunnels would be 316, but there is potential for<br />

higher alloy grades, depending on the corrosion conditions.<br />

Road tunnels have the problem of exhaust<br />

gases and de-icing salt, so high chromium and nickel<br />

14 STAINLESS STEEL INDUSTRY December 2001

grades, maybe with up to 25 percent chromium, are<br />

needed.<br />

Another important growth area is in reinforcement<br />

bars for concrete structures, like bridges and lighting<br />

columns. Everywhere you see the need for expensive<br />

refurbishment work on structures often only 30 years<br />

old. Carbon steel in concrete tends to corrode, especially<br />

if the concrete coverage is under 5 cm. Exhaust<br />

gases and de-icing salt get in. In the U.S., highway<br />

authorities automatically specify stainless steel for<br />

certain applications in bridges and tunnels. Their highways<br />

are privatised, so they look at a 40-year or more<br />

lifetime horizon. The extra cost of stainless steel bars<br />

is vastly outweighed by lower maintenance costs over<br />

the complete lifetime. "Gradually, life-cycle costing<br />

awareness is gaining ground in Europe, and that, plus<br />

a growing ecological orientation, is making people<br />

more conscious of long-term benefits," Mr. Pauly<br />

says. "Reinforcement bars are standard products and<br />

have huge potential in these applications," he adds.<br />

Where there’s fire or water, there's stainless steel<br />

Repair and relining of chimneys is also a fairly big<br />

market, especially in countries and at times when a<br />

major move from solid fuel to oil or gas is afoot. The<br />

necessary reduction in chimney diameter, to avoid<br />

condensation, is quickly and cheaply achieved by installing<br />

a thin stainless steel inner sleeve in the existing<br />

chimney. This was a big German market after reunification,<br />

and there is still constant demand for refurbishment<br />

solutions.<br />

Another growth area for stainless steel, related to construction,<br />

is plumbing, for which there are now new<br />

regulations in Europe, where the use of other metallic<br />

materials can be restricted. In some areas, such as<br />

parts of Scotland, northern France, Germany and<br />

Sweden, for example, there have been corrosion<br />

problems due to a lowering of pH values in the water<br />

down to about 6.5. Above 7 it is alkaline, below 7 it is<br />

acid. European bodies, laboratories and regulators<br />

now have a program to approve a different material,<br />

and stainless steel is the only metallic material that<br />

can be used unconditionally.<br />

<strong>Stainless</strong> swimming pool at a health club in Holmes Place,<br />

Kingston, manufactured and installed by Invarmex (UK)<br />

Nottingham.<br />

crete cracks to patch in the case of leakage, and old<br />

pool tiles can be left under the stainless steel skin.<br />

"Many pools built in the 1960s and 1970s are nearing<br />

the end of their lifetime, and we are trying to carry this<br />

technology to France, the UK and elsewhere," Mr.<br />

Pauly says.<br />

Growth on two fronts<br />

The inexorable growth in the use of stainless steel<br />

falls, it seems, into two categories. One is that of applications<br />

where stainless steel substitutes for other<br />

materials. Domestic chimneys, formerly with mainly<br />

ceramic or plastic solutions, are an example of the<br />

first case, as are railings. The other growth category is<br />

through increased demand for finished products that<br />

use stainless steel. <strong>Stainless</strong> steel cladding in elevators,<br />

for example, has grown due to refurbishment of<br />

subway stations and the increasing number of highrise<br />

buildings and shopping malls. Of the two categories,<br />

Euro-Inox predicts that promoting “substitution”<br />

applications is the principal opportunity for what will<br />

surely be a bright <strong>future</strong> for stainless steel.<br />

Swimming pool linings<br />

Again according to Mr. Pauly, today, about 150 large,<br />

public pools in Europe are lined with stainless steel,<br />

using a technology developed in Austria. In fact, the<br />

two market leaders for this are Austrian companies.<br />

The idea spread quickly in Germany, and between the<br />

two countries there are about 120 to 130 such lined<br />

pools. This is a very interesting repair solution, especially<br />

outdoors, since you can leave water in the pool,<br />

or make repairs during the winter. You have no con-<br />

Copyright <strong>British</strong> <strong>Stainless</strong> <strong>Steel</strong> <strong>Association</strong>, December 2001<br />

December 2001 STAINLESS STEEL INDUSTRY 15